G

!

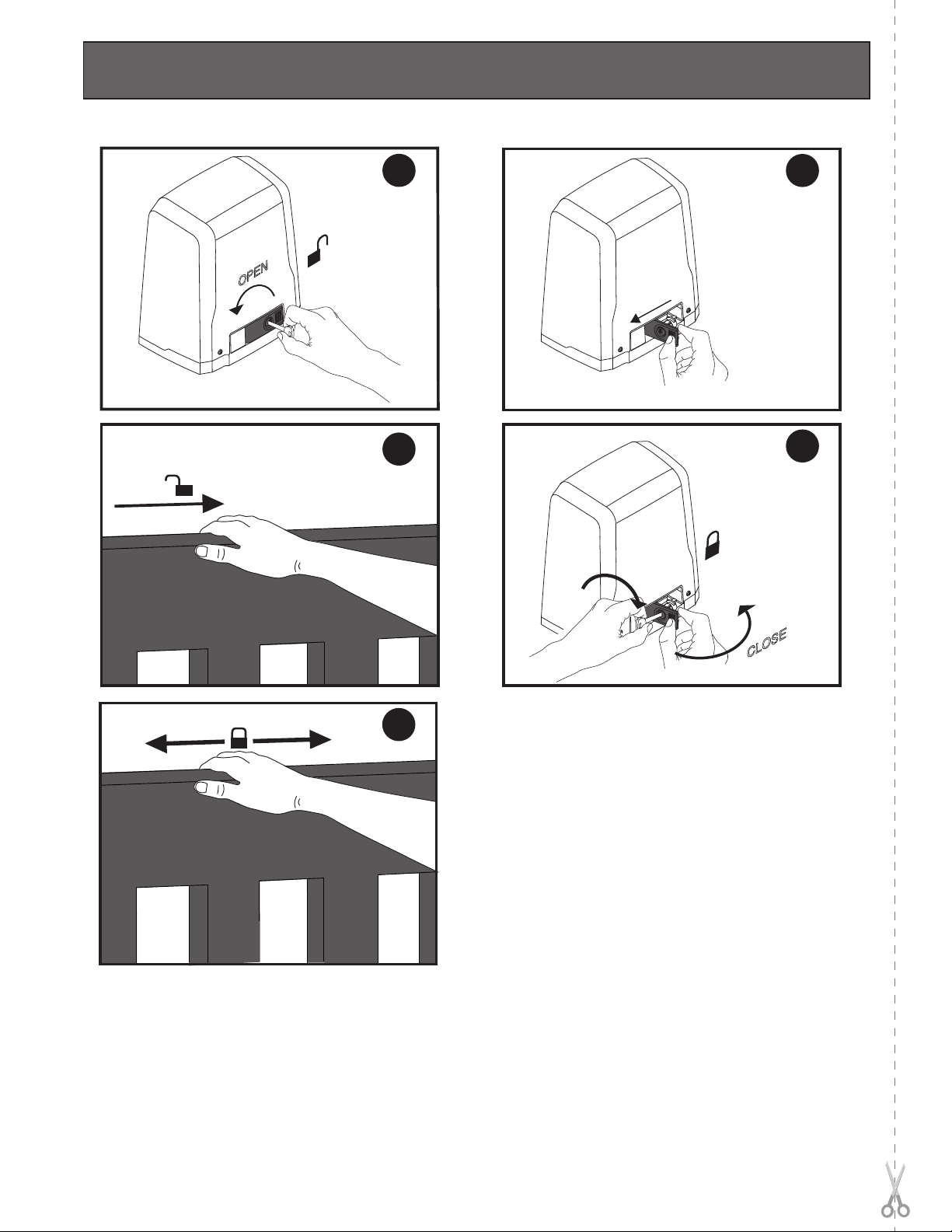

Connettore programmatore palmare,

Palmtop programmer connector,

Connecteur programmateur de poche,

Steckverbinder Palmtop-Programmierer,

Conector del programador de bolsillo,

Connector programmeerbare palmtop.

Connettore scheda opzionale,

Optional board connector,

Connecteur carte facultative,

Steckverbinder Zusatzkarte,

Conector de la tarjeta opcional,

Connector optionele kaart.

Display + tasti programmazione,

Display plus programming keys,

Acheur et touches de programmation,

Display und Programmierungstasten,

Pantalla mas botones de programacion,

Display meerdere toetsen programmeur.

