auto maskin Marine Pro 400 Series Instruction sheet

Publication P/N 1006423

Configuration Manual

400 Series / 200 Series

DCU 410E Engine Controller, P/N 1006445

RP 410E Remote Panel, P/N 1006446

DCU 408E Engine Controller, P/N 1006510

RP 210E Remote Panel, P/N 1006476

DCU 210E Engine Controller, P/N 1006475

RP 220E Remote Panel, P/N 1006472

DCU 208E Engine Controller, P/N 1006477

RP 206E Remote Panel, P/N 1006478

Table of content

1 Preface 5

1.1 About this Manual 5

1.2 Responsibilities 5

1.3 Revisions 5

1.4 Trademarks 5

2 Configuration 6

2.1 Configuration & Firmware Files 6

2.1.1 DCU Web Server Configuration

Interface 6

2.1.2 DCU User Interface Menu 6

2.1.3 USB Memory Interface 6

2.1.3.1 Configuration Files 7

2.1.3.2 Firmware Files 8

2.1.3.3 Copy Configuration File or

Event Log 8

2.2 Connecting to the DCU 8

2.2.1 To Connect to the DCU 8

2.2.2 Further Connection Settings 9

2.2.2.1 Change the IP address of

the DCU 9

2.2.2.2 IP Address Convention

9

2.2.2.3 Connect the DCU to a

Single PC 9

2.2.2.4 To Connect the DCU to a

LAN with a DHCP server 9

2.2.2.5 Connection to a LAN using

Fixed IP Addresses 10

2.2.2.6 Factory Defaults for the

DCU 10

2.2.2.7 IP Address Conflict 10

2.3 Web Server Configuration 10

2.3.1 DCU 11

2.3.2 RIO 11

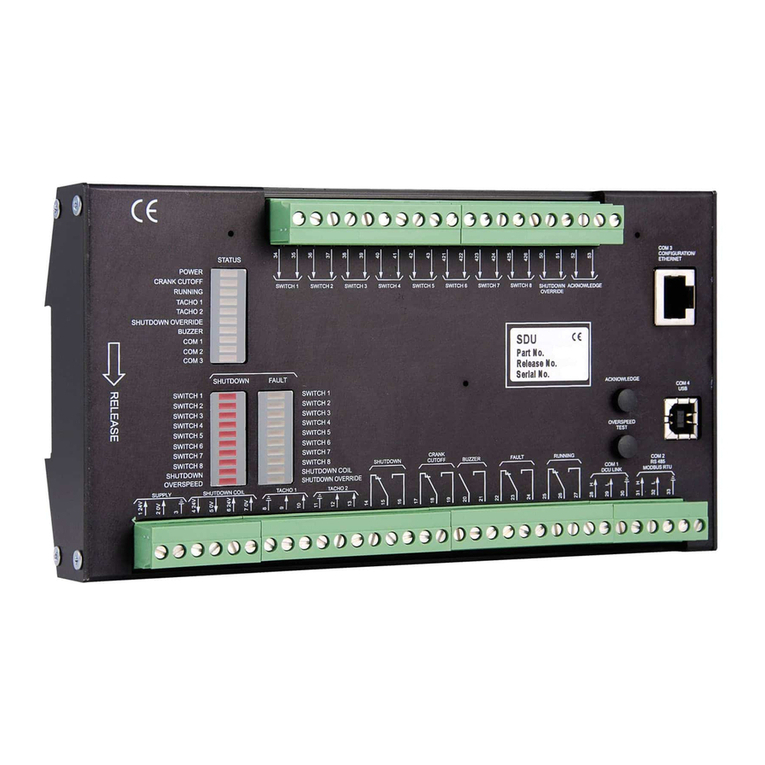

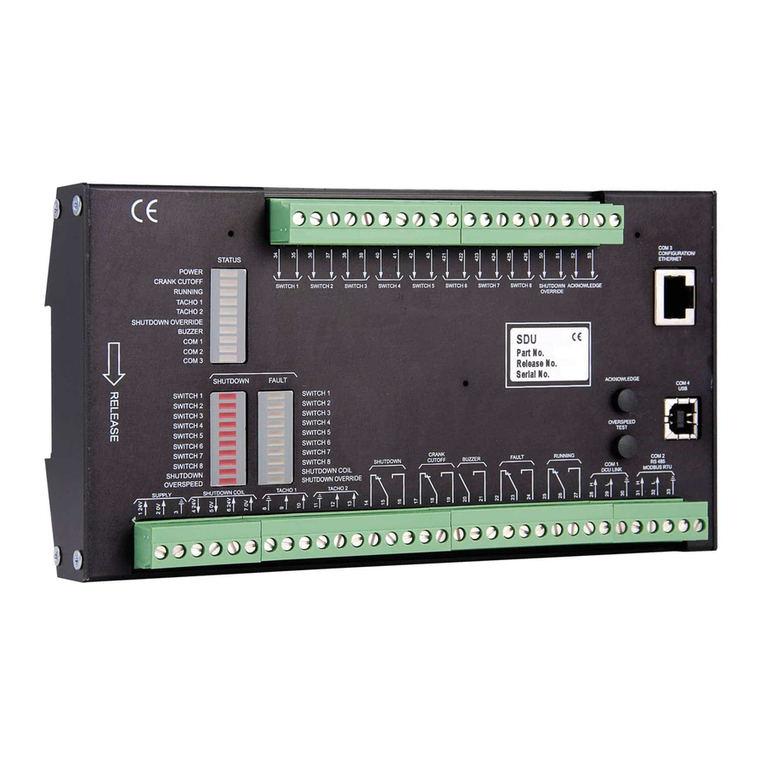

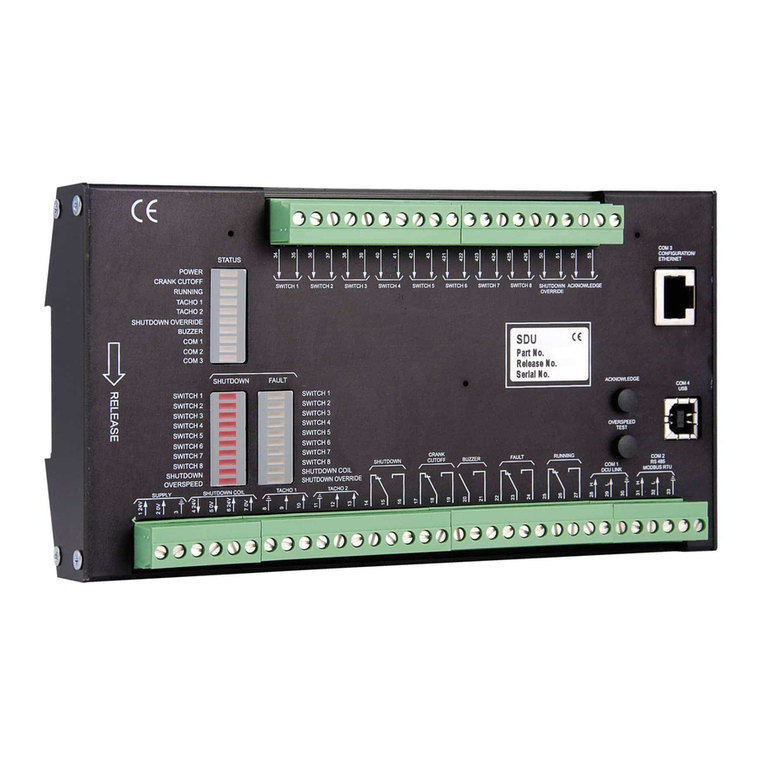

2.3.3 SDU 11

2.3.4 MK-14 11

2.3.5 Upload Wallpaper 11

2.3.6 Versions 11

2.3.7 Troubleshooting 12

