4 5

SAFETY INFORMATION

SAFETY INFORMATION SAFETY INFORMATION

SAFETY INFORMATION

Please read and understand this entire

manual before attempting to assemble,

operate, or install the product.

This manual contains information that

relates to PROTECTING PERSONAL

SAFETY and PREVENTING EQUIPMENT

PROBLEMS. It is very important to read

this manual carefully and understand it

thoroughly before using the product. The

symbols listed below are used to indicate

this information.

DANGER

Potential hazard that will result in

serious injury or loss of life.

WARNING

Hazard that could result in serious

injury or loss of life.

CAUTION

Potential hazard that may result

in moderate injury or damage to

equipment.

Note: The word “Note” is used to inform

the reader of something the operator

needs to know about the tool.

WARNING

To reduce the risk of injury, the user must

read and understand the instructions

before using this product.

1. Warning – When using this product

basic, precautions should always be

followed, including the following

2. Read all the instructions before using

the product

3. Know how to stop the product and

bleed pressures quickly. Be thoroughly

familiar with the controls.

4. Keep operating area clear of persons

5. Do not overreach or stand on unstable

support. Keep good footing and

balance at all times.

6. Follow the maintenance instructions

as specified in the manual

7. To avoid personal injury and/or

damage to property and to maximize

your power washing experience,

carefully follow all of the safety tips,

instructions, warnings and safeguards

and become familiar with all of the

controls.

8. This power washer conforms to

CSA and other safety and consumer

standards. DO NOT modify or rebuild

any part of your power washer.

9. DO NOT use your power washer

when you are under the influence of

alcohol or drugs. Use this power tool

carefully and only when you are alert.

10. Watch your balance and footing while

using your power washer. Surfaces

become slippery when wet and are

extra slippery when using a detergent

or cleaner.

11. NEVER operate the power washer in

bare feet, sandals, or open-toed shoes.

12. When using the power washer near

children, make sure they are closely

supervised by an adult to avoid injury.

NEVER let a child use the power

washer.

13. Keep fingers, hands, feet and any

part of your body clear of the stream

of high pressure water. The powerful

spray can cause blindness or blast

holes in the skin. It can break a

window if you are too close when you

pull the trigger on the spray gun.

14. ALWAYS wear eye protection to

prevent injury to eyes when operating

the power washer.

15. To avoid mishaps or injury, ALWAYS

use the trigger safety lock when not

using the power washer even if the

spraying stops for a moment.

