Bender COMTRAXX COM462RTU User manual

Manual ENCOM462RTU_D00010_04_M_XXDE / 06.2021

COMTRAXX® COM462RTU

BMS-Modbus RTU gateway for the connection of BMS-capable Bender

devices to the Modbus RTU

Software version: D0415 V1.2x

2 COM462RTU_D00010_04_M_XXDE / 06.2021

Service and support for Bender products

First-level support

Technical support

Carl-Benz-Strasse 8 • 35305 Grünberg • Germany

Telephone: +49 6401 807-760

0700BenderHelp *

Fax: +49 6401 807-629

E-mail: support@bender-service.de

Available on 365 days from 7.00 a.m. to 8.00 p.m. (MEZ/UTC +1)

* Landline German Telekom: Mon-Fri from 9.00 a.m. to 6 p.m.: 6.3 cents/30 sec.; remaining time:

6.3 cents/min.

Repair service

Repair, calibration and replacement service

Londorfer Strasse 65 • 35305 Grünberg • Germany

Telephone: +49 6401 807-780 (technical issues) or

+49 6401 807-784, -785 (commercial issues)

Fax: +49 6401 807-789

E-mail: [email protected]

Field service

On-site service

Telephone: +49 6401 807-752, -762 (technical issues) or

+49 6401 807-753 (commercial issues)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Mon-Thu 7.00 a.m. to 4.00 p.m., Fri 7.00 a.m. to 1 p.m. (MEZ/UTC +1)

COM462RTU_D00010_04_M_XXDE / 06.2021 3

COMTRAXX® COM462RTU

Table of Contents

1 General instructions ..........................................................................5

1.1 How to use this manual..............................................................................................5

1.2 Indication of important instructions and information....................................5

1.2.1 Signs and symbols ........................................................................................................5

1.3 Training courses and seminars.................................................................................5

1.4 Delivery conditions.......................................................................................................5

1.5 Inspection, transport and storage ..........................................................................6

1.6 Warranty and liability...................................................................................................6

1.7 Disposal of Bender devices........................................................................................6

1.8 Safety .................................................................................................................................7

2 Product description ...........................................................................8

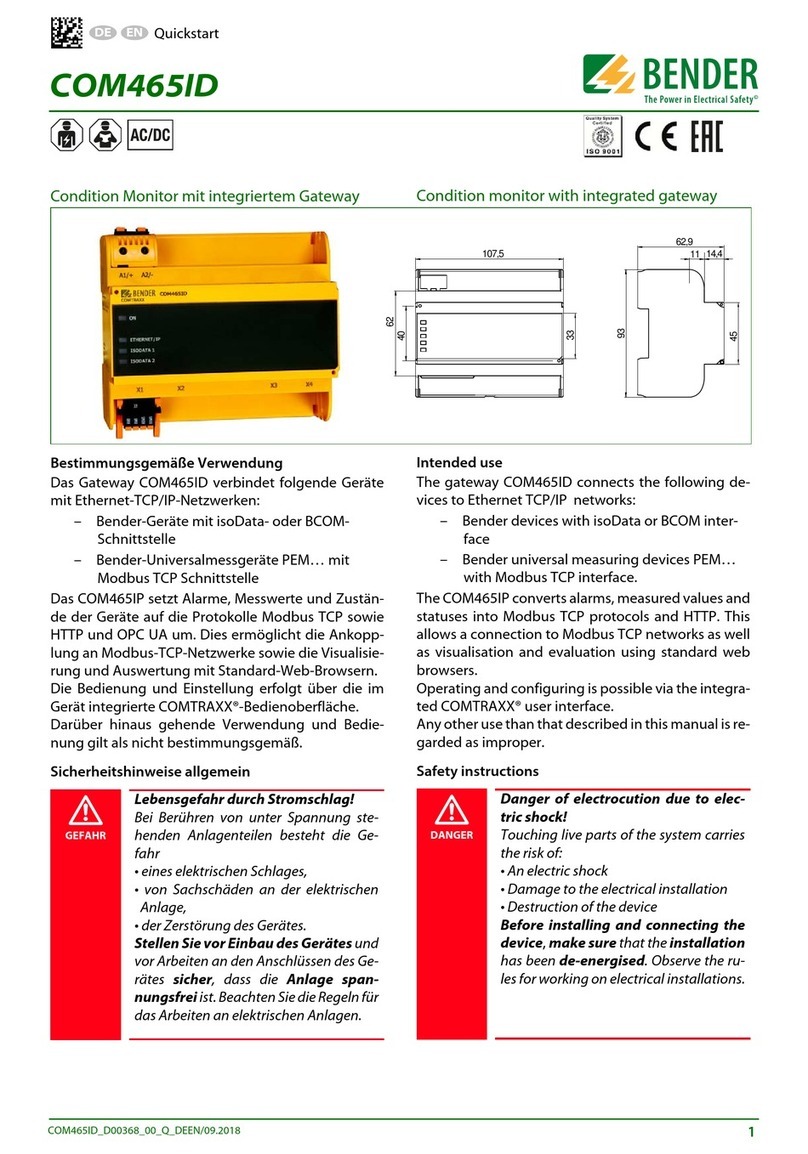

2.1 Intended use...................................................................................................................8

2.2 Address setting and termination ............................................................................8

2.3 Scope of delivery...........................................................................................................8

2.4 Short description...........................................................................................................8

2.5 Device features ..............................................................................................................9

2.6 Possible applications ...................................................................................................9

2.7 Details about the Modbus RTU................................................................................9

3 Installation, connection and commissioning ............................ 10

3.1 Preliminary considerations..................................................................................... 10

3.2 COM462RTU on the internal BMS bus................................................................ 10

3.3 Installing the device..................................................................................................11

3.4 Connecting the device.............................................................................................11

3.5 Commissioning ...........................................................................................................13

4 Operation and configuration........................................................ 14

4.1 Display and operating elements .......................................................................... 14

4.1.1 Automatic contrast setting for the display....................................................... 14

4.1.2 Display in standard mode.......................................................................................15

4.1.3 Display in menu mode............................................................................................. 15

4.2 Factory settings...........................................................................................................16

4.3 Settings on the device.............................................................................................. 16

4.3.1 Operating example: Setting BMS address ........................................................ 16

4.4 Display INFO list.......................................................................................................... 18

5 Data access using Modbus RTU protocol................................... 19

5.1 Exception code ...........................................................................................................19

5.2 Modbus requests........................................................................................................ 19

5.3 Modbus responses..................................................................................................... 20

5.4 Structure of the exception code........................................................................... 20

5.5 Modbus address structure for BMS devices.....................................................20

4 COM462RTU_D00010_04_M_XXDE / 06.2021

6 Modbus process image in the memory of the COM462RTU .. 21

6.1 Querying data..............................................................................................................21

6.1.1 Modbus function code............................................................................................. 21

6.1.2 How are the memory areas organised?.............................................................21

6.2 Memory scheme of the process image..............................................................22

6.2.1 BMS device address assignment on the Modbus .......................................... 22

6.2.2 Memory scheme of an individual BMS device ................................................ 22

6.2.3 Device type...................................................................................................................24

6.2.4 Timestamp....................................................................................................................24

6.2.5 Common alarm and device failure ...................................................................... 25

6.2.6 Channels 1 to 32 with analogue and/or digital values ................................ 25

6.2.6.1 Float = Floating point value of the BMS channels....................................................25

6.2.6.2 AT&T = Alarm type and test type (internal/external)...............................................26

6.2.6.3 R&U = Bereich und Einheit.................................................................................................27

6.2.6.4 Channel description .............................................................................................................28

6.2.6.5 Channel 33 to 64....................................................................................................................29