3 Main DCU Web Server Menu 12

3.1 Access Control 13

3.1.1 Access Control Levels 13

3.2 File 13

3.2.1 Load any File 13

3.2.1.1 Factory Default 13

3.2.1.2 User Uploaded 13

3.2.2 Delete Configuration File 13

3.2.3 Configuration Printout 13

3.2.4 Save File as 13

3.2.5 Save CANopen EDS-file 14

3.2.6 Upload to DCU 14

3.2.6.1 Firmware Update 14

3.2.6.2 Wallpaper 14

3.2.6.3 Configuration File Upload

14

3.3 I/O Configuration 14

3.4 User Interface 14

3.5 Start/Stop/Prelube 14

3.6 Engine Model 14

3.7 Service Interval 15

3.7.1 View Service Status 15

3.7.2 Configure 15

3.8 Communication 16

3.9 Miscellaneous 16

3.10 Language 17

4 I/O Configuration 17

4.1 Common I/O Configuration 17

4.1.1 Common Configuration for

Switch Channels 18

4.1.2 Common Configuration for

Analog Channels 21

4.2 Flexible I/O 24

4.3 Config Inputs 24

4.3.1 Engine Speed 24

4.3.2 Individual Speed Sensors 27

4.3.3 Engine Load 28

4.3.4 Transmission 28

4.3.4.1 Gear 28

4.3.4.2 Interlock/Indications 30

4.3.4.3 Clutch Slip 30

4.3.4.4 Clutch Temperature 32

Page 2 (99)

4.3.4.5 Clutch Pressure 32

4.3.4.6 Thrustbearing

Temperature 32

4.3.4.7 Shaft Speed 32

4.3.5 Switch 33

4.3.6 4-20 mA 34

4.3.7 PT100 34

4.3.8 Temperature Sensor 35

4.3.9 Voltage sensor 37

4.3.10 24V Input Functions 37

4.3.11 J1939 38

4.3.11.1 Configuration 39

4.3.11.2 Node Signals 39

4.3.12 Differential 39

4.3.13 Average 40

4.3.13.1 Average Signal 40

4.3.13.2 Deviation

Configuration 42

4.3.13.3 Exclude From

Average 43

4.3.13.4 Naming 43