Connettore necorsa

Limit switch connector

Connecteur de n de course

Steckverbindung Endschalter

Conector nal de carrera

Connector eindaanslag

F3 1,25A T

F1

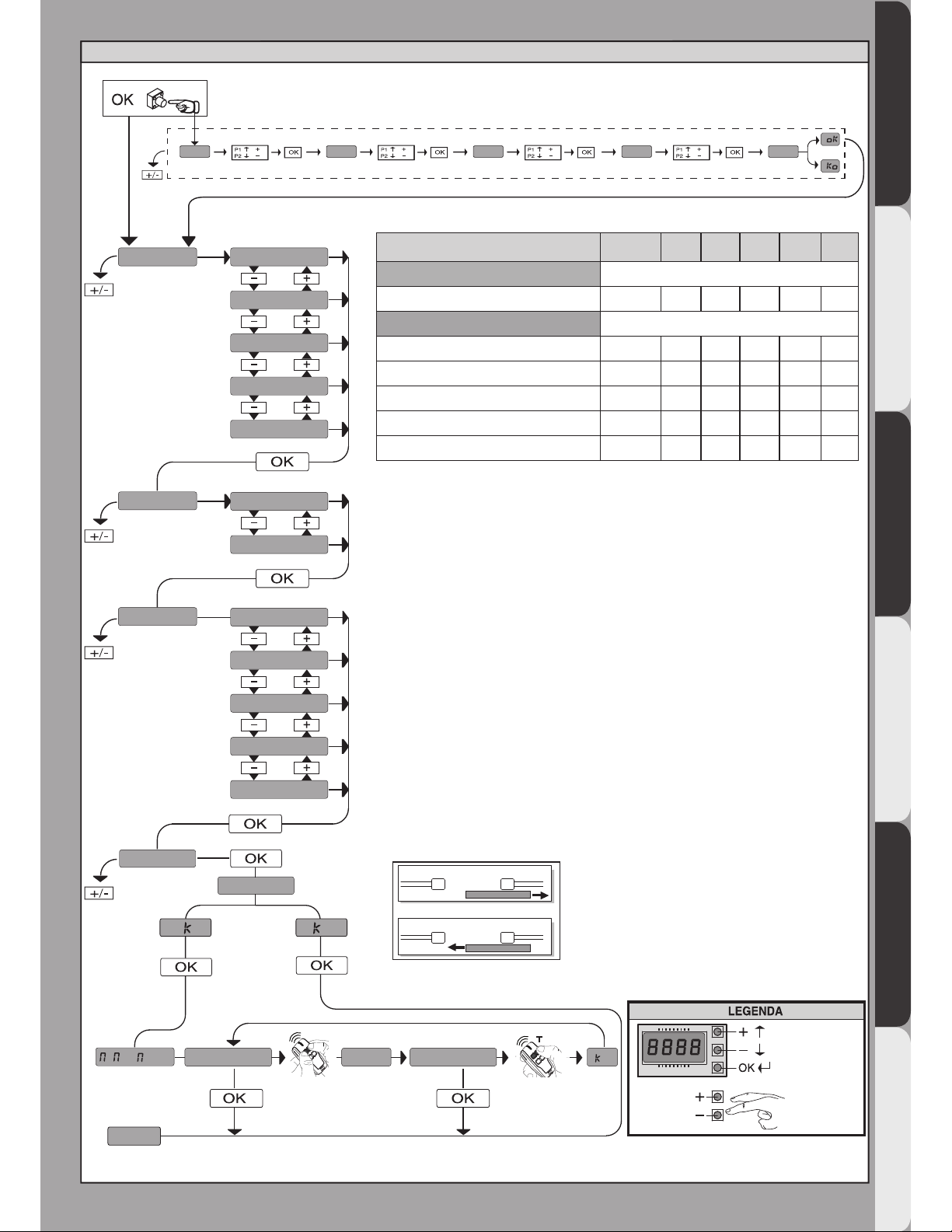

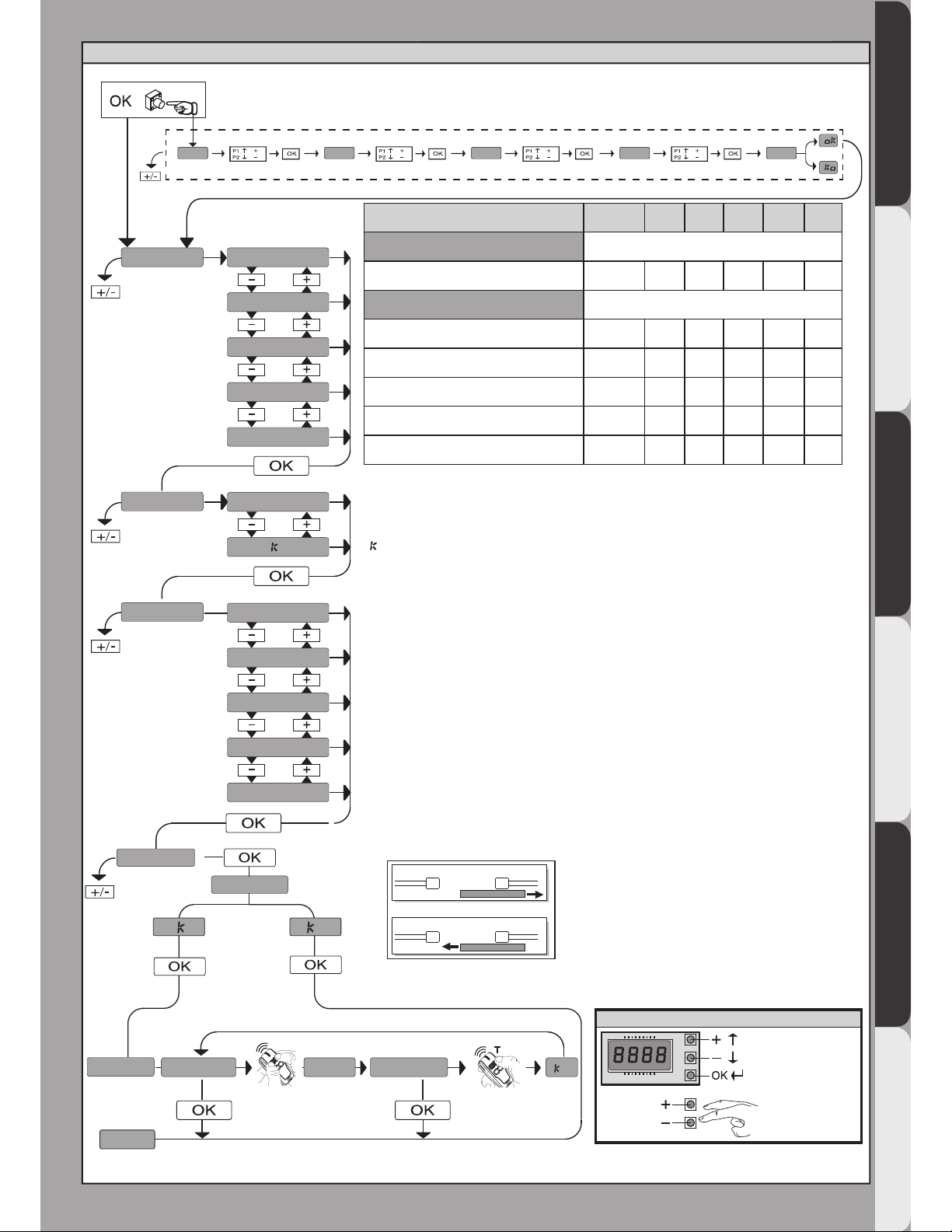

AUX 3 = 0

AUX 3 = 2

AUX 3 = 3

AUX 3 = 4

AUX 3 = 5

AUX 3 = 6

AUX 3 = 7

AUX 3 = 8

AUX 3 = 9

AUX 3 = 10

AUX 0 = 0

AUX 0 = 2

AUX 0 = 3

AUX 0 = 4

AUX 0 = 5

AUX 0 = 7

AUX 0 = 8

AUX 0 = 9

AUX 0 = 10

AUX 0 = 6 AUX 3 = 1

2

1

24 V

SCA

!

24V

20 21

AUX0 - 24V

(MAX 1A)

20 21

26 27

24V 26 27 50 51

Y#

10L N 11 20 21 26 27 50 51 52 60 61 62 70 71 72 73 74 75

Alimentazione / Power supply

Alimentation / Stromversorgung

Alimentación /Voeding

LN

220-230V ~

*

M1

+

-Motore / Motor / moteur

Motor /Eindaanslag/Encoder

AUX 3

(MAX 24V 1A)

AUX

24V -

24V +

24 VSafe+

COM

IC 1

IC 2

NO

NO

Alimentazione accessori

Accessories power supply

Alimentation des accessoires

Stromversorgung Zubehör

Alimentación accesorios

Voeding accessoires

Comandi / Commands

Commandes/Bedienelemente

Mandos/ Commando's

SAFE 1

STOP

COM

FAULT 1

SAFE 2

FAULT 2

NC

NC

NC

Sicurezze

Safety devices

Sécurités

Sicherheitsvorrichtungen

Dispositivos de seguridad

Veiligheden

S1

S2

S3

+

-

OK

24V~ 220-230V~*

!

