Bertin Technologies PRECELLYS Evolution Touch User manual

This manual suits for next models

1

Table of contents

Other Bertin Technologies Laboratory Equipment manuals

Bertin Technologies

Bertin Technologies PRECELLYS 24 Touch User manual

Bertin Technologies

Bertin Technologies Coriolis m User manual

Bertin Technologies

Bertin Technologies PRECELLYS 24 User manual

Bertin Technologies

Bertin Technologies PRECELLYS 24 User manual

Bertin Technologies

Bertin Technologies CORIOLIS Compact User manual

Bertin Technologies

Bertin Technologies Cryolys Evolution User manual

Bertin Technologies

Bertin Technologies Cryolys Evolution User manual

Bertin Technologies

Bertin Technologies Coriolis m User manual

Bertin Technologies

Bertin Technologies CORIOLIS COMPACT User manual

Popular Laboratory Equipment manuals by other brands

Christ

Christ Epsilon 1-4 LSCplus operating manual

Agilent Technologies

Agilent Technologies 5110 ICP-OES Service manual

Sonic

Sonic Sonolator Operating instructions manual

Beckman Coulter

Beckman Coulter LH 780 instructions

SPEX SamplePrep

SPEX SamplePrep Genomax 2050 Operation manual

Hakko Electronics

Hakko Electronics FT-8003 instruction manual

Nippon Genetics Europe

Nippon Genetics Europe FastGene FG-09WS manual

Olympus

Olympus U-PCD2 instructions

Omni

Omni Sonic Ruptor 400 user manual

Agilent Technologies

Agilent Technologies G1574A installation guide

Terragene

Terragene Bionova IC10/20FRLCD manual

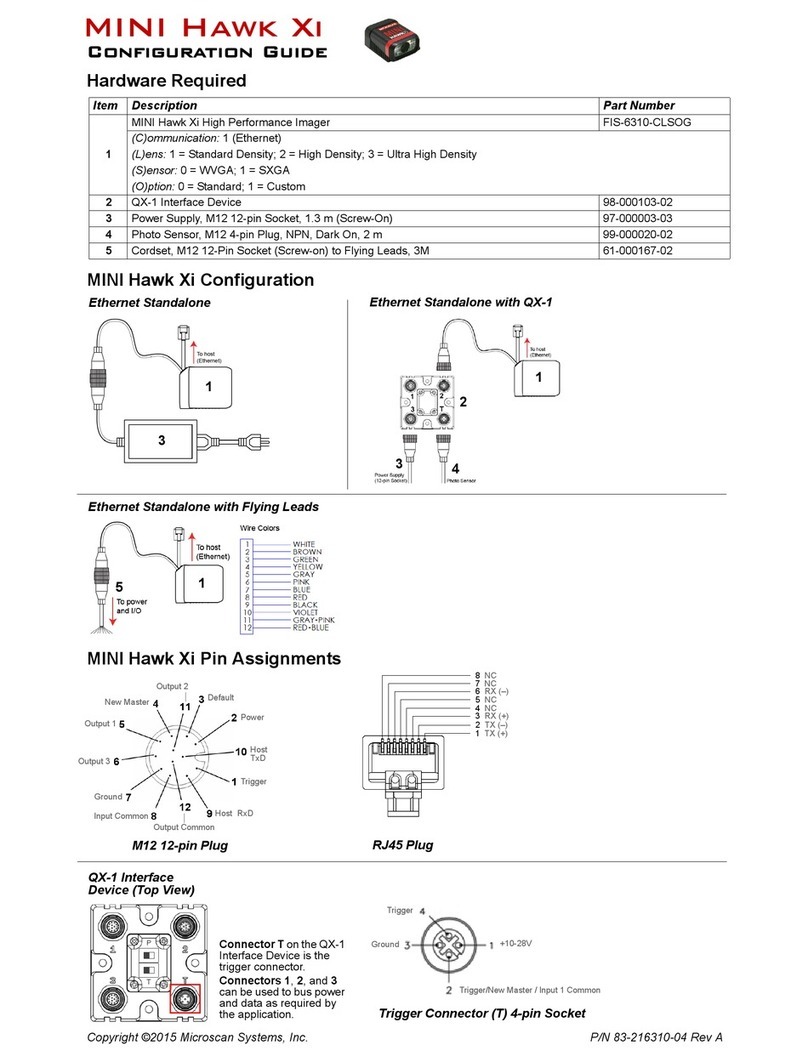

Microscan

Microscan MINI Hawk Xi Configuration guide

Sanuvox

Sanuvox S300 VOC Installer's instructions

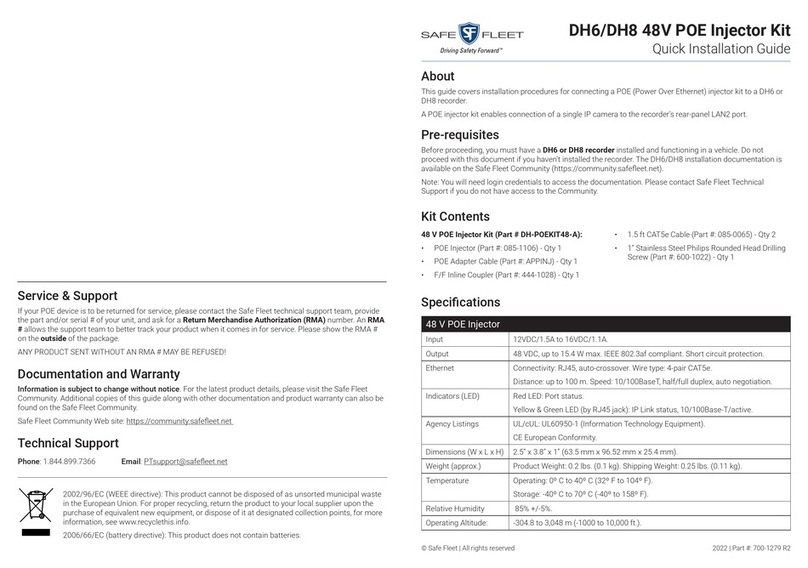

Safe Fleet

Safe Fleet DH6 Quick installation guide

diagenode

diagenode Bioruptor Pico user guide

ThermoFisher Scientific

ThermoFisher Scientific invitrogen iSort Series manual

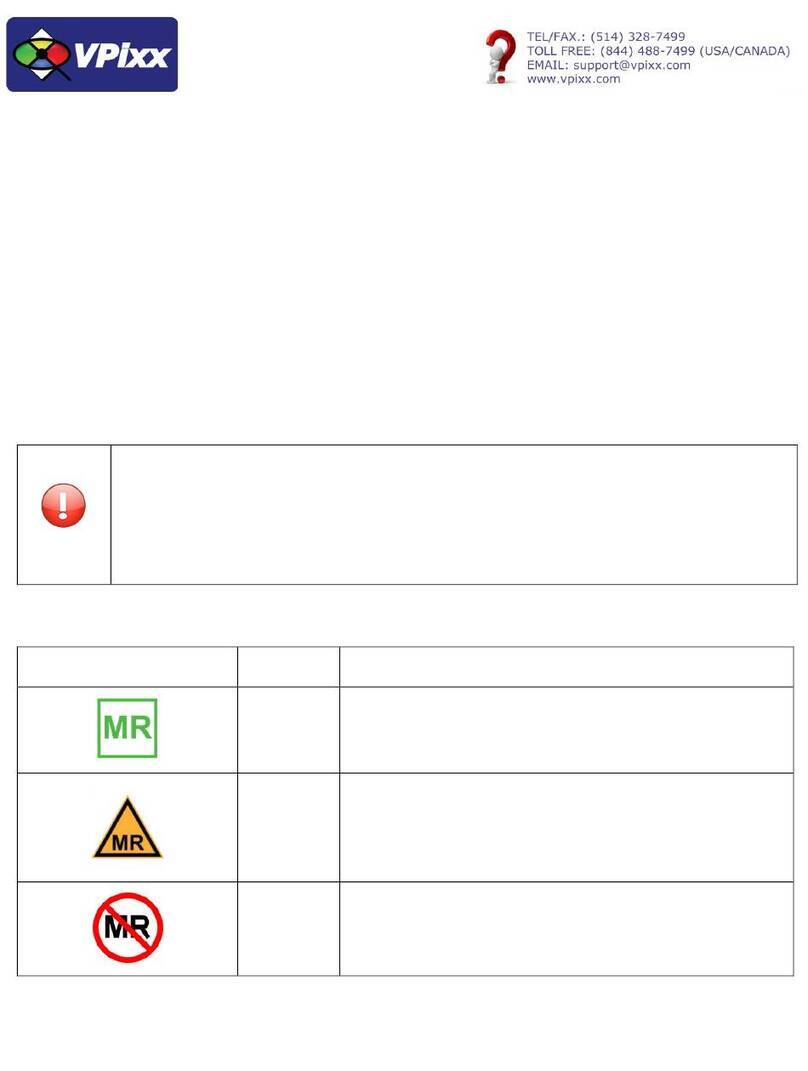

VPixx Technologies

VPixx Technologies VPX-ACC-5180 Assembly instructions

Molecular Devices

Molecular Devices QPix 450 user guide