4.3.14 Special 43

4.3.14.1 Input Voltage 43

4.3.14.2 Calculated Fuel Rate 44

4.3.14.3 Calculated Engine Hours

45

4.3.14.4 Instantaneous Fuel

Economy (DCU) 45

4.3.15 Analog Modbus 46

4.3.16 Digital Modbus 46

4.3.17 EGT (Exhaust Gas

Temperature) 47

4.3.17.1 Cylinder Deviation Event

47

4.3.17.2 Turbo Deviation Event 47

4.3.18 Constant 47

4.3.19 Logical Signal 47

4.4 Config Outputs 48

4.4.1 Common Output

Configuration 48

4.4.2 24V Output Functions 51

4.4.3 Relay Functions 51

4.4.4 Speed Relays 52

4.4.5 DM1 Functions 52

4.4.6 J1939 Outputs 53

4.4.6.1 J1939 53

5 User Interface 53

5.1 Configuration 54

5.2 Pages 55

5.3 Flow Charts 58

5.4 RP Home View Configuration 58

5.5 Controls 58

5.6 Shortcuts 60

5.7 Language 61

5.7.1 All Signals 61

5.7.2 Enabled Signals Only 62

5.7.3 Service 62

5.7.4 Built-in Events 62

5.8 Buzzer 63

6 Start/Stop/Prelube 63

6.1 Settings 63

7 Communication 69

7.1 Network Configuration 70

7.2 LSU 408 70

7.3 CANopen 70

7.4 Modbus RTU 70

7.5 Modbus TCP 71

7.6 J1939 Configuration 72

7.6.1 Configuration 72

7.6.1.1 Function Specific

Configuration 73

7.6.1.2 OEM Specific

Configuration 74

7.7 Communication Info 74

8 Miscellaneous 74

8.1 Engine Application Configuration

75

8.2 Event Configuration 76

8.2.1 Miscellaneous Events 76

8.2.2 Suppress DM1 Fault 77

8.2.3 DM1 FMI Severity 77

8.2.4 Output Event Configuration

77

8.2.5 Modbus Watchdogs 78

8.3 Counter Configuration 78

8.4 Counters 79

8.5 Acknowledge Configuration 79

Page 3 (99)

