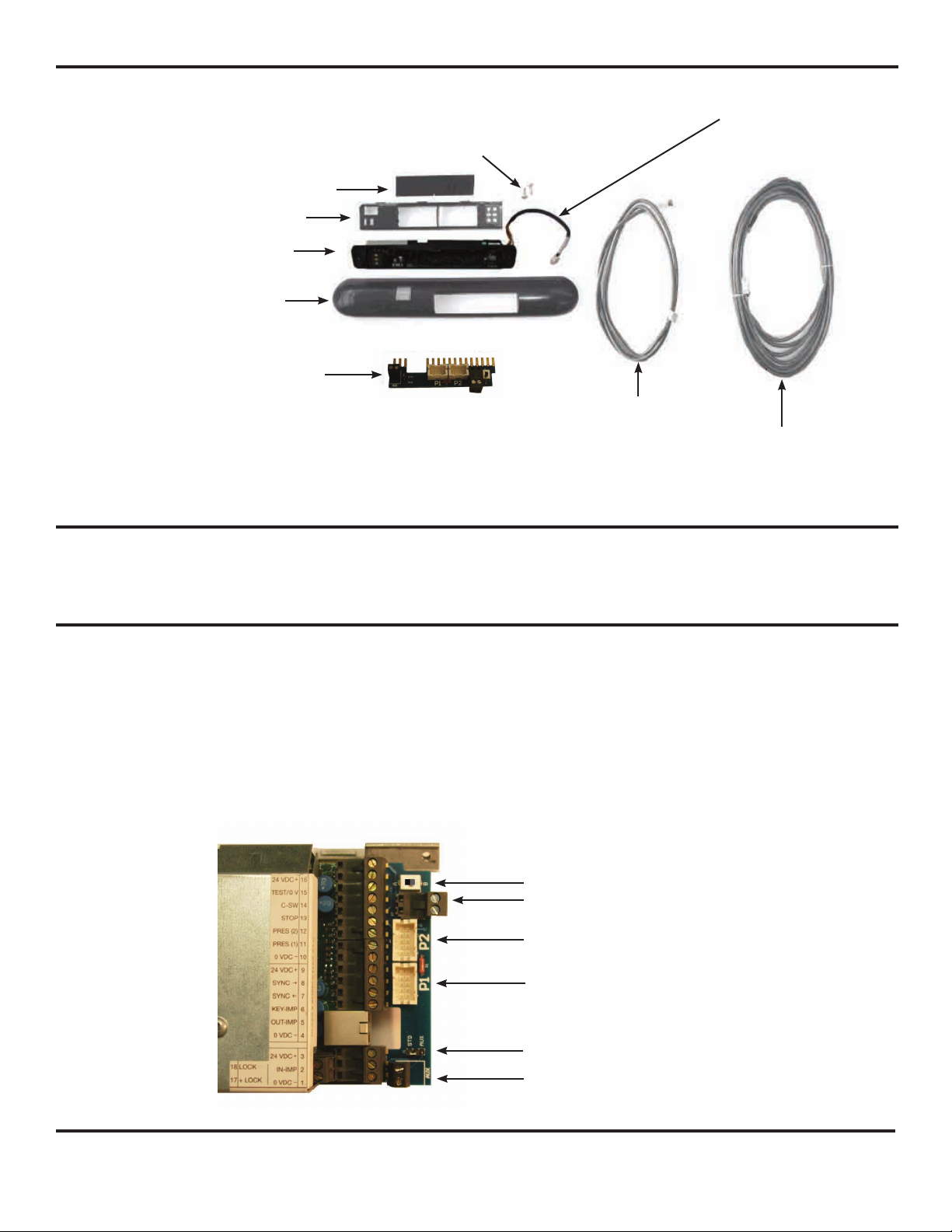

Intial Sensor Setup

1.Power up the Unislide and tune the door. (Unislide control V12.16.2 and above)

