INDEX

PAGE

SECTION 1: TECHNICAL DATA

[1] ELECTRICAL AND RADIATION DATA--------------------------------------------------------2

[2] PHYSICAL DIMENSIONS-------------------------------------------------------------------------3

[3] TUBE HEAD THERMAL CHARACTERISTICS-----------------------------------------------4

SECTION 2: PRE-INSTALLATION INSTRUCTIONS

[1] SUPPORT REQUIREMENTS----------------------------------------------------------------------5

[2] ELECTRICAL REQUIREMENTS-----------------------------------------------------------------5

[3] LOCATION OF COMPONENTS------------------------------------------------------------------6

SECTION 3: INSTALLATION INSTRUCTIONS

[1] INSTALLATION REQUIREMENTS--------------------------------------------------------------7

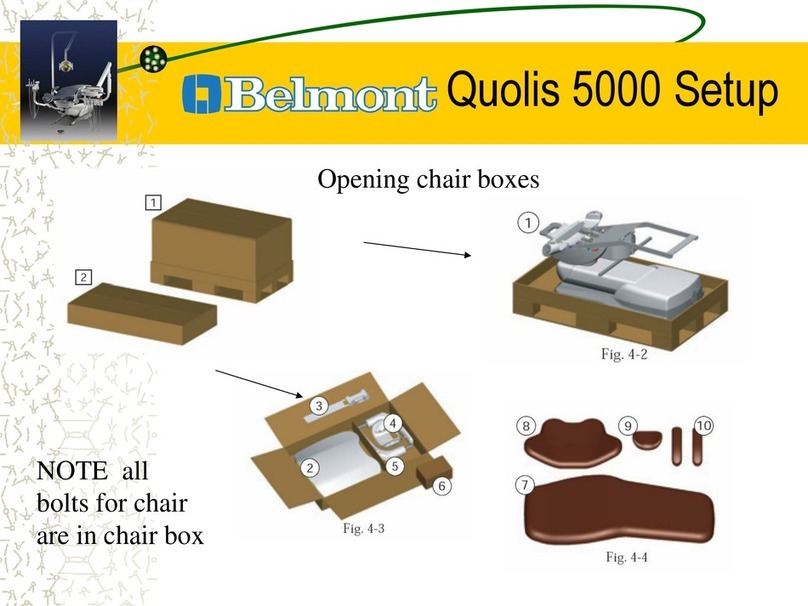

[2] UNPAC ING------------------------------------------------------------------------------------------7

[3] MAIN CONTROLLER AND ARM INSTALLATION------------------------------------------8

[4] HEAD ASSEMBLY INSTALLATION-----------------------------------------------------------12

[5] SUB CONTROLLER INSTALLATION---------------------------------------------------------14

[6] HAND EXPOSURE SWITCH (OPTION)------------------------------------------------------15

[7] EXTERNAL INTERLOC S (NOT SUPPLIED) ----------------------------------------------15

SECTION 4: POST INSTALLATION INSPECTION

[1] ARM ASSEMBLY-----------------------------------------------------------------------------------16

[2] BALANCE ARM TENSION ADJUSTMENT--------------------------------------------------16

[3] HEAD POSITIONING-----------------------------------------------------------------------------16

SECTION 5: CONTROL IDENTIFICATION AND OPERATION

[1] MAJOR COMPONENTS AND CONTROL DENTIFICATION-----------------------------17

[2] FUNCTION OF CONTROLS---------------------------------------------------------------------18

[3] OPERATING PROCEDURES--------------------------------------------------------------------21

[4] ESTIMATED AIR ERMA-----------------------------------------------------------------------21

[5] OPTIONAL HAND EXPOSURE SWITCH----------------------------------------------------21

[6] ERROR CODES------------------------------------------------------------------------------------22

[7] MAINTENANCE-----------------------------------------------------------------------------------23

[8] DISPOSAL-------------------------------------------------------------------------------------------23

SECTION 6: POST INSTALLATION CONFIRMATION

[1] CONFIRMATION OF POWER SUPPLY VOLTAGE-----------------------------------------24

[2] CONFIRMATION OF TUBE POTENTIAL COMPENSATION VALUE------------------24

[3] MA ADJUSTMENT --------------------------------------------------------------------------------24

[4] CONFIRMATION OF V AND MA------------------------------------------------------------25

[5] CONFIRMATION OF EXPOSURE WARNING & BUZZER-------------------------------25

[6] CONFIRMATION OF LINE VOLTAGE REGULATION------------------------------------25

SECTION 7: INITIAL SETTING

[1] SPEED SETTING FOR FILM AND DIGITAL IMAGING-----------------------------------26

[2] PRIORITY OF SELECTIONS--------------------------------------------------------------------27

[3] ELECTRONIC CHIME ON-OFF-----------------------------------------------------------------27

[4] ESTIMATED AIR ERMA DISPLAY SETTING---------------------------------------------27

APPENDIX 1: CIRCUIT DIAGRAM ----------------------------------------------------------------28

APPENDIX 2: MAINTENANCE CHECK LIST---------------------------------------------------29

APPENDIX 3: PARTS IDENTIFICATION

[1] CONTROLLER ASSEMBLY--------- ------------------------------------------------------------30

[2] ARM AND HEAD ASSEMBLY------------------------------------------------------------------32

-1-