18 19

1. Be certain the trigger gun is locked in the “OFF” position.

2. The nozzle assembly should be disconnected from the gun/wand

assembly at this by retracting the locking ring on the quick-connect

fitting to remove the nozzle.

NOZZLE CONNECTION

12

12 Operator's Manual

INSTALLATION & PREPARATION

WATER SUPPLY:

1. Select a water supply hose which is a quality grade of garden hose measuring

at least 3/4" ID and no longer than 50 feet.

2 Check the water inlet strainer to ensure it is clean and free of any obstructions.

As a strainer becomes obstructed, it restricts proper ow of water to the

pump. This can result in cavitations which will prematurely cause failure

of pump packings.

a. Using a screwdriver, remove the screen from the water inlet.

b. Clean or replace if necessary.

3. Connect the hoses.

a. Connect one end of the water supply hose to the water inlet of the unit.

b. Connect the other end of the hose to your pressurized water supply.

NOTE 1: Do not use a non-pressurized water supply (i.e. from a pond or

well) with this unit.

NOTE 2: When connecting the water inlet to the water supply mains, local

regulations of your water company must be observed. In some

areas, the unit must not be connected directly to the public drinking

water supply. This is to ensure there is no feedback of detergents

into the water supply. (Direct connection is permitted if a backow

preventer is installed. Check with local authorities for approval.)

NOTE 3: If there is a high mineral content in your water, it is highly

recommended that a water softener and an additional water strainer

be added to the water inlet to help prevent the possibility

of excessive scale buildup inside the heat exchanger coil. Clean

both strainers before starting your pressure washer.

NOZZLE REVIEW:

Various nozzles may be quick-connected into the end of the wand to change the

spray pattern or use the detergent feature. When using Quick Connects (Q.C.),

be certain the connection is securely locked. If not, the high pressure water

may shoot the nozzle from the wand, causing severe injury or serious damage.

To determine spray fan, refer to the actual number stamped on the nozzle. The

rst two digits indicate the spray fan in degrees, i.e.; 00=0”, 15=15°, 40=40°.

1. The 0° nozzle (RED): This is a blasting nozzle. It delivers a very concentrated

stream of water. Be cautious when using the straight narrow stream. It is

not recommended for use on painted or wood surfaces, or items attached

with adhesive backings. Uses: Removing weeds from sidewalk cracks,

stubborn stains from concrete, masonry, aluminum and steel, caked mud

from equipment, and cleaning lawn mower undersides.

2. The 15° nozzle (YELLOW): This is a chiseling nozzle. The spray should

be directed at a 45° angle to the surface and used like a scraper to remove

paint, grease and dirt. Uses: Surface preparation (removing mildew stains

and paint chips).

3. The 40° nozzle (WHITE):

This is a wash nozzle. This wide spray pattern disperses the water pressure

over a large area and is recommended for moderate washing. Uses: Washing

aluminum siding, cleaning windows, washing vehicles, spraying sidewalks,

driveways, and patios.

NOZZLE CONNECTION:

1. Be certain the trigger gun is locked in the “OFF” position. See WARNING, left.

2. The nozzle assembly should be disconnected from the gun/wand assembly

at this by retracting the locking ring on the quick-connect tting to remove

the nozzle.

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

NEVER LOOK DIRECTLY AT THE

NOZZLE ORIFICE UNLESS IT

IS DISCONNECTED FROM THE

GUN/WAND ASSEMBLY!

CONNECTION OF Q.C. NOZZLES

QUICK-CONNECT FITTING

WARNING

RISK OF SEVERE INJURY!

THE TRIGGER GUN SHOULD

ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

QUICK-CONNECT (Q.C.)

0°

15°

40°

WATER SUPPLY

1. Select a water supply hose which is a quality grade of garden hose

measuring at least 3/4” ID and no longer than 50 feet.

2 Check the water inlet strainer to ensure it is clean and free of any

obstructions. As a strainer becomes obstructed, it restricts proper

flow of water to the pump. This can result in cavitations which will

prematurely cause failure of pump packings.

a. Using a screwdriver, remove the screen from the water inlet.

b. Clean or replace if necessary.

WARNING

THE TRIGGER GUN SHOULD ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

NEVER LOOK DIRECTLY AT THE NOZZLE ORIFICE UNLESS IT IS

DISCONNECTED FROM THE GUN/WAND ASSEMBLY!