8.6 Operation Mode Configuration 80

8.7 Event Log 80

8.8 Override Configuration 81

8.9 System Voltage Configuration 82

8.10 Sea Trial 82

8.11 Custom Version Text 82

8.12 Factory Reset 82

9 Communication Interface List 82

9.1 DCU Capacity 82

9.1.1 Functionality and Content

Highlights 83

9.1.2 Total I/O capacity 83

10 RIO 410 Configuration 84

11 RP Configuration 84

11.1 Power On Wizard 85

11.2 Administration Menu 86

11.2.1 DCU Connection / Connections

86

11.2.1.1 Manually Assignment

of DCUs 87

11.2.2 DCU Alarms 87

11.2.3 DCU Acknowledge 87

11.2.4 IP Address 88

11.2.5 Cameras 88

11.2.6 Station Location 89

11.2.7 Functional Inputs 89

11.2.8 Functional Outputs 91

11.2.9 Change Password 91

11.2.10 Station Priority 91

11.2.11 Lock 93

11.2.12 Start/Stop Buttons 93

11.2.13 Web Interface 93

11.2.14 Reset to Factory Defaults

93

12 Troubleshooting 93

12.1 Password 93

Page 4 (99)

1 Preface

1.1 About this Manual

This manual has been published primarily for professionals and qualified personnel.

The user of this material is assumed to have basic knowledge in marine systems, and must

be able to carry out related electrical work.

Work on the low-voltage circuit should only be carried out by qualified and

experienced personnel.

Installation or work on the shore power equipment must only be carried out by

electricians authorized to work with such installations.

1.2 Responsibilities

It is the sole responsibility of the installer to ensure that the installation work is

carried out in a satisfactory manner, that it is operationally in good order, that the

approved material and accessories are used and that the installation meets all

applicable rules and regulations.

Auto-Maskin continuously upgrades its products and reserves the right to make

changes and improvements without prior notice.

All information in this manual is based upon information at the time of printing. For updated

information, please contact your local distributor.

1.3 Revisions

This Configuration Manual is valid for the following firmware version of the DCU Engine

Controllers.

Edition

Firmware Version

Release

Release

3.10

March 2020

Configuration Manual revision: March 2020

2 Configuration

This section explains the configuration of the DCU. All configuration except password and

network configuration is stored in a portable configuration file within the DCU.

Page 5 (99)

2.1 Configuration & Firmware Files

The DCU may be configured in one of the following three ways.

1. DCU Web Server Configuration Interface

2. DCU User Interface Manu

3. USB Memory Interface

2.1.1 DCU Web Server Configuration Interface

The DCU has a built-in web server, offering access to full configuration of the DCU.

This is the primary configuration interface.

2.1.2 DCU User Interface Menu

For quick and easy changes to the configuration, there is a configuration entry point in the

menu.

This manual will not describe the panel menu configuration interface in detail. Only

the web server menu operation is covered.

2.1.3 USB Memory Interface

Insert a USB memory stick and follow the guidelines appearing on the DCU screen.

The DCU 408E/208E does not have a screen interface and hence this method

does not work on those units.

Page 6 (99)

2.1.3.1 Configuration Files

If the USB memory stick contains configuration files, they will be listed here.

The configuration filename can only contain the following characters:

● A-z

● A-Z

● 0-9

● “_” (underscore)

● “-“ (hyphen)

The DCU 408E/208E does not have a screen interface and hence this method

does not work on that unit.

If other characters are being used, then the DCU will not “see” it. Rename the configuration

file to solve the issue.

Copy Configuration File

1. When the USB memory is inserted, the DCU asks for the administration password (4

digits).

2. The DCU then lists the configuration file(s) available on the USB memory.

3. Select file(s), then select COPY to copy these files into the User Files area in the

DCU. Note that this does not activate the file; it is merely a copy of the file into the

DCU.

Use Configuration File

Page 7 (99)

Insert USB memory stick, select a file, and then select USE to copy and activate this

configuration file.

2.1.3.2 Firmware Files

The USB memory can be used to copy a new firmware to the DCU and also any connected

RP.

If upgrading both the DCU and the RP firmware, then make sure to upgrade the

RP firmware first!

