3

DISASSEMBLY

EARLY REVISION 80 PSI OPENING PRESSURE

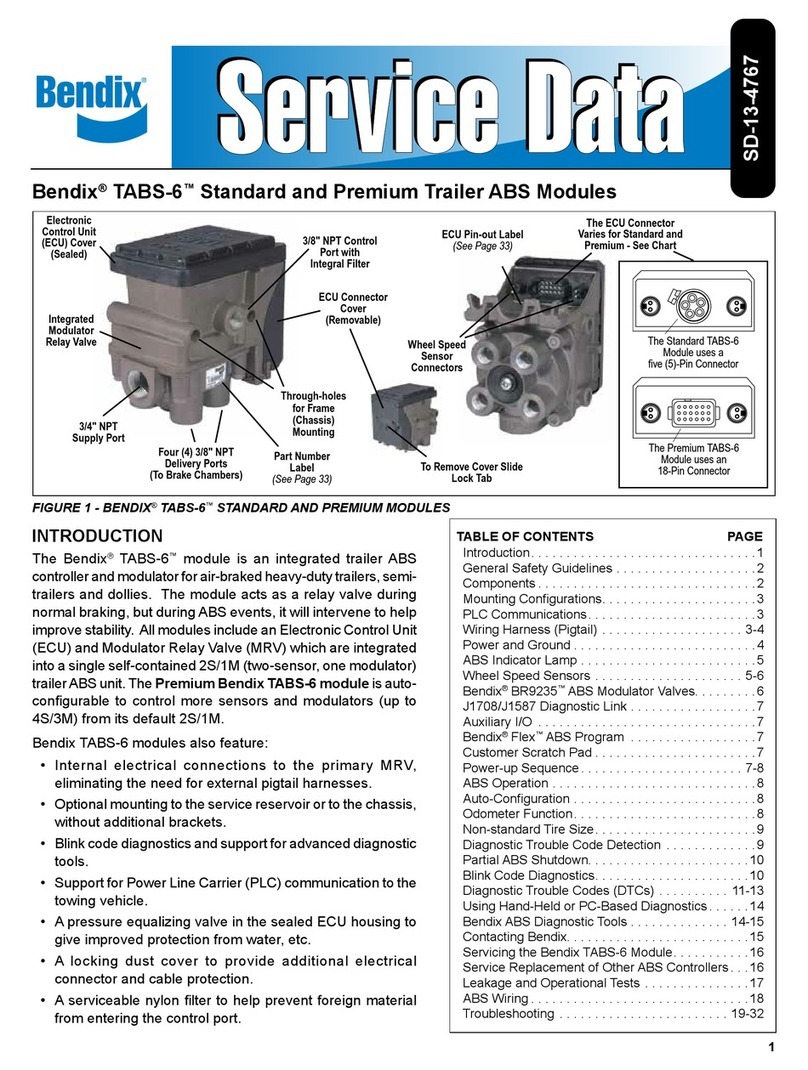

(Figure 1)

1. Removeinsertretainerring(1)Figure4withTruarcpliers.

2. Removeinsertassembly.

3. Place insert on smooth surface with plunger down.

4. Press down on exhaust diaphragm seat (9).

5. Preload spring (2) may unlock in this manner, if not,

remove exhaust diaphragm cap screw (3), washer (8),

diaphragm(5), andpreload springwhileholding theseat

downagainstthe valve spring (6) tension.

6. Separatethediaphragmseat, valve spring and plunger

assembly.

7. Removediaphragmseat o-ring(7).

8. Removevalveretainer(10)andinletvalve(4)fromplunger.

Removeplunger o-rings (12)and(13)Figure 3.

LATE REVISION 45 PSI OPENING PRESSURE

(Figure 1)

1. Remove diaphragm seat retainer ring (1) while holding

diaphragm seat (9) in body.

2. Removedatecoderingwhilestillholdingdiaphragmseat

in body.

3. Allowseatto rise until valve spring (6) force is no longer

present.

4. Remove diaphragm seat assembly, valve spring and

plungerassembly.

5. Remove diaphragm seat o-ring (7), Phillips screw (3),

washer(8) and diaphragm(9).

6. Removevalveretainerring(14), valveretainer(10), inlet

valve(4), and o-rings(12)and (13) fromplunger.

CLEANING AND INSPECTION

1. Clean all metal parts in mineral spirits and dry them

completely.

2. Inspect all parts for excessive wear or deterioration.

Inspect valve seats for nicks or burrs. Check the valve

spring for cracks or corrosion.

3. Inspecttheboresofthevalvehousingfor deep scuffing

orgouges.

Replace all parts that were discarded and any parts not

foundtobeserviceableduringinspection,usingonlygenuine

Bendix replacement parts.

ASSEMBLY

Before assembling the TP-3™valve, lubricate all o-rings,

o-ringgrooves,body boresandrubbingsurfaceswithBendix

silicone lubricant (Pc. No. 291126) or equivalent.

NOTE: When using pipe thread sealant during assembly

and installation, take particular care to prevent the

sealant from entering the valve itself. Apply the

sealantbeginningwiththe secondthreadbackfrom

the end.

EARLY REVISION-OPENING PRESSURE 80 PSI

1. Position preload spring (2) then exhaust diaphragm (5)

over stud boss in the diaphragm seat (9).

2. Place washer (8) with lip out on exhaust diaphragm,

install and tighten cap screw (3).

3. Install snap-on valve (4) on plunger (13), position and

force valve retainer (10) down over valve.

4. Installtwo(2)plungero-rings(12)and(13)intheirproper

grooves.

5. Positionvalvespring (6) on diaphragm seat (9).

6. Force plunger(3)down into checkvalveseatuntil prong

of preload spring snaps into inner cut in plunger and

holdsinsertassemblytogether.

7. Position insert sealring(3)onseatthen place complete

insertinTP-3™valve body.

8. UsingTruarcpliers,install insertretainerring(1)inTP-3™

valvebody.Makesurethatringsnapsfullyintoitsgroove

inthe valve body.

LATE REVISION-OPENING PRESSURE 45 PSI

1. Install inlet valve (4) on plunger (3).

2. Position and force valve retainer (10) down over inlet

valve.

3. Installretainerring(14) beneath the inlet valve retainer.

4. Install both plunger o-ring (12) and (13) in the proper

grooves.

5. Place plunger and valve assembly in valve body.

6. Install Phillips head screw (3), diaphragm washer (8)

(cup side up) and diaphragm (5) into diaphragm seat.

7. Place inlet valve (6) spring into plunger.

8. Install diaphragm seat o-ring in body.

9. Position diaphragm seat assembly over spring and

plunger assembly and force into the body.

10.Replace date code washer and install retaining ring (1)

makingsurethe retainingring snapsfullyintothegroove.

TESTING REBUILT TP-3™VALVES

Perform operating and leakage checks as outlined in

previoussection.