1. The name and model of the product

Table-type low speed centrifuge, model BKC-TL4II.

2. Features and applications

Table-type low speed centrifuge, model BKC-TL4II.(This machine below is short for this centrifuge

machine.),The series centrifuge is widely applied in biology, chemistry, medicine, agriculture and

forest science, food safety, blood station and clinical test.

This machine features good rigidity, high strength and corrosion proofing, owing to its high material

of steel and its surface with spurt models processing. Meanwhile, this machine possesses the

advantages of succinct structure, small volume, low noise, smooth temperature rise, high efficiency,

safe and reliable, and it is fit for the experimental analysis with fewer samples and more separation

steps.

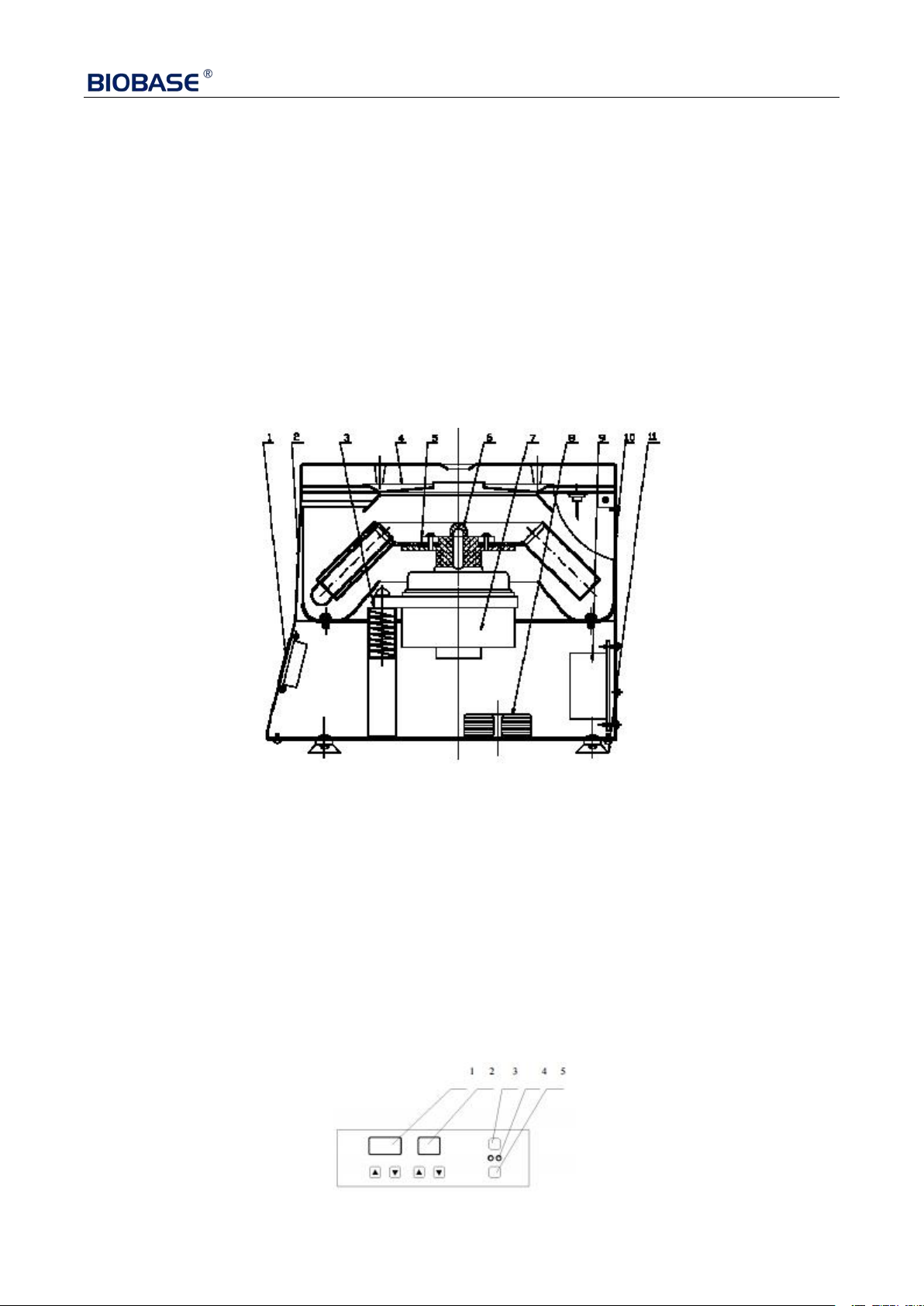

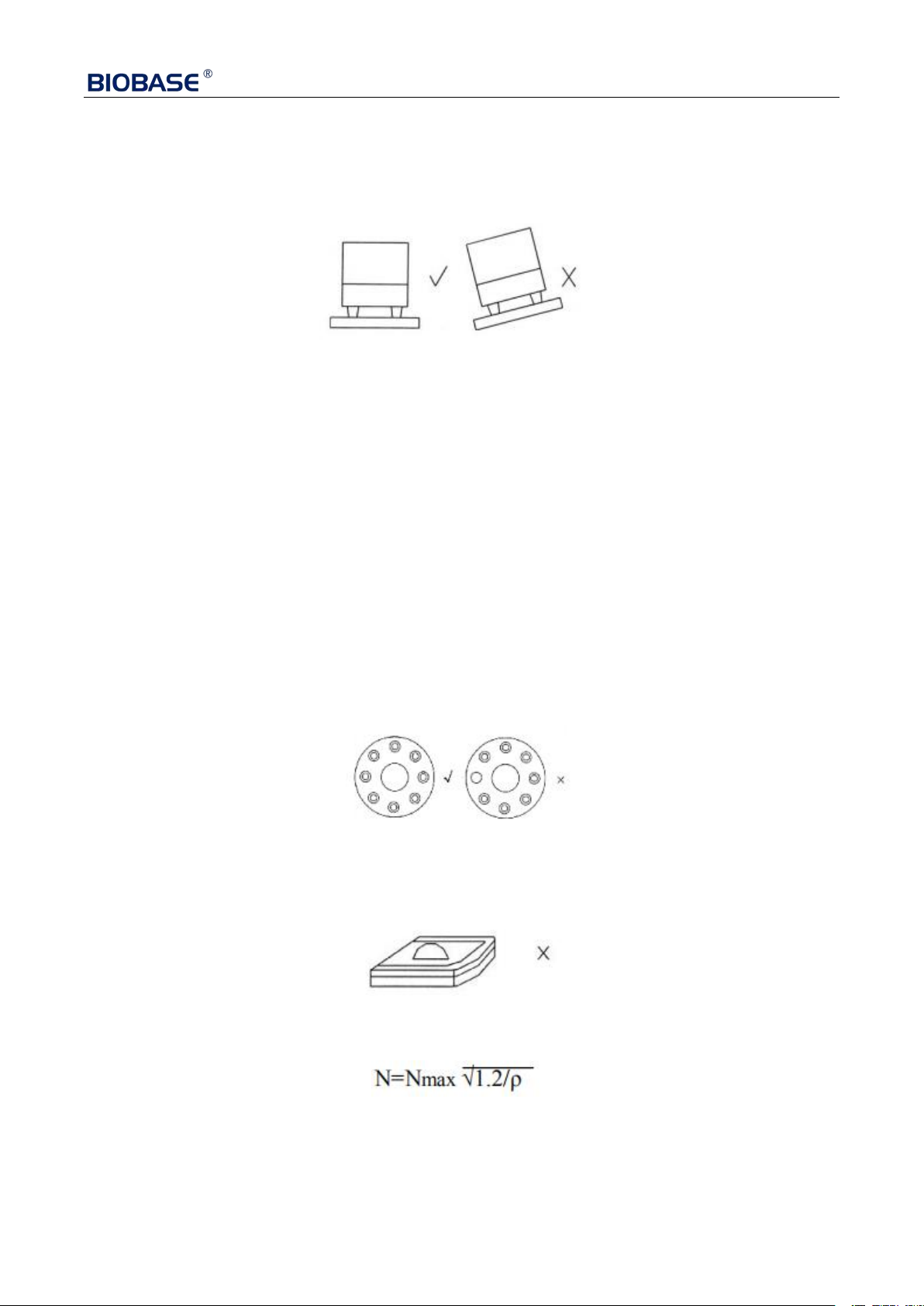

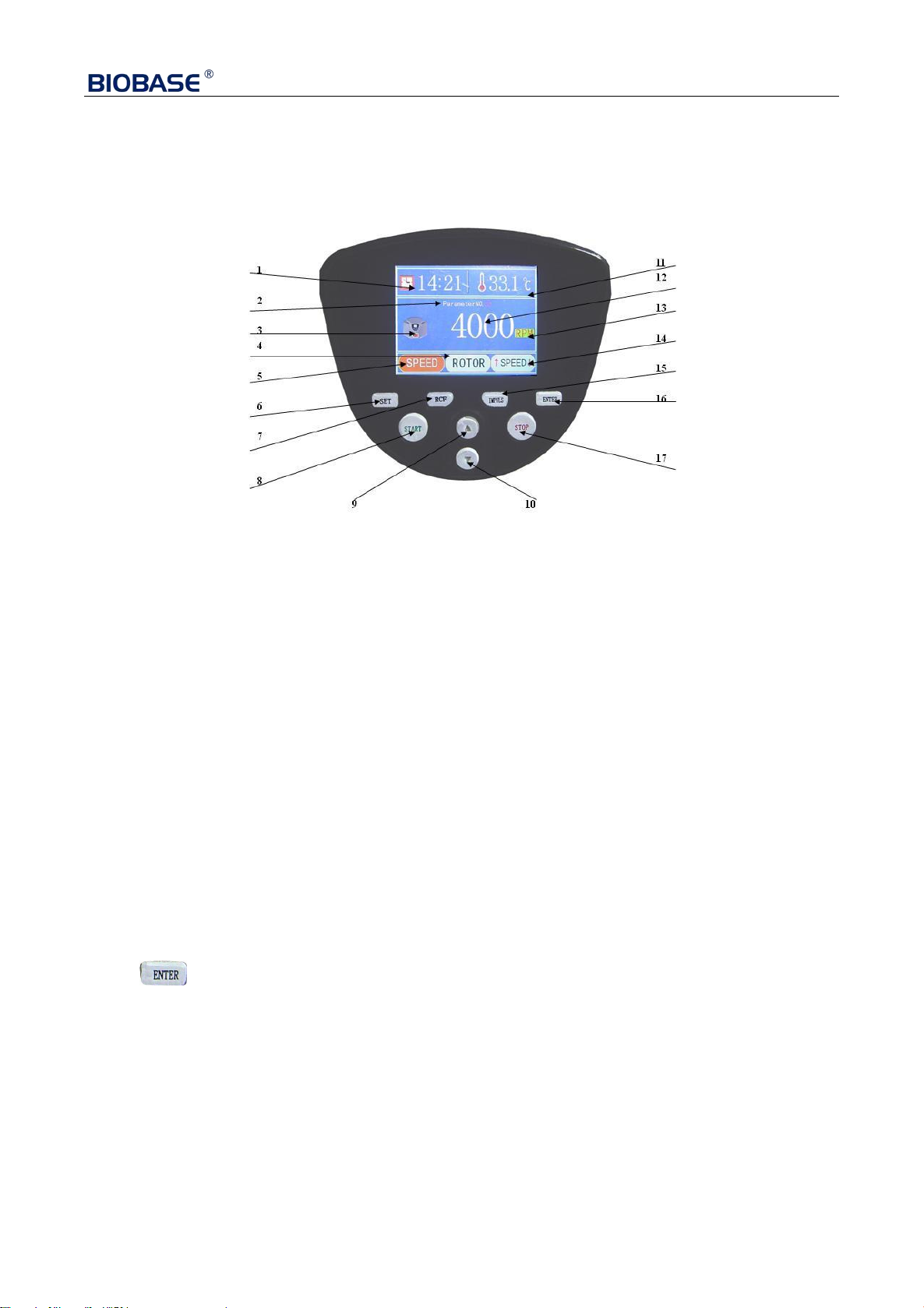

This machine adopts the advanced technologies like microcomputer control, direct drive brushless

DC motor, TFT Zhencai touch panel, mute mechatronics electronic lock and so on.