2.1.3.3 Copy Configuration File or Event Log

This function copies the current configuration file and/or the event log to the USB memory

stick. The configuration file will be named/labeled current_config.cfg

.

2.2 Connecting to the DCU

It is possible to connect to the DCU either directly or through a LAN (Local Area Network)

Ethernet network.

For use in an existing Ethernet, check the configuration of the LAN with the LAN

manager.

The components in Marine Pro, including the DCU, use fixed (not dynamic) IP addresses,

which must be set manually.

2.2.1 To Connect to the DCU

● Connect an Ethernet cable between your laptop and the DCU port COM 6 (Ethernet

port).

Either use the DCU Discover Tool, downloadable from Auto-Maskin web page, or follow the

following steps.

1. In the DCU menu, select Version Information. Note the IP address. From the factory,

the IP address is 192.168.0.101.

2. In your web browser, type the IP address, eg. http://192.168.0.101 in the address

field.

3. Press Enter, and note the login screen.

4. In the login screen, type

- Username = dcu

- Password = 1234 (from factory)

If the password is unknown or forgotten, then find the Encrypted PIN and send this

to [email protected] to obtain the correct PIN.

● Logged In: Proceed to the Web Server Configuration chapter.

● Not Logged In: Continue with connection settings as described below.

Page 8 (99)

2.2.2 Further Connection Settings

2.2.2.1 Change the IP address of the DCU

If necessary, the IP address of the DCU can easily be changed.

The last two digits in the IP address becomes the engine number.

Example: IP address 192.168.0.104 becomes Engine #4

The DCU has a fixed IP address that is set during the first power-on set up. The IP address

may also be changed later, in the DCU panel menu:

DCU 410E: Menu / Settings / Administration (locked/open) / Miscellaneous / Network

DCU 210E: Menu / Settings / Administration (locked/open) / Network Configuration

The Administration folder is password protected by a password. It will remain open for 60

minutes after valid password.

Use the up / down arrows to select each of the four groups of numbers and press edit to edit

each group.

2.2.2.2 IP Address Convention

The factory default IP of the DCU is 192.168.0.101. The first three groups must be the same

for all components in the LAN, for instance 192.168.0.X, where X is the other unit in the

LAN.

The X-figure must be unique within the LAN. Also, the two last digits in X will

represent the engine number.

Example: A DCU with the IP address 192.168.0.104 will be named Engine #4

2.2.2.3 Connect the DCU to a Single PC

First, make sure that the PC’s Ethernet network configuration is set to automatically receive

an IP address (as most PCs are). Then in the DCU panel menu:

Menu / Settings / Connect a PC…

Press the down arrow and then Toggle. The DHCP-server will now be active for 10 min.

Repeat if it takes longer than 10 min to ready the PC.

Connect the PC to the DCU with a CAT-5 Ethernet cable. The DCU’s DHCP-server will now

automatically set up the PC to communicate with the DCU. It may be necessary to use a

network reset/repair function for the PC’s Ethernet connection in order for the PC to receive

the new IP address.

Alternatively, set the IP address of the PC manually to a free IP address in the same subnet

as the DCU.

For instance, if the DCU’s IP address is 192.168.0.101, the PC may use any IP address

starting with 192.168.0 except 192.168.0.101.

2.2.2.4 To Connect the DCU to a LAN with a DHCP server

For use in a LAN with a DHCP server (Dynamic Host Configuration Protocol), the IP

addresses to be used by Marine Pro components must be set outside the IP address range

used by the DHCP server. Most DHCP servers are configured with an IP address range that

leaves room for fixed addresses outside it.

Page 9 (99)

If for instance the LANs subnet is 192.168.230 and the DHCP’s IP address range is set to 50

– 210, valid IP addresses of the DCU would be for instance 192.168.230.211, 192.168.230.7

or 192.168.230.231.

Do not use the DCU built-in DHCP-server (the Menu / Connect a PC… menu entry) in a LAN

with its own DHCP server, since two DHCP servers in the same LAN may create conflicting

IP addresses.