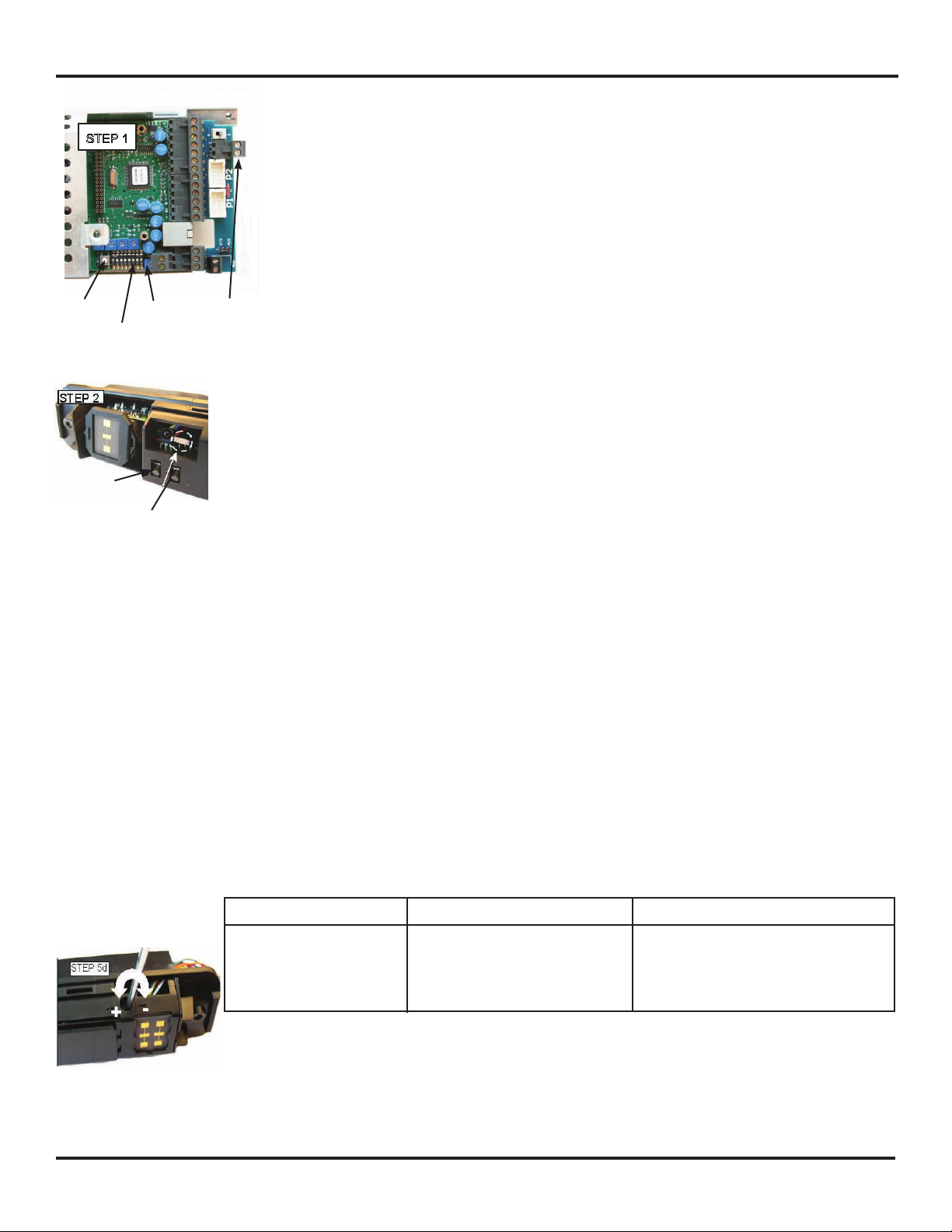

a.Remove the control cover and flip dipswitch #7 to OFF (down); turn the time

delay counterclockwise and disconnect the breakout switch terminal block and

keep P1/P2 disconnected.

b.Slide door(s) closed and with the 5-position switch in Auto mode, press the

Learn button located on the bottom edge of the control. The door should cycle

slow open - slow closed.

c.Put the 5-position switch to Hold-Open and observe the door cycle for back

check functionality and make door adjustments if required and turn the time

delay to a minimum of 1.5 seconds.

d.Connect P1 and P2 (P2 = side not intended for use during a “1-way” traffic

mode) to the adapter board.

e.Open the Unislide cover and on the Unislide control box, flip dipswitch #7 ON

(for monitoring). Close the cover to the control box.

f.Close and latch Unislide cover. Set the rotary switch to the “Auto”, two-way

traffic position. Momentarily press the reset button located next to the 5-position

switch.

2.The Ultraview sensors are factory set in “Neutral” mode. To set up the system,

the sensors will need to be designated as P1 or P2, and then the sensors will need to

be configured for the particular installation. The system will not properly function until the

sensors are designated.