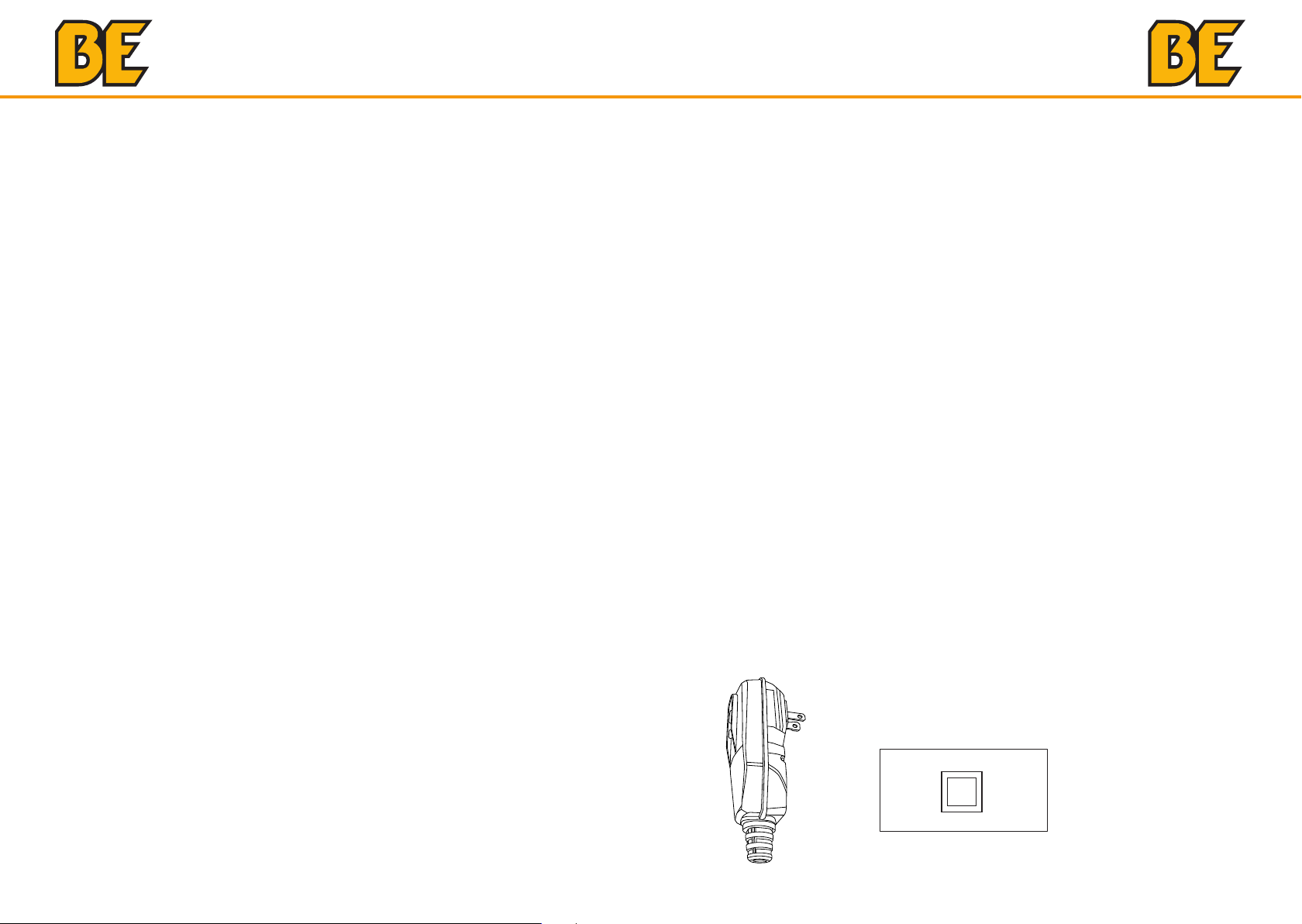

16. The power washer is equipped with

a Ground Fault Circuit Interrupter

(GFCI) which greatly reduces the

chance of electric shock while the unit

is in use. If replacement of the plug

or cord is needed, use only identical

replacement parts.

17. Point the spray gun in a safe direction

when beginning a power washing

session.

18. NEVER spray directly at a person,

animal, electrical device or the unit

itself.

