Bioer GeneQ Thermal Cycler User manual

Note: The Bioer Co. reserves the right to modify this manual at any time without

notice.

Patent materials are included in this manual. All rights reserved. No part of this manual shall be

photocopied, reproduced, or translated into other languages, without written permission from the

Bioer Co.

Patent No.:ZL 98 2 44367.6

Standard No.:YZB/ 0189 - 2008

Document Number: BYQ60410000000ESM

Document Version: FebruaryAprilJan,2009 20114 Version 2.01.68

Please read this manual carefully before the Thermal Cycler is first

operated !

Gene Q Thermal Cycler Important Note

―I―

Important Note

1 CONVENTIONS

Note:

Because of the important information in this column, please read it carefully.

Failure to follow the advice in this column will possibly result in damage or

malfunctioning of the Thermal Cycler.

Warning!

This symbol means that you should be cautious to take an

operation/procedure. Failure to follow the requirements in this column will

possibly result in personal injury.

2 SAFETY

During the operation, maintenance, or repair of the Thermal Cycler, the following safety measures

should be taken. Otherwise, the guard provided by the Thermal Cycler is likely to be damaged, the

rated safety level to be reduced, and the rated operation conditions to be affected.

The Bioer Co. shall not be in any way responsible for the consequences resulted from buyer’s not

observing the following requirements.

Note:

The Thermal Cycler, complying with the National Standard EN61010-2-010 :

2003 & EN61326-1 : 2006, is a general instrument of classⅠ, the protection

degree is IP20. It is intended for indoor use.

a) Grounding Considerations

A.C. power’s grounding should be reliable for fear of an electric shock. The 3-pin plug with the

Thermal Cycler’s power line is a safety device that should be matched with a grounded socket.

Never let the third ground pin floating. If the 3-pin plug cannot be inserted, it is recommended to ask

an electrician to install an appropriate power socket.

b) Keep Away from Electric Circuits

The operator is not allowed to open the Thermal Cycler. Changing components or adjusting certain

parameters inside the device must only be accomplished by the certificated professional

maintenance personnel. Do not change elements while the power is still on.

c) A.C. Power Considerations

Before turn on the power, always check if the mains voltage is within the required ~220-240V(or

~100-120V) and if the current rating of the power socket meet the required specification, i.e. 200W.

d) A.C. Power Line Considerations

As an accessory of the Thermal Cycler, the A.C. power line should be a default one. If it is damaged,

the A.C. power line may not be repaired, but it must be replaced with a new one. The power line

should be free of heavy objects during the Thermal Cycler’s operation. Keep the power line away

from the place where people gather regularly.

e) Connect the A.C. Power Line

While connect or disconnect the power line, you should hold the 3-pin plug with your hand. Insert

the plug thoroughly to ensure good contact between the plug and socket. Pull the plug, not the line,

when you need to disconnect to the mains.

Gene Q Thermal Cycler Important Note

―II―

f) Design Environments

The Thermal Cycler should be placed in a low-humidity, dust-free, and good-ventilation room

without caustic gas or powerful magnetic interference. In addition, water sources, such as pools

and water pipes, should be separated a distance from the Thermal Cycler.

Never cover or obstruct the openings of the Thermal Cycler, which are designed for ventilation and

to prevent the device’s interior from being too hot. When a single device is running, the shortest

distance between its openings and the nearest object is 50cm; otherwise, when two devices or

above are running at the same time, the shortest distance is 100 cm. Do not place the device on a

soft surface, because that will result in adverse ventilation near the device’s bottom openings.

Too high temperature will lead to degraded performance or failure of the Thermal Cycler. Therefore,

the device should be protected against any kind of heat sources like sunlight, ovens, or central

heating equipment.

If the Thermal Cycler is set aside for a long time, it is recommended to disconnect the power line to

mains and cover the device with a piece of soft cloth or plastic to prevent dust from entering.

Note:

Once one of the following events occurs, you are suggested to disconnect the

power line with mains, and contact the distributor or ask a certificated

maintenance worker for help.

Liquid into the device;

The device sprinkled or drenched;

The device malfunctioning, giving off abnormal sound or odor;

The device falling onto the floor or its shell damaged;

Significant changes in the device’s performance.

3 EMC Consideration

Note:

This is a class A equipment, only suitable for use in establishments other than

domestic, and those directly connected to a low voltage power supply network

which supplies buildings used for domestic purpose.

4 Protection Degree: IP 20

5 LABELS

a) Tablet

BIOER TECHNOLOGY CO., LTD.

Name: Thermal Cycler Model:TC-**/H(b)

Power:~220-240V 200W 50/60Hz

Fuse: 250V 2.5A(Φ5×20) Sort: classⅠIP20

SN: BYQ*****-*** Date: ****.**

Gene Q Thermal Cycler Important Note

―III―

HANGZHOU BIOER TECHNOLOGY CO., LTD.

Name: GeneQ Thermal Cycler

Model:TC-**/H(b)

Power: 100-120V~50/60Hz 200W

Fuse: 125V 5A(Φ5×20) Sort: classⅠIP20

SN: BYQ*****-***

Date: ****.** Made in China

b) Warning Sign

Warning!

There are two warning signs read ‘HOT SURFACE !’. The metal part near those

signs (on the block and hotlid) is not allowed to be touched by any part of the

body for fear of the body burn, during the program execution and in the short

period after the program execution!

6 MAINTENANCE

The conical holes over the block should be cleaned regularly with soaked cotton swab. That

ensures sufficient contact and thus good heat conduction between each conical hole and the tube

inside it.

In case it is smeared, the surface of the Thermal Cycler may be scrubbed with a piece of

dehydrated soft wet cloth.

7 WARRANTY AND SERVICE INFORMATION

a) Warranty

The Thermal Cycler is warranted for a period of one month, from date of shipment from the

company, to be free from defects in material and workmanship. The Bioer Co. shall be obligated,

under this warranty, to exchange the Thermal Cycler which proves to be defective as described

herein.

The Thermal Cycler is also warranted for a period of eighteen months, from date of shipment from

the company, to be free from defects in material and workmanship. The Bioer Co.’s obligation under

this warranty shall be limited to repair or exchange (at the Bioer Co.’s option) of the Thermal Cycler

Warning! During surface cleaning, the power must be off.

Corrosive scour is not allowed to clean the surface.

Gene Q Thermal Cycler Important Note

―IV―

which proves to be defective as described herein.

The buyer is responsible for freight to the maintenance shop designated by the Bioer Co. on all

warranty claims. The buyer is also responsible for the transportation expenses of the freight to the

maintenance shop. The Bioer Co. shall be responsible for the transportation expenses of the freight

to the buyer (which is only applicable to domestic buyers).

After the warranty comes due, the Bioer Co. reserves the right to charge cost price for maintenance

of a defective device.

b) Warranty Terms

The above warranty is not applicable to defective devices with incorrect use, abnormal operating

conditions, improper application, and unauthorized maintenance or alteration.

The Bioer Co. makes no express warranties other than those which are described herein.Any

descriptions in sales promotion under specific conditions shall not create an express warranty that

the goods shall conform to such description.

c) After-sell services hotline:0086-571-87774558

Note:

Once it is opened, the package should check according to the checklist. If the

buyer finds any items to be missing or damaged, do not hesitate to contact the

distributor.

After the acceptance check is passed, the buyer should fill out the check form

and send its photocopy (or fax it) to the distributor. The Bioer Co. establishes the

archives and maintenance record with the returned form.

Please store the package and packing materials in a safe place in case of future

device maintenance. The above warranty does not extend to goods damaged

as result of cheesy package.

