2. SAFE OPERATION

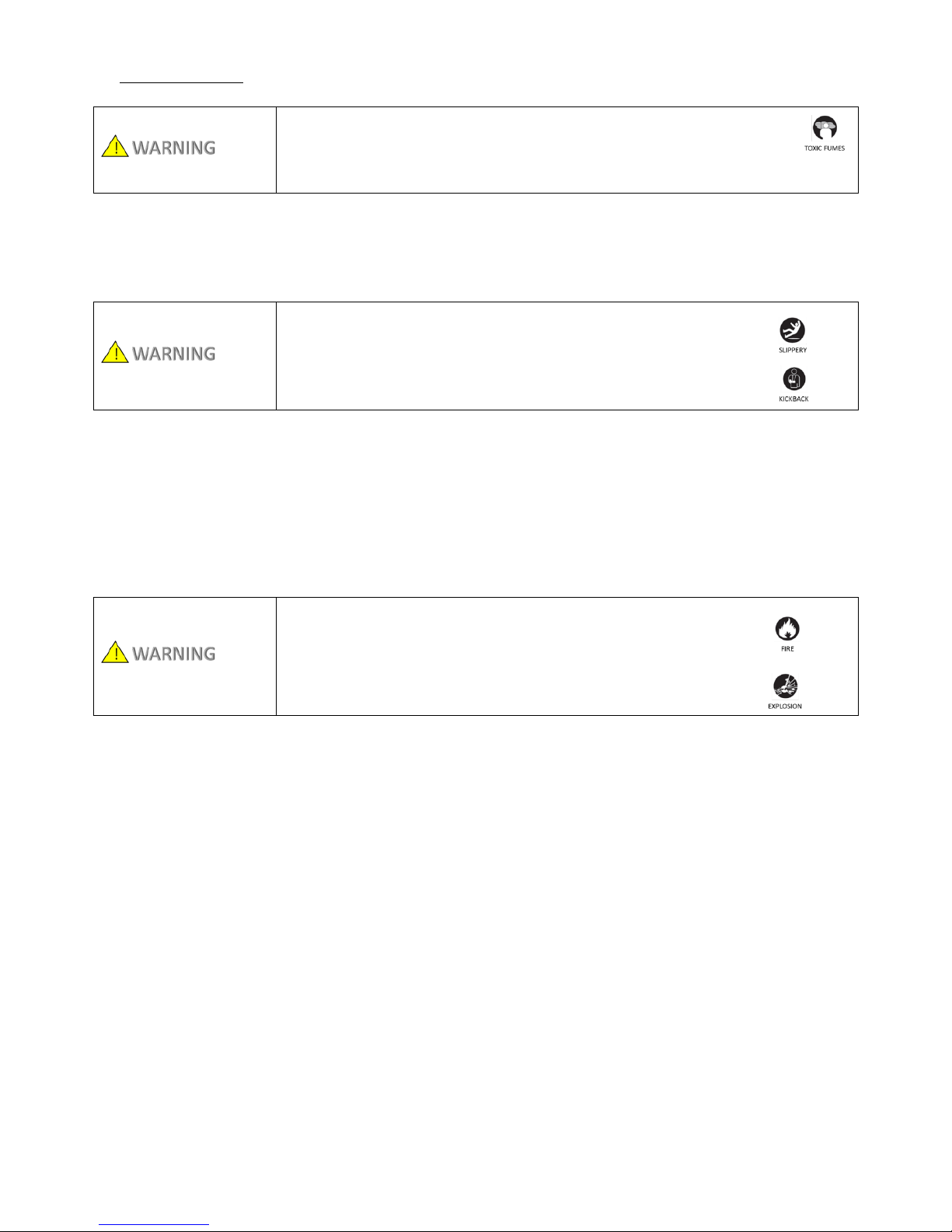

A running engine gives off carbon monoxide, an odourless,

colourless, poison gas.

Inhaling carbon monoxide can cause headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea, fainting or death.

2.1. Only operate the pressure washer outdoors in a well-ventilated area.

2.2. You must prevent exhaust gas from entering a confined area through windows, doors, ventilation

intakes, or other openings.

