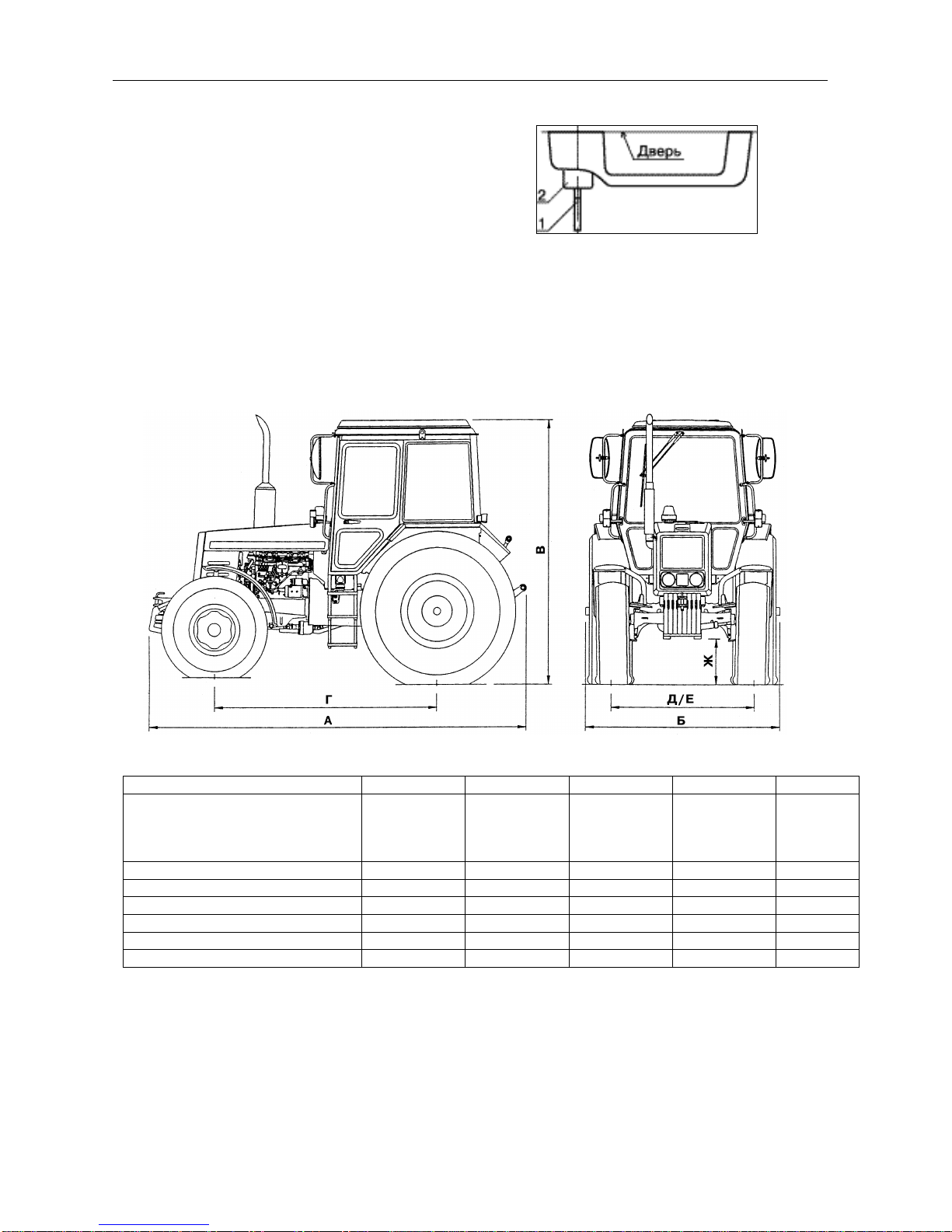

The tractor Belarus 82 P, intended for

work on rice-growing fields, features in-

creased ground clearance and, also, by

a modified propulsion gear –wide cross-

section low-pressure tyres, with well-

developed (scalloped) lugs and low-

profile tread pattern. An increased

ground clearance is achieved through

installation of an additional hub drive, as

well as the use of tyres of larger diame-

ters. The rice-field tractor is equipped

with a FDA control and parking brake in-

terlocking mechanism.