2.2.2.5 Connection to a LAN using Fixed IP Addresses

Set the IP address of the DCU to a free/available IP address within the LAN’s subnet.

2.2.2.6 Factory Defaults for the DCU

Factory defaults are valid at initial startup only.

● IP address: 192.168.0.101

● Subnet Mask: 255.255.255.0

● Default Gateway: 192.168.0.1

For later resets, the current IP configuration will be kept even through the manual Factory

reset operation.

DHCP IP address range: 101 – 199 within the subnet defined by the DCUs IP address.

2.2.2.7 IP Address Conflict

Two or more DCU units with the same IP address should not be connected in the same

network. The result may be that a PC or RP 410E remote panel will be able to address one

of the DCU units only.

Change the IP addresses until all units have a unique address.

2.3 Web Server Configuration

Once logged in, the DCU can be configured. The following are the Web Server main menu

items.

This chapter is not applicable for the RP products.

When logged in, the browser displays the following.

Page 10 (99)

The Home screen lists the following menu items.

2.3.1 DCU

This is the top level menu for the entire DCU configuration.

All configuration performed, except password and network configuration, is stored in the

portable configuration file within the DCU.

2.3.2 RIO

This is the top level menu for the optional expansion I/O modules, the RIO modules.

All configuration performed is stored in the portable configuration file within the DCU.

2.3.3 SDU

This is the menu top level for the SDU 404/410 safety unit configuration.

The SDU is mandatory in classed installation.

All configuration performed is stored in the portable configuration file within the DCU. If a

SDU is attached the configuration is transferred to the SDU as well.

2.3.4 MK-14

The relays on the optional relay module MK-14 can be assigned a function here.

All configuration performed is stored in the portable configuration file within the DCU.

2.3.5 Upload Wallpaper

A user wallpaper can be uploaded, and can be used as background for instruments, popups

and other dialogs.

2.3.6 Versions

This top level menu item lists the hardware and software version of the DCU, and the

software version of the SDU.

If contacting Auto-Maskin for help or questions regarding your product, the data in

the Versions page provide vital data that might help speed up the resolution to

your enquiry.

Page 11 (99)

2.3.7 Troubleshooting

The troubleshooting section makes it possible to troubleshoot I/O and communication on the

DCU, and also the RIO units.

The following can be verified for the DCU:

● Supplies

● Switch inputs

● 4-20 mA inputs

● PT100 inputs

● Voltage inputs

● Communication channels

● J1939 Nodes

● MK-14 outputs

● Outputs (functional 24V outputs and relays)

● Inputs (functional inputs)

● Run sources (engine running indications)

● RPM sources (which sources are in use) and their priority

● Diagnostics

The following can be verified for the RIO:

● Versions

● Supplies

● Switch inputs

● 4-20 mA inputs

● PT100 inputs

● TC

● 0-5V

● Outputs

3 Main DCU Web Server Menu

Page 12 (99)

3.1 Access Control

The DCU configuration is protected with a PIN code.

Select this option to change the PIN code. First, type in the old PIN, and then the new PIN

twice.

If the PIN is unknown or forgotten, then find the encrypted code and send this to

[email protected] to obtain the correct PIN.

3.1.1 Access Control Levels

If enabled, the DCU supports three levels of access control.

● Factory (highest priority)

● Dealer

● User

Each access control level can lock any configuration, making it impossible to change for

lower priority access.

When access control is enabled, make sure to close your browser after use (when

logging out) to prohibit any unauthorized access.

3.2 File

This section provides functions for management of configuration files and other file

operations, such as upgrading of firmware and uploading of custom wallpapers.

3.2.1 Load any File

To change the configuration of the DCU, load a new configuration file.

When a configuration file is selected, the panel will restart with the new

configuration file.

3.2.1.1 Factory Default

From here, a predefined factory configuration file can be opened.

3.2.1.2 User Uploaded

This lists the files previously uploaded to this DCU. Pick a file to select a new configuration

for the DCU.

Note! To get access to the configuration file, it needs to be uploaded to DCU first. See

“Upload to DCU” for more information.