Gene Q Thermal Cycler Contents

CONTENTS

CHAPTER 1 INTRODUCTION.................................................................................................................... 1

1 PCR Technique......................................................................................................................................1

2 PCR Applications...................................................................................................................................1

3 PCR Thermal Cyclers...........................................................................................................................2

4 Common PCR Thermal Cyclers......................................................................................................... 2

5 Features of the Gene Q Thermal Cycler........................................................................................... 3

CHAPTER 2 SPECIFICATIONS................................................................................................................4

1 Normal Operating Conditions..............................................................................................................4

2 Transportation and Storage Conditions.............................................................................................4

3 Basic Parameters..................................................................................................................................4

4 Performance...........................................................................................................................................5

5 Software Functions............................................................................................................................... 5

CHAPTER 3 PREPARATIONS.................................................................................................................... 6

1 Instructure Description......................................................................................................................... 6

2 Keyboard Diagram................................................................................................................................ 7

3 Key Functions........................................................................................................................................ 7

4 Inspection before Power-on................................................................................................................ 8

5 Power-on Procedures...........................................................................................................................8

CHAPTER 4 OPERATION GUIDE..............................................................................................................9

1 How to Run a PCR Program............................................................................................................... 9

2 How to edit a PCR program.............................................................................................................. 10

3 How to Set System Parameters....................................................................................................... 14

CHAPTER 5 UPGRADE OF SOFTWARE................................................................................................. 16

1 To Install Upgrading Software...........................................................................................................16

2 To Modify, Repair or Remove the Upgraded Software................................................................. 18

3 Preparation before Upgrading.......................................................................................................... 19

4 How to Upgrade the Software...........................................................................................................19

CHAPTER 6 FAILURE ANALYSIS AND PROCESSING...................................................................... 21

1 Failure Analysis and Processing Procedures................................................................................ 21

2 Blocks Error Message........................................................................................................................ 22

APPENDIX 1 Connection Diagram (1/2)..............................................................................................23

APPENDIX 2 Parameter Value & Meaning......................................................................................... 25

Gene Q Thermal Cycler Chapter 1 Introduction

—1—

CHAPTER 1 INTRODUCTION

This chapter briefly introduces PCR technique and its applications, PCR thermal cyclers, and the

characteristics of our Gene Q Thermal Cycler.

1 PCR Technique

PCR (Polymerase Chain Reaction), or cell-free molecule cloning, is a technique for amplifying

nucleic acids in vitro, emulating natural DNA replication process. The PCR technique, using two

DNA strands to be amplified as template, and a pair of synthetic oligonucleotides as primers, rapidly

reproduces the specific DNA pieces under the catalysis of a thermostable DNA polymerase.

Because of its simplicity, rapidity, specificity, and sensitivity, PCR has been widely applied to all

fields of life sciences since its invention by Mullis in 1983 and the discovery of the thermostable

DNA polymerase by Erlich in 1989. Great achievements have been obtained in PCR’s applications

in such areas as cytology, virology, oncology, genetics, forensics, and immunology. PCR technology

is a milestone in the history of modern molecular biology.

2 PCR Applications

Research Areas

Gene cloning, DNA sequencing, mutation analysis, gene recombination

and mutagenesis, identification and adjustment of DNA sequence of

protein structure, detection of gene extension, construction of synthetic

genes, construction of cloning and expression carrier, detection of

polymorphism of a gene’s inscribed enzyme;

Clinical Diagnoses

Bacteria(spirochaeta, rickettsia, diphtheria bacillus, colon bacillus,

dysentery bacillus, and clostridium); Virus(HTLV, HIV, HBV, HCV, HPVS,

EV, CMV, EBV, HSV, measles virus, rotiform virus, B19 virus, and Lhasa

virus); Parasite(malaria); Human hereditary diseases(Lesh-Nyhan

syndrome, hemophilia,BMD, and DMD);

Immunology

HLA locus typing, qualitative analysis of T-cell receptor or antibody

diversification, immune body gene mapping, quantitative analysis of lymph

genes;

Human Genome

Project

Identification of DNA markers using discrete repetitive ;

Sequence, construction of a genetic linkage map(detection of DNA,

polymorphism, or semen mapping ); Construction of a physical map,

sequencing, and map expression;

Forensics Specimen analysis in the venue, and HLA-Dqαlocus typing;

Oncology

Pancreas cancer, rectum cancer, lung cancer, thyroid gland cancer,

melanin cancer, and leukemia;

Social and Colony

Biology

Genetic species research, evolution research, animal protection research,

ecology, environmental sciences, and experimental genetics;

Paleontology Specimen analysis in archeology and museum;

Biology Diagnosis of animal hereditary diseases and detection of plant pathogeny.

Gene Q Thermal Cycler Chapter 1 Introduction

—2—

3 PCR Thermal Cyclers

A PCR thermal cycler is a key device throughout the PCR experiment. Its performance determines

the accuracy of the experimental results. Its parameters, such as temperature keeping and

temperature ramp rate, play an extremely important role in DNA denaturation, annealing and

extension.

Chief Specifications of a PCR Thermal Cycler:

Temperature display

accuracy

The bias between display temperature and practical temperature,

directly affects the quality of DNA annealing, elongation, and

denaturation, and should be reduced to an accepted level;

Heating/Cooling Rate

Higher cooling/heating rate can greatly decrease the experimental time

and maintain the enzyme’s activity;

Temperature

Uniformity

Excellent temperature uniformity guarantees consistent amplification

conditions for the same batch of reaction samples and then avoids

false positive or negative of the results caused by mismatched

operating conditions;

Temperature Control

Accuracy

Higher temperature control accuracy ensures temperature stability

during the PCR amplification reaction, and therefore increase the

reliability of the experimental results;

Intelligent Degree

More intelligent thermal cycler means less labor intensity for test

personnel and ensures the whole PCR reaction to be accomplished

successfully.

4 Common PCR Thermal Cyclers

a) Gradient Water Bath Thermal Cyclers

A gradient water bath thermal cycler consists of three water baths operating at different

temperatures. An automatic mechanical manipulator soaks the sample tube containing reactants in

the three water baths cyclically, and thus finishes the three processes of denaturation, annealing

and extension.

This device has high temperature control accuracy, high heating/cooling rate, and excellent

temperature uniformity. However, its intelligent level is very low, and it cannot accomplish some

relatively complex PCR processes. There are other disadvantages associated with this type of

thermal cycler, such as liquid evaporation in the bath, lack of the soak mode, inability of long-term

operation without human interference, temperature fluctuation caused when the sample tube is put

into the bath during heating/cooling process, and last but not least, the pollution issue. As a result,

this kind of thermal cycler has gradually been abandoned in the market.

b) Compressor Cooling Thermal Cyclers

At the center of a compressor cooling thermal cycler is located a block made of good conduction

material (aluminum or silver), over which several conical holes are distributed. Each of the conical

holes has the same shape as a standard microcentrifugal tube to ensure good contact between the

two. The resistance heater on the block’s outside bottom is responsible for block heating, whereas

the compressor takes charge of block cooling. Controlling the heater and compressor with a

microcomputer completes the required heating, cooling, and temperature keeping processes.

This device has much higher intelligent level and smaller size compared to a gradient water bath

thermal cycler. Nevertheless, the compressor’s inertia not only limits the cooling rate (to about

1℃/sec), but also increases the temperature undershoot. Moreover, there exists temperature

gradient over the block near the inlet and outlet of the compressor’s evaporation pipe (lower

temperature near the inlet area and higher temperature near the outlet area).

Gene Q Thermal Cycler Chapter 1 Introduction

—3—

c) Thermoelectric Cooling Thermal Cyclers

These are the most advanced thermal cyclers by far. A thermoelectric cooling thermal cycler also

has a metal block at its center (like a compressor cooling thermal cycler). A thermoelectric module

closely attached to the block’s outside bottom accomplishes Block heating and cooling. Not only

does this device inherit such features as high intelligent level and small size from a compressor

cooling thermal cycler, but it also has higher temperature control accuracy and heating/cooling rate,

thanks to the module’s excellent temperature response characteristics. And the temperature

uniformity across the block is much better compared to a compressor cooling thermal cycler

because the modules are distributed over the block’s outside bottom.

During its early development, a thermoelectric module was not able to withstand rapid and frequent

heating or cooling for long. With improved workmanship, this difficulty has been overcome. Current

long service-life thermoelectric modules have the capability of enduring such harsh conditions in a

thermal cycler. As result, thermoelectric cooling thermal cyclers have gradually dominated the

market.

5Features of the Gene Q Thermal Cycler

The Gene Q Thermal Cycler is a thermoelectric cooling thermal cycler. It features:

a) Reliable and stable operation, because the thermoelectric module is manufactured via the

U.S. ITI’s thermoelectric cooling technique and the Japanese quality management model;

b) High heating/cooling (heating rate ≥5.0℃/sec., and cooling rate ≥4.0℃/sec.), which greatly

reduces experimental time;

c) Automatic temperature ramp control, which allows different heating/cooling ramp settings

so that the device can emulate other thermal cycler’s temperature control process;

d) Automatic temperature and time increments/decrements during cycling program

execution,

e) optimizing the PCR amplification conditions;

f) Automatic link among files, allowing a complex PCR amplification program to be executed;

g) The soak mode at a temperature up to 4℃without human interference, after normal

cycling program execution;

h) Instant inspection of total execution time and remaining execution time;

i) Optional heated lid, preventing the sample in a centrifugal tube from evaporation, which

makes paraffin oil unnecessary and operation more convenient, and reduces the sample

processing time;

j) Auto-restart in case of power failure, restoring the data before interrupting and continuing

to perform the previously interrupted program.

Gene Q Thermal Cycler Chapter 2 Specifications

—4—

CHAPTER 2 SPECIFICATIONS

This chapter describes the Thermal Cycler’s operation, transportation and storage conditions, basic

parameters, performance and functions.