CONNECTION OF Q.C. NOZZLES QUICK-CONNECT (Q.C.)

12

12 Operator's Manual

INSTALLATION & PREPARATION

WATER SUPPLY:

1. Select a water supply hose which is a quality grade of garden hose measuring

at least 3/4" ID and no longer than 50 feet.

2 Check the water inlet strainer to ensure it is clean and free of any obstructions.

As a strainer becomes obstructed, it restricts proper ow of water to the

pump. This can result in cavitations which will prematurely cause failure

of pump packings.

a. Using a screwdriver, remove the screen from the water inlet.

b. Clean or replace if necessary.

3. Connect the hoses.

a. Connect one end of the water supply hose to the water inlet of the unit.

b. Connect the other end of the hose to your pressurized water supply.

NOTE 1: Do not use a non-pressurized water supply (i.e. from a pond or

well) with this unit.

NOTE 2: When connecting the water inlet to the water supply mains, local

regulations of your water company must be observed. In some

areas, the unit must not be connected directly to the public drinking

water supply. This is to ensure there is no feedback of detergents

into the water supply. (Direct connection is permitted if a backow

preventer is installed. Check with local authorities for approval.)

NOTE 3: If there is a high mineral content in your water, it is highly

recommended that a water softener and an additional water strainer

be added to the water inlet to help prevent the possibility

of excessive scale buildup inside the heat exchanger coil. Clean

both strainers before starting your pressure washer.

NOZZLE REVIEW:

Various nozzles may be quick-connected into the end of the wand to change the

spray pattern or use the detergent feature. When using Quick Connects (Q.C.),

be certain the connection is securely locked. If not, the high pressure water

may shoot the nozzle from the wand, causing severe injury or serious damage.

To determine spray fan, refer to the actual number stamped on the nozzle. The

rst two digits indicate the spray fan in degrees, i.e.; 00=0”, 15=15°, 40=40°.

1. The 0° nozzle (RED): This is a blasting nozzle. It delivers a very concentrated

stream of water. Be cautious when using the straight narrow stream. It is

not recommended for use on painted or wood surfaces, or items attached

with adhesive backings. Uses: Removing weeds from sidewalk cracks,

stubborn stains from concrete, masonry, aluminum and steel, caked mud

from equipment, and cleaning lawn mower undersides.

2. The 15° nozzle (YELLOW): This is a chiseling nozzle. The spray should

be directed at a 45° angle to the surface and used like a scraper to remove

paint, grease and dirt. Uses: Surface preparation (removing mildew stains

and paint chips).

3. The 40° nozzle (WHITE):

This is a wash nozzle. This wide spray pattern disperses the water pressure

over a large area and is recommended for moderate washing. Uses: Washing

aluminum siding, cleaning windows, washing vehicles, spraying sidewalks,

driveways, and patios.

NOZZLE CONNECTION:

1. Be certain the trigger gun is locked in the “OFF” position. See WARNING, left.

2. The nozzle assembly should be disconnected from the gun/wand assembly

at this by retracting the locking ring on the quick-connect tting to remove

the nozzle.

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

NEVER LOOK DIRECTLY AT THE

NOZZLE ORIFICE UNLESS IT

IS DISCONNECTED FROM THE

GUN/WAND ASSEMBLY!

CONNECTION OF Q.C. NOZZLES

QUICK-CONNECT FITTING

WARNING

RISK OF SEVERE INJURY!

THE TRIGGER GUN SHOULD

ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

QUICK-CONNECT (Q.C.)

0°

15°

40°

12

12 Operator's Manual

INSTALLATION & PREPARATION

WATER SUPPLY:

1. Select a water supply hose which is a quality grade of garden hose measuring

at least 3/4" ID and no longer than 50 feet.

2 Check the water inlet strainer to ensure it is clean and free of any obstructions.

As a strainer becomes obstructed, it restricts proper ow of water to the

pump. This can result in cavitations which will prematurely cause failure

of pump packings.

a. Using a screwdriver, remove the screen from the water inlet.

b. Clean or replace if necessary.

3. Connect the hoses.

a. Connect one end of the water supply hose to the water inlet of the unit.

b. Connect the other end of the hose to your pressurized water supply.

NOTE 1: Do not use a non-pressurized water supply (i.e. from a pond or

well) with this unit.

