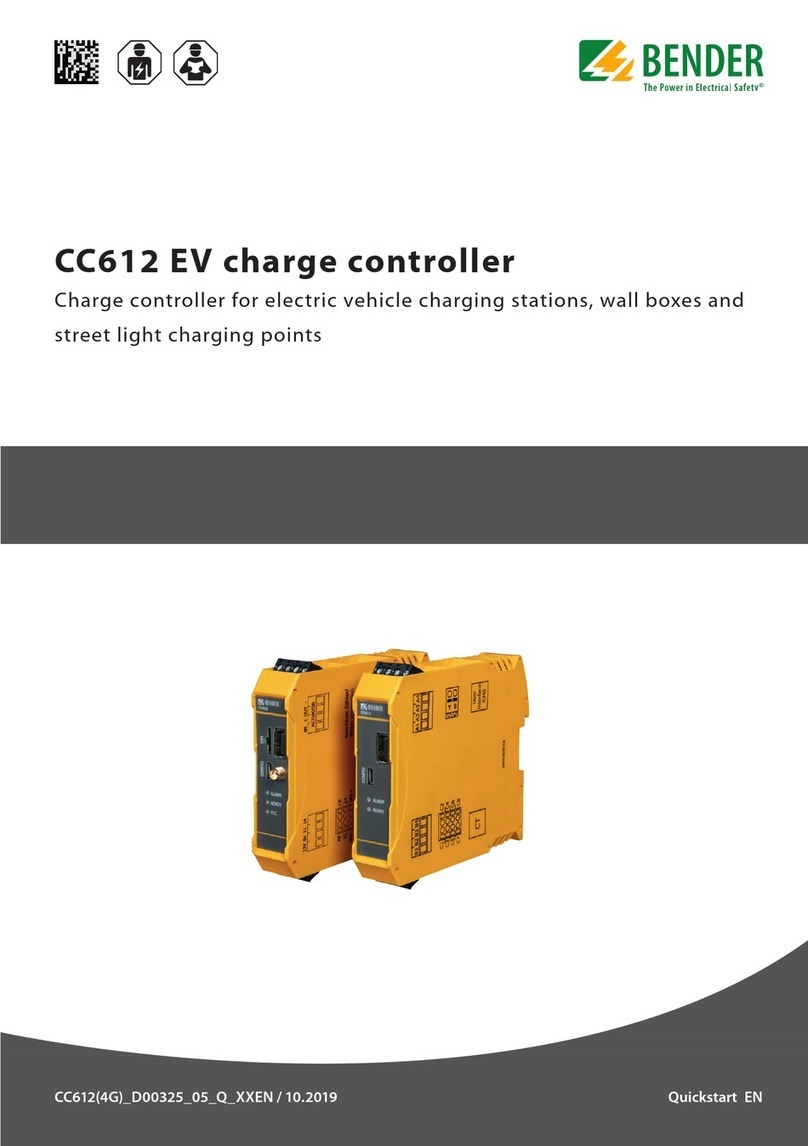

Bender CC613-H Series User manual

Manual ENCC613-Hxx_D00423_02_M_XXEN/11.2020

CC613-Hxx charge controller

Charge controller for wallboxes

2 CC613-Hxx_D00423_02_M_XXEN/11.2020

Service and support for Bender products

First-level support

Technical support

Carl-Benz-Strasse 8 • 35305 Grünberg • Germany

Telephone: +49 6401 807-760

0700BenderHelp *

Fax: +49 6401 807-629

E-mail: support@bender-service.de

Available on 365 days from 7.00 a.m. to 8.00 p.m. (MEZ/UTC +1)

* Landline German Telekom: Mon-Fri from 9.00 a.m. to 6 p.m.: 6.3 cents/30 sec.; remaining time: 6.3

cents/min.

