VACUUM PACKAGING MACHINES

1. SETTING

UP

THE MACHINE:

Beforechoosing thesite

for

the machine,please considerthatyou will also need room

for

packaged and non-packaged products apart from the space needed

for

the

machine itself.

Keep in mind that the machine must not be set up upon uneven ground. Especially

with mobile models,theweight

of

the pump mightthen causewarping

of

themachine.

Then the lid will notfit correctly.

Before starting to work, check the oil view glass on the pump,

if

there is a sufficient

quantity

of

oil in the pump. Never use oil other than recommended by the producer.

Neverexceed maximum quantity

of

oil indicated, when adding orchanging oil. Verify

weekly.

Normal ambient temperature for the vacuum pump is between 10 to 70°C.

For

temperature below 10°

C;

it is recommendedtouse

sy

ntheticoil. Pleaseconsultfactory

and pump manufacturer manual for more information orwhen ambient temperature

are outside normal limits.

2. ELECTRICALCONNECTION:

Electrical connections must be made by qualified personnel. This person must make

sure thattheelectrical entries correspond tothe propervoltage and amperage

of

the

machine. GROUNDING INSTRUCTIONS: This appliance must be grounded. In

the

event

of

malfunction

or

breakdown, grounding provides a path

of

least resistance

for

electriccurrentto reduce the risk

of

electric shock.This appliance is equipped with a

cord having an equipment-grounding conductorand a grounding plug. The plug must

be plugged into an appropriate outlet that is properly installed and grounded in

accordance

wi

th all local codes and ordinances.

DANGER Improperconnection

of

theequipment-grounding conductor can result in a

risk

of

electric shock. The conductor with insulation having an outer surface that is

greenwith

or

withoutyellow stripes is theequipment-grounding conductor. Ifrepair

or

replacement

of

the cord orplug is necessary,donotconnecttheequipment-grounding

conductor to a live terminal. Check with a qualified electrician or serviceman

if

the

grounding instructionsare notcompletely understood, or

if

in doubtasto whetherthe

appliance is properlygrounded. Do notmodifythe plug providedwith the appliance

if

it

will notfitthe outlet; have a proper outlet installed

by

a qualified electrician.

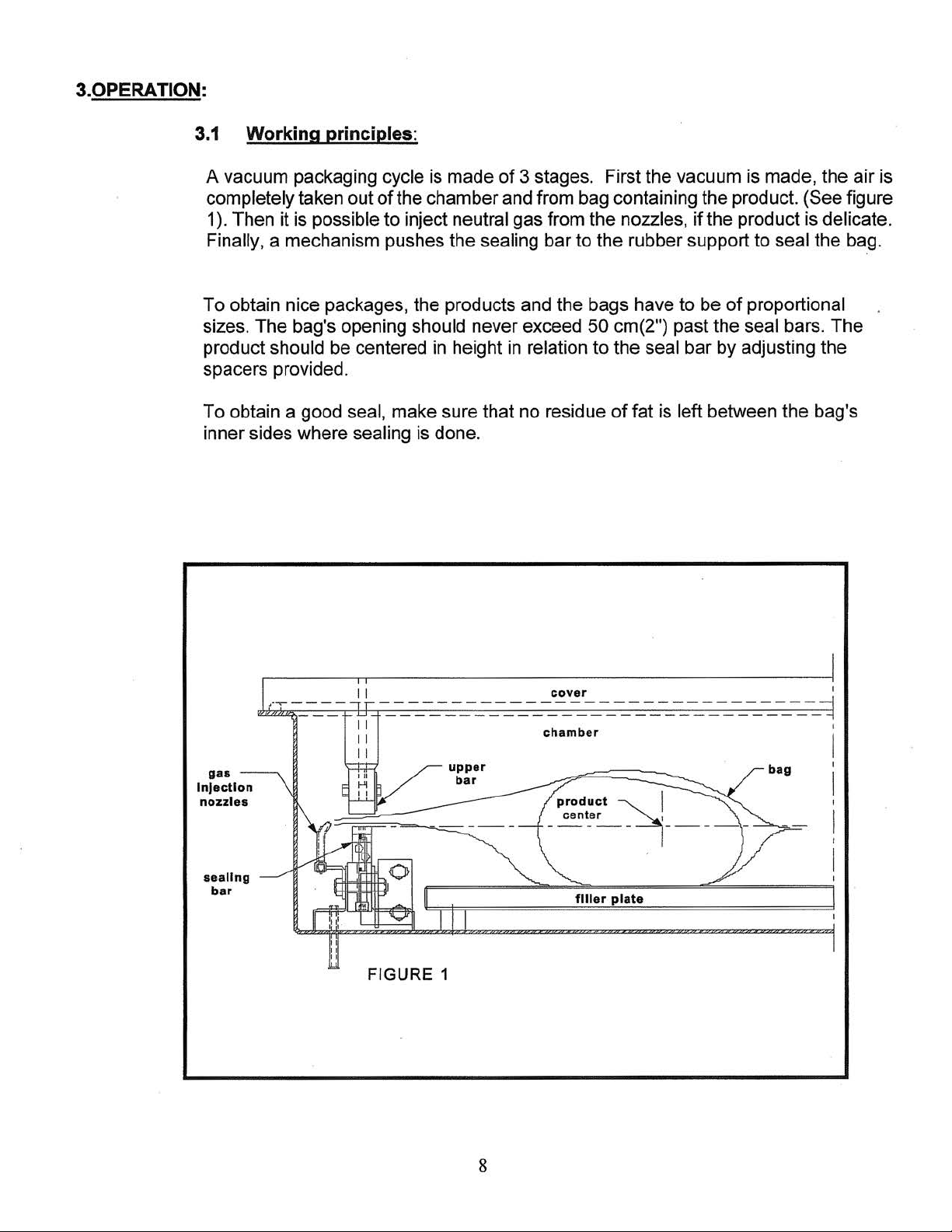

All vacuum machines are supplied wi

th

an electrical schematic drawing.

An

important step in connecting the machine is to make surethat the pump turns in

its correct rotation.

The pump should notrotate more than 3

to

4 seconds in the wrong rotation

or

it

maycause serious damage. The proper rotation is indicated by an arrowon the

pump motor. 7