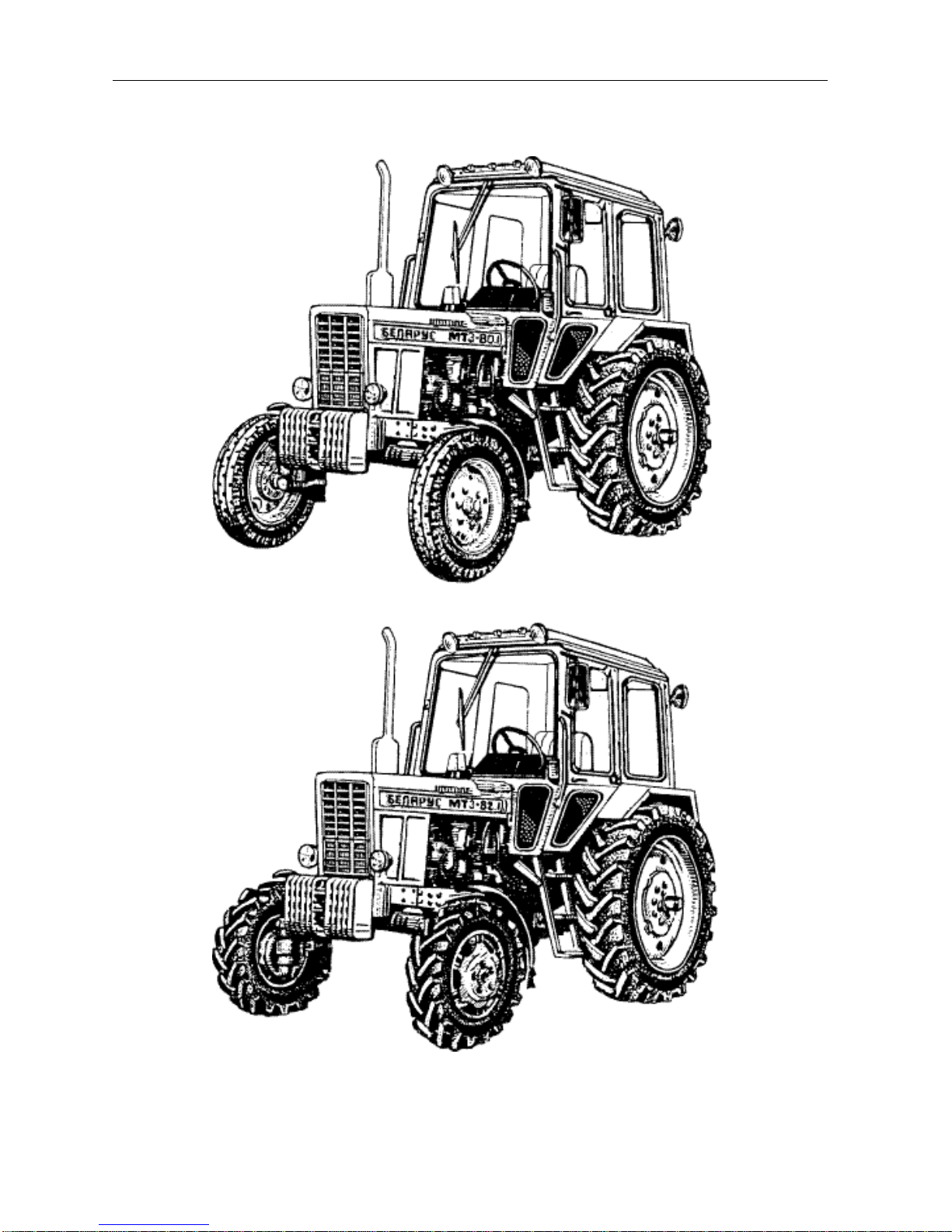

The Tractor Hitch Linkage System in-

corporates a hydraulic system and a rear

hitch linkage. The hydraulic system com-

prises an oil pump, distributor, draft control,

rear and external hydraulic cylinders. Trac-

tor may be shipped as equipped with a

draft (position) control system or without

this system.

The Rear Hitch Linkage is a four-link

mechanism, with length-adjustable drop

links.

A RHL fixing mechanism is provided to

hold mounted implements at the extreme

upper position on transport missions.

When running with trailed machines, a

cross-bar with a hitch yoke can be used,

while on transport missions —install a

towing arrangement with a self coupling

device and a hydraulic pick-up hook.

Трактор оборудован пневматической

системой управления тормозами при-

цепов с пневматическим или гидрав-

лическим приводом тормозов.

Electrical Equipment —d.c., 12 V rated

voltage.

Tractor (Unitized) Cab is a safety sealed

frame-and-panel structure, equipped with a

single torsion seat, adjustable to operator’s

height and weight. An additional seat (op-

tion) can be installed. Cab windows are

safety heat-absorbing monolithic glass. The

cab is furnished with a heating and air-

ventilation system, a dome light, windscreen

wipers, sun visor, rear-view mirror. Natural

ventilation of the cab is achieved through

opened sunroof, rear and side windows.