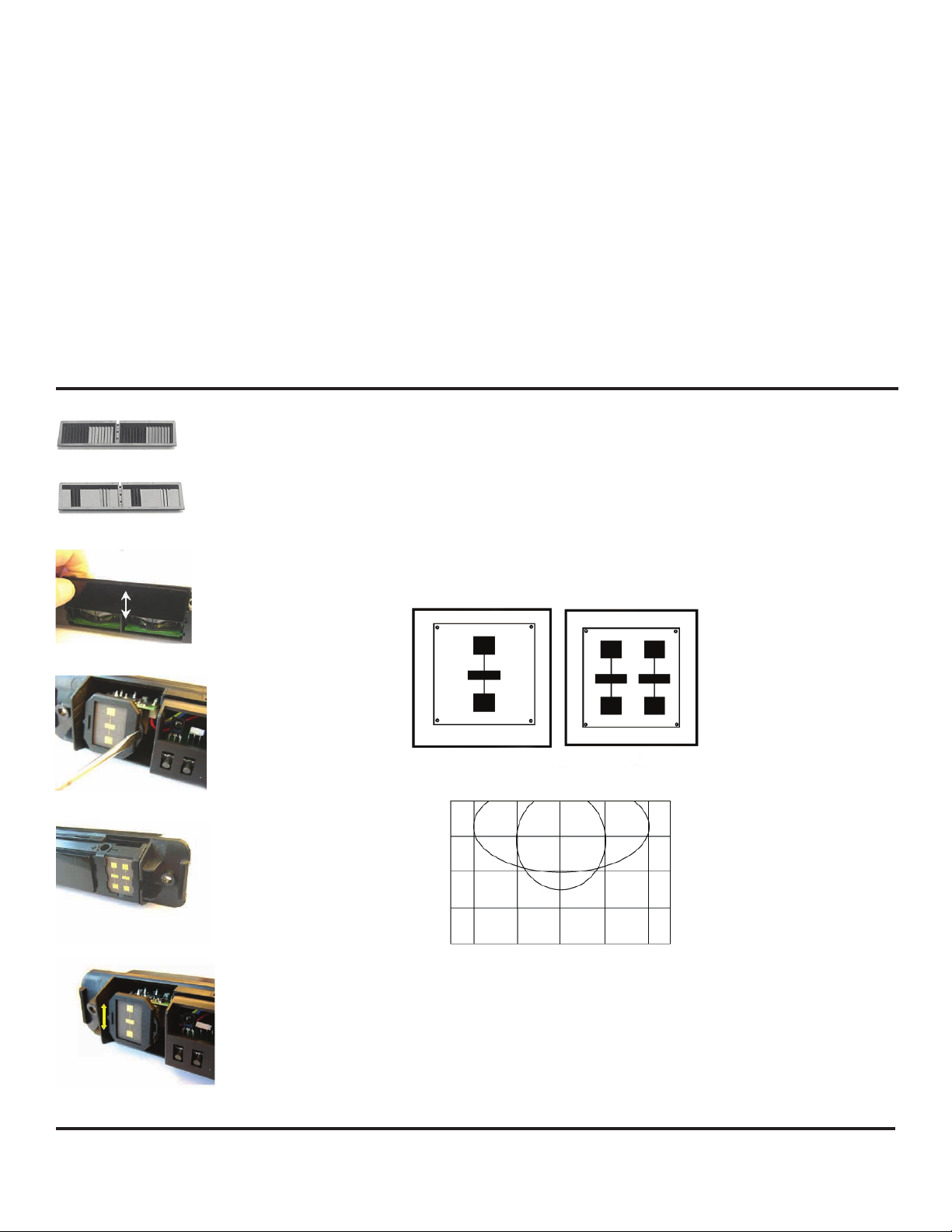

3.On the sensor to be designated as P1, confirm that it is connected to P1 at the interface

board then press the left push button for 3 seconds and release.The LED will flash green once

(meaning set to P1), and then steady red. The sensor will establish communication with the

other sensor and the LED on both sensors will flash slowly green (1 Hz) for 2 minutes

duration, and the other sensor will automatically be designated P2.

4.If the sensor is designated incorrectly, press and hold the left push button of the P1

sensor for 5 seconds and the sensor will return to neutral mode. The LED will flash green

three times when the push button is released. Then repeat step 2.

5.Mechanically adjust the presence field of each sensor for the installation.

a.Launch a setup of the system by momentarily pressing and releasing the right

push-button (on either sensor), and then step away from the pattern. This will

launch a setup for both sensors at the same time. Adjust one sensor at a time

thereafter. Keep traffic away from the sensor’s pattern.

If the right push-button is pressed for 3 seconds, the sensor will be in a

manual set-up mode. The sensor will flash red, then green a number of

times. To return to the standard mode press the right push button again for

3 seconds until the LED light stops flashing and then release.