AUX 0 - 24V

(MAX 1A)

24V

OPEN

CLOSE

S1

S2

+S1

+

-S2

-

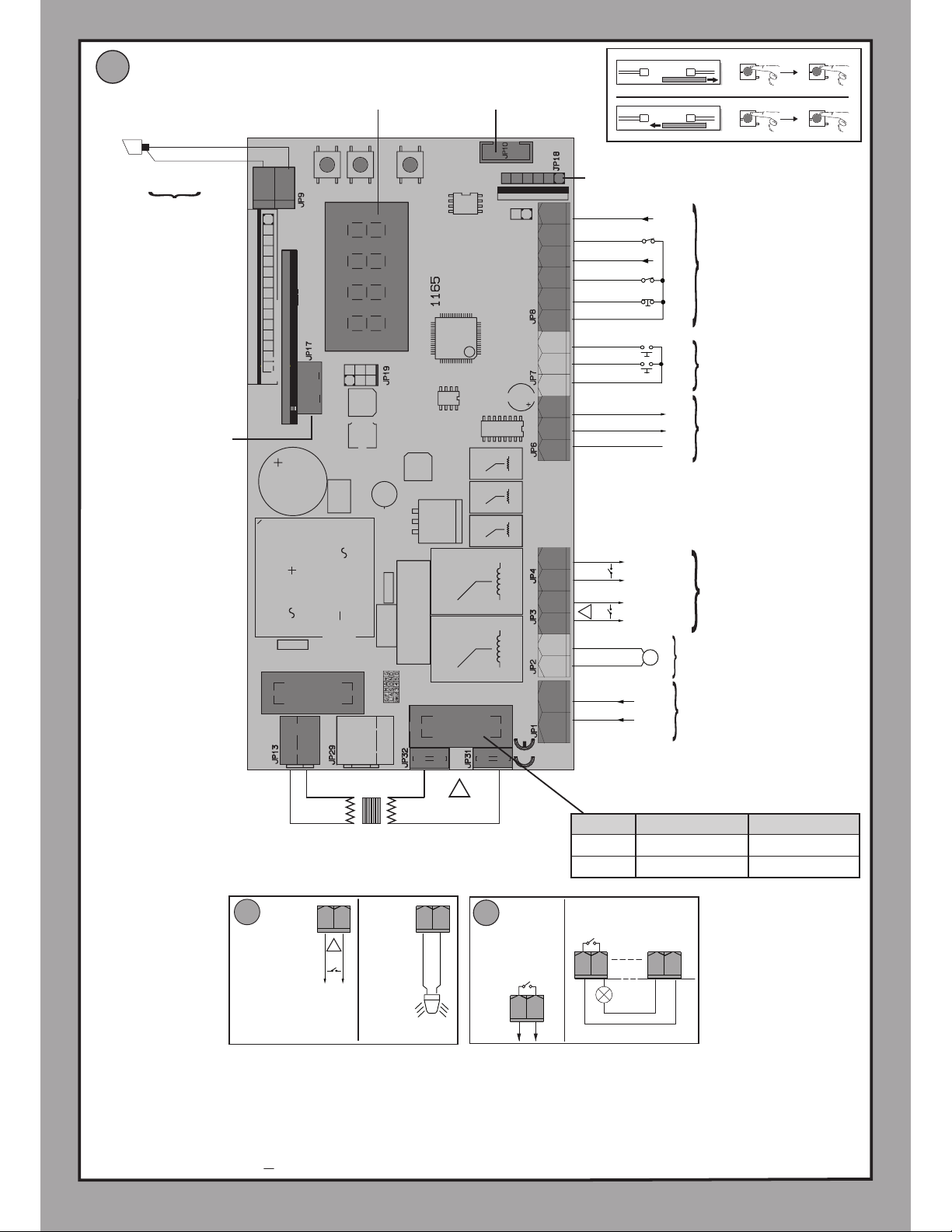

X1

X1 X1

X1

OPEN

CLOSE STOP

STOP

**Con logica inversione direzione di apertura = 000 (DIR=DX)

**With reverse logic, opening direction = 000 (DIR=right)

** Avec logique inversion direction d’ouverture = 000 (DIR=DRT)

**Mit Inversionslogik Ö nungsrichtung = 000 (DIR=rechts)

**Con lógica inversión dirección de apertura = 000 (DIR=DER)

**Met logica omkering openingsrichting = 000 (DIR=R)

**

ANT.

ANT

SHIELD

F1

DEIMOS ULTRA BT A 400 DEIMOS ULTRA BT A 600

110-120V 1,6AT 1,6AT

220-230V 0,8AT 1AT

Antenna

Antenne

Antena

Antenne

4 - DEIMOS ULTRA BT A 400 - DEIMOS ULTRA BT A 600

D811980 00100_13