3

INSTALLING

Cleanair lines connectingto valve.

Inspect all lines and/or hoses for damage and replace as

necessary.

Installvalve and tightenmounting bolts.

Connectair lines to valve(Plugany unused ports).

Testvalve as outlinedin “Operating andLeakageTests.”

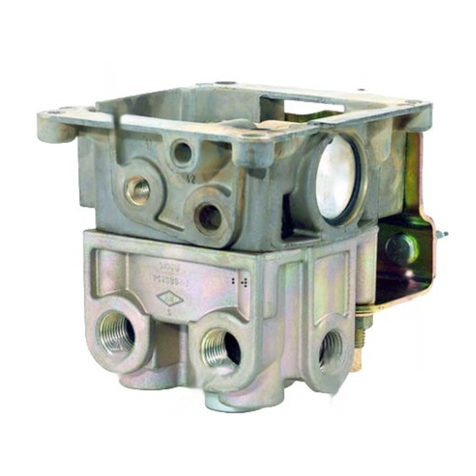

DISASSEMBLY

NOTE: Priortodisassembly,marklocationofcover tobody

to facilitate assembly.

1. Remove cover cap screws (1). Remove cover (2) with

relaypiston (4) and spring(6)(if so equipped).

2. Removerelay piston(4) fromcover.

3. Removepiston o-ring (3)from piston (4)and cover seal

o-ringfrom body.

4. Removeexhaust covercap screws,(19) exhaustcover,

andremove inlet/exhaustvalve insert(8) frombody(7).

5. Remove exhaust seat (5) from relay piston (4) and

exhaustcheck valve(18).(Remove onlyifnewpartsare

to be installed).

INLET/EXHAUSTVALVE INSERTDISASSEMBLY

NOTE: Ifcompleteinlet/exhaustvalveisreplaced,disregard

steps 6 to 9.

6. Depressand holdvalveguide downagainstvalvespring

tensionand removeretainer (16).

7. Remove valve insert seal o-ring (13), valve guide (14),

spring(12),andvalveretainer(11).

8. Removethe inlet/exhaust valve(9) fromitsbody (10).

9. Removeinner o-ring(15)from valveguide(14).

CLEANING AND INSPECTION

Washall metal partsinmineral spirits; wipeall rubber parts

dry. Inspect all parts for signs of wear and/or deterioration.

Inspect springs for cracks, distortion or corrosion.

Inspect inlet seat and exhaust seat for nicks and burrs and

replace as necessary. It is recommended that all rubber

partsbereplaced, and that any partshowingsigns of wear

ordeterioration bereplaced.

ASSEMBLY

NOTE: All torques specified in this manual are assembly

torques and can be expected to fall off after

assembly. Do not retorque after initial assembly

torques fall. (For assembly, hand wrenches are

recommended)

1. Priorto assembly, lightlylubricatethe relaypiston guide

post,o-rings,coverboreandinletbodywithDowCorning

Silicone 55-M Pneumatic grease (Bendix Pc. No.

291126).

INLET/EXHAUSTVALVEASSEMBLY

NOTE: If newinlet/exhaustvalve assembly insert isused,

disregard Steps 2 to 6.

2. Installinlet/exhaustvalve(9)overvalvebody(10),smooth

surfaceup.

3. Positionvalve retainer(11)overinletvalvebody(10)and

valve.

4. Installinletvalvespring(12)overinletbody(10)andinstall

o-ring(15) inthe innergroovein thevalve guide(14).

5. Depress and hold guide down against inlet spring and

installretainer ring(16) (A9/16"twelve pointsocket can

be used to push the retainer ring down until it snaps in

thegroove inthe inletvalvebody).

6. Installvalve insertseato-ring (13).

COMPLETEVALVEASSEMBLY

7. Install insert (8) in valve body (7), install exhaust cover

(17) and secure with 10-24 screws (19) torque to

approximately20-30inchpounds.

8. Installexhaust checkdiaphragm (18)into exhaustcover

(17).

9. Installcover sealo-ring.

10. Install relay piston o-ring (3) on relay piston (4), then

positionrelaypiston in cover.

11. If valve utilizes relay piston spring (6) position spring

overguide inbody.

12. Position cover/relaypiston assemblyin correctrelative

positionwith body;ifequipped withpiston returnspring,

make sure exhaust seat is centered inside spring.

13. Installcovercapscrews.Torquetoapproximately80-120

inchpounds.

14. Test valveas outlinedin “Operatingand leakageTests”

section.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.