Bianchi 1885 User manual

Assembly Manual

Road Bike

Assembly Manual Road Bike

2

Assembly Manual

Road Bike

I. Unpacking the box 4

II. Getting the front wheel ready 4

III. Fitting the front wheel 5

IV. Fixing the front wheel into the fork 7

V. Adjusting the handlebars 7

VI. Fitting the saddle 8

VII. Fitting the pedals 8

VIII. Test run 9

IX. Bike maintenance guidelines 10

Assembly Manual Road Bike

3

Dear Customer,

Congratulations on the purchase of your new bike.

With the aid of this Assembly Manual you will be able to

complete the assembly of your road bike / cyclo cross bike in

your home in a couple of steps. All of the necessary assembly

work and pre-adjustments to the gears and brakes have already

been done by our bike tters.

You only need to straighten the handlebars, t the front

wheel and t the saddle and pedals. All of the tools

needed to t these components can be found in the

accessories box enclosed.

Important: It is essential that you also read the manufacturers’

own operating manuals to fully understand all of the technical

features of your bike.

Assembly Manual Road Bike

4

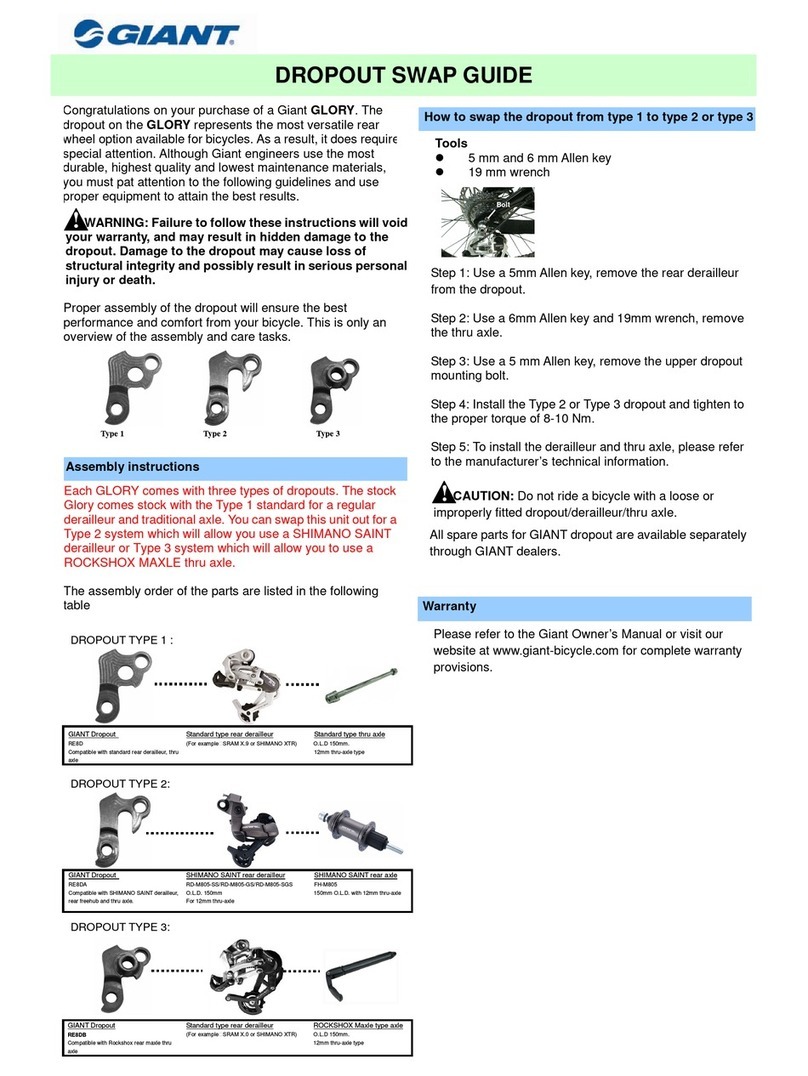

I. Unpacking the box

Open up the special shipping box and remove the rectangular

protective cardboard on the rear wheel.

Take the wheel out of the box, followed by the saddle and

then the bike frame, which has the rear wheel already tted.