Provision is made for the change of angle of

the steering wheel column within 15 deg., as

a matter of convenience when entering and

leaving the cab or operating the tractor, as

well as for height adjustment within 100 mm.

Also provided is a three-step sideboard and

handrails.

Installation of a unitized cab is paralleled

with installation of a small-size cab on cer-

tain tractor batches, against a separate or-

der.

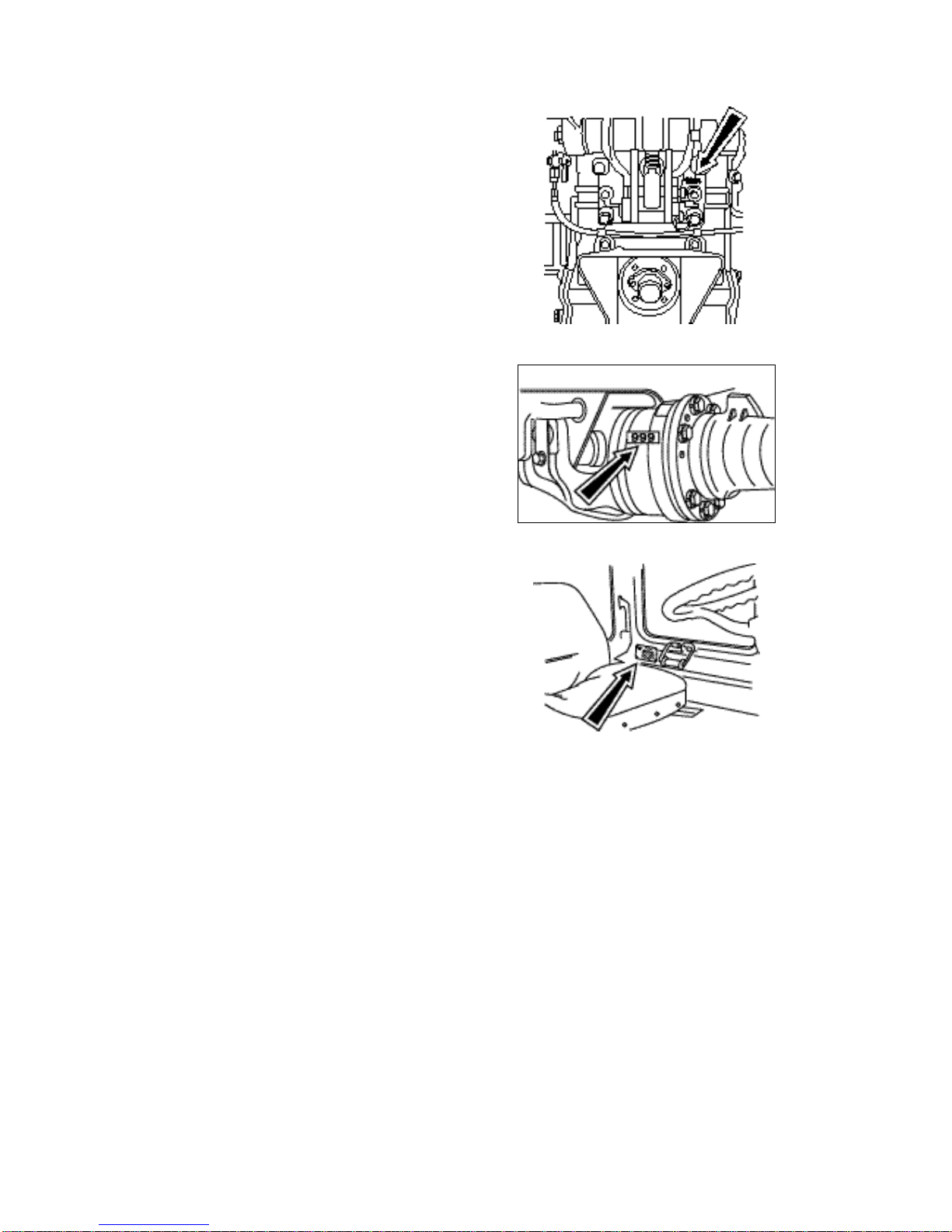

The diesel-engine cover is attached to the

radiator grille facing frame by hinges; in its

open position it is fixed with an arresting

catch.

