Berkel 823 User manual

Other Berkel Kitchen Appliance manuals

Berkel

Berkel VOLANO B2 User manual

Berkel

Berkel BES300 User manual

Berkel

Berkel 300M Owner's manual

Berkel

Berkel 823E User manual

Berkel

Berkel 919A User manual

Berkel

Berkel 350 User manual

Berkel

Berkel 250 User manual

Berkel

Berkel X13 Owner's manual

Berkel

Berkel 450A User manual

Berkel

Berkel 909/1 User manual

Berkel

Berkel 829A-PLUS Owner's manual

Berkel

Berkel 909FS Owner's manual

Berkel

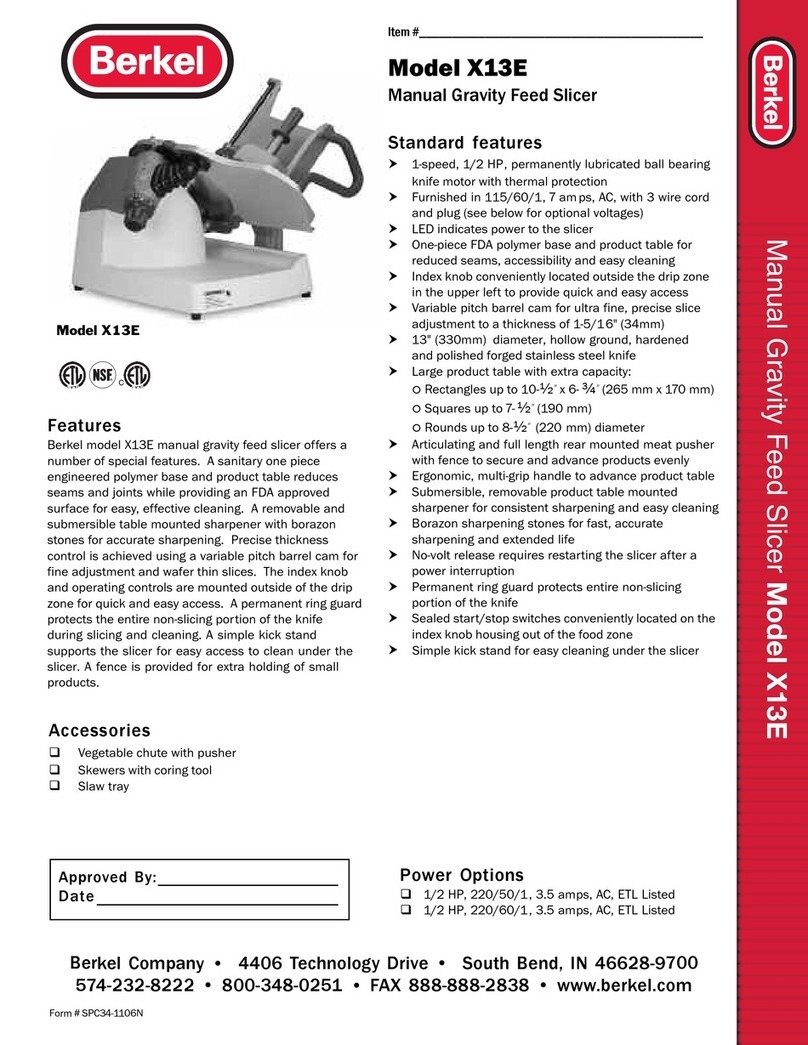

Berkel X13E User manual

Berkel

Berkel 909AS User manual

Berkel

Berkel DOMINA Series User manual

Berkel

Berkel BSFTM Instruction Manual

Berkel

Berkel B12A-SLC Owner's manual

Berkel

Berkel X13E User manual

Berkel

Berkel 909/1 Owner's manual

Berkel

Berkel RED LINE 220 User manual

Popular Kitchen Appliance manuals by other brands

Tayama

Tayama TYG-35AF instruction manual

AEG

AEG 43172V-MN user manual

REBER

REBER Professional 40 Use and maintenance

North American

North American BB12482G / TR-F-04-B-NCT-1 Assembly and operating instructions

Presto

Presto fountain popper instruction manual

Westmark

Westmark 1035 2260 operating instructions