16 17

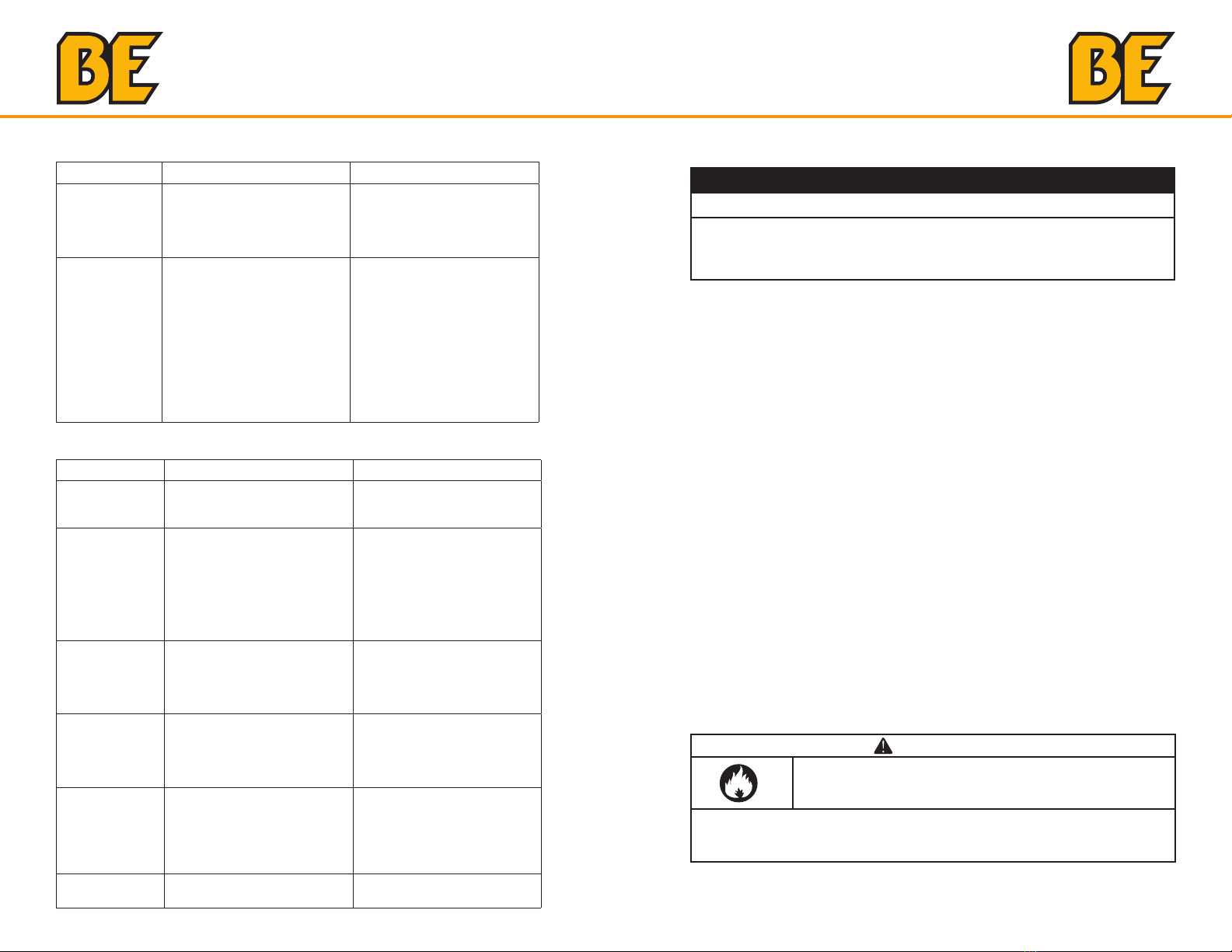

troubleshooting

Problem Causes Correction

Motor will not

start and there

is no humming

sound

1. Not plugged in

2. “RESET” button on GFCI not

pushed

3. Circuit breaker has tripped or

fuse is blown

1. Plug in

2. Push “RESET” button

3. Reset breaker or replace fuse

Power source

circuit continues

to trip or blow

fuses

1. Too much load already on

circuit

2. Extension cord is too long

or of improper gauge, causing

voltage drop

3. Pump is stuck due to dirt,

mineral build up, or ice

4. Motor malfunction

1. Reduce load on circuit and try

another compatible amp circuit

2. See section on extension

cords

3. Unplug unit. If temp. is below

freezing do not use. Thaw in

warm area.

4. Take it to your closest Baldor

dealer for servicing

* All motor servicing is to

be taken to manufacturer’s

authorized service outlets

ELECTRIC MOTOR

PUMP

Problem Causes Correction

No low pressure

detergent

delivery

1. Using wrong nozzle

2. Siphon hose or filter is

plugged

1. Insert black soaper nozzle

2. Unplug siphon hose

Unit does not

reach required

pressure

1. Restricted or insucient water

supply

2. Unsuitable or worn out nozzle

3. Regulator set too low

1. Check supply hose, faucet

and inlet water filter. Must be

connected to water source that

provides 6GPM.

2. Replace nozzle

3. Reset unloader by turning

knob (clockwise increases

pressure)

Thermal Relief

Valve is open

and discharging

water from side

of pump

1. Water temperature is too high

2. Pump has operated more

than 3 mins without pulling

trigger

1. Use cool water only.

2. Pull trigger at least 30

seconds every 3 mins. Replace

Thermal Relief Valve.

Leak in the

fittings

1. Water leak in high pressure

fittings, hose or gun

1. Use teflon tape or pipe sealant

to tighten hose fitting, replace

hose or gun

**If problem continues, take to

your pressure washer dealer

Pump oil is low 1. Normal use consumes oil over

time

1. To gauge the oil level, look

directly into the sight glass.

Oil level should always be at

the center dot. Do not overfill

replace w/ SAE 30W non

detergent mineral oil

Oil is milky in

color

1. Seals have worn from use and

water has leaked in

1. Bring unit to your local service

center to have seals replaced.

storage

Winter Storage

To protect the unit from freezing temperatures:.

1. Use Pump Saver to treat pump. This minimizes freezing

damage and lubricates pistons and seals. Contact your local

dealer for Pump Saver Solution. To use Pump Saver, make

sure the pressure washer is turned o and disconnected from

supply water. Read and follow all instructions and warnings

given on the Pump Saver container.

2. If pump saver is not available, connect a 3 ft. section

of garden hose to water inlet adapter. Pour RV-antifreeze

(antifreeze without alcohol) into hose. Pull recoil handle twice.

Disconnect 3 ft. hose.

3. Store unit in a clean, dry area (heated area preferred).

Long Term Storage

If you do not plan to use the pressure washer for more than

30 days, you must prepare the motor and pump for long term

storage.

Storing the Motor

See the engine operator’s manual for instructions on how to

properly prepare the engine for storage.

NOTICE

You must protect your unit from freezing temperatures.

• Failure to do so will permanently damage your pump and

render your unit inoperable.

• Freeze damage is not covered under warranty.

Other Storage Tips

1. Cover unit with a suitable protective cover that does not

retain moisture.

WARNING

Storage covers can be flammable.

• DO NOT place a storage cover over a hot pressure washer.

• Let equipment cool for a sucient time before placing the cover on

the equipment.

2. Store unit in a clean and dry area.