b.The sensor will automatically go through a set-up and the LED will flash red/green

a number of times. The door will open, then close while the LED is flashing (the

sensors are learning the influence of the door) - this will take approximately

16 seconds

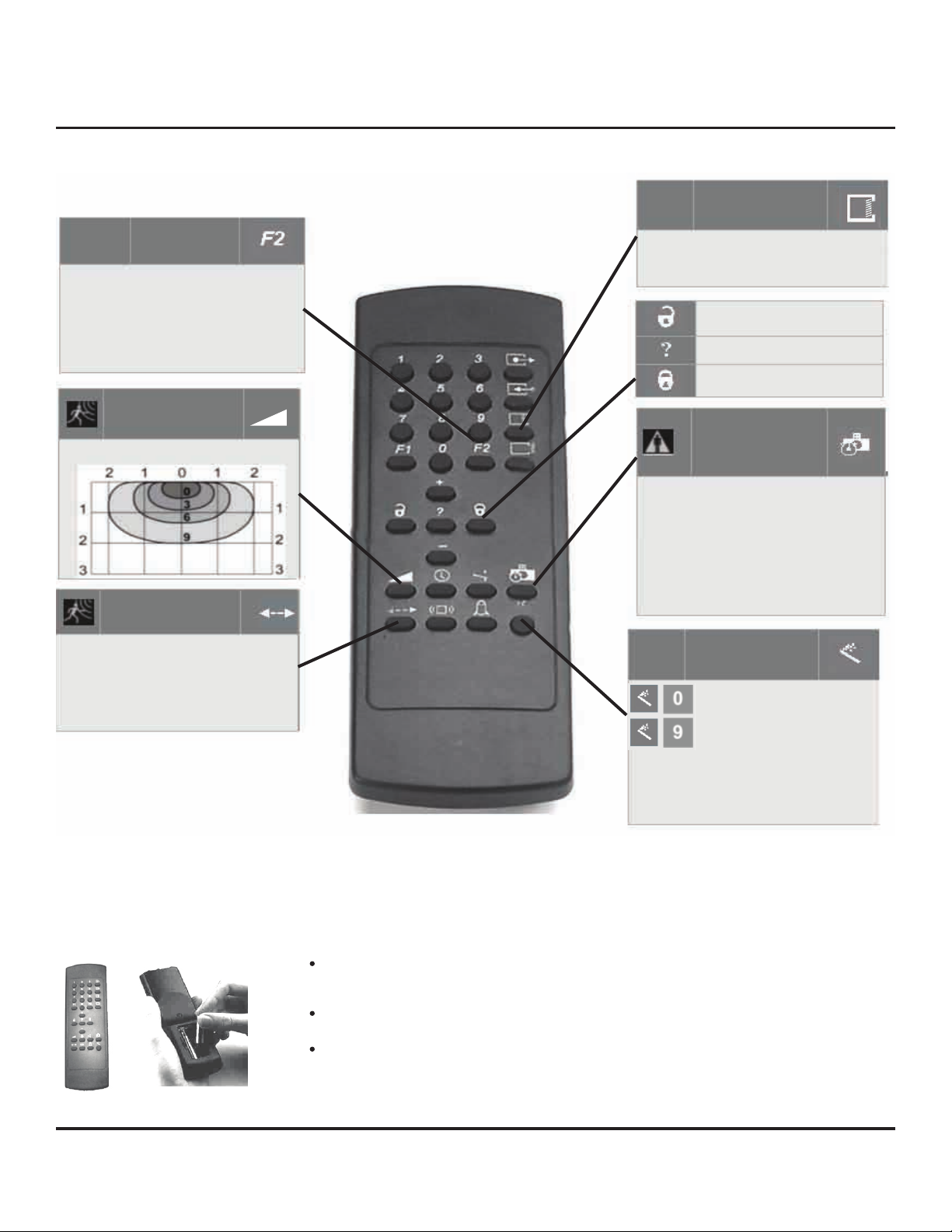

c.The LED will display one of four conditions:

d.If needed, turn the adjustment screw with a small screwdriver ½ revolution, then

repeat step 5a.

e.Repeat steps ‘a’ through ‘d’ for the other side of the door.

f.If any operator adjustments are made a new setup must be launched.

6.Connect the break-out switch connector (see picture Step 1) and secure the header cover.

7.(Once the Unislide and Ultraview covers are installed and secured in place). Launch a final

set-up via the remote control (magic wand 0)

Ultraview US23-0640-09 07-30-09 V4

© Copyright 2009 Besam US Inc. May not be reprinted without ermission 5

LED STATUS MEANING ACTION

(after pushing right pushbutton)

Rapid flashing RED

Rapid flashing Green

None

ORANGE

Presence pattern is too close to door

Presence pattern is too far from door

Presence pattern is properly positioned

ERROR

Adjust screw counterclockwise(+)

Adjust screw clockwise(-)

None

See Troubleshooting Guide on pg. 11

BREAKOUT

SWITCH

TIME

DELAY

DIP

SWITCH#7

LEARN

BUTTON

1.)PRESS LEFT

BUTTON

2.)OBSERVE LED

Note: Before connecting and tuning the sensors, complete all operator adjustments and verify

proper operation of the door system for compliance with applicable ANSI standards

STEP 1