The features of this machine are as followed:

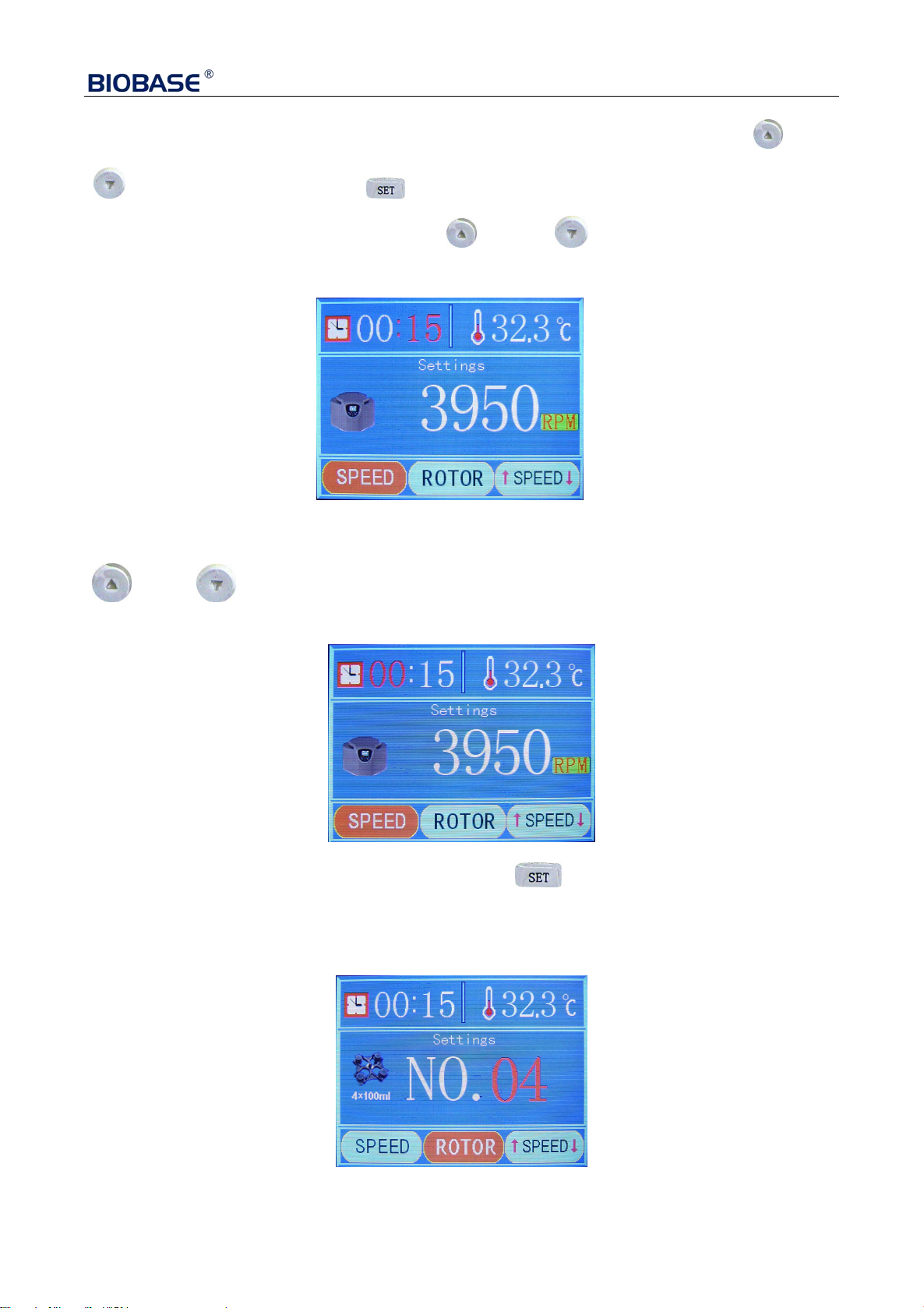

Step 1: Set up the rotor mode, the rotating speed and the needed time.