1 Normal Operating Conditions

Ambient temperature: 10℃30℃

Relative humidity: ≤70%

Power supply: ~220-240V, 50/60Hz ,200W

100-120V~, 50/60Hz, 200W

Note:

Before power-on, please check if the above operating conditions are

satisfied. Pay special attention to the power line’s reliable grounding.

2 Transportation and Storage Conditions

Ambient temperature: -20℃~+55℃

Relative humidity: ≤80%

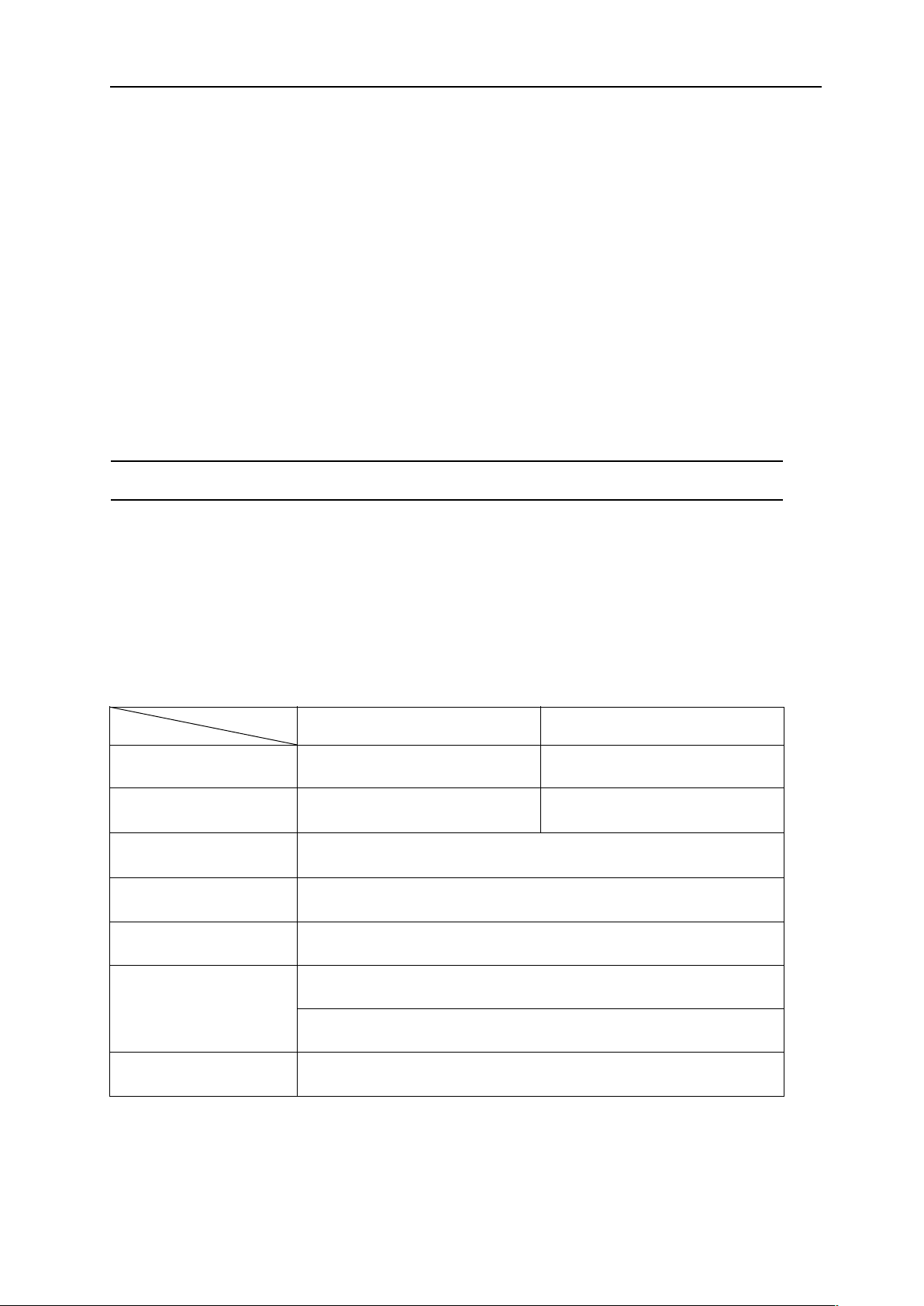

3 Basic Parameters

Model

Parameters TC-18/H(b) TC-24/H(b)

Sample Number 18 24

Tube Volume (ml) 0.5 0.2

Size (mm) 297×212×200(L×W×H)

Display Screen 320×240 LCD

Weight (kg) 3.2

Fuse

250V 2.5A (Ф5×20mm)

125V 5A (Ф5×20mm)

Computer Interface RS232

Gene Q Thermal Cycler Chapter 2 Specifications

—5—

4 Performance

Temperature range: 4℃~99℃

Heating rate: ≥5.0℃/sec(max)

Cooling rate: ≥4.0℃/sec(max)

Temperature control accuracy: ≤±0.3℃

Temperature uncertainty: ≤±0.2℃

Temperature display accuracy: ≤±0.5℃

Block temperature uniformity: ≤±0.5℃

Hotlid work temperature range: 105℃±5℃

Note:①Testing conditions for performance above:

Ambient temperature:23±5

℃

,humidity≤70%

②Testing temperature for temperature control accuracy and block temperature uniformity:55

℃,

72

℃,

95

℃

Max. number of cycles: 99

Max. procedures within a cycle: 9

Max. temperature keeping time: 599 min. 59 sec.

Max. incubation and in situ time: 99 hour 59 min.

Programs storage: 100

5 Software Functions

File editing and saving

File accessing, modifying and deleting

Automatic file link

Heating/cooling ramp setting

Automatic temperature and time increments/decrements during cycling program execution

Instantly displaying the data at each phase of program execution

Pause of program execution

Stop of program execution

Auto-restart in case of power failure

Sound alarm

Estimating total program execution time and remaining program execution time

Date and time (year, month, day, hour, minute, second) display and calibration

Protecting the device from further damage and alarming in case of failure

Note:

The above software functions are listed just as a reference. The Bioer Co.

reserves the right to modify the software functions without notice.

Gene Q Thermal Cycler Chapter 3 Preparations

—6—

CHAPTER 3 PREPARATIONS

This chapter introduces the Gene Q Thermal Cycler’s mechanical structure, the keyboard and each

key’s functions, and some preparations before power-on.

