5of 9 REF: CCU/IO-485.DOC REV: C June 20, 2000

For all installations -

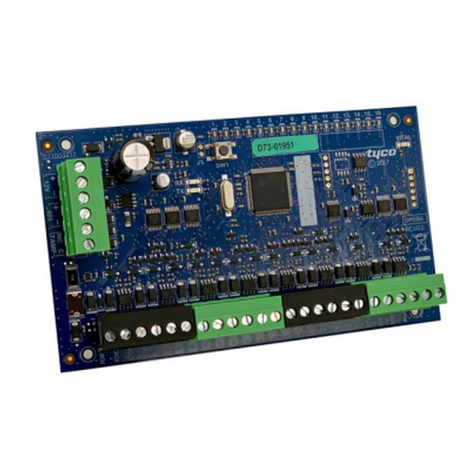

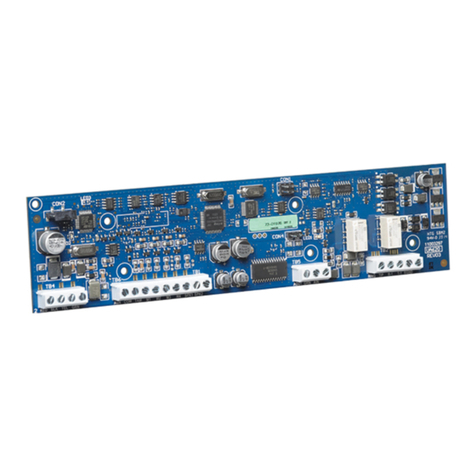

•For normal operation a jumper should be in place across A on JP20.

•If hardware supervision is required connect the relay output from the CCU/IO-485 to a suitable

input on the FIP (software supervision does not require this). The relay socket is located next to the

power connector. The relays will energise when Supervision failure is detected.

•Connect the 24V DC power source to the supplied connector. The power connector is next to the

CHN_C port. Pin connections are:

PWR (+24VDC) RETURN/COM(0V) BATTERY(24V)

These connections are written on the board. If the 24V power source is Uninterruptible, then

there is no need to connect the BATtery connection.

Pin number Function

1 24V

2 COM

3 BAT

Connecting the inputs and outputs to the CCU/IO-485:

•The outputs on the CCU/IO-485 are relays that have a common ( COM ), normally open ( NO ) and

normally closed ( NC ) output, as shown in the Board Layout ( page 1 ). When the relay is not

energised the common line in shorted to the normally closed line. When the relay is energised the

common line is shorted to the normally open output.

•The inputs on the CCU/IO-485 run off a 20mA loop. To obtain supervision on these inputs a 220

ohm terminating resistor must be added across the remote end. For inputs that are a distance from the

CCU/IO the line should be powered by a higher voltage to allow for line loss ( note that the value of

the supervision resistor also changes ). Refer to Appendix A for details.

Operation of LEDs:

•CHN_A has a Green and a Yellow LED. The green LED glows when the port is operating correctly.

The yellow LED glows when the port is not operating correctly, or there has been supervision failure

on this port.

For the CCU/IO-485:

•Each output relay has two leds associated with it. When the relay is energised and switches the green

LED glows. If the relay fails to switch when it is energised the yellow LED glows.

For the CCU/I-485:

•The LEDs used for the output relay on the CCU/IO-485 are unused on the CCU/I-485.