On a separate order, the tractor may be

supplied with optional extras: a drive pul-

ley, side P.T.O., rear P.T.O. shaft replace-

able tail-end (21 splines), reverse-reducer,

additional counterweights, P.T.O.-2 tail-end

guard, wheels with 18,4L-30; 9,5-42 tyres,

starting pre-heater, automatic coupler СА-

1, hydraulic pick-up hook (ТСУ-2), pneu-

matic adapter, a cross-bar of the coupling

device (ТСУ-1-Ж), device ТСУ-З-К(haul-

and-draw coupler arrangement), break-

away couplings with bracket, coupling hos-

es, left-hand adjustable drop link, auxiliary

spacer-ring piece for mounting rear

wheels, first aid kit, additional seat, and

others. Besides, the tractor can be

equipped with a travel speed superreducer

which is purchased separately by the user,

on his own. Also, the tractor should be

equipped with a gearbox suitable for instal-

lation of the speed superreducer.

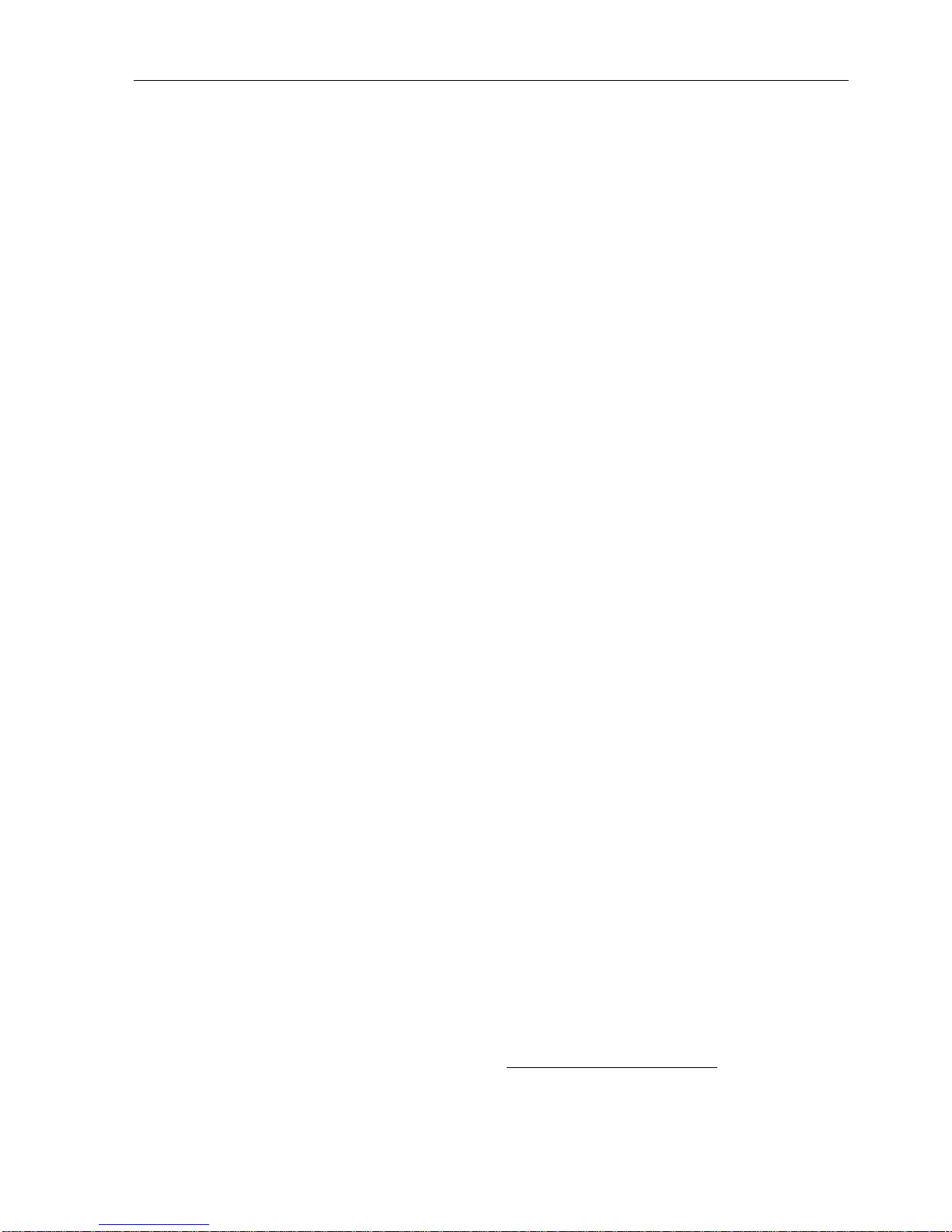

The left-hand cab door can be locked. To

open thedoor-lock from the outside:

•insert a provided key 1 (Fig. 2а) into

the slot in the barrel 2 of the handle;