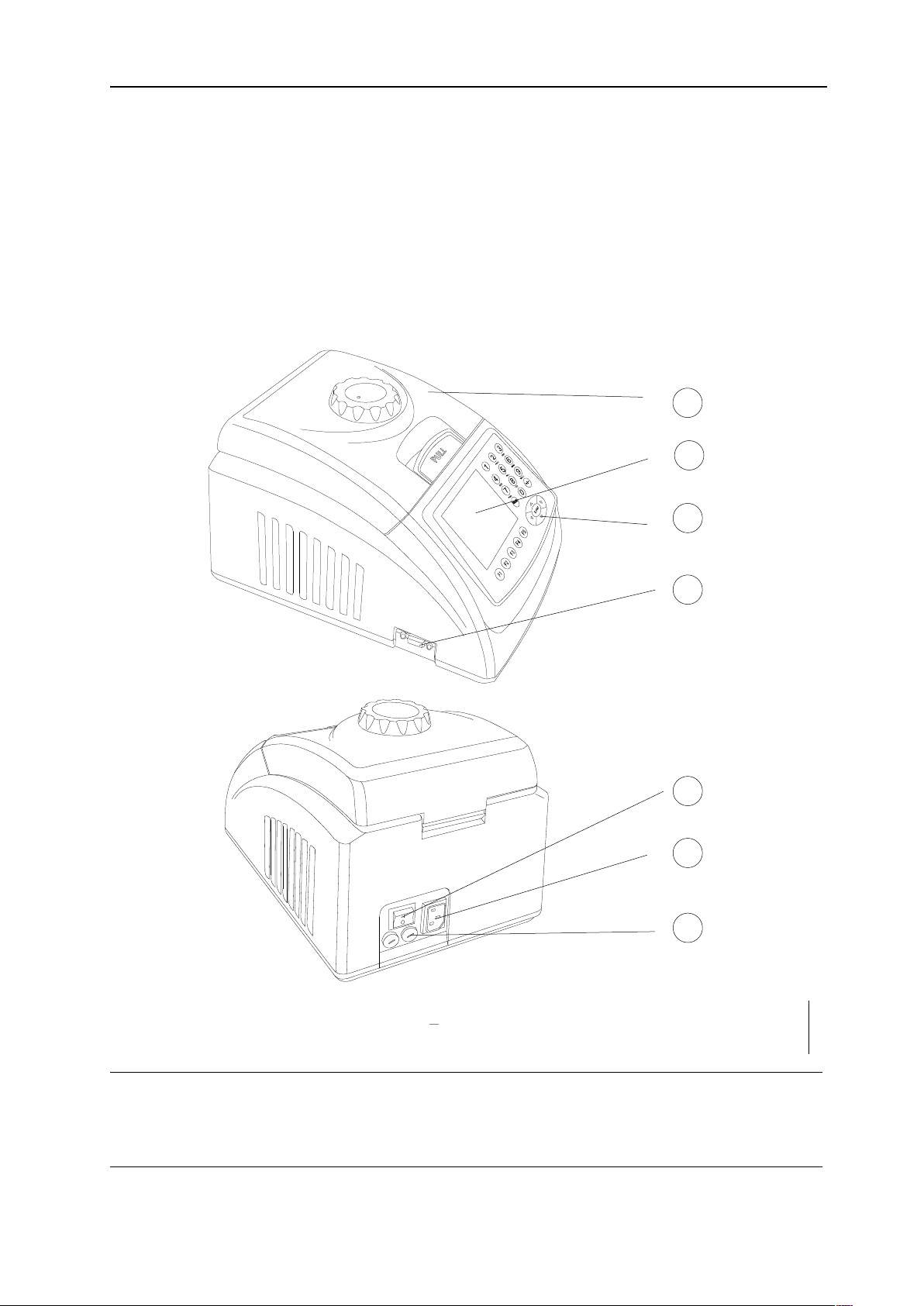

1 Instructure Description

①Heated lid & Block ②Block LCD display ③Keyboard ④RS232 interface

⑤Power switch ⑥Power connecter ⑦Fuse Socket

Note:

1 The fuse specifications are as follows: 250V 2.5A(or 125V 5A), φ5×20mm. The

fuse should be replaced with one that meets those specifications. If you need

certificated fuses, please contact the distributor or manufacturer.

2 If you need exchange block, please refer to appendix b Indication to exchange

blocks.

4

3

2

1

7

6

5

Gene Q Thermal Cycler Chapter 3 Preparations

—7—

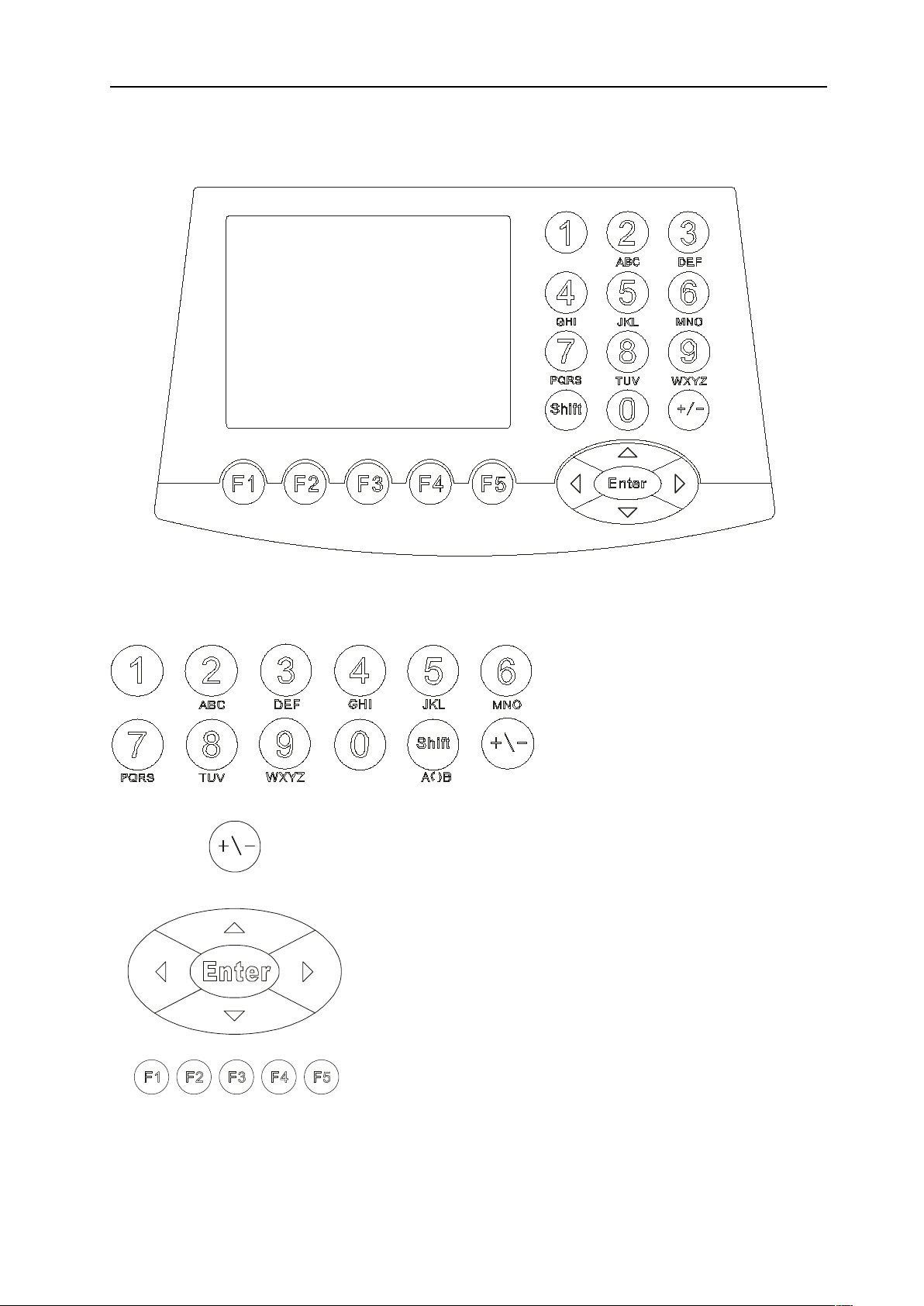

2 Keyboard Diagram

3 Key Functions

“Function”,change “+, -” when editing process temperature and

modifying time.

“Right/Left”,moving the cursor one position to the left or right

when pressing during file parameter setting.

“Up/Down”,moving the cursor one position to the up or down

when pressing during file parameter setting.

“Enter” ,press it to accept the present parameters setting

displayed on the screen when setting documents.

“Menu”, press any button to accept the current items displayed

above the button.

“Digit & Letter”, select the

letter by pressing in

succession.

Gene Q Thermal Cycler Chapter 3 Preparations

—8—

4 Inspection before Power-on

Before switch the power on, please ensure that:

1) Supply voltage falls within the specified limits (refer to Chapter 2);

2) The plug has been inserted into the power socket reliably;

3) The grounding of the power line is reliable.

5 Power-on Procedures

Turn on the power (i.e. turn the power switch to position ‘1’), the Thermal Cycler will beep twice, and

the LCD will display “self test …”. That means the device is under self-testing, which will last for

about 1-2 minutes. Please wait patiently. After the self-testing is passed, the main menu is

displayed, and the device is ready for operations such as editing, accessing, modifying, or deleting

a PCR amplification file.

Gene Q Thermal Cycler Chapter 4 Operation Guide

—9—

CHAPTER 4 OPERATION GUIDE

There are eight kinds of block units suitable to Gene Q Thermal Cycler. In this chapter, we will

explain in details on operations of every kind of block unit, for example, how to edit, access, modify,

delete, or run a PCR amplification file, how to set parameters under different block unit.

Warning! Please turn off the power immediately and contact the distributor if abnormal

sound or display appears after power-on, or if failure alarm and display are found

in the process of the device’s self-testing.

Note:

If the number of samples is less than the number of conical holes of the block, the

sample tubes should be evenly distributed over the block, in order to ensure that

the heated lid will stably press on the top of the sample tubes, so that both the

block’s load and the temperature distribution in each tube are even.

Note:

Before closing the cover, please revolve the knob counter-clockwise according to

the knob diagram till there sound "dang, dang....." Please note that the knob can

be tightened by revolving clockwise, but can be loosed by revolving

counter-clockwise.

After closing the cover but before power on, please revolve the knob clockwise till

it sound "dang,dang....." Revolve the knob one more turn.

At the beginning of revolving the knob clockwise or counter-clockwise, you can

hear "dang,dang...."sound,press the release key by your finger; meanwhile,

revolve the knob counter-clockwise for two turns, thus to loose the release key to

revolve the knob.

