8

5) Adjust the closing limit switch cam, the SWC LED turns off.

If braking is required in the closing phase, the limit switch triggering should be anticipated.

6) Cut off power supply.

7) Move the door half-way and lock it again.

8) Reset power supply. The STOP, PHOT, SWO and SWC LED’s should light up.

9) Give a step-by-step control signal by pressing the appropriate button or using the remote control.

10) The door should move in the opening phase. In the negative, it is sufcient to invert the speed wires (6<>8) of the motor and

the limit switch inputs (SWO<>SWC).

11) Adjust Time and Operating and Motor power logic.

If braking is required, move DIP3 to ON and adjust the braking time of trimmer TSLOW.

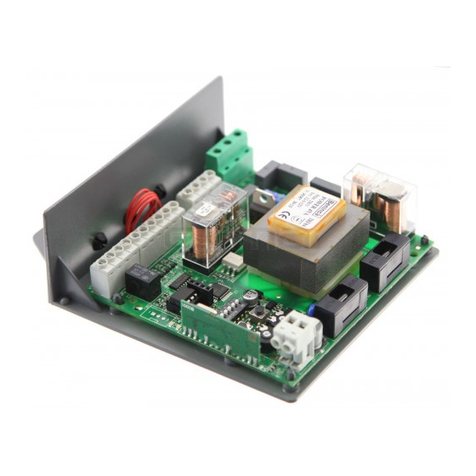

TO ADJUST THE MOTOR POWER

WARNING! This adjustment affects the safety level of the automatic system.

Check that the thrust applied onto the wing complies with regulations in force.

On the power supply transformer, a Faston connector (T1) is provided which allows to adjust motor power to 4 different levels. By

positioning the Faston (T1) on 120, the minimum power is obtained, by moving the Faston to 210 the maximum power is obtained.

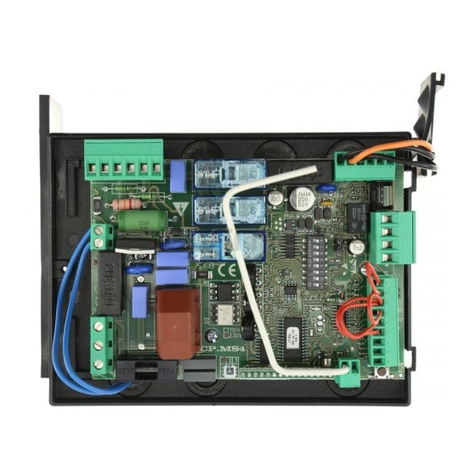

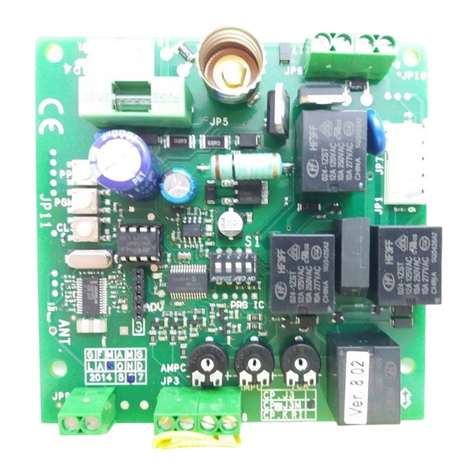

FUNCTIONS OF THE TRIMMERS

TCA It allows to adjust the automatic closure time. Check Dip-Switch N°1= On.

The adjustment varies from 1s minimum to 90s maximum

TSLOW With Dip-Switch 3 On, it adjusts the slowdown cycle time from 1 to 12 secs.

With Dip-Switch 3 Off, it adjusts the work time from 10 to 120 secs. In this case the slowdown option is disabled.

DIP-SWITCH FUNCTIONS

DIP 1 “TCA” The automatic closure is enabled or disabled

Off: disabled automatic closure

On: enabled automatic closure

DIP 2 “Prelam.” Forewarning ashing light enabled or disabled

Off: disabled forewarning ashing light

On: enabled forewarning ashing light. The ashing light is activated 3 s before the starting of the motor.

DIP 3 “Rall.” Enables or disables the slowdown cycle.

Off: Slowdown disabled. The TSLOW trimmer adjusts the motor work time from 10 to 120 secs.

Set a work time longer than the duration of an operation.

On: Braking in both opening and closing phases.

N.B.: the braking phase starts when the limit switches are triggered.

By using trimmer “TSLOW”, preset a braking time slightly higher than the time required to complete the

operation.

DIP 4 “P.P. Mod” The operating mode of “P.P. Push button” and of the transmitter are selected.

Off: Operation: OPEN > STOP > CLOSE > STOP >

On: Operation : OPEN > CLOSE > OPEN >

DIP 5 “PHOT. AP.” The photocells in the opening phase are enabled or disabled.

Off: enabled photocells in the opening phase.

On: disabled photocells in the opening phase.

DIP 6 “Cond.” The multi-at function is enabled or disabled.

Off: disabled multi-at function.

On: enabled multi-at function. The P.P. (Step-by-step) impulse or the impulse of the transmitter have no

effect in the opening phase.

DIP 7 “Spunto” The motor start pickup is enabled or disabled.

Off: disabled pickup.

On: enabled pickup. At the beginning of each operation the maximum torque of the motor is for approx. 2s.

DIP 8 “Radio” Only for “RI” versions. Enables or disables transmitters with programmable codes

On: Radio receiver enabled exclusively for rolling-code transmitters.

Off: Receiver enabled for both rolling-code and programmable transmitters (self-learn and dip-switch) .

LED DIAGNOSTICS

The control system has a series of self-diagnostics LED’s which allow to check all functions:

SW1 LED It switches off when the SWO opening limit switch is triggered

SW2 LED It switches off when the SWC closing limit switch is triggered

STOP LED It switches off when the STOP push button is pressed

PHOT LED It switches off when the photocells are not aligned or if obstacles are present

OPN LED It switches on when the OPEN push button is pressed

CLS LED It switches on when the CLOSE push button is pressed

PP LED It switches on when the PP push button is pressed

PGM LED It ashes to show the correct operation of the control unit.

5 quick ashes, followed by a pause, of LED PGM indicate the activation of the safety edge.

CONFIGURATION WITH BUILT-IN RECEIVER (ONLY “RI” VERSIONS)

The control unit is tted with a built-in radio module for receiving remote controls both with xed codes and variable codes (see

dip-switch 8 functions), with a frequency of 433.92MHz.