2.3. DO NOT start or run engine indoors or in an enclosed area, even if windows and doors are open.

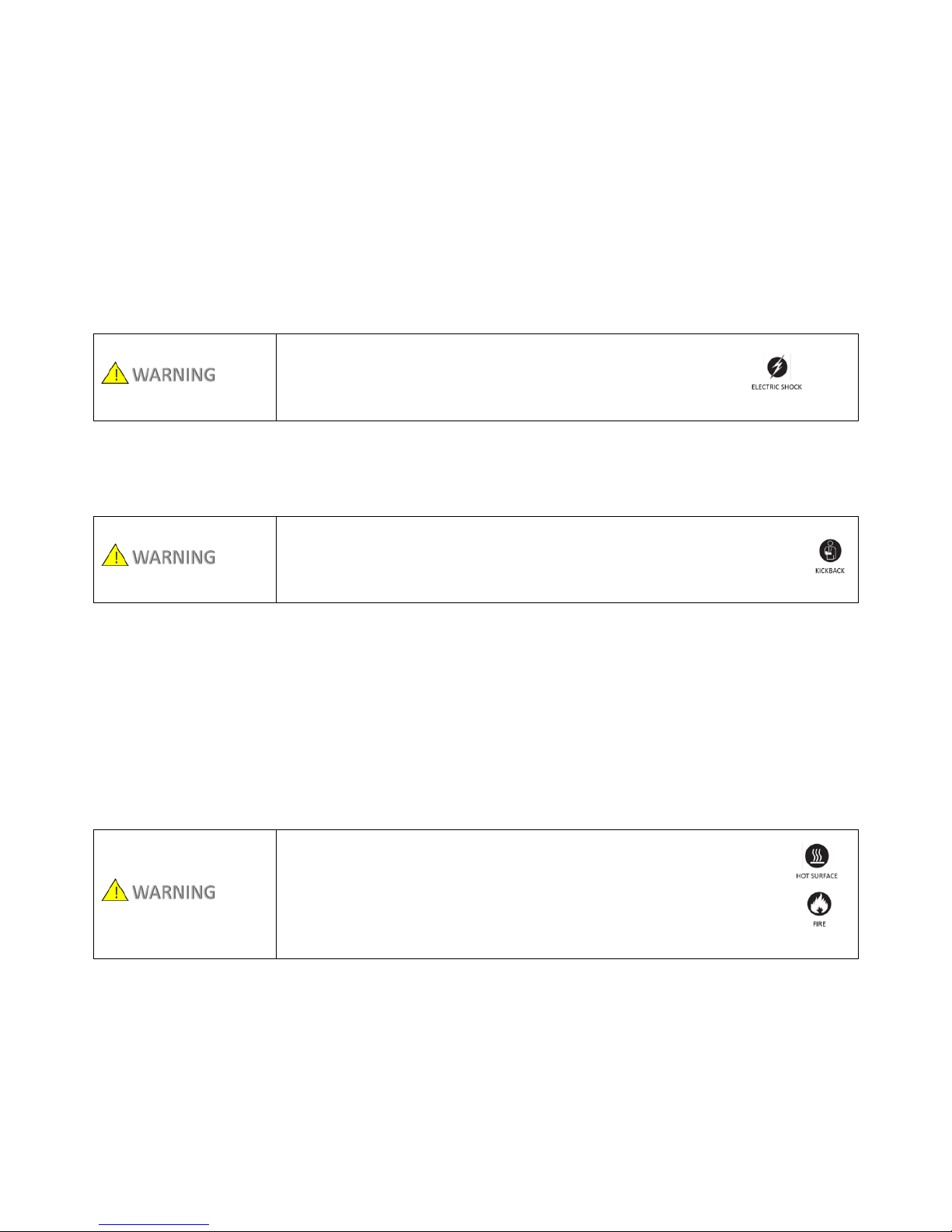

2.4. You must operate pressure washer from a stable surface.

2.4.1. The cleaning area should have adequate slopes and drainage to reduce the possibility of a

fall due to slippery surfaces.

2.4.2. DO NOT use the pressure washer from a ladder, Use with extreme caution when operating

from scaffolding, or any other similar location.

2.4.3. Take a firm grip of the spray gun with both hands when using the high pressure spray to

avoid injury when spray gun kicks back.