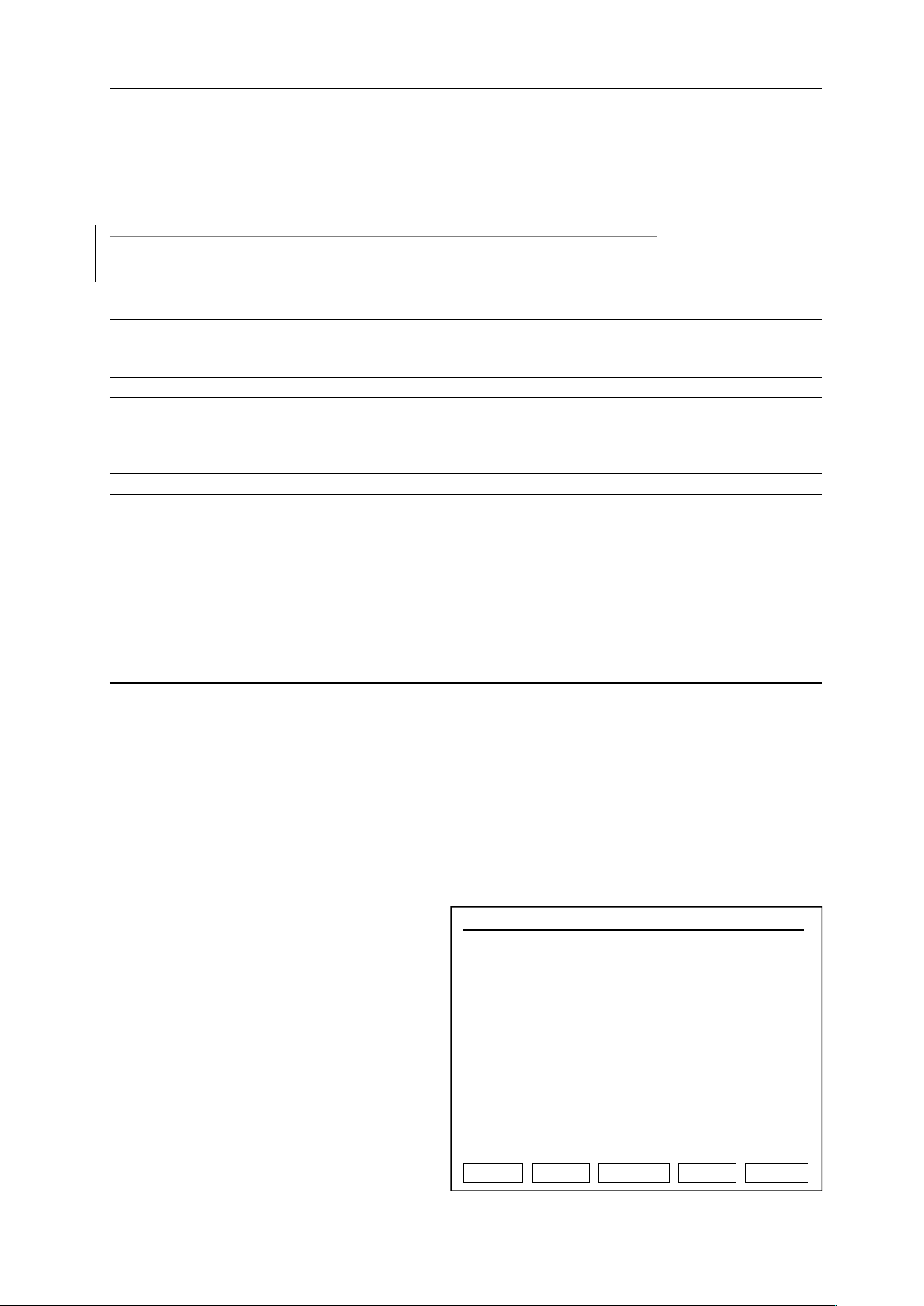

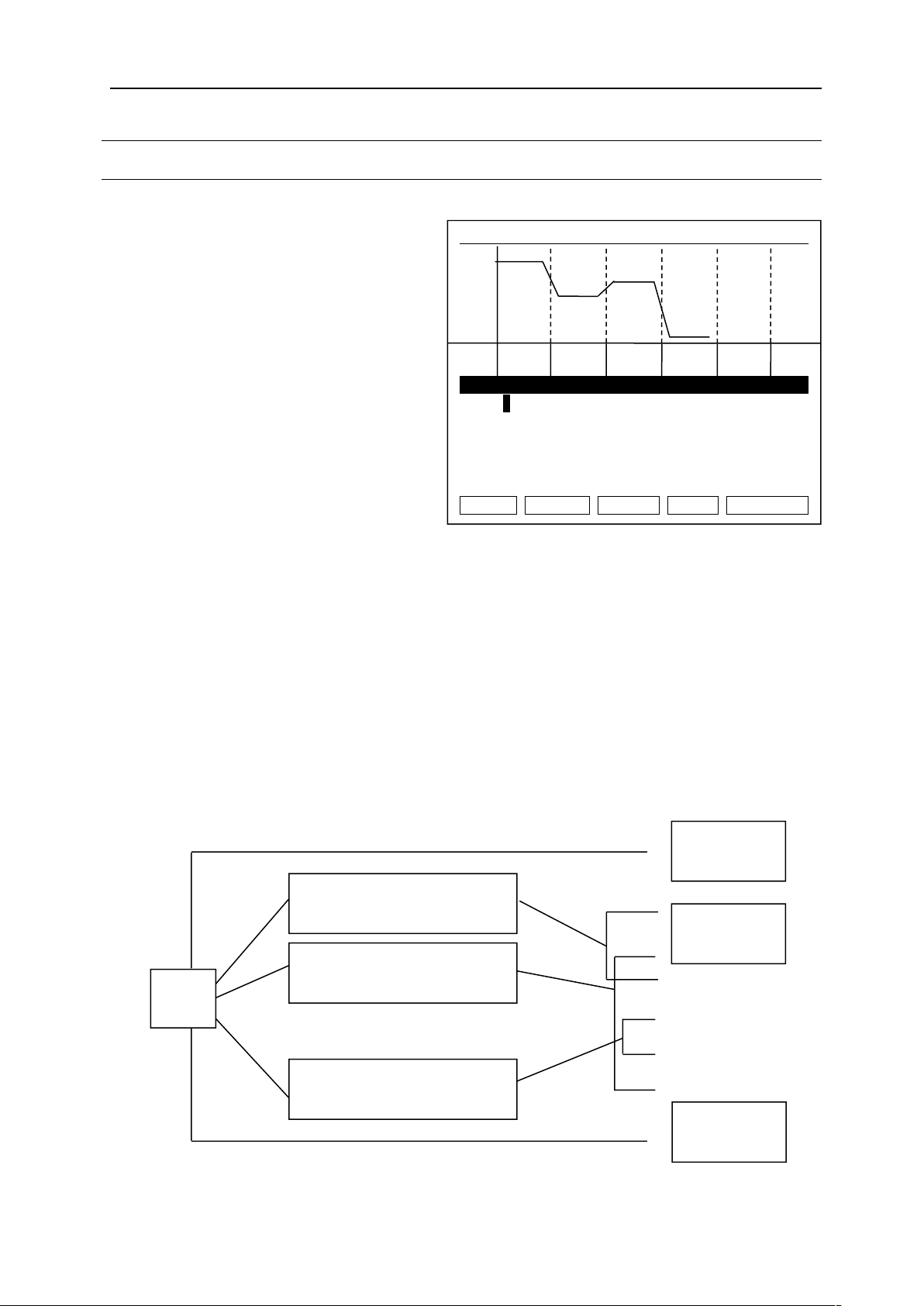

1How to Run a PCR Program

Switch the power on, Gene Q Thermal Cycler will beep twice, and it shows the power supply is

connected well. The screen will display “Self testing ”,and the instrument will carry on self

testing. The self-testing needs about 1~2 minutes and please wait patiently. If the self-testing is

successful, the screen will display the main interface.

On the left top of the main interface it displays

the state of Hot lid.

On the central area it displays Bioer Co.

information, software version number, block

model, default file, default user, control mode

and sample volume.

Press “File” to enter file list interface.

Press “System” to enter system

parameter setting interface.