3.2.2 Delete Configuration File

Delete any number of configuration files on the DCU. It is only the user uploaded

configuration files that can be deleted. The configuration files supplied from the factory will

always be available and can not be deleted.

3.2.3 Configuration Printout

This gives a quick overview of the current configuration.

Page 13 (99)

3.2.4 Save File as

This saves the current configuration of the DCU into a file. The default file extension is .cfg.

3.2.5 Save CANopen EDS-file

DCU 410E/408E only.

This saves the CANopen I/O electrical datasheet to a file on your PC.

3.2.6 Upload to DCU

Uploaded files are files transferred to the DCU.

The built-in firmware can be updated whenever there is a new firmware available.

New configuration files can be added to the DCU panel.

3.2.6.1 Firmware Update

Select the new DCU panel firmware to upload. The file name shall be

dcu410_<release>.tar.gz.

The latest firmware release can be obtained from the Auto-Maskin web site.

Before upgrading the DCU it is recommended to take a backup of the current

configuration file, see “Save File as” chapter.

When upgrading a DCU to a new firmware it is recommended to also upgrade any

connected RPs to the latest available firmware as well.

If upgrading an RP it is similarly recommended to upgrade related DCUs.

3.2.6.2 Wallpaper

Select a picture file for the DCU. The file must be of type .png. Only one user wallpaper may

be uploaded. Uploading a new file will remove the old one.

3.2.6.3 Configuration File Upload

Select a user configuration file for the DCU. The file must be of type <file_name>.cfg.

When uploaded, the file is stored in the DCU, and is later available for use from the User

Uploaded files section.

3.3 I/O Configuration

Described in a separate chapter.

3.4 User Interface

Described in a separate chapter.

3.5 Start/Stop/Prelube

Described in a separate chapter.

Page 14 (99)

3.6 Engine Model

home / dcu / engine model

The default name is “Engine”.

Name the engine better, for example “Auxiliary” or “Doris”.

The last two digits in the DCU IP address becomes the engine number. If the IP

address is 192.168.0.110, then the engine in this example is named “Auxiliary

#10”.

3.7 Service Interval

See and configure regular service intervals.

home / dcu / service interval

3.7.1 View Service Status

This will list the number of hours until the next service is due.

3.7.2 Configure

Up to four different timers can be configured to indicate it is time for engine service.

The default text “Service 1” can be changed by selecting the assign custom name link.

Page 15 (99)

home / dcu / service interval / configure

Service Enabled selects whether the service interval timer is active or not.

Next Service At selects the hour counter value in the DCU for the first service. Note that this

happens only one time. This is useful if the first service should have a shorter interval than

the regular service interval.

Then Every selects the service interval in hours. The DCU will indicate every time this

number of hours has elapsed.

Example

Current DCU hour counter is 123 hours.

● Next Service At: 150 hours

● Then every: 250 hours

The first service notification will appear in 27 hours, then every 250 hours. All hours are

engine running hours.

Pre-Warning Enabled enables an information popup whenever the service is within 10 % of

the service interval.

3.8 Communication

Described in a separate chapter.

Page 16 (99)

3.9 Miscellaneous

Described in a separate chapter.

3.10 Language

See Language description in the User Interface chapter.

This section is identical.

4 I/O Configuration

The I/O section holds menu items for input and output channels. Input channels are sensors

going in to the DCU (eg. Switch Input, 4-20 mA Input) and output channels are sensors

being controlled by the DCU (eg. 24 V Output, J1939 Output).

Always remember to press the Submit button after each change on the

configuration pages.

No changes are saved until this button is pressed.

4.1 Common I/O Configuration

Much of the configuration is common for all channels. This section describes the common

configuration.

Naming

Each channel can be configured with a custom name for all supported languages. The

naming of the channel in the panel is determined using the following prioritization.

1. Use channel custom name in selected language, if any.

2. Use channel custom name in English, if any.

3. Use channel default name in selected language.

Channel Use

Each channel can be individually configured for display on DCU, RP or both. In addition,

each channel can be individually configured for event.

The channel use configuration defines how the channel is configured according to the

following table.