6.3 Reference data records of the process image.................................................29

6.3.1 Address assignment of the reference data record ........................................ 30

6.3.2 Reference value on channel 1 ............................................................................... 30

6.3.3 Reference value on channel 2 ............................................................................... 30

6.3.4 Explanation of how to access floating point values .....................................31

6.4 Channel descriptions for the process image ................................................... 31

6.5 Modbus control commands...................................................................................37

7 Technical data.................................................................................. 40

7.1 Tabular data .................................................................................................................40

7.2 Dimension diagram................................................................................................... 41

7.3 Standards, approvals, certifications ....................................................................42

7.4 Ordering details.......................................................................................................... 42

8 Troubleshooting.............................................................................. 43

8.1 Malfunctions ................................................................................................................43

8.2 What should be checked?.......................................................................................43

8.3 Where to find help?................................................................................................... 43

COM462RTU_D00010_04_M_XXDE / 06.2021 5

COMTRAXX® COM462RTU

1 General instructions

1.1 How to use this manual

This manual is intended for qualified personnel working in electrical engineering and elec

tronics! Part of the device documentation, in addition to this manual, is the enclosed

“Safety instructions for Bender products”.

Read the manual before installing, connecting and commissioning the device.

Always keep the manual within easy reach for future reference.

1.2 Indication of important instructions and information

I Danger! Indicates a high risk of danger that will result in death or serious injury if

not avoided.

I Warning! Indicates a medium risk of danger that can lead to death or serious injury, if

not avoided.

I Caution! Indicates a low-level risk that can result in minor or moderate

injury or damage to property if not avoided.

i

Information can help to optimise the use of the product.

1.2.1 Signs and symbols

Disposal Temperature range protect from dust

protect from wetness Recycling RoHS

guidelines

1.3 Training courses and seminars

www.bender.de > Know-how-> Seminars.

1.4 Delivery conditions

The conditions of sale and delivery set out by Bender apply. These can be obtained from Bender

in printed or electronic format. The following applies to software products:

“Software clause in respect of the licensing of standard software as part of

deliveries, modifications and changes to general delivery conditions for

products and services in the electrical industry.”

Die Elektroindustrie

6 COM462RTU_D00010_04_M_XXDE / 06.2021

General instructions

1.5 Inspection, transport and storage

Check the shipping and device packaging for transport damage and scope of delivery.

The following must be observed when storing the devices:

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to property are excluded

in case of:

• Improper use of the device.

• Incorrect mounting, commissioning, operation and maintenance of the device.

• Failure to observe the instructions in this operating manual regarding transport, com-

missioning, operation and maintenance of the device.

• Unauthorised changes to the device made by parties other than the manufacturer.

• Non-observance of technical data.

• Repairs carried out incorrectly.

• Use of accessories and spare parts not recommended by Bender.

• Catastrophes caused by external influences and force majeure.

• Mounting and installation with device combinations not recommended by the

manufacturer.

This operating manual and the enclosed safety instructions must be observed by all persons

working with the device. Furthermore, the rules and regulations that apply for accident

prevention at the place of use must be observed.

1.7 Disposal of Bender devices

Abide by the national regulations and laws governing the disposal of this device.

For more information on the disposal of Bender devices, refer to

www.bender.de -> Service & support.

COM462RTU_D00010_04_M_XXDE / 06.2021 7

COMTRAXX® COM462RTU

1.8 Safety

If the device is used outside the Federal Republic of Germany, the applicable local standards and

regulations must be complied with. In Europe, the European standard EN 50110 applies.

I Danger! Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of

• A fatal electric shock

• Damage to the electrical installation

• Destruction of the device

Before installing and connecting the device, make sure that the installation has been

de-energised. The rules for working on electrical systems must be observed.