If the default file has no password, press

“Run” to enter running mode or enter the

interface displaying sample volume input

window. If the default file has password,

press “Run”, thus a dialog box will be

Main interface

Hotlid=off 2008-11-01 10:05:00

BIOER

Bioer Technology Co.,Ltd

Version: 2008-2.0

Default User: BIOER

Default File: PCR1

Module Select: 24*0.2

Control Mode: Block

File System Run

Gene Q Thermal Cycler Chapter 4 Operation Guide

—10 —

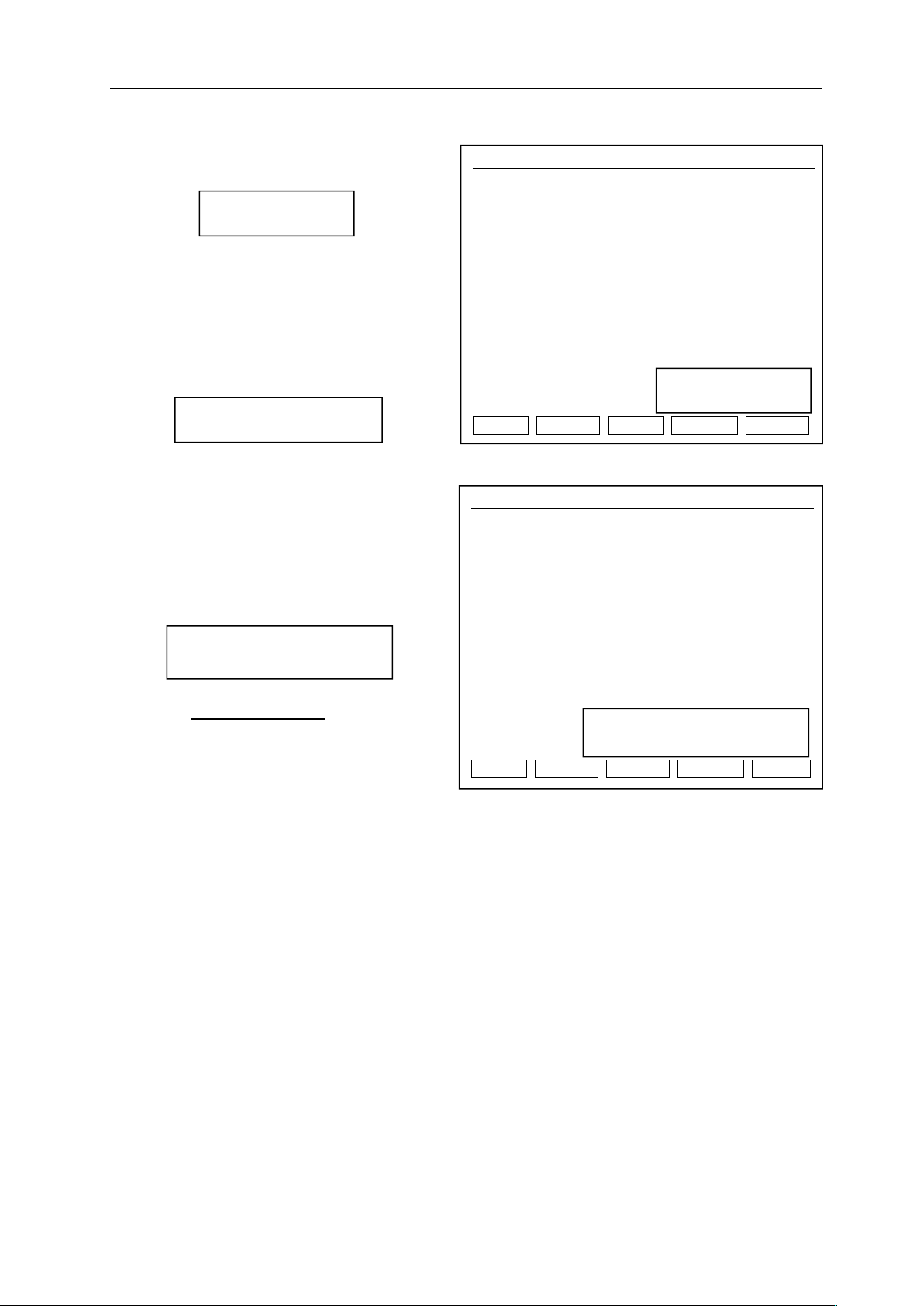

Hotlid=off 2008-07-28 10:05:00

BIOER

Bioer Technology Co.,Ltd

Version: 2008-2.0

Default User: BIOER

Default File: PCR1

Module Select: 24*0.2

Control Mode: Block

Back Run

showed to indicate the user to input the

password.

Press digtal button to enter password

directly. Press “Back” to go back the main

interface. Press “Accept” to confirm the

password, thus to enter file running

interface or sample volume input window.

If the password is wrong, there will be

displayed a dialog box as below:

If the current Control Mode is Block mode,

press “Accept” button to enter file running

interface. If the current Control Mode is

Tube mode, press “Accept” button, thus

there will be displayed a dialog box to

indicate the user to input the sample

volume.

Press Character button to input sample

volume according to practical condition.

Under Tube mode, the overshooting

temperature and keeping time will be

dirrerent in the case of different sample

volume.

Press “Back” to go back the main interface.

Press “Run” to enther file running interface.

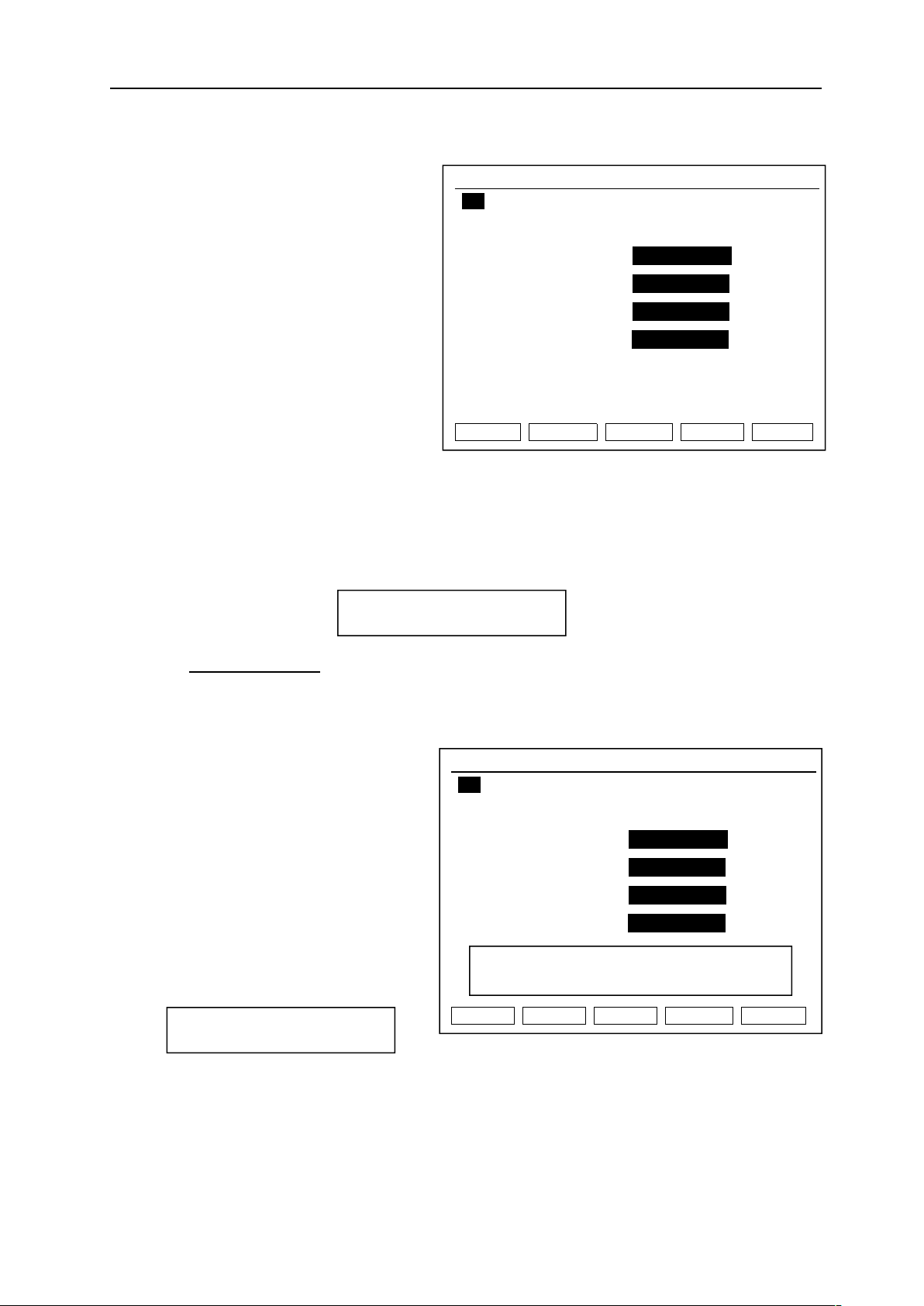

2How to Edit a PCR Program

Press “File” on the main interface to enter file list interface. There are 3 files listed in the form as

showed in the picture. When the flashing bar is flashing in the User Column, select users through

pop-up key; at this time, the File Name Column will display the relative files of the selected user

dynamically. Shift to the File Name Column, where the flashing bar will flash, thenselect relative

user’s file through pop-up key.

