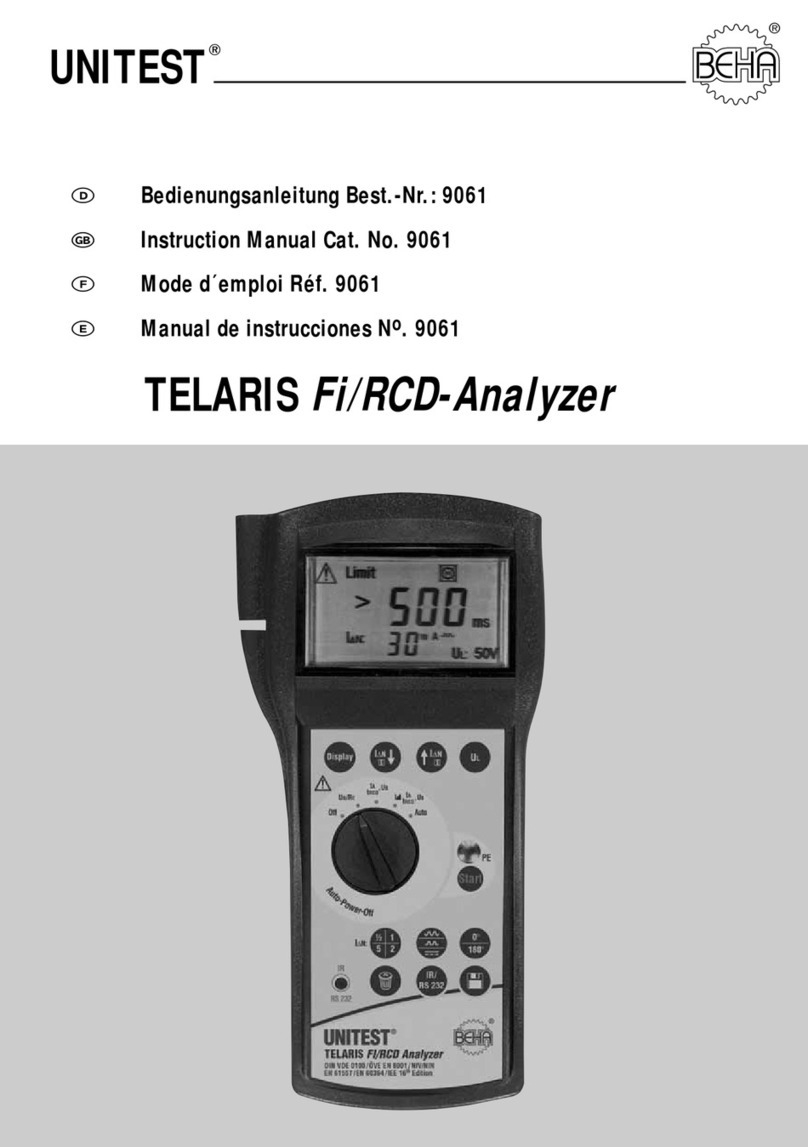

If symbol „turn plug by 180°" (7) appears, turn

the mains plug by 180° and connect to the

socket or exchange the N and L connectors at

the test instrument.

If the symbol for socket error (6) is displayed

on the screen, an error within the mains has oc-

curred. If a voltage is present between N and

PE exceeding the pre-selected contact voltage

limit (50V/25V), "UB>UL" is displayed on the

screen (4).

To perform a complete socket test touch the

contact electrode PE (25) and observe the di-

splay on the screen. You may only achieve a

valid result when touching the contact electro-

de PE (25)!

If the error signal is audible and the 'Attention'

(1) and 'Socket Error' (6) symbols are display-

ed on the screen, we are dealing with a PE error.

I.e., either the PE is not connected or a high vol-

tage (phase) is present at PE.

The measurement may only be started if the

socket is faultfree and the measurement adap-

ter has been connected by respecting correct

polarity.

Press the "Start" key (26) to start the measure-

ment. During the measurement ' - ' is displayed

on the screen.

Read the measurement result displayed on the

screen. The loop resistance is displayed on the

large result field (12), the short-circuit current

IPSC is displayed on the small result field (14).

If the resistance measured is larger than

1999ΩThe attention symbol (1) and '>1999Ω'

are displayed on the screen. As there is no valid

measurement value for RS, the short-circuit

current IPSC cannot be calculated and di-

splayed. '---' appears on the small result field

(14).

The short-circuit current is calculated using the

mains voltage and the loop resistance. For this,

the value 230V is used as mains voltage if the

actual mains voltage amounts to approx. 230V.

If the measurement value differs considerably

from 230V, the actual measurement value is

used for short-circuit current calculation.

Supply system preloading and voltage fluctu-

ations can lead to erroneous measurement re-

sults. Therefore, you are advised to perform

several measurements and to compare the me-

asurement results

If several measurements are carried out, inter-

rupted only by „short" breaks, the internal over-

temperature protection of TELARIS 0100 plus

is triggered and the symbol for overtempera-

ture (20) appears on the display. The next loop

impedance measurement can only be started,

once the instrument has cooled down and after

the symbol (20) has gone out. Instrument da-

mage is therefore avoided..

Measurement results can be saved by pressing

key „Store" (27).

If the user wishes to save the condition infor-

mation of a faulty socket, first press the "Start”

key (26). After hearing the "error signal”, the

"Store” key (27) can be pressed.

19

Loop Impedance Measurement / Prospektive Short-Circuit Current Measurement