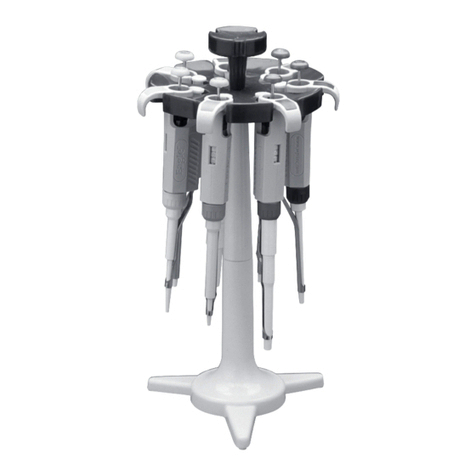

MPS-4

World Precision Instruments i

Copyright © 2020 by World Precision Instruments. All rights reserved. No part of this publication may

be reproduced or translated into any language, in any form, without prior written permission of World

Precision Instruments, Inc.

CONTENTS

ABOUT THIS MANUAL ................................................................................................................... 1

INTRODUCTION .............................................................................................................................. 1

Notes and Warnings................................................................................................................. 2

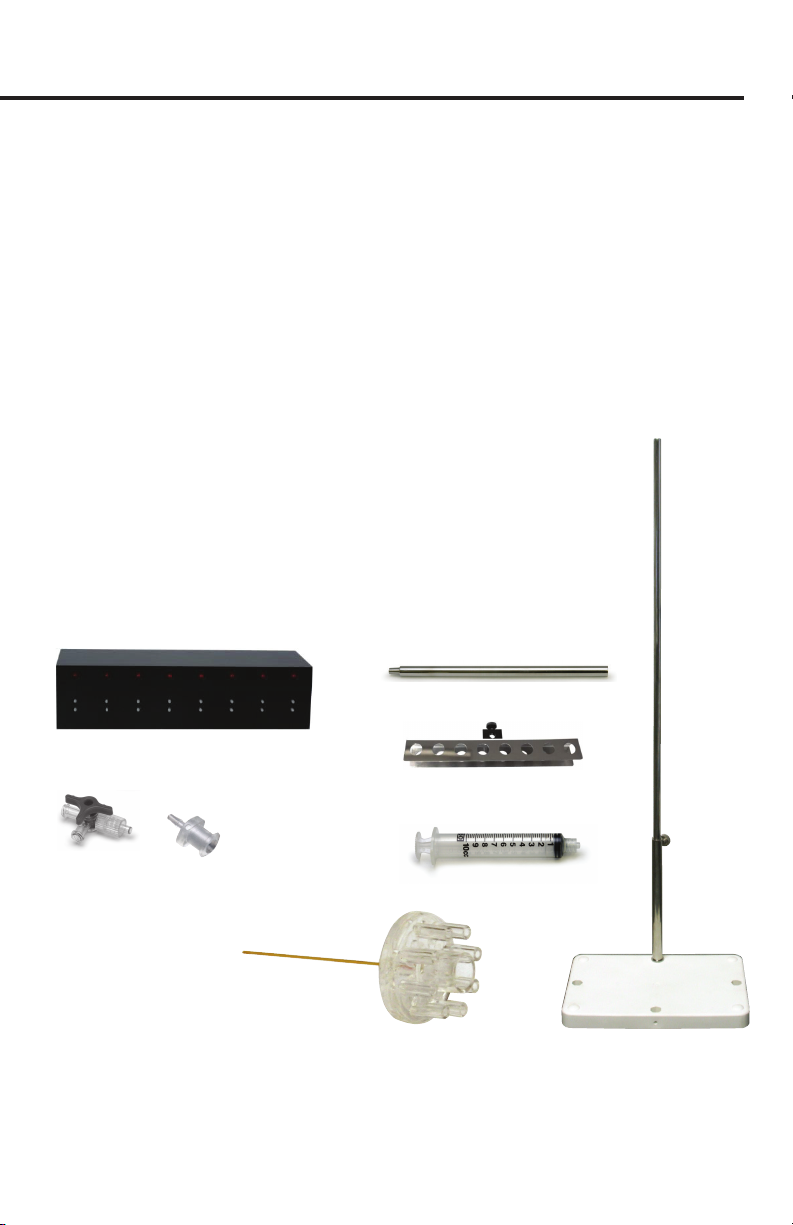

Parts List...................................................................................................................................... 3

Unpacking................................................................................................................................... 4

INSTRUMENT DESCRIPTION ........................................................................................................ 4

Hardware Installation............................................................................................................... 4

OPERATING INSTRUCTIONS......................................................................................................... 5

Software Installation................................................................................................................. 6

Installation............................................................................................................................. 6

Startup ................................................................................................................................... 6

Creating a New Perfusion Experiment ................................................................................ 6

Set the Experiment Time......................................................................................................... 7

Preset Each Channel’s Perfusion Time ................................................................................ 7

Saving Your Experimental Parameters................................................................................ 9

Mode Selection .................................................................................................................... 9

Computer Perfusion Control Modes............................................................................10

Run Perfusion.....................................................................................................................10

Hardware Testing Procedure...............................................................................................11

Testing Drug Delivery.............................................................................................................12

MAINTENANCE ..............................................................................................................................13

Cleaning.....................................................................................................................................13

TROUBLESHOOTING ...................................................................................................................13

APPENDIX A: DETERMINING FLOW RATE................................................................................14

Theoretical Calculation ..........................................................................................................14

APPENDIX B: DISABLE DRIVER SIGNATURE ENFORCEMENT (WIN10) .............................15

APPENDIX C: HOW TO INSTALL AN UNSIGNED DRIVER ON WINDOWS 8 ..................... 19

APPENDIX D: INSTALL THE MPS-4 SOFTWARE ON WINDOWS 10....................................22

WARRANTY .....................................................................................................................................31

Claims and Returns ................................................................................................................31

Repairs.......................................................................................................................................31