Hotlid=off 2008-07-28 10:05:00

BIOER

Bioer Technology Co.,Ltd

Version: 2008-2.0

Default User: BIOER

Default File: PCR1

Module Select: 24*0.2

Control Mode: Block

Back Accept

Enter password

-

Please enter sample volume:

020μl

Please enter sample volume:

020μl

Password error. Try again.

-

Enter password

-

Gene Q Thermal Cycler Chapter 4 Operation Guide

—11 —

Press “Edit” to edit the file indicated by

the cursor.

Press “New File”to edit a new file.

Press “Delete” and the system will alarm

“Do you want to delete the file? Please

select ‘F3’or ‘F4’”, then according to

the alert to select(Delete)or (Back).

Press “Back” to go back to the main

interface.

If the file has no password, press “Edit” to

enter file editing interface; While if the file

has password, press “Edit”, thus a dialog

will be displayed to indicate the user to

enter the password.

Press Character button in the main

interface to input the password directly.

Press “Back” to go back file list interface.

Press “Accept” to confirm the password,

and then the system will enter the file

editing interface,

If the file has no password, press “Run” to

enter file running interface or sample

volume input interface. If the file has

password, press “Run”, a dialog box will be displayed for inputting the password. Press “Back”

to go back the file list interface. Press “Accept” to confirm the password, and then the system

will enter file running interface of sample volume input window.

After press “Run” in the file list interface, and

input the password(If the file has Password.):

If the current Control Mode is Block mode,

Press “Accept” to enter file running

interface; while if the current Control Mode

is Tube mode, press “Accept”, thus a

dialog box will be displayed for inputting

sample volume.

Press Character button to input sample

volume according to practical condition.

Press “Back” to go back file list interface.

Press “Run” to enter file running interface.

Hotlid=off 2008-07-28 10:05:00

No. User File Name Save Time

1BIOER1* PCR1 2007-07-28

2

BIOER2

PCR2*

2007-07-28

3 BIOER3 PCR3 2007-07-28

Back Accept

Enter password

-

Please enter sample volume:

020μl

Enter password

-

Hotlid=off 2008-07-28 10:05:00

No. User File Name Save Time

1BIOER1* PCR1 2008-07-28

2

BIOER2

PCR2*

2008-07-28

3 BIOER3 PCR3 2008-07-28

Edit New File Delete Back Run

Hotlid=off 2008-07-28 10:05:00

No. User File Name Save Time

1BIOER1* PCR1 2008-07-28

2

BIOER2

PCR2*

2008-07-28

3 BIOER3 PCR3 2008-07-28

Back Run

Please enter sample volume:

020μl

Flie List Interface

Gene Q Thermal Cycler Chapter 4 Operation Guide

—12 —

Hotlid=off 2008-11-01 10:05:00

100

75

50

25

0

Temp 1c 95.0 2c 55.0 3c 72.0 4 04.0

Time 01:00 02:00 01:45 00:00

Seg. Temp(C) Time Ramp(C/s) +Temp +Time

1c 95.0 01:00 #.# +0.0 +0:00

2c 55.0 02:00 #.# +0.0 +0:00

3c 72.0 01:45 #.# +0.0 +0:00

4 04.0 00:00 #.# +0.0 +0:00

Cycle1:×10 From 01 to 03

+Seg. +Cycle Delete Back Save/Run

Note:

The sign “*” at the top of User and File indicates the current running file is default

one, which can be modified in the parameter setting interface.

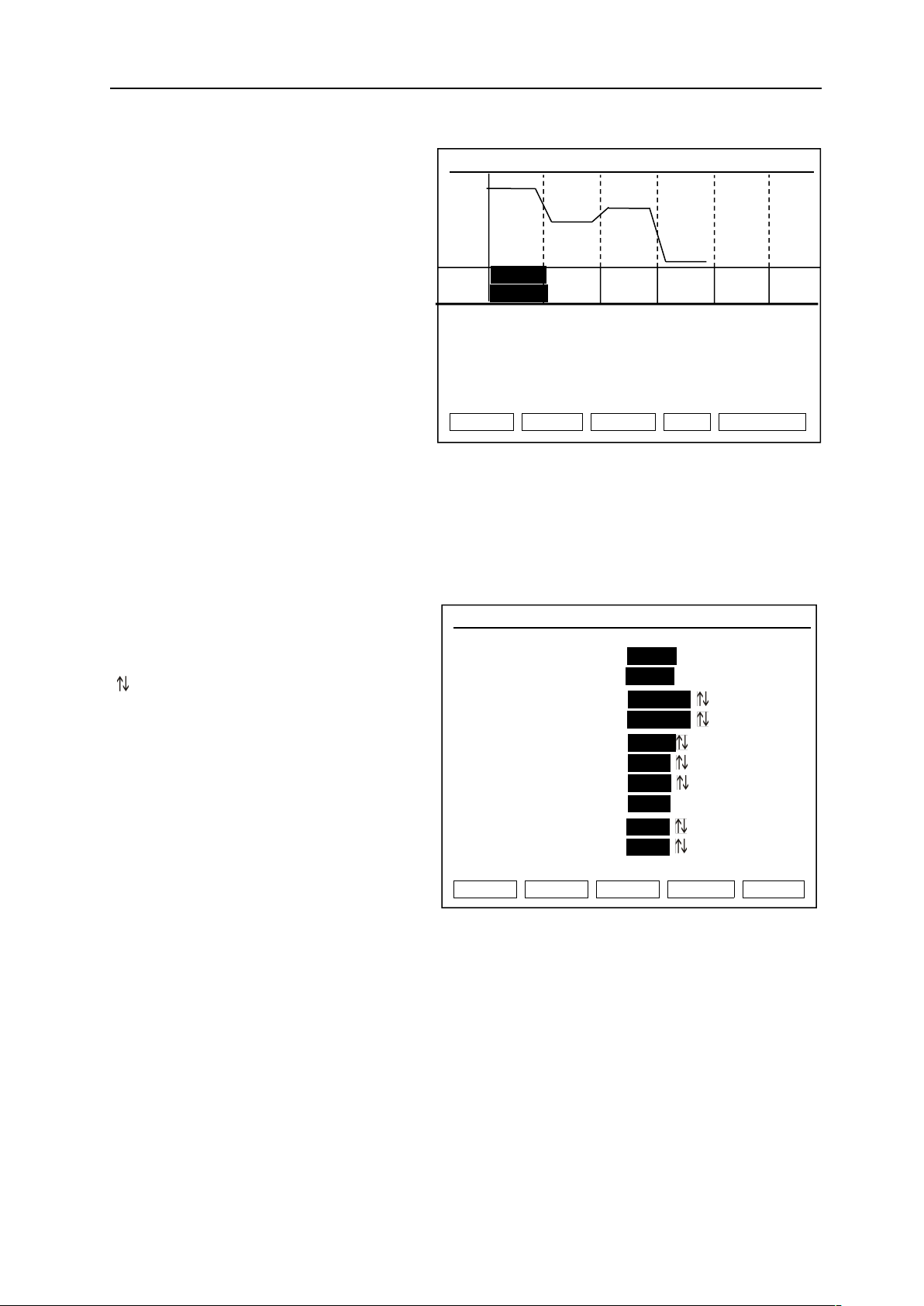

In this interface, you can edit sections and

segments of the file. A File is comprised by

sections and segments. And the sections

contain many segments, which you can set

cyclers to be run (refer to the figure). Move

cursor by pressing “Up/Down” and “Right

/Left”, and the position that the cursor

reaches will be displayed in white on a black

background. Press “Digit & Letter” to modify

parameter settings. Press “+/-” to change +/-.

Press “+Seg.” to enter segment edit

interface. In every segment, you can set

setting temperature (Temp), duration

(Time), Ramping rate (Ramp),

temperature increment of every cycler

(+Temp) and time increment of every

cycler (+Time). Press “Delete” to delete

the present segment.

Press “+Cycle” to enter segment edit interface, where you can set cycle numbers and initial

cycle segment. The figure shows a cycle from the first segment to the third one, and there are

totally 10 times cycles.

Press “+Cycle” repeatedly to add sections (max.: 5 sections ). Press “Delete” to delete the

present segment. Move cursor by pressing “Up/Down” to enter the former segment or the

latter.

Press “Save” to enter file save interface.

Press “Back” to go back to File List Interface.

Special Warning:

1. For the new edited PCR program, please save first then run it, otherwise the file file can’t be

run;

2. When setting “Time” as “--:--”, the hotlid will be closed automatically when the block reaches

the target temperature.

