7

DISASSEMBLY

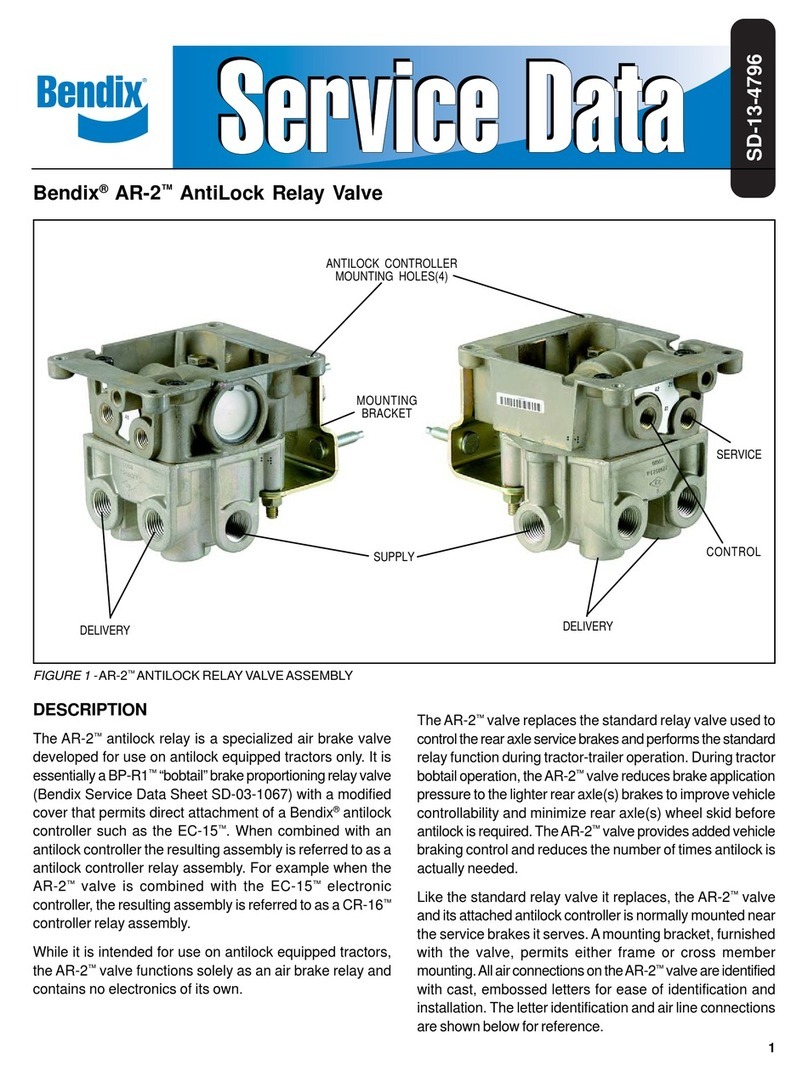

GENERAL

The following disassembly and assembly procedure is

presented for reference purposes only and presupposes

that the appropriate maintenance kit is on hand at the time

of disassembly. The instructions provided with the

maintenance kit should always be used in lieu of those

presentedhere.Refertofigure6throughoutthedisassembly

andassembly procedure.

CAUTION: The AR-1™valve may be lightly clamped in a

benchvise duringdisassembly,however,over clampingwill

cause damage to the valve and result in leakage and/or

malfunction. If a vise is to be used, position the valve so

thatthejawsbearonthesupplyportsonopposingsides of

thevalve’sbody.

1. Removeallair fittings and plugsfromthevalve.

2. Markthe relationshipoftheantilock electroniccontroller

andvalvecoverto the body (5). Note the position of the

mountingbracketandmarktherelationshipofthebracket

tothevalvebody,cover,andantilockcontroller.Remove

andretain thefourcapscrews andlockwashers (1)that

secure the controller to the cover (15), then carefully

remove the electronic controller without damaging its

gasket(2).

3. Whileholding theexhaustcover(4),removeanddiscard

the retaining ring (3) that secures it to the body (5).

4. Remove and discard the exhaust cover (4) along with

both o-rings (6 & 7).

5. Removeand discard the valve spring(8),valveretainer

(9),andthevalve assembly (10) from the body (5).

6. Remove and retain the two cap screws (11) and lock

washers(12)thatsecurethe cover (15) to the body (5).

Removeandretainthetwobolts (13),lock washers(12),

and nuts (14) that secure the cover (15) and mounting

brackettothevalve body (5).

7. Separatethecover(15) and mounting bracket from the

body(5), then remove anddiscardthesealing ring (16).

Removeandretainthetwocapscrewsand lockwashers

(26) that secure the bracket to the cover (15).

8. Removeand retaintherelay piston(17)and relaypiston

spring (19) from the body (5). NOTE: The relay piston

spring, item 19 is not used in all valves.

9. Removeand discardtheo-ring(18)fromtherelay piston

(17).

10. Removeandretaintheservice portcap nut(20)fromthe

cover(15), then separateanddiscardthe cap nuto-ring

(21)from the cap nut.

11. Remove and discardthequickexhaustdiaphragm(22)

fromthe cover(15).

12. Remove the quick exhaust diaphragm retaining screw

(23),thediaphragmwasher (24)and thediaphragm (25)

fromthe cover(15).

CLEANING & INSPECTION

1. Usingmineral spiritsoranequivalent solvent,cleanand

thoroughlydryallmetal parts.

2. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superficial corrosion and/or pitting on the exterior

portion of the body (5) and cover (15) is acceptable.

Replacetheentirevalveiftheinteriorofthebodyorcover

exhibit signs of corrosion or pitting.

3. Inspectthe bores of boththebody (5) and cover(15)for

deep scuffing or gouges. Replace the entire valve if

either are found.

4. Make certain all air channels and exhaust passages in

thevalve cover (15) areclearand free ofobstruction.

5. Inspect the pipe threads in the body (5). Make certain

they are clean and free of thread sealant.

6. Washall non-metalliccomponentsin asoap and water

solution making certain to rinse and dry thoroughly.

Inspect each non-metallic component for cracks, wear

ordistortion. Replacetheentire valveifthese conditions

are found.

7. Ifthe valvewasequipped with arelaypiston spring(19),

inspect it for signs of corrosion, pitting and cracks.

Replace as necessary.

8. Inspect all air line fittings for corrosion and replace as

necessary.Makecertaintoremove alloldthreadsealant

before reuse.

ASSEMBLY

1. Priortoassembly,lubricateallo-rings,seals,andpistons,

aswellas body bores, using the lubricant provided with

the Bendix maintenance kit.

2. Installthe valveretainer(9)ontheinletandexhaustvalve

(10) so that the flange of the retainer (9) surrounds the

rubberportionofthevalve.Installtheinletandexhaust

valvein the body(5).

3. Installthe inlet andexhaustvalve return spring(8)in the

body(5).

4. Installthe large andsmalldiametero-rings (7 &6)in the

exhaust cover (4), then install the exhaust cover in the

body(5) taking carenotto damage theo-rings.Hold the

exhaustcoverinplace.

5. While depressing the exhaust cover (4), install the

retainingring(3)inthebody(5).Makecertaintheretainer

(3) is fully seated in its groove in the body.

6. IftheAR-1™valvewasequippedwitharelaypistonreturn

spring(19), installthespring in the body, large diameter

first.