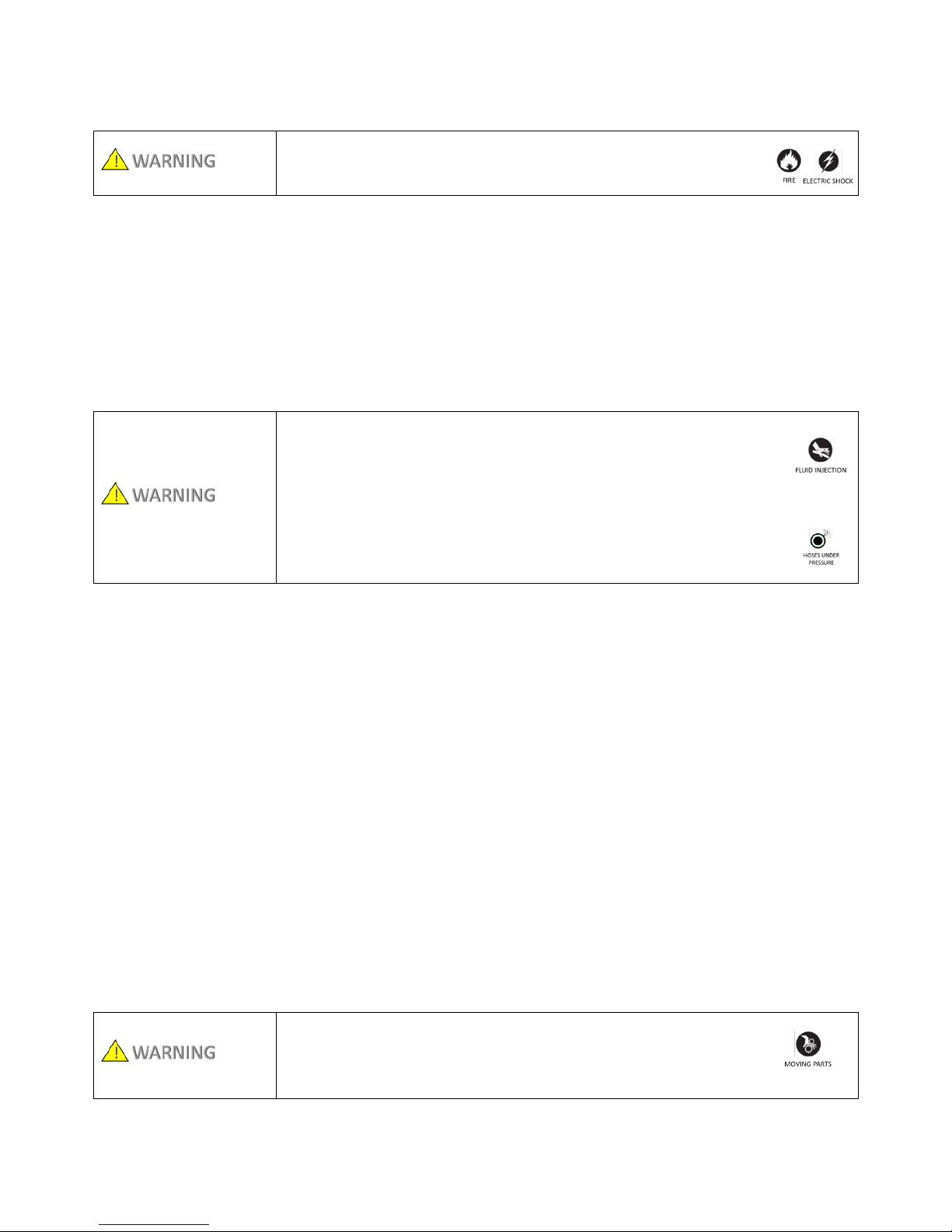

Fuel and its vapours are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

2.5. When adding or draining fuel.

2.5.1. DO NOT overfill tank. You must allow space for fuel expansion.

2.5.2. Turn the pressure washer OFF and let it cool at least 2 minutes before removing fuel

cap. Loosen cap slowly to relieve pressure in tank.

2.5.3. Only fill or drain fuel tank outdoors.

2.5.4. If any fuel is spilt, wait until it evaporates before starting engine.

2.5.5. You must keep fuel away from sparks, open flames, pilot lights, heat, and other

ignition sources.

2.5.6. DO NOT use near any naked flames, other sources of ignition and lighting cigarettes?

2.6. When starting equipment.

2.6.1. Make sure that spark plug, exhaust, fuel cap, and air cleaner are in place.

2.6.2. DO NOT crank engine with spark plug removed.