Mobile phone: higher, depending on mobile phone tariff

Repair service

Repair, calibration and replacement service

Londorfer Strasse 65 • 35305 Grünberg • Germany

Telephone: +49 6401 807-780 (technical issues) or

+49 6401 807-784, -785 (commercial issues)

Fax: +49 6401 807-789

E-mail: [email protected]

Field service

On-site service

Telephone: +49 6401 807-752, -762 (technical issues) or

+49 6401 807-753 (commercial issues)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Mon-Thu 7.00 a.m. to 4.00 p.m., Fri 7.00 a.m. to 1 p.m. (MEZ/UTC +1)

CC613-Hxx_D00423_02_M_XXEN/11.2020 3

CC613-Hxx charge controller

Table of content

1 General instructions .........................................................................5

1.1 How to use this manual..............................................................................................5

1.2 Indication of important instructions and information ...................................5

1.2.1 Signs and symbols........................................................................................................5

1.3 Training courses and seminars.................................................................................5

1.4 Delivery conditions.......................................................................................................5

1.5 Inspection, transport and storage ..........................................................................5

1.6 Warranty and liability...................................................................................................6

1.7 Disposal of Bender devices........................................................................................6

1.8 Safety.................................................................................................................................6

2 Function...............................................................................................7

2.1 Intended use...................................................................................................................7

2.2 Product features (depending on the variant).....................................................7

2.3 Product description......................................................................................................7

2.4 Functional description ................................................................................................7

2.4.1 General functions (depending on the variant) ..................................................8

2.4.2 Load current and cooling control (temperature monitoring)......................8

3 Dimensions and mounting ..............................................................9

3.1 Dimensions......................................................................................................................9

3.2 Mounting..........................................................................................................................9

4 Connection ....................................................................................... 10

4.1 Connection conditions............................................................................................. 10

4.2 Connection type 2 plug...........................................................................................10

4.2.1 Charging system with permanently attached type 2 cable....................... 10

4.2.2 Charging system with type 2 socket-outlet.....................................................12

4.2.3 Connection locking actuators (depending on the variant)........................ 14

4.3 Connectivity.................................................................................................................15

4.3.1 USB configuration interface (CONFIG) ...............................................................15

4.3.2 Ethernet interface (depending on the variant)...............................................15

4.3.3 STATUS LED.................................................................................................................. 15

4.3.4 12 V power supply..................................................................................................... 15

4.3.5 Contactor connection...............................................................................................15

4.3.6 Weld check ...................................................................................................................15

4.3.7 Alternative connection switching contact contactor................................... 16

4.3.8 PE monitoring..............................................................................................................17

4.3.9 Control Pilot (CP) and Proximity Pilot connections (PP)..............................17

4.3.10 Emergency opener ....................................................................................................17

4.3.11 Residual direct current monitoring module (RDC-M)...................................17

4.3.12 Connectivity with Modbus meters (depending on the variant)...............17

4 CC613-Hxx_D00423_02_M_XXEN/11.2020

5 Configuration and testing............................................................. 19

5.1 Configuration...............................................................................................................19

5.1.1 Local configuration of parameters ......................................................................19

5.1.2 Factory settings...........................................................................................................20

5.1.3 Testing and system boot process ........................................................................20

5.1.3.1 Ethernet.....................................................................................................................................21

5.1.4 Plug locking and unlocking (depending on the variant)............................ 21

5.1.5 Charging........................................................................................................................21

6 Technical data.................................................................................. 22

6.1 Tabular data .................................................................................................................22

6.2 Ordering details..........................................................................................................25

6.3 Document revision history ..................................................................................... 26

CC613-Hxx_D00423_02_M_XXEN/11.2020 5

CC613-Hxx charge controller

1 General instructions

1.1 How to use this manual

This manual is intended for qualified personnel working in electrical engineering and electroics! Part

of the device documentation, in addition to this manual, is the enclosed "Safety instructions for

Bender products".

Read the manual before mounting, connecting and commissioning the device.

Always keep the manual within easy reach for future reference.

1.2 Indication of important instructions and information

I Danger! Indicates a high risk of danger that will result in death or serious injury if not avoided.

I Warning! Indicates a medium risk of danger that can lead to death or serious injury if not avoided.

I Caution! Indicates a low-level risk that can result in minor or moderate injury or damage to property if

not avoided.

i

Information can help to optimise the use of the product.

1.2.1 Signs and symbols

Disposal Temperature range Protect from dust

Protect from mois-

ture

Recycling RoHS directives

1.3 Training courses and seminars

www.bender.de > Know-how-> Seminars.

1.4 Delivery conditions

The conditions of sale and delivery set out by Bender apply. These can be obtained from Bender in printed or

electronic format.

The following applies to software products:

"Softwareklausel zur Überlassung von Standard- Software als Teil von Lieferungen, Ergänzung

und Änderung der Allgemeinen Lieferbedingungen für Erzeugnisse und Leistungen der

Elektroindustrie" (software clause in respect of the licensing of standard software as part of deliv-

eries, modifications and changes to general

delivery conditions for products and services in the electrical industry)

1.5 Inspection, transport and storage

Check the shipping and device packaging for transport damage and scope of delivery. The following must be

observed when storing the devices:

Die Elektroindustrie

6 CC613-Hxx_D00423_02_M_XXEN/11.2020

General instructions

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to property are excluded in case of:

Improper use of the device.

• Incorrect mounting, commissioning, operation and maintenance of the device.

• Failure to observe the instructions in this operating manual regarding transport, commissioning,

operation and maintenance of the device.

• Unauthorised changes to the device made by parties other than the manufacturer.

• Non-observance of technical data.

• Repairs carried out incorrectly

• Use of accessories and spare parts not recommended by Bender

• Catastrophes caused by external influences and force majeure.

• Mounting and installation with device combinations not recommended by the manufacturer.

This operating manual and the enclosed safety instructions must be observed by all persons working with the

device. Furthermore, the rules and regulations that apply for accident prevention at the place of use must be

observed.

1.7 Disposal of Bender devices

Abide by the national regulations and laws governing the disposal of this device.

For more information on the disposal of Bender devices, refer to

www.bender.de -> Service & support.

1.8 Safety

If the device is used outside the Federal Republic of Germany, the applicable local standards and regulations

must be complied with. In Europe, the European standard EN 50110 applies.

I Danger! Risk of electrocution due to electric shock! Touching live parts of the system carries the risk of:

• A fatal electric shock

• Damage to the electrical installation

• Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-energised. The rules

for working on electrical systems must be observed.

CC613-Hxx_D00423_02_M_XXEN/11.2020 7

CC613-Hxx charge controller

2 Function

i

Local access to the charge controller

Local access to the charge controller is possible either as operator or as manufacturer. Further details are

described in chapter 5.1.1.

Operator access is possible via the http://192.168.123.123/operator:

- User name: operator

- Password: yellow_zone

The manufacturer can access the manufacturer area via the URL http://192.168.123.123/manufacturer:

- User name: manufacturer

- Password: orange_zone

i

The default passwords should be changed to prevent unauthorised access.

2.1 Intended use

The CC613-Hxx charge controller, hereinafter referred to as "charge controller", is the main component of a

charging system. It is intended for use in wallboxes installed in domestic environments. The CC613-HB variant

is designed for the use of a permanently attached cable and the CC613-HEM-X2 variant controls type 2 socket

outlets and permanently attached charging cables. The charge controller enables a setup that complies with

the requirements of current standards, e.g. IEC 61851-1 and IEC 62955.

2.2 Product features (depending on the variant)

• Charge controller in accordance with IEC 61851-1 (mode 3 charging)

• Residual direct current monitoring module (external RCD type A required), different cable lengths

can be selected

• Integrated emergency opener for actuator control (locking/unlocking) and monitoring of the 12 V

supply voltage

• Can be integrated in single- or three-phase systems up to 80 A

• 3 USB interfaces:

– 1 CONFIG interface for local configuration and installation of software updates

– 2 USB host interfaces

• Control Pilot and Proximity Pilot communication (acc. to IEC 61851-1)

• Internal temperature sensor to reduce the charging current depending on the ambient tempera-

ture

• ISO 15118 Powerline Communication (PLC) for plug & charge or autocharge

• Ethernet-interface

2.3 Product description

The charge controller is designed for use in compact wallboxes and primarily controls the charging process of

an electric vehicle. It monitors the internal hardware of the wallboxes.

Refer to "Ordering details" for product variants.

2.4 Functional description

The charging system consists of an RCD type A and a contactor. These are directly connected to a type 2 sock-

et-outlet, or to a permanently attached cable (see chapter "Charging system with type 2 socket- outlet").

8 CC613-Hxx_D00423_02_M_XXEN/11.2020

Function

2.4.1 General functions (depending on the variant)

• The charging system can be equipped with a meter. A Modbus meter is required for digital reading

of the energy consumption. The Modbus RTU wires are attached directly to the charge controller.

• A 12 V power supply is needed for operation.

• Power flow toward the vehicle is enabled by enabling the contactor via an integrated 230 V control

relay in the charge controller.

• For fault current detection in an AC charging system, the charge controller features an integrated

residual direct current monitoring module (RDC-M) which uses an externally connected current

transformer. With the integrated monitoring of the DC fault current, only an RCD type A is required

in the charging system.

• Data exchange between the electric vehicle and the charging system is possible via ISO 15118 com-

pliant Powerline Communication (PLC).

• Data management and control functionality of the charge controller:

– Termination of the charging process after tripping of the residual current device (RCD) due to a

residual current.

– Detection of critical fault currents by the RCM sensor. For the vehicle owner, this can be an early

warning, provided that the charge controller is connected to an energy management system

and that it supports this function.

i

The charge controller with residual direct current monitoring module (RDC-M) only works in combination

with the measuring current transformer (to be ordered separately).

I Caution! Risk of damage when pulling out the measuring current

transformer plug! If the measuring current transformer plug is pulled out

using too much force, the enclosure and the internal components may be

damaged. Use needle-nose pliers to unlock the measuring current transfor-

mer plug.

2.4.2 Load current and cooling control (temperature monitoring)

The charge controller is equipped with a temperature sensor, which allows the temperature in the environ-

ment of the charge controller to be estimated. Based on this estimation it is possible to dynamically reduce

the charging current or even suspend charging. This feature can serve to maintain the temperature inside the

enclosure within the permissible range for the components used in a charging system. Two temperature

thresholds for charging current reduction and charging interruption can be set via the Manufacturer tab.

i

The actual temperature is affected by heat generated by the controller itself.

CC613-Hxx_D00423_02_M_XXEN/11.2020 9

CC613-Hxx charge controller

3 Dimensions and mounting

3.1 Dimensions

Abb. 3–1 Note: Dimensions in mm acc. to ISO 2768 - m

* Dimensions incl. antenna socket (depending on the variant)

3.2 Mounting

i

DIN rail mounting

Lateral distance to other equipment: 6 mm (self-heating)

In horizontal mounting position the max. operating temperature is reduced by 15 °C (refer to "Other" in the

technical data).

111 (112,3*)

23,5

99

2.

Click!

3.

1.

10 CC613-Hxx_D00423_02_M_XXEN/11.2020

Connection

4 Connection

4.1 Connection conditions

I risk of electric shock! Parts of the system may be live (charge controller terminals up to 230 V, charging

station 400 V). Before touching parts of the system, ensure that it has been de-energised.

I Caution! Risk of injury from sharp-edged terminals! Handle enclosure and terminals with care.

i

Information:

• PE is connected to "0V"; reference level for Control Pilot (CP communication) must be at the same

level as the power supply (IEC 61851 series of standards).

• Lay cables only inside the wallbox and not in parallel with power cables.

• Cable lengths (except Modbus, Ethernet, Power IN and charging cable): < 3 m.

• Maximum cable length Ethernet: 100 m.

• Maximum cable length Modbus: 250 m.

• The Ethernet shield is directly connected to PE.

• External Modbus must be terminated by the customer with a terminating resistor of 120 Ω.

i

For further information on connection, refer to the manuals of the accessories (e.g. W15BS).

4.2 Connection type 2 plug

4.2.1 Charging system with permanently attached type 2 cable

L1

L1

L3

NPE

L2/N

L1

CS CP

PE

PP

CP

PE

L1 N

L3

L2

L2

N

PE

CC613-Hxx_D00423_02_M_XXEN/11.2020 11

CC613-Hxx charge controller

12 CC613-Hxx_D00423_02_M_XXEN/11.2020

Connection

4.2.2 Charging system with type 2 socket-outlet

Wiring diagram

top front bottom

N

L3

L2

L1

PE

J

M

–

+

q

CP

PP

PE

NL1

L2

L3

PE

0V

CP

B Mod.

PP

PE

+12V

A Mod.

D

B

A

C

J

H

F

L

H

WA

24

WB

23

B

B

HS2

A

HS1

AC

DC

0 V

12 V

n

p

H

V

m

o

12

CT

0V

PE

B Modbus

CP

+12V

PE

A Mod.

PP

WA

Relais 23

WB

Relais 24

230V only

Opto1 In-

Motor A

Motor HS1

Relais 13

Opto1 In+

Motor B

Motor HS2

Relais 14

GND2 Modbus

B2 Modbus

A2 Modbus

User

interface

RJ45

ETH1

10/100 Mbit

USB

Host

Side view from right

CC613-Hxx_D00423_02_M_XXEN/11.2020 13

CC613-Hxx charge controller

Legend

A Connection measuring current transformer (CT) mRCD type A

B 12 V supply, PE, Modbus meter, CP, PP nVoltage supply DC 12V

C 2x USB type A (depending on the variant) oMeasuring current transformer (CT)

with plug

D Connection Ethernet (depending on the variant) pContactor

F Conguration interface qType 2 socket-outlet

H Weld check, relay for contactor control rated for 230V/4 A

J Locking (depending on the variant)

L STATUS LED

Terminal assignment

B

0V Input 0V

+ 12V Supply voltage +12V

PE Input PE

PE Input PE

B Mod. Modbus meter B

J

A Mod. Modbus meter A

CP Control Pilot A Actuator A: Locking actuator output negative

PP Proximity Pilot B Actuator B: Locking actuator output positive

HS2 Actuator HS2: Locking input actuator switch

H

WA Weld check input L1 HS1 Actuator HS1: Locking 12V output actuator switch

23 Relay 23: Switching contact

contactor

WB Weld check input N

24 Relay 24: Switching contact

contactor

I Caution! Switching contact contactor and weld check at terminal H are only suitable for mains voltage

(230 V)!

Not permitted for SELV/PELV voltages.

i

For variants with a permanently attached charging cable, the terminals J for plug locking and the wiring of

the Proximity Pilot (PP) to terminal B are not required.

14 CC613-Hxx_D00423_02_M_XXEN/11.2020

Connection

4.2.3 Connection locking actuators (depending on the variant)

Type 2 socket-outlet (actuator type) Actua-

tor

A HS1 B HS2

Socket-outlet actuator wiring

• Mennekes (31016, 31023, 31024, 31038)

• Bals (801191-801195, 80300, 9743205000,

9743211000)

• Walther Werke (9743211000)

• Harting

Hella

Wire 3

(///)

Wire 1

(/)

Wire 2

(//)

• Walther Werke Eco Slim 32 A (9743205180)

with connection cable (790000001)

Wire 3

(black)

Wire 1

(blue)

Wire 2

(red)

• Phoenix Contact (1624129) Küster BU/BN BU/YE BU/RD BU/GN

Example Hella actuator:

Example Küster:

M

CP

PP

PE

NL1

L2

L3

B

HS2

A

HS1

M

CP

PP

PE

NL1

L2

L3

In+

B

14

HS2

In-

A

13

HS1

BU/YE

BU/RD

BU/BN

BU/GN

CC613-Hxx_D00423_02_M_XXEN/11.2020 15

CC613-Hxx charge controller

4.3 Connectivity

4.3.1 USB configuration interface (CONFIG)

The USB configuration interface (CONFIG) on the front panel of the charge controller is connected to a con-

ventional laptop, PC or tablet computer via a micro USB cable. This interface allows local configuration of the

charge controller. In addition, it enables the installation of software updates (for a configuration description,

refer to chapter "Configuration and testing"). The web interface can be accessed via the IP address

192.168.123.123.

4.3.2 Ethernet interface (depending on the variant)

The charge controller can be connected to an existing Ethernet network via an Ethernet interface. For further

information, refer to chapter "Configuration and testing".

4.3.3 STATUS LED

The "STATUS" LED on the front panel indicates the following system states:

Power on/system not ready for operation

System is starting

System started, not ready for operation yet

System ready for operation

System error

4.3.4 12 V power supply (depending on the variant)

The charge controller is supplied with power from a 12 V main voltage source at the +12 V and 0V connec-

tions.

4.3.5 Contactor connection

The charge controller controls the contactor, which in turn controls the power flow toward the vehicle. The

contactor is controlled via a relay in the charge controller, the contacts of which are rated for 230 V/4 A.

4.3.6 Weld check

By means of the measuring lines WA/WB (terminal designation) an impermissible closing of the contactor con-

tacts, e.g. welding/sticking, can be detected.

16 CC613-Hxx_D00423_02_M_XXEN/11.2020

Connection

Wiring diagram

I risk of a short circuit! According to DIN VDE 0100-430, devices for protection against a short circuit can be

omitted for the coupling of terminals WA and WB if the wiring is carried out in such a manner as to reduce

the risk of a short circuit to a minimum. (A short-circuit-proof and earth-fault-proof wiring is recommen-

ded). The connecting lines WA and WB to the system to be monitored must be designed as spur lines. No

load current may be conducted through the terminals.

4.3.7 Alternative connection switching contact contactor

Detail of wiring diagram chapter "Charging system with type 2 socket outlet"

The control voltage of the contactor can alternatively be supplied directly via a common fuse of the 12-V

power supply. For this purpose, the fuse must be selected accordingly.

I Caution: DC fault currents, caused by the contactor or the control relay, are not detected.

H

WA

24

WB

23

CP

PP

PE

NL1

L2

L3

L1L2L3N

PE

D

B

A

C

H

WA

24

WB

23

AC

DC

0 V

12 V

n

p

H

V

m

o

CC613-Hxx_D00423_02_M_XXEN/11.2020 17

CC613-Hxx charge controller

4.3.8 PE monitoring

The PE monitoring checks whether there is a connection from the CC613 to PE. For this purpose, L1 must be

connected to WA. The cable length is limited by its capacitance per unit length.

I Pe monitoring does not replace tests (example: protective conductor resistance).

I the Ethernet shield and the USB shield are directly connected to PE. This must be taken into account in

the test!

I hV test: WA is coupled to PE via a protective circuit and with approximately 140 kΩ. Above 500 V, a

leakage current flows to PE. Test voltages above AC 1000 V/1 sec. are not permissible!

4.3.9 Control Pilot (CP) and Proximity Pilot connections (PP)

The Control Pilot (CP) and Proximity Pilot (PP) contacts connect the charge controller to the socket-outlet, en-

abling it to communicate with the vehicle and the cable plug. The PP contact detects the presence of the plug

and the CP contact exchanges control signals between the electric vehicle and the charging station (see IEC

61851).

i

PP is not required if the charging cable is permanently attached.

4.3.10 Emergency opener

The emergency opener is integrated as a circuit group in the charge controller. In the event of a power failure,

the plug of the charging cable is automatically unlocked so that it can be removed

4.3.11 Residual direct current monitoring module (RDC-M)

For residual current detection in an AC charging system, an integrated residual direct current monitoring

module (RDC-M) is used. This module uses an external magnetically shielded measuring current transformer.

This allows the use of a residual current device (RCD) type A instead of an RCD type B. The relay in the charge

controller is de-energised if, during the charging process, a fault current

IΔn ≥ DC 6 mA flows.

4.3.12 Connectivity with Modbus meters (depending on the variant)

The use of a meter is not mandatory. It is necessary if measured values are required during normal operation.

The meter is connected to the Modbus meter interface (terminal B) of the charge controller. Various Modbus

meters are currently supported, including:

• ABB B23 series

• B-Control EM300-LR/EM300-LR (TCP)

• Carlo Gavazzi EM200/EM340

• Eastron SDM120/SDM220/ SDM630 series

• Finder

• Garo EM270/GNM1D/GNM3D/GNM3T/GM3T

• IME CE4DMID31

18 CC613-Hxx_D00423_02_M_XXEN/11.2020

Connection

• inepro PRO1/PRO2/PRO380

• NZR EcoCount S85

• Optec

• Phoenix Contact EEM-MB371 (TCP)

• Saia ALE3

• Siemens 7KT1666/7KM2200 (TCP)

Meter Slave ID Baud rate Parity Data Bit Stop Bit

1 9600 N (none) (except Saia) -> even 8 1

Additional Modbus meters can be included in future software updates upon customer request. Refer to the

Manufacturer tab on the web server for a list of supported Modbus meters.

The Modbus meter interface is terminated with a terminating resistor of 120 Ω.

i

With use of a Modbus TCP meter it is possible to read the energy demand of external consumers (e.g. resi-

dential buildings). Depending on this, the maximum charge current can be set.

CC613-Hxx_D00423_02_M_XXEN/11.2020 19

CC613-Hxx charge controller

5 Configuration and testing

5.1 Configuration

The following options are available for configuring the charging system:

Access to web interface via the following interfaces:

• Micro USB configuration interface (CONFIG)

• Ethernet interface

5.1.1 Local configuration of parameters

In order to locally configure the charging system via the charge controller, it is necessary to connect a micro

USB cable to a laptop, PC or tablet computer with a standard USB host interface. Once connected, the charge

controller is recognised as a USB network adapter.

i

The USB configuration interface (CONFIG) emulates a Remote Network Driver Interface Specification

(RNDIS) network when it is connected to a Windows, Linux or Mac computer. For Windows 10 and higher,

Linux and Mac operating systems, this virtual network is automatically detected. No driver is required.

On a Windows host device with a different Windows operating system the driver for the RNDIS network

adapter must be manually selected:

• Open the device manager on the control panel.

• Right click the "RNDIS/Ethernet Gadget" menu item located at "Other devices" and select "Update

driver software".

• Select the option "Browse my computer for driver software".

• Then click on the option "Select from a list of device drivers on my computer".

• Select the category "Network adapters" from the list.

• In the window that appears, select the manufacturer "Microsoft Corporation" and the network

adapter "Remote NDIS Compatible Device". The device driver is then installed and the system rec-

ognises the charge controller as a network adapter.

The web interface for configuration can be accessed with an ordinary browser. The charge controller uses the

local IP address 192.168.123.123 with the subnet mask 255.255.255.0 via the configuration interface. The con-

nected device automatically receives a corresponding IP address via the Dynamic Host Configuration Protocol

(DHCP) after the connection has been established. The communication with the charging system is based on

this IP address.

Each parameter is adequately described on the respective web interface tab. For further information on the

parameters, refer to the State, Operator and Manufacturer tabs.

The State tab of the charging system control interface can be accessed via the URL http://192.168.123.123. It

only provides status information.

Besides displaying status information, parameters of the Operator and Manufacturer tab can be set:

The Operator tab of the charging system control interface can be accessed via the URL

http://192.168.123.123/operator. To access this tab, user name and password are required:

• User name: operator

• Password: yellow_zone

20 CC613-Hxx_D00423_02_M_XXEN/11.2020

Configuration and testing

The Manufacturer tab of the charging system control interface can be accessed via the URL

http://192.168.123.123/manufacturer. To access this tab, user name and password are required:

• User name: manufacturer

• Password: orange_zone

i

The default passwords should be changed to prevent unauthorised access.

The manufacturer can also change the user passwords and parameters via the Operator tab.

Application of changed parameters

Parameter changes are not necessarily applied after submission. To submit all changed parameters, click the

"Save & Restart" button at the bottom of the tab. A message indicating a necessary restart may appear.

I automatiC reboot of the charge controller! In order to ensure perfect functionality, the charge controller

carries out a regular system reboot.

i

After the web configuration interface has been accessed or while a vehicle is connected, the charging point

will suppress system reboots for at least 2 minutes to allow all parameters to be configured.

5.1.2 Factory settings

i

Resetting to factory settings deletes all settings except the serial number.

Click the "Operator Default & Restart" button on

the Operator tab to reset changed parameters

of the operator configuration to default.

Click the "Settings Default & Restart" button on

the Settings tab to reset changed parameters to

default.

Click the "Manufacturer Default & Restart" button on the Manufacturer tab to reset changed parameters of

the manufacturer configuration to default. Click the "Factory Reset & Restart" button to reset the charge con-

troller to factory settings.

5.1.3 Testing and system boot process

After completing the configuration, the charge controller must be tested for operability. This can be done us-

ing a vehicle simulator. The following is checked:

• Successful boot process

• Connection to meter possible (meter configuration)

• Plug locking and unlocking works (depending on the variant)

This manual suits for next models

2

Table of contents

Other Bender Controllers manuals

Bender

Bender ISOMETER isoMIL425HV User manual

Bender

Bender CC612 User manual

Bender

Bender CC612 EV User manual

Bender

Bender CC611 User manual

Bender

Bender PRC470 Series User manual

Bender

Bender ICC1324 User manual

Bender

Bender CC613 User manual

Bender

Bender CC612 User manual

Bender

Bender ISOMETER isoPV425 with AGH420 User manual

Bender

Bender RC48C User manual