Remove the accessories box (Fig. 1)

Fig. 1

II. Getting the front wheel ready

Remove the two plastic protective covers on the hub of the

wheel

Open up the package of accessories and take out the quick

release skewer

Fig. 2 Quick release skewer

A

B

C

D

Loosen the acorn nut (B) on the quick release skewer and

remove the springs (C)

Insert the quick release skewer with the spring (D) into the

hub axle (Fig. 3 and 4)

Fig. 3 Fig. 4

From the other side replace the second spring (C) onto the

skewer and gently tighten the acorn nut (B)

Assembly Manual Road Bike

5

III. Fitting the front wheel

Once the front wheel is ready to be tted into the fork, proceed

as follows (depending on the type of brakes):

Important: Get a second person to help you when tting the

front wheel or alternatively use a bike stand.

Remove the plastic protection from the fork dropouts (Fig. 5)

Fig. 5 Remove protection from the fork

a.) Wheel with calliper brakes

Lift the mountain bike by its stem with one hand

Open up the adjustment lever so that it is pointing upwards

(Fig. 6)

Fit the front wheel in the direction it is to rotate

Fig. 6 Fig. 7

Close the quick release skewer on the hub of the front wheel -

more details about this under Point IV

Close the adjustment lever on the calliper brakes once the

wheel has been tted, so that it points downwards (Fig. 7)

Important: Make sure, when tting the front wheel, that the

fork dropouts are sitting completely on the axle!

Attention: Check that the front wheel is rotating freely. The

wheel has not been tted properly if the wheel is not running

straight or if the brake is clearly rubbing!

Assembly Manual Road Bike

6

b.) Wheel with cantilever brakes

Lift the cyclo cross bike by its stem with one hand

Fit the front wheel in the direction it is to rotate

Close the quick release skewer on the hub of the front wheel -

more details about this under Point IV

Important: Make sure, when tting the front wheel, that the

fork dropouts are sitting completely on the axle!

Now t the cantilever brake by pressing together both calliper

arms with one hand so that the faces of the brake pads sit at

against the rim of the wheel (Fig 8)

Using the other hand, pull the cable towards the right-hand

brake arm so that the cable tting can be connected to the brake

arm (Fig. 9)

Fig. 8 Fig. 9

Attention: Check that the front wheel is rotating freely. The

wheel has not been tted properly if the wheel is not running

straight or if the brake is clearly rubbing!

Assembly Manual Road Bike

7

IV. Fixing the front wheel into the fork

Close the quick release skewer by rotating the lever by 180°

(Fig. 10 and 11)

Fig. 10 Fig. 11

Attention: If the quick release skewer is correctly closed, the

word “Close” should be legible on the outside of the lever!

Attention: When tightening the quick release lever (A) it should

meet resistance at about the halfway point. Otherwise you will

have to increase the tension using the acorn nut (B) on the

opposite side of the hub! (c.f. page 2, Fig. 2)