NOTE 2: When connecting the water inlet to the water supply mains, local

regulations of your water company must be observed. In some

areas, the unit must not be connected directly to the public drinking

water supply. This is to ensure there is no feedback of detergents

into the water supply. (Direct connection is permitted if a backow

preventer is installed. Check with local authorities for approval.)

NOTE 3: If there is a high mineral content in your water, it is highly

recommended that a water softener and an additional water strainer

be added to the water inlet to help prevent the possibility

of excessive scale buildup inside the heat exchanger coil. Clean

both strainers before starting your pressure washer.

NOZZLE REVIEW:

Various nozzles may be quick-connected into the end of the wand to change the

spray pattern or use the detergent feature. When using Quick Connects (Q.C.),

be certain the connection is securely locked. If not, the high pressure water

may shoot the nozzle from the wand, causing severe injury or serious damage.

To determine spray fan, refer to the actual number stamped on the nozzle. The

rst two digits indicate the spray fan in degrees, i.e.; 00=0”, 15=15°, 40=40°.

1. The 0° nozzle (RED): This is a blasting nozzle. It delivers a very concentrated

stream of water. Be cautious when using the straight narrow stream. It is

not recommended for use on painted or wood surfaces, or items attached

with adhesive backings. Uses: Removing weeds from sidewalk cracks,

stubborn stains from concrete, masonry, aluminum and steel, caked mud

from equipment, and cleaning lawn mower undersides.

2. The 15° nozzle (YELLOW): This is a chiseling nozzle. The spray should

be directed at a 45° angle to the surface and used like a scraper to remove

paint, grease and dirt. Uses: Surface preparation (removing mildew stains

and paint chips).

3. The 40° nozzle (WHITE):

This is a wash nozzle. This wide spray pattern disperses the water pressure

over a large area and is recommended for moderate washing. Uses: Washing

aluminum siding, cleaning windows, washing vehicles, spraying sidewalks,

driveways, and patios.

NOZZLE CONNECTION:

1. Be certain the trigger gun is locked in the “OFF” position. See WARNING, left.

2. The nozzle assembly should be disconnected from the gun/wand assembly

at this by retracting the locking ring on the quick-connect tting to remove

the nozzle.

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

NEVER LOOK DIRECTLY AT THE

NOZZLE ORIFICE UNLESS IT

IS DISCONNECTED FROM THE

GUN/WAND ASSEMBLY!

CONNECTION OF Q.C. NOZZLES

QUICK-CONNECT FITTING

WARNING

RISK OF SEVERE INJURY!

THE TRIGGER GUN SHOULD

ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

QUICK-CONNECT (Q.C.)

3. Connect the hoses.

a. Connect one end of the water supply hose to the water inlet of the

unit.

b. Connect the other end of the hose to your pressurized water supply.

4. Follow the incoming water requirements listed below:

a. Water pressure must be a minimum of 20 pounds per square

Inch (PSI) and a maximum of 125 PSI. (A typical outdoor faucet will

generally supply this PSI if turned completely “ON”.)

b. Incoming GPM must be approximately one gallon more than the

outgoing GPM stated on the pressure washer nameplate. (You can

check GPM by timing how long it takes to fill a 5 gallon container.)

c. Incoming water temperature must not exceed 125°F. Excessive

pump damage may result if the water temperature exceeds this

acceptable level.

5. Never allow the unit to operate without the incoming water line

attached and the water supply is completely turned on.

NOTICE

• If there is a high mineral content in your water, it is highly recommend-

ed that a water softener and an additional water strainer be added

to the water inlet to help prevent the possibility of excessive scale

buildup inside the heat exchanger coil.

UNLOADER

The unloader has been preset at the factory.

4. The 65° nozzle: (included in dual lance.) This is a detergent

nozzle. The broad spray pattern distributes solution over vast

areas. Uses: Detergent application, misting or rinsing.

16 HS-SERIES Operator's Manual

INSTALLATION & PREPARATION

UNLOADER:

The unloader has been preset at the factory.

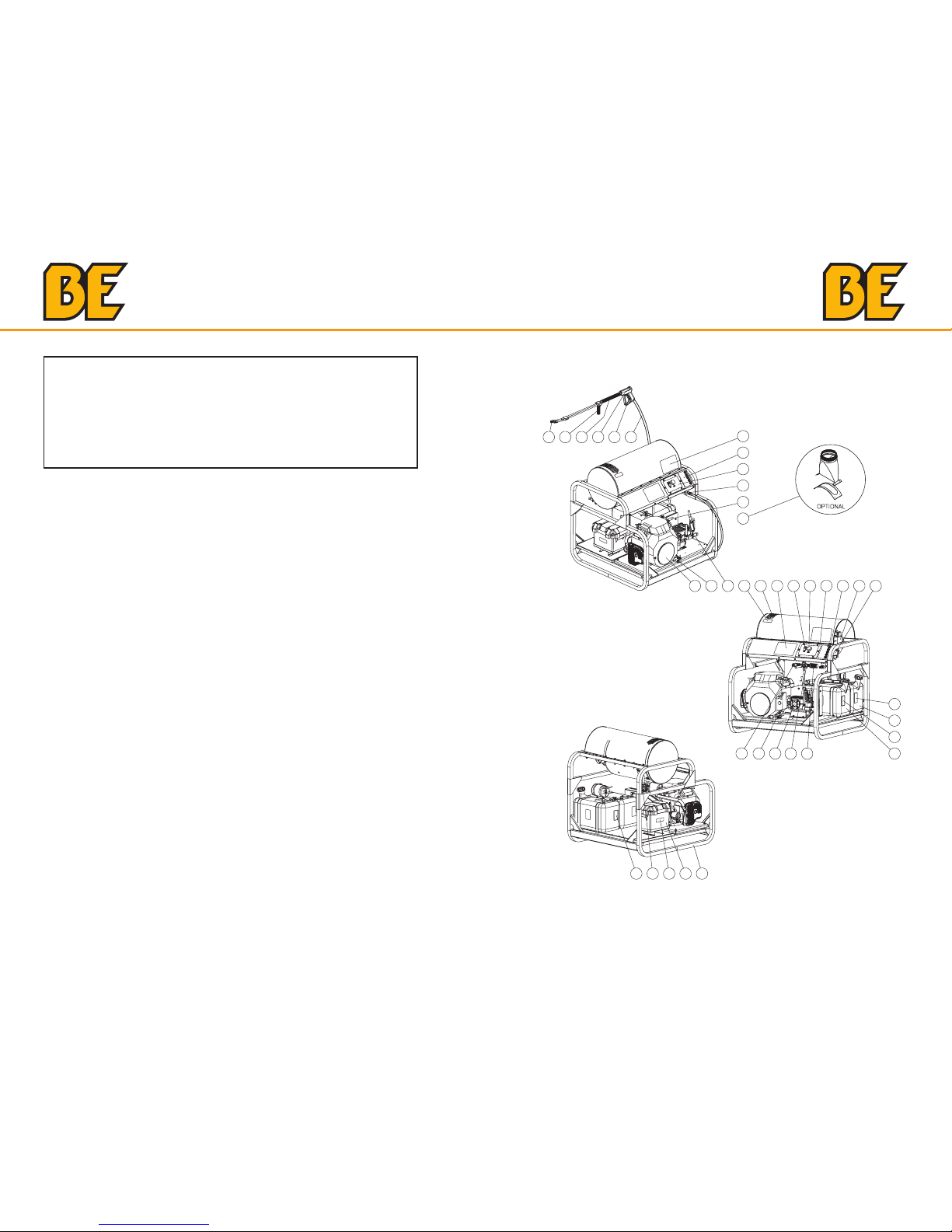

PRE-START INSPECTION PROCEDURES:

Before starting the unit, perform the following procedures:

1. Check the oil level in the pump.

2. Inspect the water inlet strainer. Clean or replace if necessary. See "Water

Supply" pg. 15.

3. Check all hose connections to ensure they are securely tightened.

4. Inspect for system water leaks, oil leaks and fuel leaks. If a fuel leak is

found, DO NOT START UNIT! See "Risk of Explosion or Fire" warnings, pgs.

4-5. Be sure that all damaged parts are replaced and that the mechanical

problems are corrected prior to operation of the unit. If you require service,

contact Customer Service.

5. Inspect high pressure hoses for kinking, cuts and leaks. If a cut or leak is

found, DO NOT USE HOSE! Replace hose before starting unit. See "Risk

of Injection" warnings, pg. 6. Be sure that all damaged parts are replaced

and that the mechanical problems are corrected prior to operation of the

unit. If you require service, contact Customer Service.

END OF PREPARATION INSTRUCTIONS

UNLOADER VALVE

INSTALLATION & PREPARATION INSTALLATION & PREPARATION