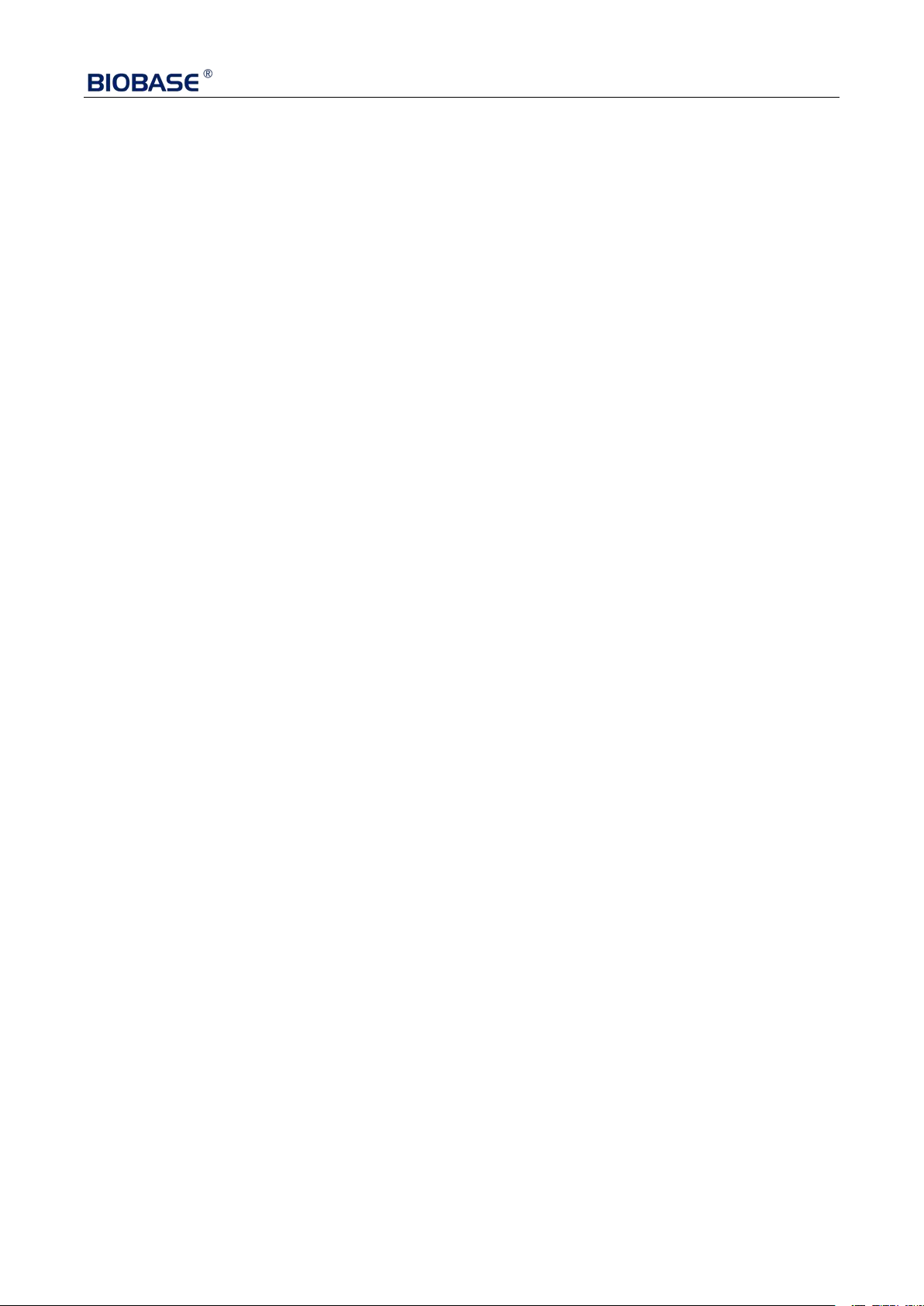

The vibration-absorption effect of this machine works very well by the application of its special

damper. This machine also has a self-balance function.

Step 2: Set up the rotor mode, the rotating speed and the needed time.

The special PWM-controlled speed control system assures its high control accuracy and its fast

acceleration and deceleration function, which provides different acceleration and deceleration time

to be freely chosen. To meet the requirement of labs, the brushless DC motor also assures the

operation of the machine in a quiet working state. The carbon brush doesn’t need to be replaced, so

there are no carbon pollutions.

Step 3: Set up the rotor mode, the rotating speed and the needed time.