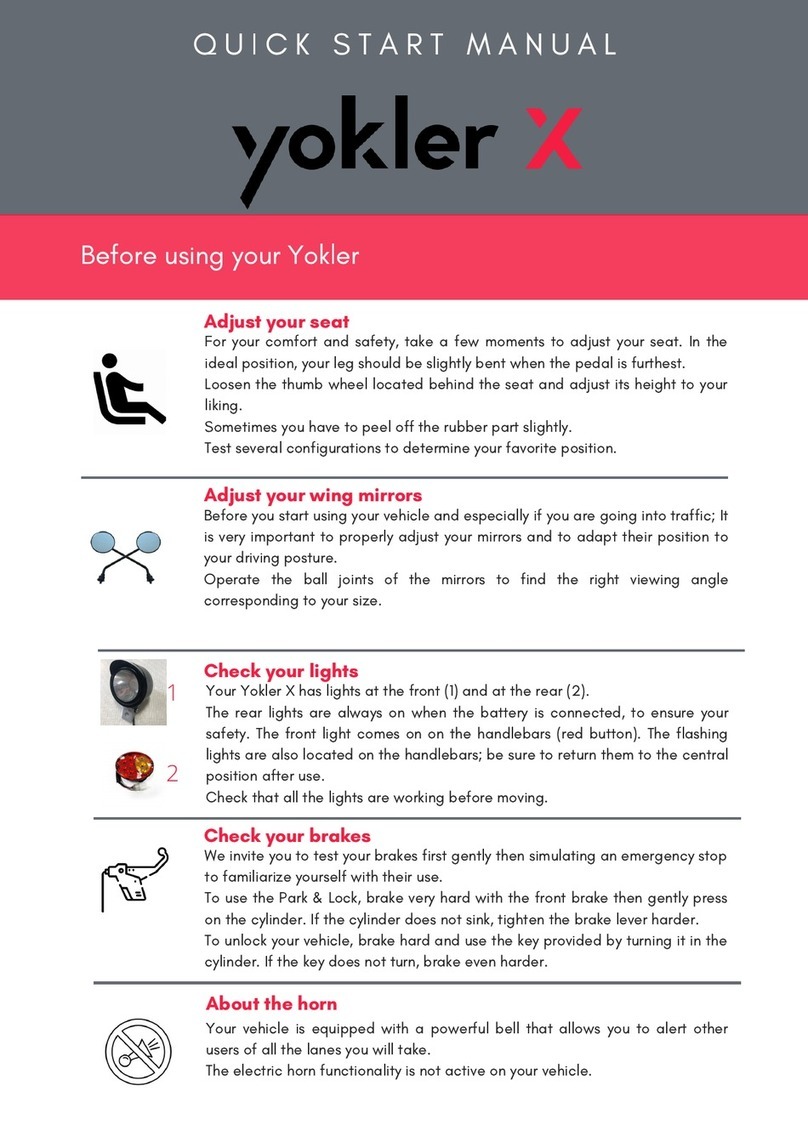

V. Adjusting the handlebars

Use the multifunctional tool supplied.

Select the correct Allen key to loosen the stem locking screws

on the handlebars (Fig. 12)

Once you have adjusted the handlebars to suit your position,

tighten the locking screws on the front cross-wise.

Make the necessary adjustments to your handlebars. Make

sure that the handlebars are centrally aligned in the stem clamp

(Fig. 13)

Fig. 12 Fig. 13

Attention: Make sure that there is an even tightening torque on

all of the stem locking screws. The clearance of the stem clamp

has to be identical, otherwise there is a risk of a serious material

defect on the handlebars!

Assembly Manual Road Bike

8

VI. Fitting the saddle

Use the multifunctional tool supplied.

Insert the seat pin into the seat tube and adjust the height of

the saddle (g. 14)

Fig. 14 Fig. 15

Attention: Ensure when adjusting the height of the saddle that

the seat pin is not pulled out further than the maximum height!

Failure to comply with this can result in serious material defects

or accidents! (Fig. 15)

VII. Fitting the pedals

Take out both pedals from the box of accessories, should they

have been ordered.

Identify the right-hand pedal and screw it in a

clockwise direction to the right-hand crank (Fig. 16)

Screw on the left-hand pedal in the same way in an

anti-clockwise direction to the left-hand crank

Tighten both pedals with a 15 mm spanner and, after a few

miles, check once again that they are still tightly tted (Fig. 17)

Fig. 16 Fitting the right-hand pedal

to the right-hand crank

Fig. 17 Tighten the right-hand

pedal in a clockwise direction

Important: The right-hand crank is always on the side of the

chainset.

Attention: Failure to note the markings on the pedals or tting

the pedals with force will inevitably damage the threads!

Assembly Manual Road Bike

9

VIII. Test run

Your new road bike is now ready to ride and you should take it

out for a test run straight away. (Fig. 18)

Fig. 18

Important: Before heading out, check once again that all of the

screws and quick release ttings are tight on your bike.

Important: In your own interest, we would recommend that

you have your bike inspected after approx. 100 km. Bikes cannot

always be correctly adjusted without a certain period of runnin-

gin. Mechanical components, like brakes, gears and bearings

have to be checked and readjusted after a certain time.

An initial inspection by qualied technicians will guarantee that

your bike has a long life so that you can enjoy unlimited cycling

enjoyment.

Important: Keep a note of your frame number! The frame

number is generally located on the bottom bracket – the position

may vary with different manufacturers (seat pin, head tube). It

is easiest to note down your frame number on the invoice for

your bike.

Attention: Road bikes, which do not have lights, do not comply

with the requirements of § 67 of the German Road Trafc

Licensing Regulations (StVZO). Please be aware that these

sports bikes are not permitted to travel on public roads.

Attention: It is essential that you also read the manufacturers’

operating manuals to fully understand all the information and

technical features of your new bike.

Assembly Manual Road Bike

10

IX. Bike maintenance guidelines

Attention: The rst inspection should take place after around

100km i.e. 6 weeks. Screws are to be tightened and cables

should be adjusted accordingly.

Important: Inspections should be carried out regularly (after

100km i.e. 6 weeks, after 500km i.e. 6 months, after 1000km

i.e. 1 year, after 2000km i.e. 2 years, and then once a year).

Have fun with your new bike!

Assembly Manual Road Bike

11

Space for notes:

Table of contents

Other Bianchi Bicycle manuals