BELARUS-920.4/952.4 Operating manual

4

1 TRACTOR DESCRIPTION AND OPERATION

1.1 Tractor designation

Tractor “BELARUS - 920.4” is manufactured on the base of tractor “BELARUS - 920.3”.

Tractor “BELARUS - 952.4” is manufactured on the base of tractor “BELARUS - 952.3”.

Tractors “BELARUS - 920.4 / 952.4” are designed for executing various agricultural works

with mounted, semi-mounted and trailed machines and implements, for loading-unloading works,

transportation works and for driving stationary agricultural machines; they are supplied to con-

sumers in the Republic of Belarus and abroad.

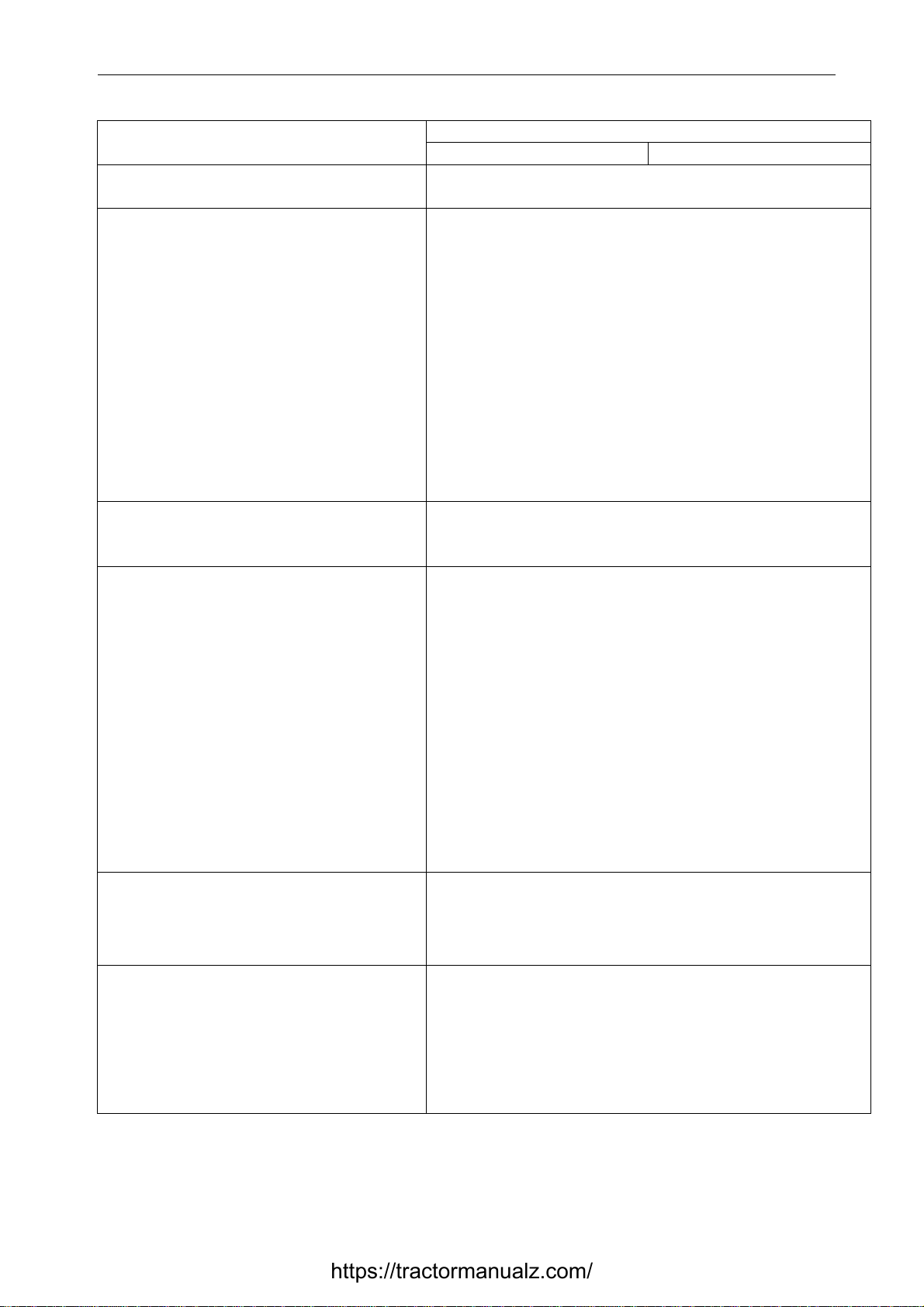

1.2 Technical characteristics

1.2.1 General description

The tractors “BELARUS - 920.4/952.4” represent universal row-crop tractors of drawbar

category 1.4.

The tractors “BELARUS - 920.4” are equipped with engine D-245.43S3А, produced by

Minsk motor works, with electronic control system, with power of 62 kW. Engine conforms to en-

vironmental requirement of stage III A according to harmful substance emission.

Tractors “BELARUS - 952.4” is equipped with engine D-245.5S3А, produced by Minsk

motor works, with electronic control system, with power of 70 kW. Engine conforms to environ-

mental requirement of stage III A according to harmful substance emission .

Clutch coupling: friction, single-disk, closed-circuit, mechanically controlled.

Clutch facings: cerametallic.

Gearbox: mechanical, synchronized, with synchronized accelerator, doubling number of

gears.

Rear axle: with main gear, differential and final drives. Differential lock control: electrohy-

draulic.

Front driving axle: with main gear, self-locking differential, final drives (planetary-

cylindrical reduction gears). Front driving axle drive: transfer case with automatic engagement of

FDA, two cardan shafts and intermediate bearing with overload clutch.

Service brakes: multidisk, oil-bath lubricated (“wet”), installed on the shafts of driving pin-

ions of hub drives; parking brake – independent, with independent manual control.

Trailer brake drive: hydraulic, interconnected with tractor brake control or combined

pneumatic drive interconnected with tractor brake control.

Hydraulic system: remote-cylinder with hydraulic hoist, with rear right-hand duplicated

outlets of hydraulic system.

Rear lift linkage NU-2, with adjustable braces; NU lower links: telescopic; rod interlock-

ing: outer, by means of telescopic tie-rods.

Rear power take-off shaft (PTO): separate, two-speed (540 and 1000 min-1) and synchro-

nous, rotation direction – clockwise from the side of shank end. PTO shanks: PTO 1 (6 or 8

splines, 540 min-1), PTO 2 (21 splines, 1000 min-1).

Cabin: unified, protection, securing safety, microclimate, protection against noise and vi-

bration. Cabin is equipped with an electric wipers for front and rear windows and front window

washer, climatic unit and cabin heater, Grammer sprung seat, adjustable according to operator’s

height and weight. Additional front working headlights are installed on the brackets of front lamps.

https://tractormanualz.com/