Channel Use

DCU

RP

Display

Event

Display

Event

Not in use

Event

X

X

Page 17 (99)

DCU

X

DCU + Event

X

X

X

RP

X

RP + Event

X

X

X

DCU + RP

X

X

DCU + RP + Event

X

X

X

X

Silent Event

DCU + Silent Event

X

RP + Silent Event

X

DCU + RP + Silent Event

X

X

Sea Trial Only

1

Select Not in use if the channel shall be disabled.

Select Event if the channel shall make any form of event. An event can be a warning, an

alarm, a load reduction or an engine shutdown.

Select Silent Event for an active channel, but no panel alarms. The event will be available

on communication only.

Select DCU and/or RP if the channel is to be displayed on a page.

The Sea Trial Only option is used to tag a channel for use in Sea Trial Mode only. This is

only applicable for a DCU that will provide data logging during a sea trial. Choosing this

option makes the channel active for viewing and data logging only when Sea Trial Mode is

active on the DCU.

Normally, and in most cases, the selection should be “DCU + RP + Event”, as

highlighted in the table above. This makes sure the channel is displayed in the

DCU and in the RP, if – or when – the RP is installed.

1 Can be displayed when Sea Trial mode is active.

Page 18 (99)

4.1.1 Common Configuration for Switch Channels

Any switch input channel can be configured to either be used as a configurable input

function, or as an ordinary channel.

If a function is configured, the DCU will automatically disable the ordinary channel

use.

Function

Whenever a function is configured, that function will be assigned to the switch channel. The

following functions are available for the switch channels. The highlighted functions are the

most typically being used.

The function is activated when the input is connected to 24V. The function is deactivated

when the input is left open, or connected to 0V.

Function Name

Description

None

The channel is being used as an (ordinary)

engine sensor switch input.

Local Mode

Sets the panel to local mode, meaning all

external commands are blocked.

Remote Mode

Sets the panel to remote mode, meaning all

local commands are blocked.

Backlight 100%

Force backlight to 100%

Prelube Override

The configured prelube sequence is aborted.

Prelube Complete

Signal shall come from the prelube system,

notifying the panel that the prelube sequence is

completed. The panel will leave the prelube

phase and commence start.

Start Disabled

Start is disabled.

Automatic Mode

210E only. The panel accepts automatic

start/stop signals.

Page 19 (99)

Automatic Start

210E only. Panel will commence the start

sequence. Requires Automatic mode.

Automatic Stop

210E only. Panel will commence the stop

sequence. Requires Automatic mode.

Automatic Start/Stop

Panel will commence start when active, and

commence stop when inactive. Requires

Automatic mode.

Remote Start

210E only. Same as the local start button.

Disabled if panel in local mode.

Remote Stop

210E only. Same as the local stop button.

Disabled if panel in local mode.

Local Start

Local Start button

Local Stop

Local Stop button

Local Acknowledge

Used to acknowledge all events in the alarm list.

Local/Remote Acknowledge

Used to acknowledge all events in the alarm list

Remote Acknowledge

Used to acknowledge all events in the alarm list

Silence Buzzer

Silences the buzzer. Edge triggered.

Load Reduction Override

Puts the DCU in load reduction override mode.

Shutdown Override

210E only. Makes all the configured shutdown

channels into alarm channels, so engine will not

shut down automatically.

Engine overspeed shutdown is however always

enabled.

In Gear

210E only. From gearbox on prop. Engines.

Disables start attempts.

In Neutral

Neutral gear indication. Overrides any other In

Gear signal if configured.

In Gear (Ahead)

From gearbox on prop. Engines to indicate

Ahead gear.

In Gear (Astern)

From gearbox on prop. Engines to indicate

Astern gear.

Toggle Crank Mode

Toggle between crank modes.

Power On

Toggle Sleep mode.

Use As configures the function used. Select None if the channel is to be used as an ordinary

switch input channel.

Input State makes it possible to invert the behaviour of the function.

Page 20 (99)

Other manuals for Marine Pro 400 Series

8

This manual suits for next models

17

Table of contents

Other auto maskin Marine Equipment manuals

auto maskin

auto maskin Marine Pro Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin Marine Watch S Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin LT Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin S Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin Marine Pro 200 Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual