17

Emergency Reserve Manifold

2005715.05

When the ERM is in operation there is provision for

an alarm output to warn when the running bank

contents is typically below half. The ERM contents

gauge should then be locally monitored. The Bank

valves can be used to cycle the left and right banks

allowing for empty cylinders to be changed while

keeping continues supply to the pipeline.

CAUTION: The following procedures

4.2 to 4.7 are only typical guides, where there

areconictswiththehospital’semergency

procedure,thehospital’spolicieswilltake

precedence.

4.2 Procedure to prime ERM.

4.2.1 The following procedure must be carried

out once the commissioning (section 3) is complete

and the system is ready to be put into use.

4.2.2 Ensure the high-pressure isolation valve

on the left-hand bank is fully open, the right-hand

bank isolation valve is closed, and all cylinder

valves on both banks are fully closed. Correct as

required, see section 4.7 Cylinder Operation.

4.2.4 Ensure the connecting pipeline is ready for

use. Slowly open the line valve ‘B’ (Item 9, gure

1).

4.3 Procedure when mains sup-

ply fails.

4.3.1 The following steps relate to gure 1 & 2,

and detail how to operate the ERM in the event of

the main supply system failing to supply gas at the

correct distribution pressure.

4.3.2 Ensure the ERM line valve ‘B’ is open. Close

main supply line valve (Shown as valve ‘A’ in gure

2).

4.3.3 Ensure that one of the high-pressure

bank isolation valve is fully open, the other bank

isolation valve is closed, and all cylinder valves on

both banks are fully closed. Correct as required.

4.3.4 The pressure regulator will be set below

the nominal distribution system pressure. This

should now be increased to the full distribution

pressure by increasing the line regulator setting,

until the correct distribution pressure can be

obtained.

4.3.5 Once the ERM is in operation there is

provision for an alarm output to warn when the

running bank contents is typically below half.

The ERM contents gauge should then be locally

monitored for cycling the cylinder banks for

continuous supply (see section 4.4 for bank cycling

procedure).

4.4 Procedure to cycle banks &

changing cylinders.

4.4.1 Refer to hospitals/site policy for safe

cylinder handling (See section 4.6 for typical

cylinder handling safety check list) when moving

the cylinders into place ready for connection to the

tailpipes.

4.4.2 When the running bank pressure falls to

the pressure for changing cylinder (for typical

changeover pressures see table 5). Slowly open the

standby bank isolation valve (see gure 1). With

the standby bank now operating as the running

bank, close the high pressure isolation valve and

cylinder valves for the empty cylinder bank.

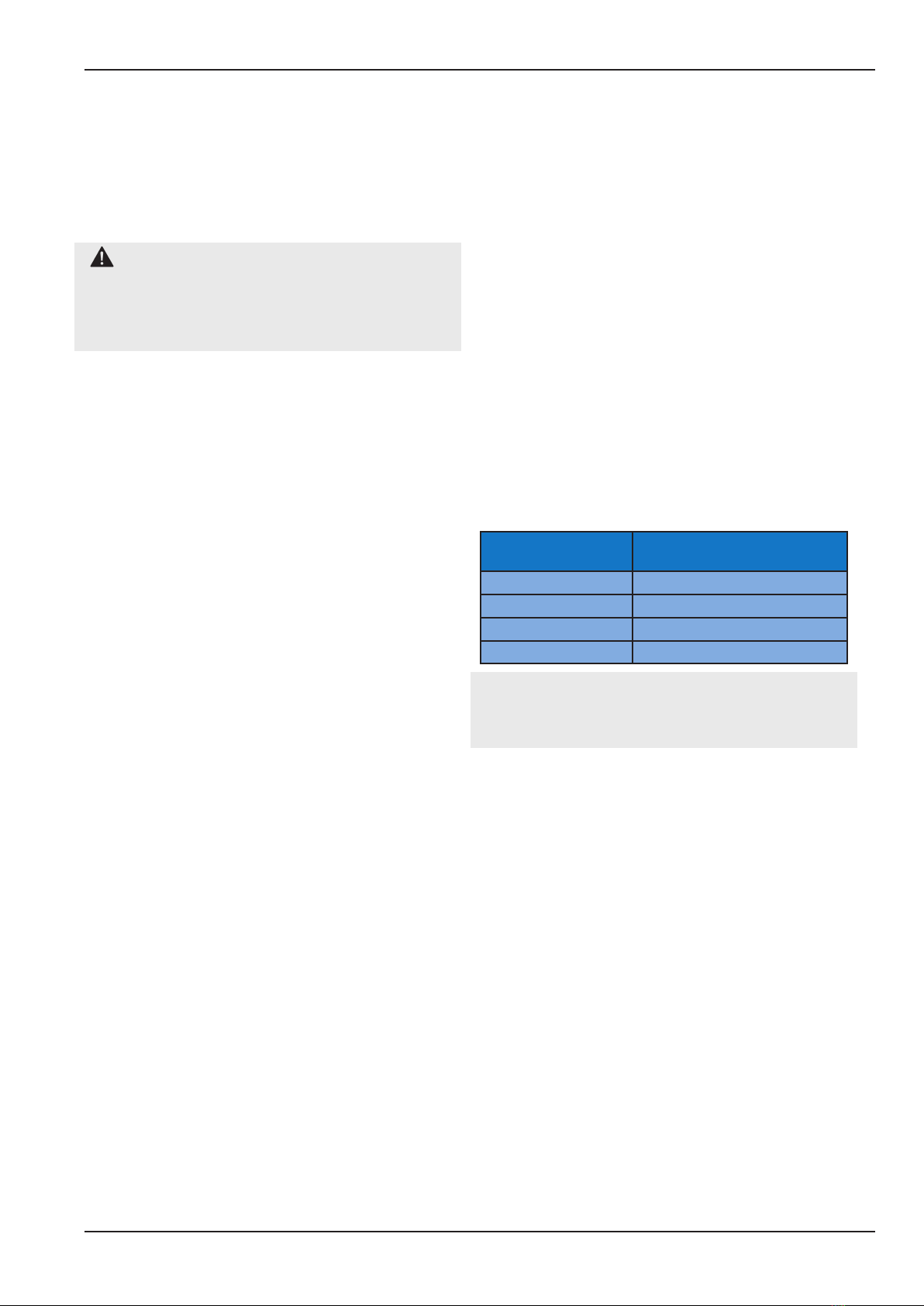

Table 4: Typical cylinder bank changeover

pressure.

Nominal Supply

pressure

Typical Cylinder changeover

4 Bar 15 Bar (50 Bar Cyl. and Below)

4 Bar 20 Bar (137 Bar Cyl. and above)

7 Bar 30 Bar

11 Bar 30 Bar

Note - Values in table 5 are only for reference

as a typical guide, refer to hospital emergency

procedure policy.

4.4.3 For the empty cylinder/s disconnect the

tailpipe from the cylinder (see gure 13) by either

undoing the handwheel or unscrewing the nut

at the cylinder end, depending on the cylinder

connection type.

4.4.4 Replace the empty cylinder/s and reconnect

the tailpipes. Slowly open the cylinder valves (see

section 4.7 - Cylinder operation.

4.4.5 Repeat this section each time the running

bank drops to the changeover pressure until the

main supply is fully operational.

4.5 Procedure to reinstate main

supply.

4.5.1 The following steps detail how to reinstate

the mains supply once it has been returned to

normal operation.

4.5.2 Slowly open valve ‘A’ (See gure 2).

4.5.3 Complete the steps in section 3, followed by

4.2