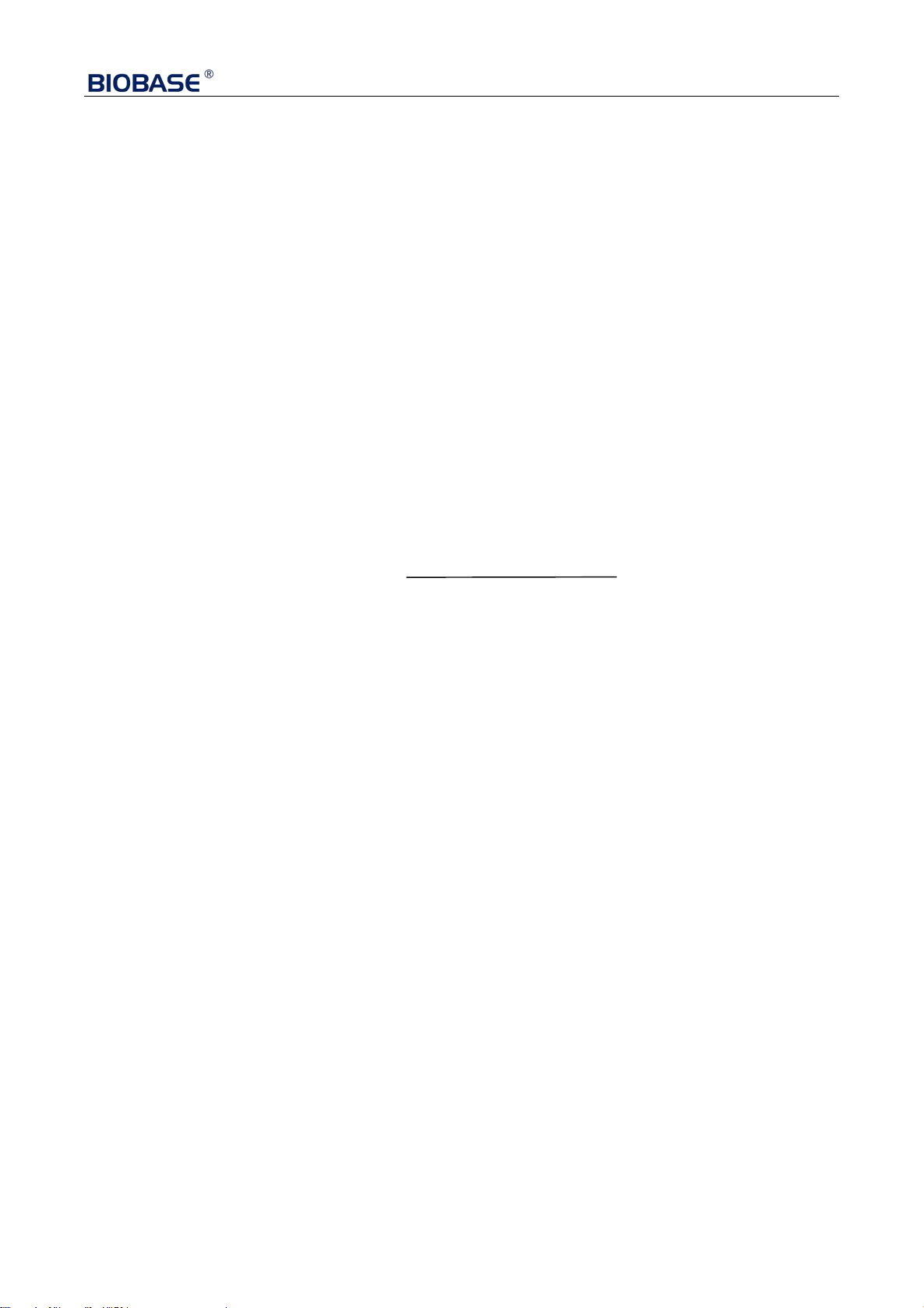

This machine has a parameter-saving function, and it can calculate the RCF value automatically.

Step 4: Set up the rotor mode, the rotating speed and the needed time.

There are many rotors with different levels. The tube frame can be replaced, and there are many

tubes, convenient to choose.

Step 5: Set up the rotor mode, the rotating speed and the needed time.

This machine has a protective function owing to its electronic lock. When its faceplate is uncovered,

the centrifuge machine cannot be operated.

This machine can be safely operated in the environment with the temperature within 5 to 40

centigrade, under RH<80%, and without conducting dust, explosive gas and corrosive gas.