3

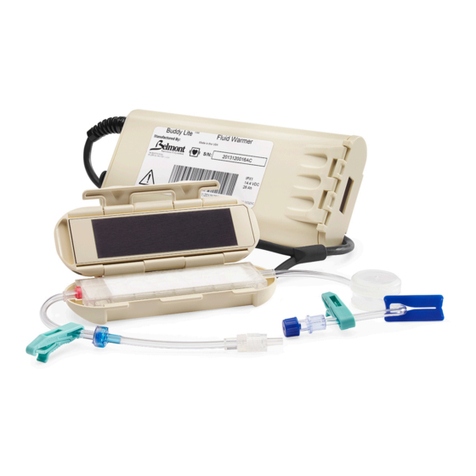

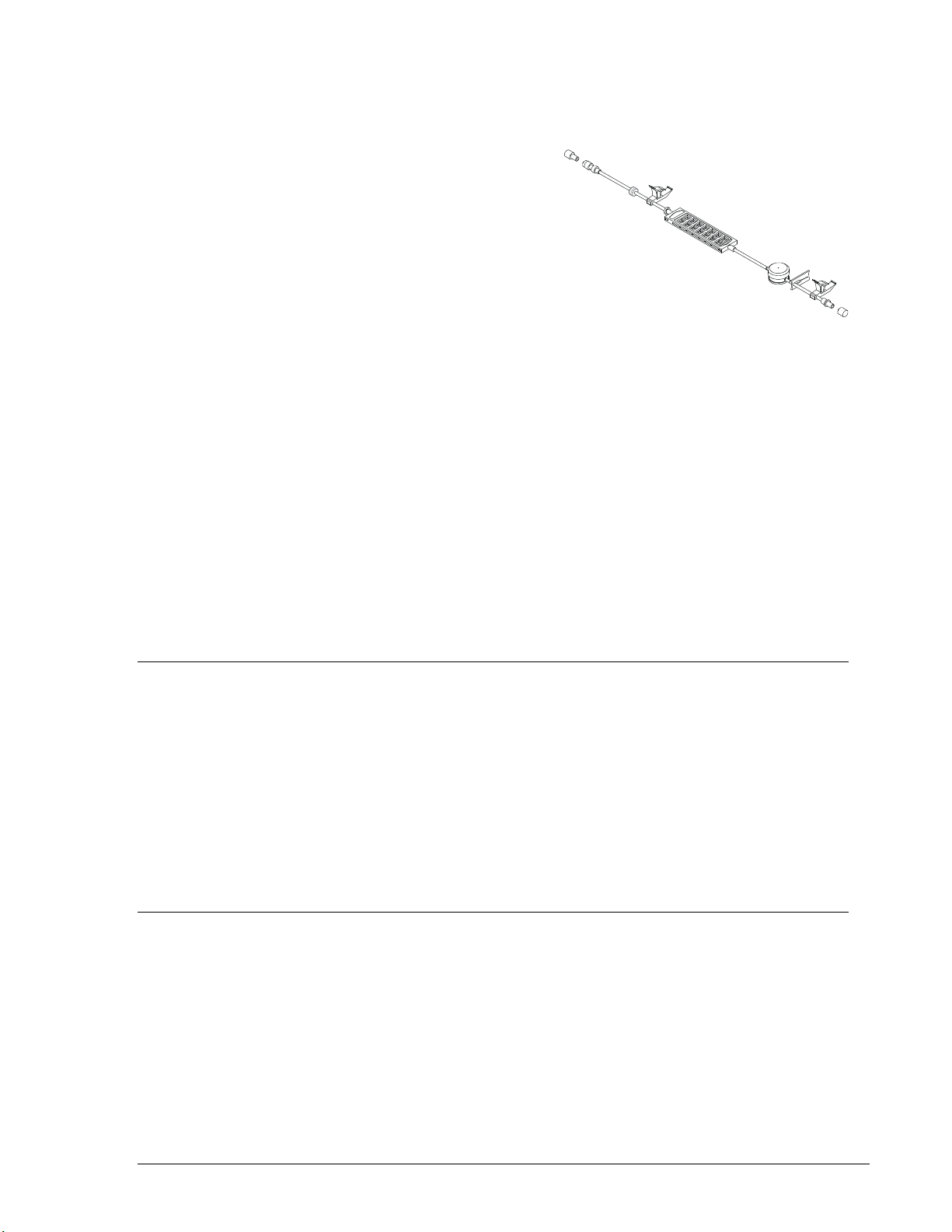

The disposable set has a sterile fluid path,

and is intended for single use only.

The disposable set has standard luer connectors

and can be connected to any standard catheter.