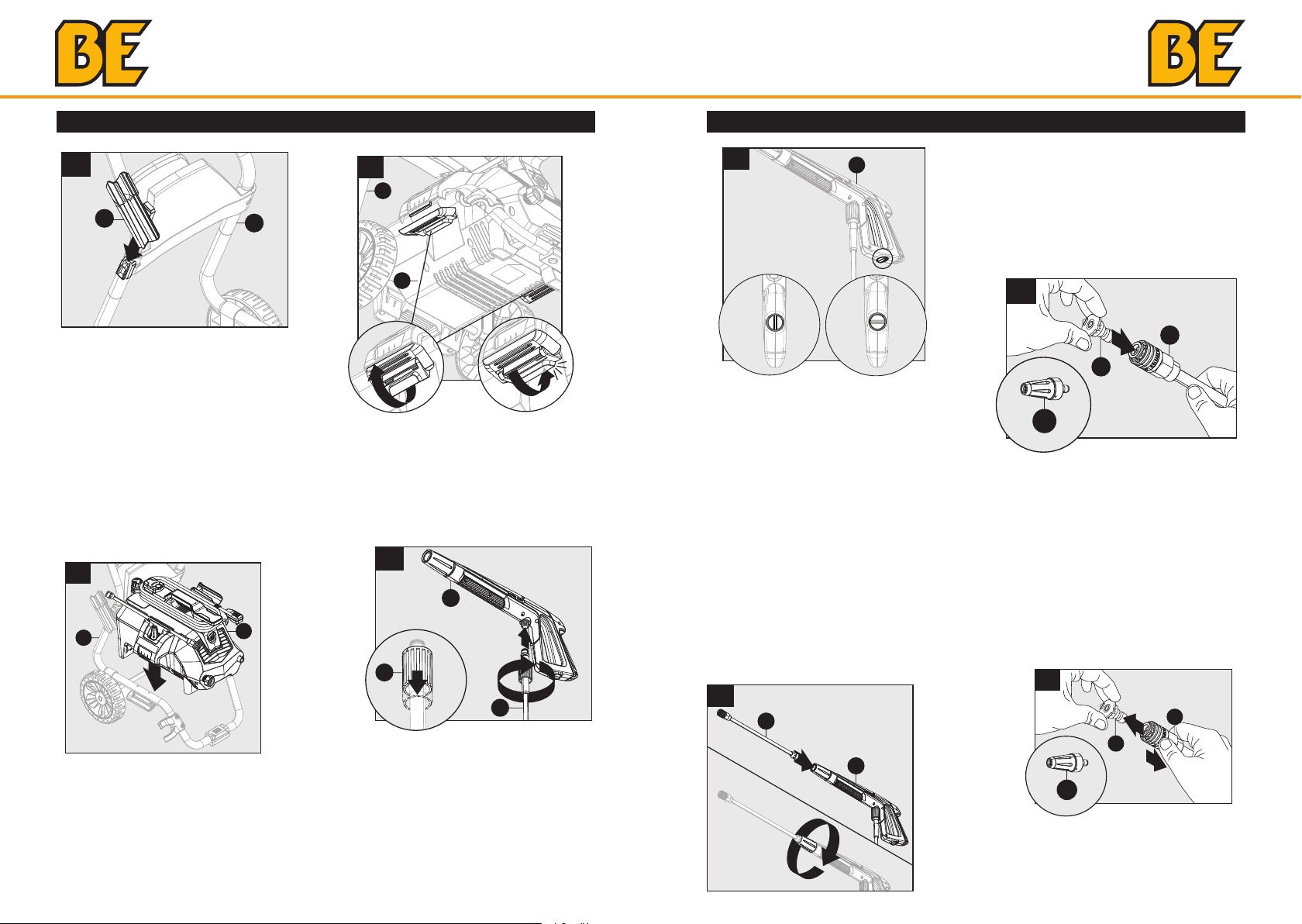

19. When first using the spray gun, hold

the spray gun and lance with two

hands when pulling the trigger (one

hand to pull the trigger and the other

to stabilize the gun assembly) until

you get used to the “kickback” from

the spray gun.

20. When you press the power switch

to turn o the power washer, water

pressure may remain in the system.

To discharge the pressure, point the

spray gun in a safe direction and pull

the trigger.

21. NEVER spray flammable liquids.

22. NEVER use the power washer in areas

that contain combustible dust, liquids

or vapors.

23. Avoid contact of the pressure hose

with sharp objects and examine the

hose regularly. Replace if damaged.

Due to the high pressure involved, it

cannot be repaired if cut or damaged.

24. Only use detergent specifically

formulated for power washers and

follow instructions on the detergent’s

label.

25. Protect eyes, lungs, and skin from

exposure to detergent. Dish or

laundry soap is too thick and will clog

the nozzle of your detergent bottle.

IMPORTANT: Store the power washer

indoors to prevent the water in the

unit from expanding under freezing