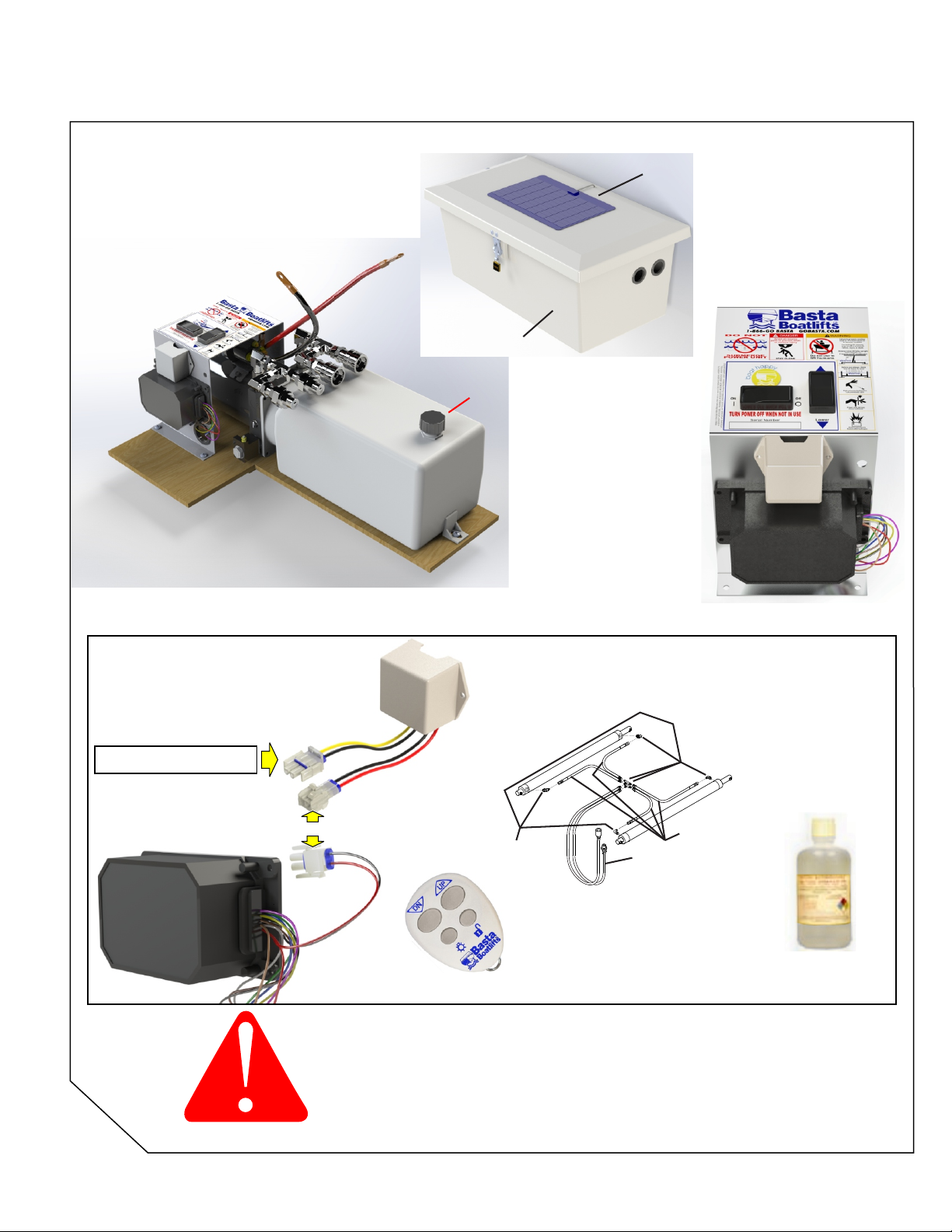

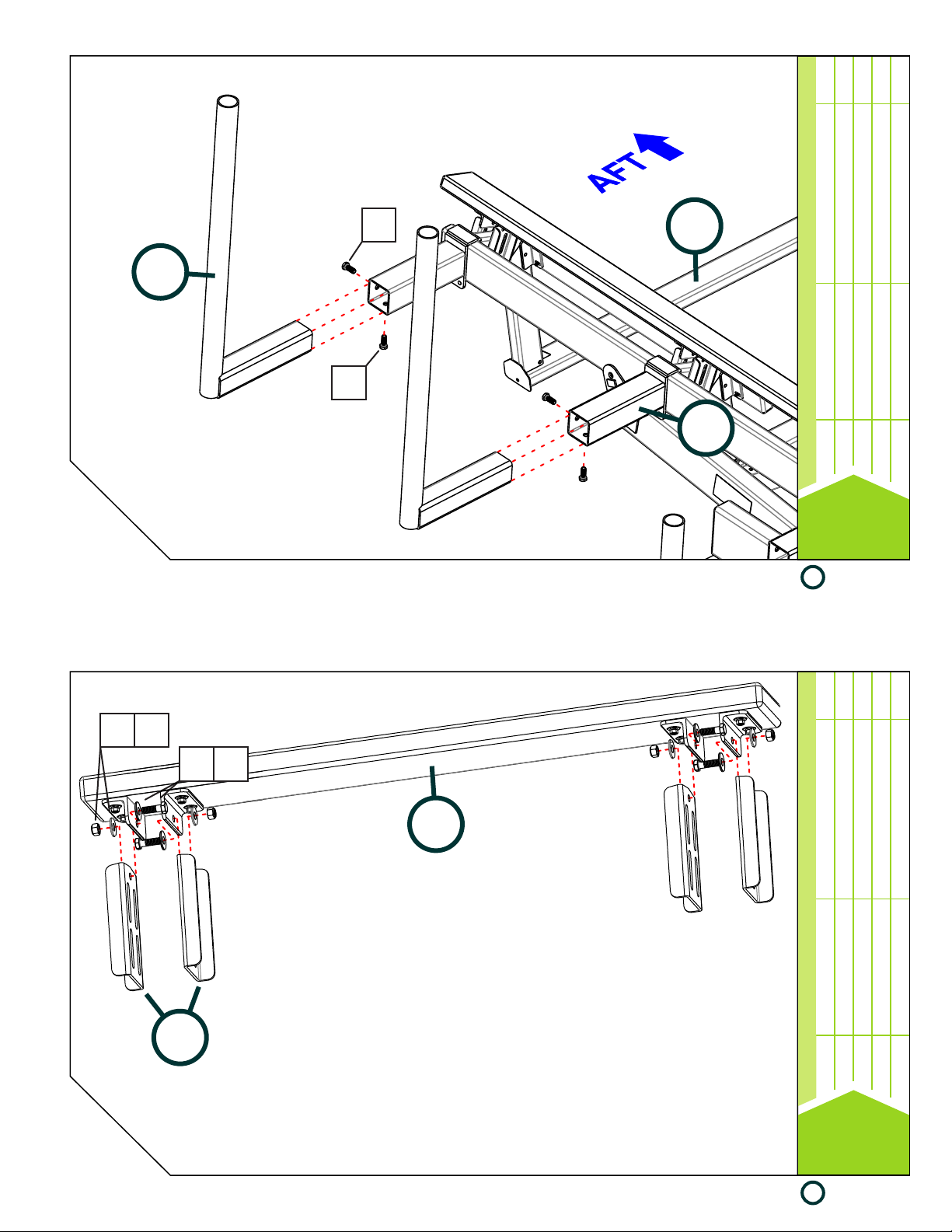

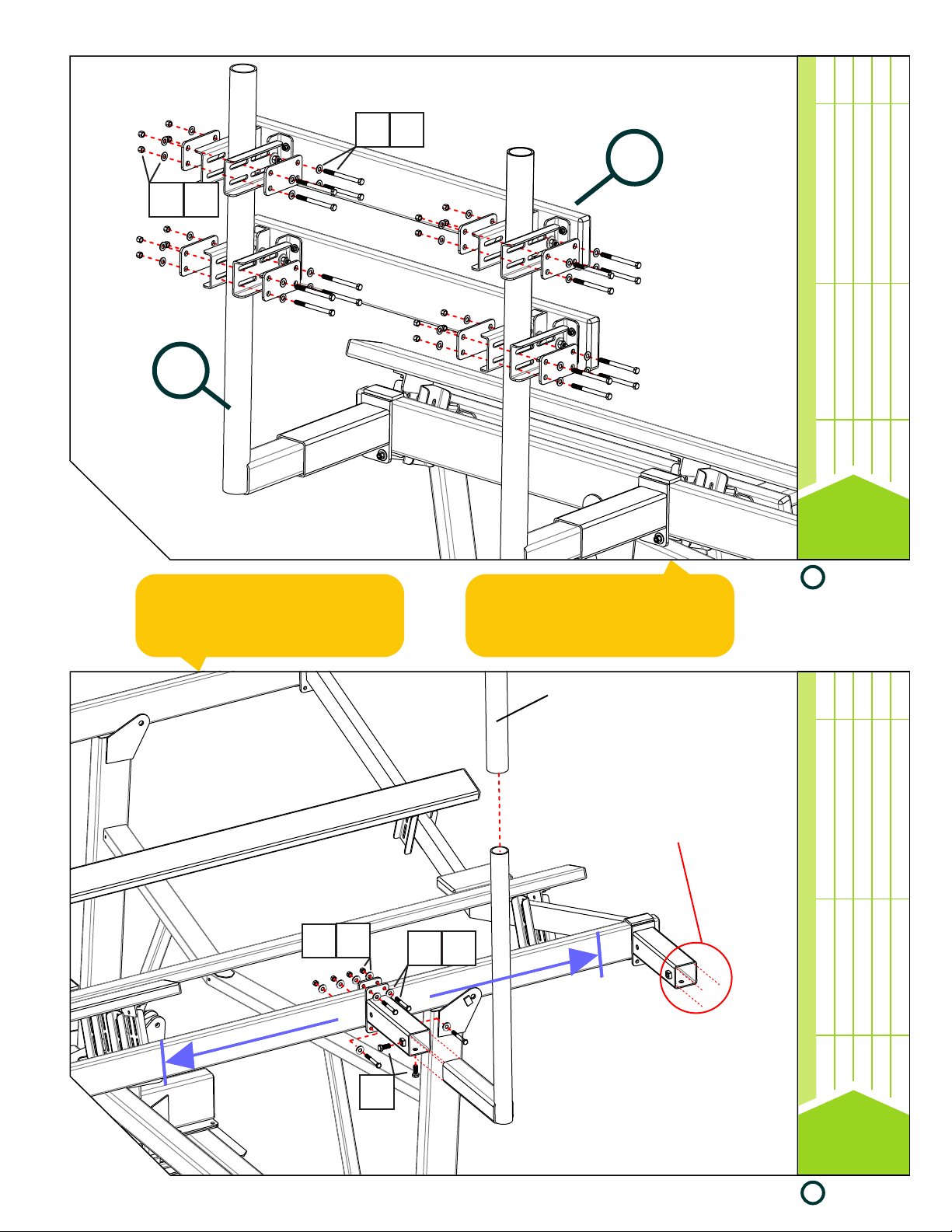

Basta Boatlifts Over-Center 24k60 User manual

Other Basta Boatlifts Lifting System manuals

Basta Boatlifts

Basta Boatlifts Over-Center 2k40 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 12k64 User manual

Basta Boatlifts

Basta Boatlifts 2x2k50 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 10k53 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 4.5k37 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 7k51 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 36k60 User manual

Basta Boatlifts

Basta Boatlifts 8k53 User manual

Basta Boatlifts

Basta Boatlifts Over-Center BM4050SP User manual

Basta Boatlifts

Basta Boatlifts Over-Center 18k59 User manual

Popular Lifting System manuals by other brands

Maxon

Maxon RAILGATE RCM-1250 C Maintenance manual

Upright

Upright SL26SL Service manual

Shenxi

Shenxi SC Series instruction manual

Challenger Lifts

Challenger Lifts 4P14EFX Installation, operation & maintenance manual

Rotary Lift

Rotary Lift 200 Series installation instructions

Haklift

Haklift VAINOSH230 Original instructions