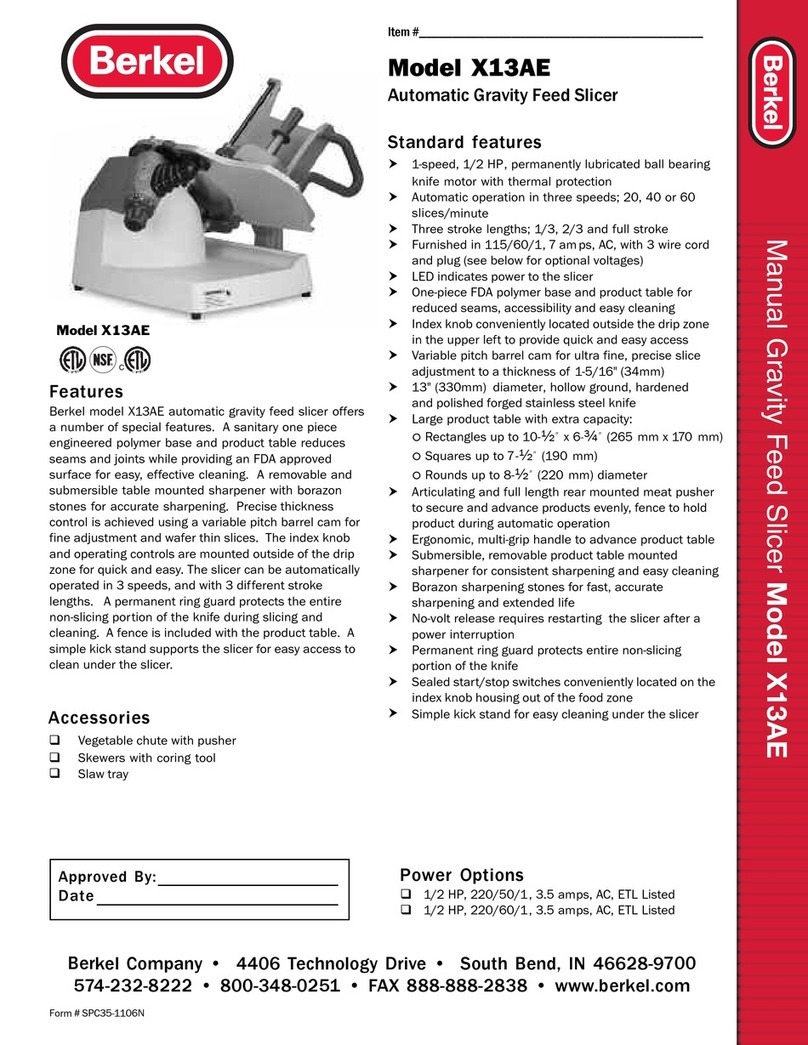

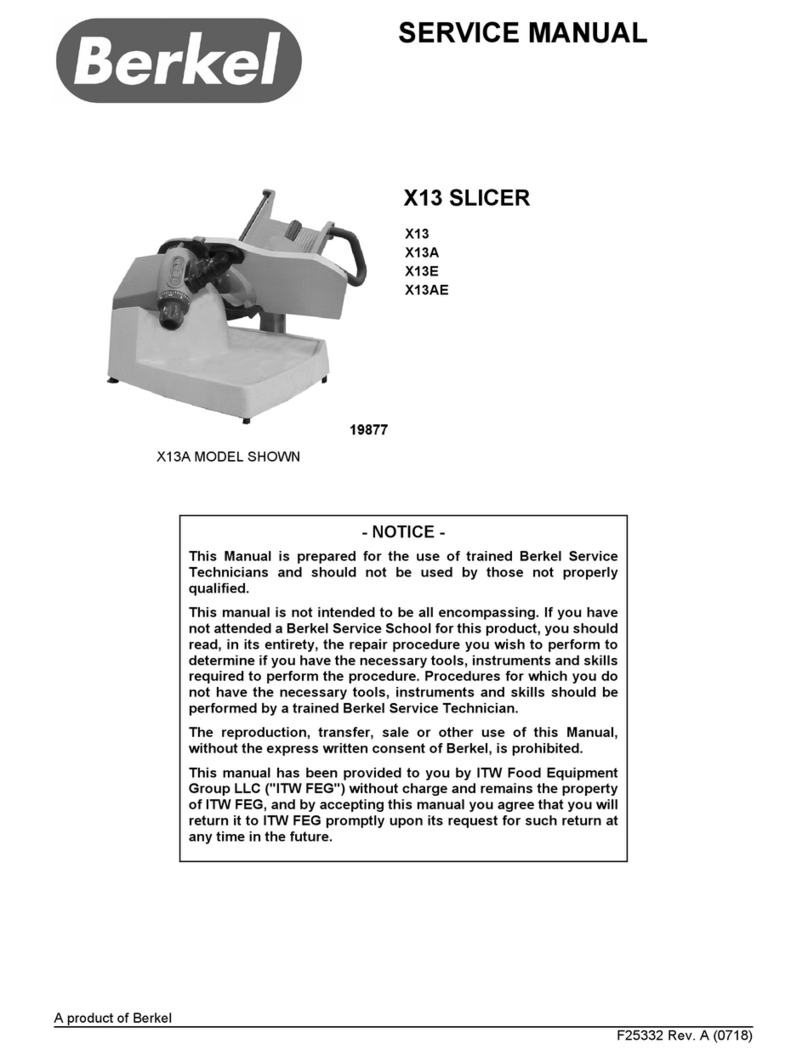

X13 & X13A OWNER/OPERATOR MANUAL • 7

Operat on

General

1. Check to see that the center plate and product table are in place on the slicer and the au e plate is

completely closed. The holes in the bottom of the center plate fit over the bottom mountin studs in the

rin uard and the center plate lockin knob at the top of the center plate fits over the top ed e of the

rin uard. The product table slides completely onto the support arm and is secured with the red

product table lockin knob. The table can only be removed if the thickness control knob is closed and

the product table is pulled to the front of the slicer.

2. If the slicer is an automatic, then make sure the automatic en a e knob on the ri ht side of the table

support arm is pushed in, towards the left.

3. Plu the slicer in. The pilot li ht, between the start and stop buttons will illuminate.

4. Push the reen ON button and the slicer blade will start to turn. Press the red STOP button to stop the

knife.

Automat c Operat on

5. If you have an automatic slicer, with the slicer stopped, pull the automatic en a e knob fully out on the

ri ht side of the machine. This will put the slicer in the automatic mode.

6. Push the speed selection button to chan e the speed:

One illuminated LED indicates 20 slices per minute (slow speed)

Two illuminated LED’s indicates 40 slices per minute (medium speed)

Three illuminated LED’s indicates 60 slices per minute (hi h speed)

7. Pushin the stroke len th selection button chan es the len th of the stroke. This allows smaller products

to be sliced quicker, without the table movin any faster. Make sure the stroke len th is lon er than the

width of the product.

One illuminated LED indicates 1/3 of the total possible stroke len th

Two illuminated LED’s indicates 2/3 total possible stroke len th

Three illuminated LED’s indicates full stroke len th

8. Press the reen START button and the product table will slowly come to its forward position to find its

home position. Once it ets back to the home position, then it will start to o back and forth at the

preset speed and stroke len th.

9. Push the red STOP button and the table will complete its stroke and stop in the home position.

10. As lon as the slicer remains in the automatic mode it will remember its home position and always start

ri ht up when the reen START button is pushed. It will always start slow and radually build up to its

full speed. This is the “soft start” feature.

11. Each time you take the slicer out of the automatic mode, and then back into the automatic mode, it will

always find its home position before it starts to run (as indicated in step #8).

12. Each time you active the slicer into automatic mode, the last speed and stroke len th settin s will be

remembered until power is disrupted from the slicer (i.e. disconnectin the power cord from the outlet).

Once power is reconnected to the slicer, the default for automatic is slow speed and full stroke len th.