8 COM462RTU_D00010_04_M_XXDE / 06.2021

Product description

2 Product description

2.1 Intended use

The BMS-Modbus RTU gateway COM462RTU connects the serial Bender BMS bus to the serial

Modbus RTU. The gateway converts alarms, measured values and statuses from the BMS bus to

Modbus RTU. Control commands can be converted from Modbus RTU to BMS bus.

This allows connection to Modbus networks. The gateway is operated on the internal BMS bus.

2.2 Address setting and termination

In order to ensure proper functioning of the BMS-Modbus RTU gateway COM462RTU, correct

address assignment and termination of the BMS bus and the Modbus RTU is of utmost

importance.

I Caution! Assigning addresses that are already used by existing devices in the BMS or Modbus

RTU networks concerned may cause serious malfunctions.

Ensure correct address setting and termination of the COM462RTU. For details refer to

„Inbetriebnahme“ auf Seite 22.

Interface on the Modbus RTU side

i

The COM462RTU is always operated as slave on the Modbus RTU side. Therefore, the

COM462RTU and its Modbus RTU has to be communicated to the Modbus RTU master.

Interface on the BMS side

COM462RTU can be operated as master or slave.

2.3 Scope of delivery

You will receive:

• the COM462RTU

• an operating manual

2.4 Short description

The BMS-Modbus RTU gateway COM462RTU contains a Modbus RTU slave that converts BMS data

for a Modbus master.

A setting menu makes it possible to configure the COM462RTU using the setting menu (see

„Commissioning“ auf Seite 13).

COM462RTU_D00010_04_M_XXDE / 06.2021 9

COMTRAXX® COM462RTU

2.5 Device features

• Setting of address data for the BMS bus and Modbus RTU and date and time setting

using the internal operating menu.

• Time synchronisation for all BMS bus devices

• Operation on the internal BMS bus

• Modbus RTU data access to the internal BMS bus, max. 150 BMS devices

• Commands can be sent from an external application (e.g. visualisation software) to BMS

devices and measured values read.

2.6 Possible applications

• The use of professional visualisation programs by converting BMS data to Modbus RTU

protocols.

• Observing and analysing Bender products that support communication, such as RCMS,

EDS and MEDICS® systems.

2.7 Details about the Modbus RTU

The Modbus RTU (Remote Terminal Unit) field bus has been specified by Modicon, a company

under the Schneider Automation brand and made available to the market license-free.

Modbus uses the serial hardware interface RS-485 and communicates via a two-wire, twisted

copper wire. A transmission rate of 19200 baud is standard.

• Master-slave communication

• Up to 32 bus devices per network, or up to 247 bus devices (with repeater)

• Baud rate between 1200 and 57600 bit/s

• Diagnostics mechanisms

10 COM462RTU_D00010_04_M_XXDE / 06.2021

Installation, connection and commissioning

3 Installation, connection and commissioning

i

If you are familiar with the configuration of Modbus RTU networks, you can carry out the

connection of the COM462RTU by yourself. Otherwise please contact your EDP

administrator!

3.1 Preliminary considerations

1. Have all the questions as regards the installation been answered by the technician

responsible for the installation?

2. The device is operated on the internal bus. Is the BMS address to be set known?

If, apart from the COM462RTU, an alarm indicator and test combination MK800 is

connected to the internal bus, the COM462RTU must not have the address 1 (master).

You will find more detailed information on the BMS topic, in particular about the wiring

of bus devices, in the separate document "BMS bus". You can download the document

from the download area of the website www.bender.de.

3. Is the Modbus RTU address to be set known?

3.2 COM462RTU on the internal BMS bus

Bender systems such as EDS46x/49x, RCMS46x/49x and MEDICS communicate with each other via

the Bender measuring device interface BMS.

The BMS-Modbus RTU gateway COM462RTU provides the coupling between the BMS bus and

Modbus RTU networks. The following block diagram illustrates the operation of the gateway in an

internal BMS bus..

Abb. 3–1 Block diagram of a coupling between an internal BMS bus and Modbus RTU

COM462RTU

D+ D- D- D-D+ D+

D-D+

Modbus/RTU

COM462RTU_D00010_04_M_XXDE / 06.2021 11

COMTRAXX® COM462RTU

i

Internal and external BMS bus

The majority of Bender devices communicate via the internal BMS bus. Individual

devices, such as MK800, TM800 or Bender panels can communicate via both the internal

BMS bus (BMS i) and the external BMS bus (BMS e). The BMS-Modbus RTU gateway

COM462RTU can only communicate via the internal BMS bus (BMS i).

3.3 Installing the device

Possible methods of mounting:

• DIN rail mounting

• Screw mounting with 2 x M4 (dimension diagram on Seite 41)

i

When installing the device, please take into consideration that the device is only to be

used in locations that are protected from unauthorised entry! This can be installation in

a switch cabinet, for example.

3.4 Connecting the device

For UL applications, the following is to be observed:

• Supply voltage Us: see nameplate and ordering details

• Maximum ambient temperature: 55°C

• For use in pollution degree 2 environments

• Use 60/70°C copper lines only

• Tightening torque for terminals: 0.5…0.6 Nm

12 COM462RTU_D00010_04_M_XXDE / 06.2021

Installation, connection and commissioning

Connect the terminals and sockets on the COM462RTU according to the wiring diagram.

Terminal Description

A1, A2 Connection to the supply voltage, 6 A fuse recommended, two-pole fuses should be used in IT systems.

For UL and CSA applications, it is mandatory to use 5 A fuses.

A, B Connection to the BMS bus (internal) with shielded cable

(e.g. J-Y(St)Y 2x0.8).

AMB, BMB Connection Modbus RTU with shielded cable

(z. B. J-Y(St)Y 2x0.8).

Ron/off

(A, B)

Switch for BMS bus termination. When the device is installed at the end of the bus, set the terminating switch

to "on".

RMBon/off

(AMB, BMB)

Switch for Modbus RTU termination.When the device is installed at the end of the bus, set the terminating

switch to "on".

IN1,

GND1/2,

IN2

Currently has no function (digital inputs)

11, 14 Currently has no function (alarm relay K1)

IN3,

GND3/4

IN4

Currently has no function (digital inputs)

A1 A2

AB

IN3 IN4

GND

3/4 BMB

AMB

IN1 IN2

GND

1/2 14

11

A2

A1

6 A 6 A

US

RMB

(AMB, BMB)

BMS-Bus

RS-485

Modbus/RTU

RS-485

AMB BMB

ALARM

COM

ON MENU

INFO

ESC

COM462RTU_D00010_04_M_XXDE / 06.2021 13

COMTRAXX® COM462RTU

3.5 Commissioning

1. Apply the supply voltage to the COM462RTU. The green "ON" LED lights up.

2. Set language and time.

3. Set the BMS bus. The COM462RTU is operated on the internal BMS bus.

4. Set the Modbus RTU.

For details about the settings, refer to the chapter „Settings on the device“ auf Seite 16.

14 COM462RTU_D00010_04_M_XXDE / 06.2021

Operation and configuration

4 Operation and configuration

4.1 Display and operating elements

Legend

1"ON“ LED lights when supply voltage is applied.

2"COM" LED lights when the gateway is responding to BMS requests.

3"ALARM“ LED, lights to signal an internal device error on the COM462RTU.

4"INFO" button, to query the COM462RTU for device-specific information.

"ESC" button to exit the menu function without changing parameters.

5„p“ button: to move up in the menu, to increase values

6„q“ button: to move down in the menu, to decrease values

7"MENU" button for starting and exiting the menu.

„ “ button to confirm parameter change.

8LC display for standard and menu mode.

4.1.1 Automatic contrast setting for the display

The display contrast control is factory set to an optimum value. In exceptional cases, it may be

necessary to adjust the contrast manually.

Press and hold the buttons "ESC" and „ “ simultaneously. All available contrast modes are

continuously indicated in an infinite loop: minimum contrast, maximum contrast, no contrast

(lasting some seconds), then the same cycle starts again. If the button „q“ is additionally pressed,

the contrast modes will be displayed in the opposite direction.

Release the button as soon as the desired level of contrast is reached.

ALARM

COM

ON MENU

INFO

ESC

COMTRAXX®

COM462

3

2

1

4

5

6

7

8

COM462RTU_D00010_04_M_XXDE / 06.2021 15

COMTRAXX® COM462RTU

4.1.2 Display in standard mode

Network-related parameters will be indicated.

Legend

1Device type

2BMS address of the COM462RTU

3Modbus address of the COM462RTU

4Current date and time

4.1.3 Display in menu mode

Use the "MENU" button to switch to the Menu mode.

A blinking cursor supports menu navigation.

• You can access the individual menus by means of the „p“ or „q“ button.

• Press the „ “ button to confirm the selection of a menu or any setting you changed.

• To leave the respective menu level or discard a setting which is not confirmed yet, press

the "ESC" button.

i

Menu mode is exited if no button is pressed for longer than five minutes.

1

2

3

4

COM462RTU

Address:1

Modbus:240

22.06.2013 12:34

Exit

1. Settings

2. Info

16 COM462RTU_D00010_04_M_XXDE / 06.2021

Operation and configuration

Menu item Function Page

Exit Exit menu mode

1. Settings Make the necessary settings for this

device

16

2. Info Display information on device type and

firmware versions.The same informa-

tion as indicated in the standard mode

when pressing the "INFO" button.

18

4.2 Factory settings

All factory settings you will find in the table on Seite 17.

4.3 Settings on the device

The menu is divided into three levels. All menu items listed in the table can be called up via the

main menu item "1. Settings" in the top menu level. All control buttons are explained on Seite

14.

4.3.1 Operating example: Setting BMS address

The following example shows the operating principle. All settings are carried out in the same way.

1. Press the "MENU" button on the COM462RTU.

2. Select "1. Settings" > "1. Interface" > "1. Address". The factory-set BMS address will be

displayed and can be changed now.

3. Modify the addresses using the button „p“ or „q“.

4. Confirm the modified BMS address with „ ”.

COM462RTU_D00010_04_M_XXDE / 06.2021 17

COMTRAXX® COM462RTU

Menu level 2 Menu level 3 Factory setting Description

1. Interface 1. Address 2 Set the BMS address of COM462RTU: 1…99

(internal BMS bus)

2. Interval 2 s Set the cycle time 1…3s for the sequence:

• Querying alarms in the BMS bus

• Querying new bus devices

• Offering the BMS master function

3. Failure monitoring 5 Number of BMS bus cycles until a BMS device

failure is signalled.The setting is only effec-

tive when the COM462RTU has the master

function on the BMS bus (address 1).

Adjustable cycles: 1…10

2. Modbus 1. Address 2 Set the Modbus RTU address for COM462RTU:

2…247

2. Baud rate 19200 Set the baud rate

3. Parity even Set the parity

4. Control off Switch on or switch off the control commands

via Modbus

3. Language 1. English Deutsch Selection of the operating language

2. Deutsch

3. Français

4. Clock 1. Format d.m.y Date format: m-d-y/d.m.y

2. Date 01.01.2010 Date

3. Time 00:00 Time

4. Summertime off Select Central European SummerTime:

off = Function switched off

DST = Automatic switchover, USA, CDN

CEST = Automatic switchover, Central Europe

on = Set time zone +1 h

5. Password 1. Password 000 Enter/change password: 0…999

2. Status off Enable/disable password protection for

parameter setting via the buttons of the

COM462RTU

6. Service For authorised Bender Service personnel only.

18 COM462RTU_D00010_04_M_XXDE / 06.2021

Operation and configuration

4.4 Display INFO list

Open the "INFO" menu:

• In standard mode: press the "INFO" button or

• In menu mode: select function "2. Info"

This menu displays information about the device and the software. Navigate in the list using the

„q“ resp. the „p“ button.

1. Name of the device

2. BMS address

3. Order number

4. Serial number

5. Software version

6. Manufacturer's address

Please have this information to hand if you need to contact us for assistance by telephone.

COM462RTU

Address:1

Device:B95061022

S:0123456789

COM462RTU_D00010_04_M_XXDE / 06.2021 19

COMTRAXX® COM462RTU

5 Data access using Modbus RTU protocol

Request to the COM462RTU are sent using the function code 0x03 (Read Holding Registers). The

COM462RTU generates a function-related response and returns it.

5.1 Exception code

If a request cannot be answered for whatever reason, the COM462RTU sends a so-called

exception code with which possible faults can be narrowed down.

Exception code Description

0x01 Impermissible function

0x02 Impermissible data access

0x03 Impermissible data value

0x04 Slave device error

0x05 Acknowledgement of receipt (answer will be time-delayed)

0x06 Request not accepted (repeat request, if necessary)

0x08 Memory: Parity Error

0x0A Gateway path not available

0x0B Gateway error

5.2 Modbus requests

The required words of the process image can be read from the "Holding Registers" in the

COM462RTU using the function code 0x03. For this purpose, the start address and the number of

the registers to be read out have to be entered.

A complete bus image including all devices and device parameters is stored in these "Holding

Registers". This image represents the current statuses and values of up to 150 BMS devices for

each monitored internal BMS bus. The operating manuals of the devices indicate which channel

contains which information. Example: In the table below, Words 0 and 1 are to be read out from

the "Holding Registers“ 0x100 and 0x101.

Byte Name Example

Byte 0 BMS address of the COM462RTU 0x02

Byte 1 Function code 0x03

Byte 2, 3 Start address 0x01 00

Byte 4, 5 Number of registers 0x00 02

Byte 6, 7 CRC16 0x12 34

20 COM462RTU_D00010_04_M_XXDE / 06.2021

Data access using Modbus RTU protocol

5.3 Modbus responses

The responses consist of 2 bytes per register.

Byte Name Example

Byte 0 BMS address of the COM462RTU 0x02

Byte 1 Function code 0x03

Byte 2 Number of data bytes 0x04

Byte 3…6 Information 0xAB CD 01 23

Byte 7, 8 CRC16 0x12 34

5.4 Structure of the exception code

Byte Name Example

Byte 0 BMS address of the COM462RTU 0x02

Byte 1 Function code (0x03) + 0x80 0x83

Byte 2 Data 0x04

Byte 3, 4 CRC16 0x12 34

5.5 Modbus address structure for BMS devices

Function Address range Number of bytes Number of words

Device type 0x00…0x09 20 bytes 10 words

Timestamp 0x0A…0x0D 8 bytes 4 words

Common alarm 0x0E

(High byte)

1 byte 0.5 words

No BMS bus connection 0x0E

(Low byte)

1 byte 0.5 words

Unused 0x0F 2 bytes 1 word

Channel 1…32 0x10…0x8F 32 x 8 bytes 128 words

Alarm and test

Channel 33…64

0x90…0xFC 218 x 8 bytes 109 words

Other manuals for COMTRAXX COM462RTU

1

Table of contents

Other Bender Gateway manuals

Bender

Bender COMTRAXX COM463BC User manual

Bender

Bender COMTRAXX COM465ID User manual

Bender

Bender COMTRAXX COM460IP User manual

Bender

Bender COM465IP User manual

Bender

Bender COMTRAXX COM462RTU User manual

Bender

Bender COM465IP User manual

Bender

Bender COMTRAXX COM463BC User manual

Bender

Bender COMTRAXX COM463BC User manual

Bender

Bender COMTRAXX COM465ID User manual

Bender

Bender COMTRAXX COM463BC User manual