It contains two thin films, which contact the heater plates

for rapid heating of the fluid, and

two internal microporous membranes to

vent out-gassed air that is generated

during heating, see Figure 2. Figure 2: The buddyTM Disposable set

The set is color-coded and keyed to ensure proper placement in the Heater Unit, blue at the

input from a fluid administration set. Both heater plates are heated during operation. There is

a built in valve in the disposable set to prevent air entrainment into the patient and a pressure-

regulating valve at the input to protect the set and the patient from unintended exposure to

high pressure applied to the IV line. This valve will allow increase flow by application of

pressure, up to 300 mmHg, but will prevent pressure higher than this from reaching the set or

IV line distal to it. There is also a check valve at the output to prevent a back flow.

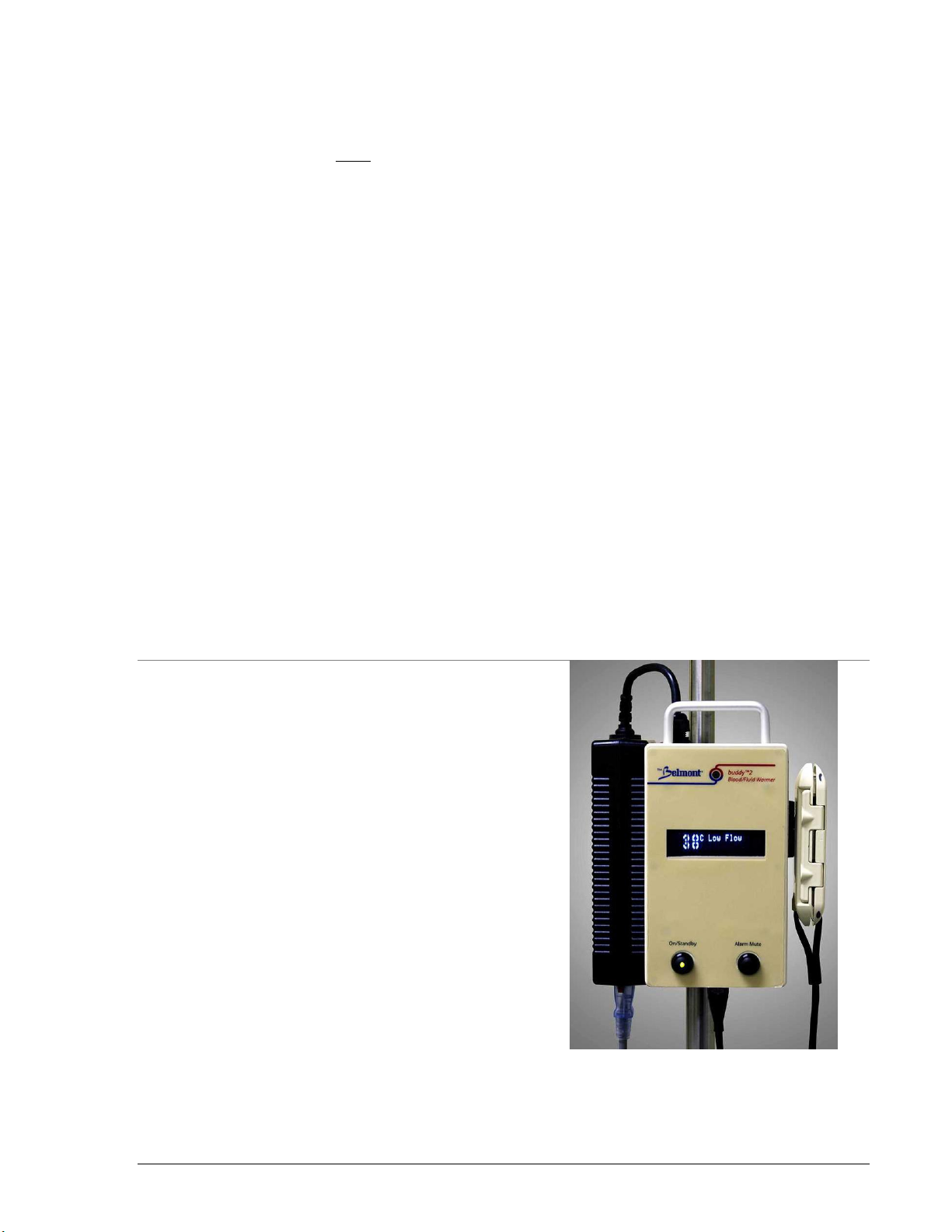

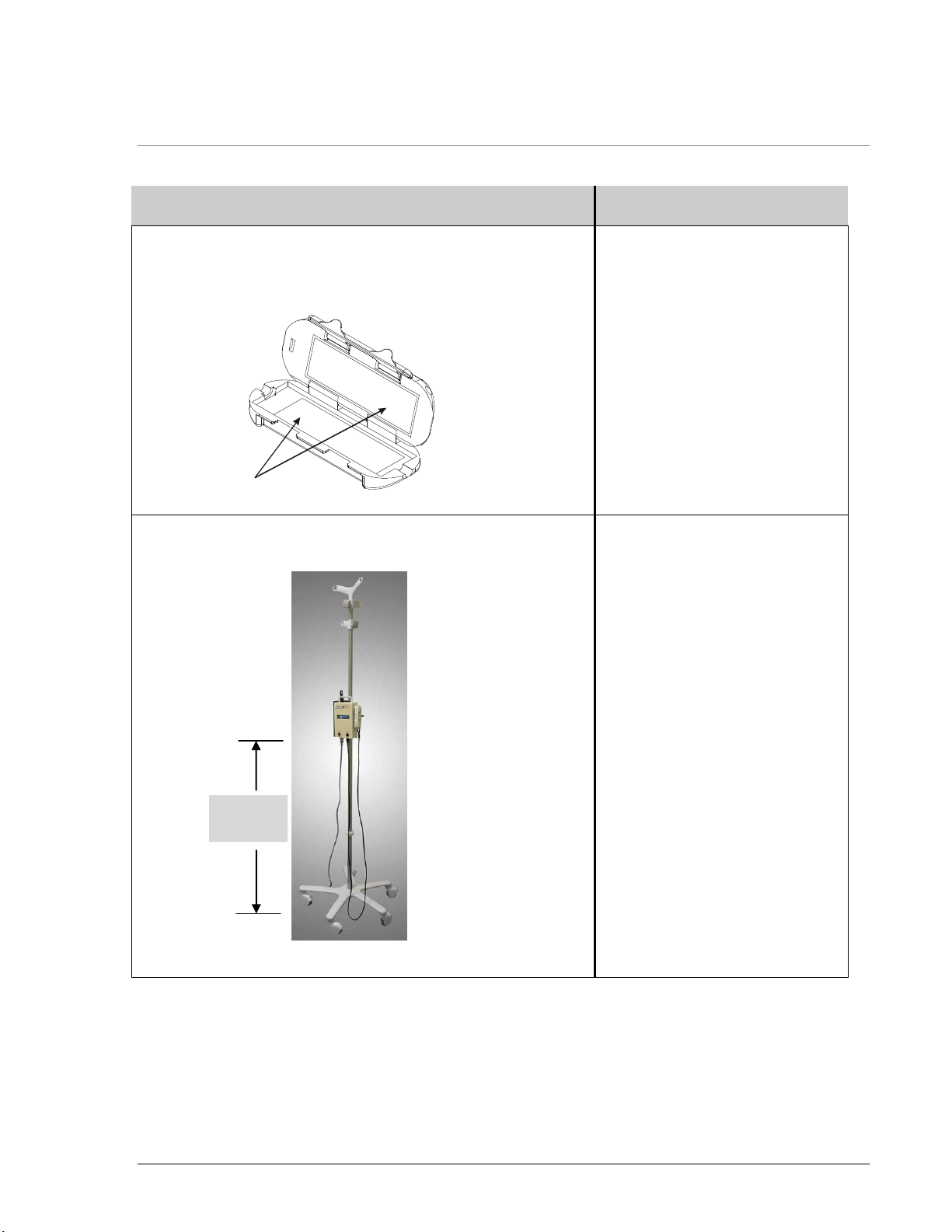

SYSTEM AND TEMPERATURE MONITORING

Blood or replacement fluid is heated as it passes through the disposable that is in contact with

the heater plates in the Heater Unit. Thermistors on the heater boards control and measure the

temperature of heater plates that in turn control the temperature of the infusate. The Power

Module displays the infusate temperature and alerts the user to alarm conditions. An over

temperature condition causes the unit to stop heating and issue an audible alarm. The low

temperature message (no audible alarm) informs the user that the flow rate is too rapid for the

device to maintain the temperature above 31 degrees Centigrade.

ALARMS AND ALARM MESSAGES:

Under any alarm condition, the system sounds an audible alarm, flashes a red LED, and

displays an alarm message on the screen. Certain alarms, such as Over Temperature, No

Heat/Check Connection, Over Current, Probe Fault and System Reset indicate system

problems and are always active.

The Empty Set/Check For Air alarm may be enabled or disabled from the front panel. If

this alarm is disabled, the message is still displayed, and the red LED is lit to alert the Operator.