File Edit Interface

Relation of sections and segments in a file

File

section 1

Cycle1 ×** From ** to **

Seg. 1

Seg. 2

Seg. 16

section 2

Cycle2 ×** From ** to **

·

·

·

·

·

·

section 5

Cycle5 ×** From ** to **

Gene Q Thermal Cycler Chapter 4 Operation Guide

—13 —

In this interface press “Digit & Letter” to

enter the file name. Press “Enter” to move

the cursor forwards one position. Select

User and File Name through pop-up key.

Click left button to delete characters while

clicking right button to move the cursor.

Press “Caps” key to shift the capital or small

letter, and there will be a capital or small

letter indication on the left top of the screen.

(as the example: abc)

Press “Main” to go back to the main

interface.

Press “Save” to save the file. When the

file is normally saved, the system will

remind “File have been saved. Please

continue another operation”, Press

“Enter” to cancel the reminding bar. If the file was used, the system will remind you to rename

(Rename)or continue to save (Save).

If the current Control Mode is Block mode, press “Run” to enter file running interface; if the

current Control Mode is Tube mode, press “Run”, thus a dialog box for indicating to input

sample volume will be displayed.

Press Character button to input sample volume according to practical condition. Press “Back”

to go back file save interface. Press “Run” to enter file running interface.

Enther the file save interface, if the user press “Run” without pressing “Save”, the system will

remind “The modifications will be lost after running. Do you still want to run?”

Press “No” to go back file save

interface.

Press “Yes” to enter file running

interface and sample volume input

interface. (Note: the modification here

cannot be saved after the program is

running over.)

Press “Yes”, if the current Control

Mode is Block mode, the program will

enter file running interface; if the

current Control Mode is Tube mode,

the system will pop up a dialog box of

sample volume input:

The user can input Sample Volume (Unit: Micro liter) by the same way as that of the main

interface. Press “Back” to go back to File List Interface, Press “Run” to enter into file running

interface.

Hotlid=off 2007-07-28 10:05:00

abc

User:BIOER

File Name:PCR1

Password:

Password confirm:

No Yes

File Save Interface

Hotlid=off 2007-07-28 10:05:00

abc

User:BIOER

File Name:PCR1

Password:*****

Password confirm:*****

Main Caps Save Run

Please enter sample volume:

050μl

The modifications will be lost after running.

Do you still want to run?

Please enter sample volume:

050μl

Gene Q Thermal Cycler Chapter 4 Operation Guide

—14 —

When the file is normally running, “

” at

“Now Running” will continuously flash.

When running is over, the system will

remind “File running is over ,Press ‘Enter’

back to the main interface.”.

Press “Stop” and it will remind “Do you

want to stop running? Please select

‘F1’ or ‘F3’”.According to the reminding

information to select “Stop” or “Start”.

Press “Pause” and it will remind

“Pause state now. Press ‘F3’ to

continue running.” According to the

reminding information you can select

“Strat” to continue.

Press “View File” to view edited PCR

programs.

Press “Skip” to stop current

temperature and run the next.

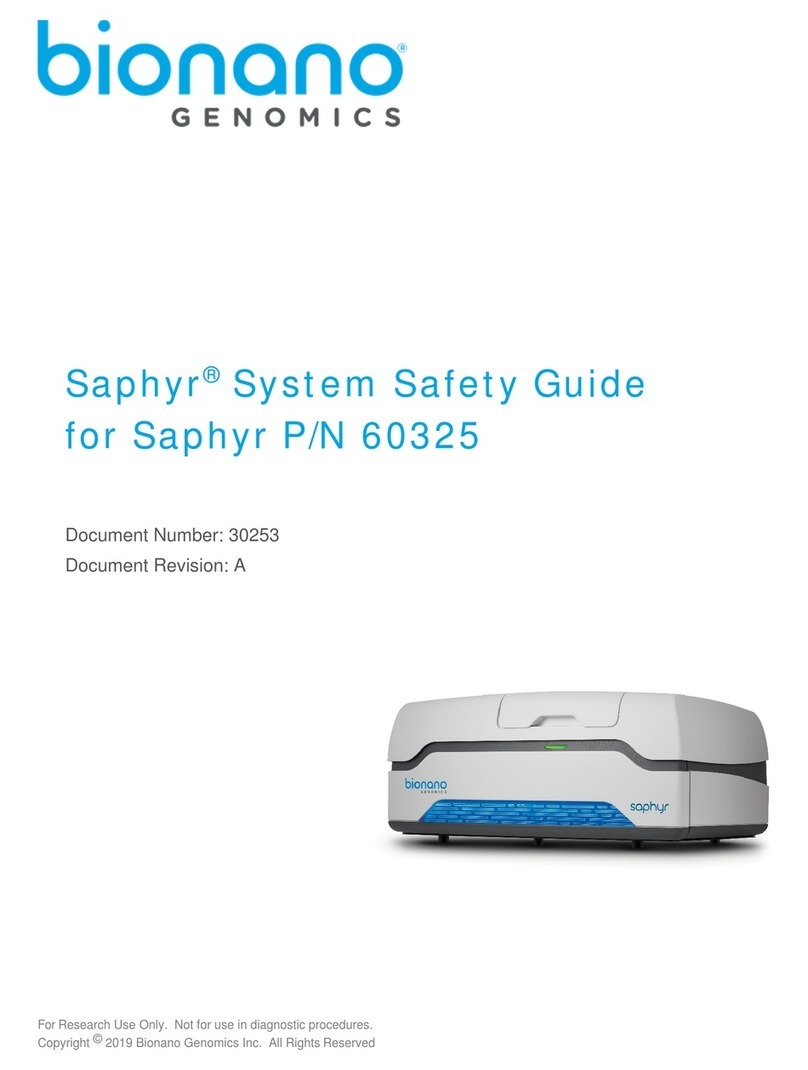

3How to Set System Parameters

In the main interface press “System” to

enter system parameter setting interface.

Press “Enter” to move the cursor to next

item. The option is followed by the symbol

“ ”. Press “Up/Down” to roll the option for

selecting, and other information can be

entered by pressing “Digit & Letter”. Press

“Right/Left” to move cursor’s position.

Press “Back” to go back to the main

menu.

Press “Save” to save parameters.

Special Reminding: When set the

parameter, please press the “Save”,

otherwise the parameter remains the

original one.

3.1 “Date”and“Time”stand for default time after power-on.

3.2 “Default File” and “Default User” stand for name and user of default running procedure after

power-on.

3.3 “Module Select” stands for module type, including two optional modes, named “18*0.5” and

“24*0.2”. Selecting the module type according to the real situation.

3.4 “Control Mode” stands for default control model after power-on, including two optional modes,

named “Block” and “Tube”.

“Block” mode subjects to simple temperature control during the course of cooling & heating

only. Compared to the block, cooling & heating rate of reagent is a little slower, therefore, the

actual change of reagent’s temperature is different from the setting procedure. The actual time

for reagent to reach & keep the setting temperature is far shorter than the setting time.

File running interface

System Parameter Setting Interface

Hotlid=off 2007-11-1 10:05:00

100

75

50

25

0

Temp 1c 95.0 2c 55.0 3c 72.0 4 04.0

Time 1:00 02:00 01:45 00:00

File Name:PCR1

User: BIOER Now Running

1c Temp=00.0 Time=00:00 Cycle 01 of 10

Total Time: 00h 56m Remainig Time:00h 56m

Stop Pause Start Skip View File

Hotlid=off 2007-07-28 10:06:00

Date(yy-mm-dd): 07-07-28

Time(hh-mm-ss): 10:06:19

Default User: BIOER

Default File: PCR1

Module Select: 24*0.2

Control Mode: Block

Hotlid Temp: OFF

Block Temp: 10C

Key Sound: OFF

Run End Sound: ON

Back Save

This manual suits for next models

2

Table of contents

Other Bioer Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

TSE

TSE Calorimetry PhenoMaster Hardware operating instructions

Shimadzu

Shimadzu ICPE-9000 instruction manual

MELAG

MELAG Careclave 618 Technical manual

Goobay

Goobay 20319 user manual

BioNano Genomics

BioNano Genomics Saphyr System System Safety Guide

Thermo Scientific

Thermo Scientific STP420D instruction manual

Conrad

Conrad LUM-U260S-01 operating instructions

TestEquity

TestEquity 1007H Operation and service manual

cavitation

cavitation RF SUPER user manual

Fisher Scientific

Fisher Scientific Fisherbrand Isotemp FBG Series Installation and operations

Xiitech

Xiitech 1060 Operation Intructions

Leica

Leica CM1520 Instructions for use