1523.6-0000010 OM

4

2.17.3 Remote buttons of RLL control system ...................................................................52

2.17.4 Troubleshooting of RLL electronic control system ..................................................53

2.17.5 Front lift linkage control...........................................................................................54

2.18 HLL pump control.......................................................................................................54

2.19 HLL valve group section control (remote cylinders) ...................................................55

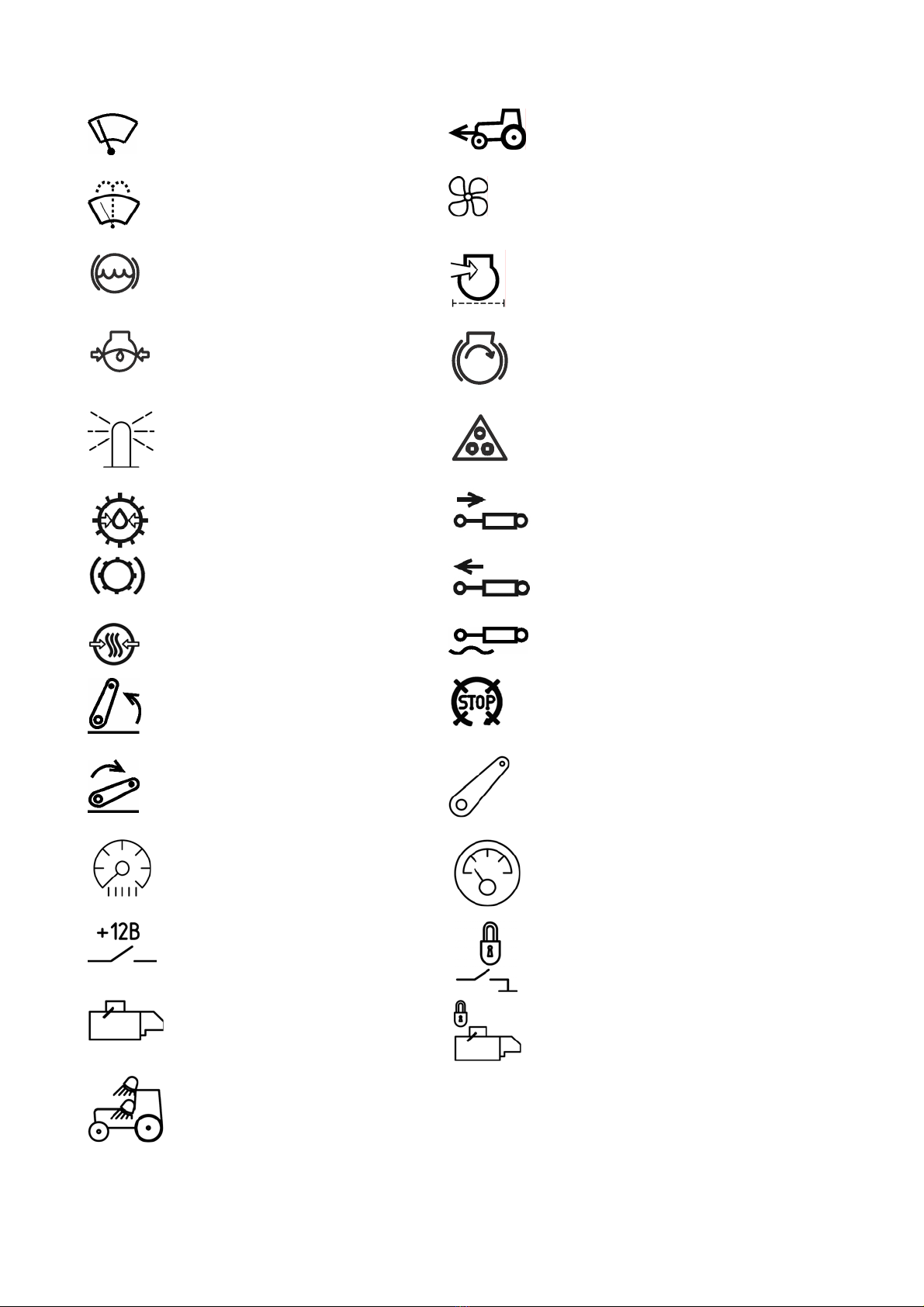

2.20 Switching unit and electric cutout fuses .....................................................................56

2.20.1 General information ................................................................................................56

2.20.2 Switching unit and fuses for electrical equipment ...................................................56

2.20.3 Fuses for electronic systems of rear axle DL, FDA, GB reduction unit, FPTO and

RLL control ........................................................................................................................63

2.20.4 Fuses for engine electronic control system.............................................................64

2.21 Cab locks and handles...............................................................................................65

2.21.1 Cab door locks........................................................................................................65

2.21.2 Side window opening ..............................................................................................65

2.21.3 Rear screen opening...............................................................................................66

2.21.4 Cab hatch opening..................................................................................................66

2.21.5 Cab emergency exits ..............................................................................................66

2.22 Seat and its adjustments............................................................................................67

2.22.1 General information ................................................................................................67

2.22.2 Adjustments of “BELARUS” seat. ...........................................................................67

2.22.3 Adjustments of “Grammer” seat..............................................................................68

2.23 Control of the transmission hydraulic system pump drive ..........................................69

2.24 Control of the pneumatic system compressor............................................................69

2.25 Connector elements of the electrical equipment ........................................................70

2.25.1 Socket to connect coupled agricultural equipment..................................................70

2.25.2 Connection of additional electrical equipment of coupled machines.......................70

2.26 Creeper control ..........................................................................................................71

2.26.1 Creeper control on tractors with GB16x8 ................................................................71

2.26.2 Creeper control on tractors with GB 24x12 .............................................................72

2.27 Gears and ranges shifting of GB 24х12 .....................................................................72

2.28 Fuel tanks ..................................................................................................................74

2.29 SCR system operation ...............................................................................................74

2.29.1 Tank for SCR system liquid ....................................................................................74

2.29.2 Indication of SCR system operation........................................................................75

3 INTENDED USE OF TRACTOR.....................................................................................77

3.1 Safety measures while preparing tractor for operation.................................................77

3.2 Tractor use...................................................................................................................78

3.2.1 Boarding the tractor ..................................................................................................78

3.2.2 Engine start and preparation for it.............................................................................78

3.2.3 Start of tractor movement, GB shifting ......................................................................80

3.2.4 Tractor stop...............................................................................................................81

3.2.5 Engine stop...............................................................................................................81

3.2.6 Leaving the tractor ....................................................................................................82

3.2.7 PTO use....................................................................................................................82

3.2.8 Selection of optimal inner pressure in tires depending on operational conditions and

load on tractor axles ..........................................................................................................85

3.2.8.1 Selection of optimal inner pressure in tires depending on operational conditions

and load on tractor axles....................................................................................................85

3.2.8.2 Tire inflation ...........................................................................................................86

3.2.9 Rear wheel track formation .......................................................................................87

3.2.10 Rear wheel twinning................................................................................................88

3.2.11 Front wheel track formation ....................................................................................89

3.3 Safety measures while tractor operation......................................................................91