Bioer GenePure Pro NPA-32P User manual

GenePure Pro

Nucleic Acid Purification System

NPA-32P

Users’ Manual

Han gz ho u Bioe r Tec h n o l og y Co. , Ltd .

Caution:

Hangzhou Bioer Technology Co., Ltd. reserves the right to modify this

manual at any time without notice.

This document contains proprietary information protected by copyright. All rights

reserved. Without prior written consent from Hangzhou Bioer Technology Co., Ltd., any

part of the manual shall not be duplicated, reproduced or translated into any other

languages.

Product Technical Requirements No.: Z. H. X. B. No. 20150371

Product record No.: Z. H. X. B. No. 20150371

Document No.:BYQ66260000000 SM

Document Version: July 2017, Version 1.0

Before the initial use of this instrument, please carefully

read this manual!

Operation Manual for Automatic Nucleic Acid Purification System

―I―

Important Notes

1 General Practice

Caution

:

Because of the important information in this column, please read it carefully. Failure to

follow the advice in this column will possibly result in damage or malfunctioning of

the machine.

2 Safety

During the operation, maintenance, or repair of the machine, the following safety measures should be

taken. Otherwise, the guard provided by the machine is likely to be damaged, the rated safety level to

be reduced, and the rated operation conditions to be affected.

Hangzhou Bioer Technology Co. Ltd. shall not be in any way responsible for the consequences

resulted from buyer’s not observing the following requirements.

a) Grounding Considerations

A.C. power’s grounding should be reliable for fear of an electric shock. The 3-pin plug with the

machine’s power line is a safety device that should be matched with a grounded socket. Never let the

third ground pin floating. If the 3-pin plug cannot be inserted, it is recommended to ask an electrician

to install an appropriate power socket.

b) Keep Away from Electric Circuits

The operator is not allowed to open the machine. Changing components or adjusting certain

parameters inside the device must only be accomplished by the certificated professional maintenance

personnel. Do not change elements while the power is still on.

c) A.C. Power Considerations

Before turn on the power, always check and insure that the mains voltage is within the required A.C.

100-240V and insure that the current rating load of the power socket meet the required specification.

d) A.C. Power Line Considerations

As an accessory of the machine, the A.C. power line should be a default one. If it is damaged, the A.C.

power line can not be repaired, but must be replaced with a new one. The power line should be free of

heavy objects during the machine’s operation. Keep the power line away from the place where people

ambulate frequently.

e) Connect the A.C. Power Line

While connect or disconnect the power line, you should hold the 3-pin plug with your hand. Insert the

plug thoroughly into the socket to ensure good contact between the plug and socket. Pull the plug, not

the line, when you need to disconnect to the mains.

Operation Manual for Automatic Nucleic Acid Purification System

―II―

f) Design Environments

The machine should be placed in a low-humidity, dust-free, and good-ventilation room without caustic

gas or powerful magnetic interference. In addition, water sources, such as pools and water pipes,

should be separated a distance from the machine.

Never cover or obstruct the openings of the machine, which are designed for ventilation and to prevent

the device’s interior from being too hot. When a single device is running, the shortest distance between

its openings and the nearest object is 25cm; otherwise, when two devices or above are running at the

same time, the shortest distance is 40 cm. Do not place the device on a soft surface, because that will

result in adverse ventilation near the device’s bottom openings.

Too high temperature will lead to degraded performance or failure of the machine. Therefore, the

device should be protected against any kind of heat sources like sunlight, ovens, or central heating

equipment.

If the machine is set aside for a long time, it is recommended to disconnect the power line to mains and

cover the device with a piece of soft cloth or plastic to prevent dust from entering.

Caution

:

Once one of the following events occurs, you are suggested to disconnect the power

line with mains, and contact the distributor or ask a certificated maintenance worker

for help.

Liquid into the device;

The device sprinkled or drenched;

The device malfunctioning, giving off abnormal sound or odor;

The device falling onto the floor or its shell damaged;

Significant changes in the device’s performance.

3WARRANTY AND SERVICE INFORMATION

a) Warranty

Hangzhou Bioer Technology Co., Ltd. is responsible for the replacement for failures caused by

material and manufacturing defects within 1 month after goods delivery.

Hangzhou Bioer Technology Co., Ltd. is responsible for maintenance of failures caused by material

and manufacturing defects within 12 months after goods delivery. Hangzhou Bioer Technology Co.,

Ltd. is responsible for selectively repairing and replacing instruments with confirmed defects within

warranty period.

Maintained products shall be sent to maintenance department designated by Hangzhou Bioer

Technology Co., Ltd. by the user. The freight incurred thereof shall be borne by the user. Hangzhou

Bioer Technology Co., Ltd. will bear the freight incurred by returning instrument. (For domestic users

only)

For maintenance out of warranty period, Hangzhou Bioer Technology Co., Ltd. will charge for certain

maintenance cost.

b) Warranty Terms

The above warranty is not applicable to defective devices with incorrect use, abnormal operating

Operation Manual for Automatic Nucleic Acid Purification System

―III―

conditions, improper application, and unauthorized maintenance or alteration.

Hangzhou Bioer Technology Co., Ltd. makes no express warranties other than those which are

described herein. Any descriptions in sales promotion under specific conditions shall not create an

express warranty that the goods shall conform to such description.

Caution

:

After unpacking, immediately check the goods against the packing list. In case of

damaged or missed goods, please immediately contact the supplier.

After qualification of acceptance, properly fill in the product acceptance sheet and send

(or fax) the copied sheet to the supplier for filing and maintenance.

After unpacking, the packing box and packing materials shall be well kept for future

repair. For the damage of instrument occurring during transporting to the repair

department due to improper package, Hangzhou Bioer Technology Co., Ltd. shall bear

no liabilities.

All upgrades of the equipment and software shall be operated by the engineer of the

manufacturer. Bioer company shall not be liable for any equipment failure caused by

unauthorized updates and modifications.

After-sale Service Hotline: +86–571-87774558

Contents

Chapter I Introduction............................................................................................................................1

1 Instrument Features.........................................................................................................................1

2 APPLICATIONS.............................................................................................................................. 1

Chapter II Features................................................................................................................................. 2

1. Normal Working Conditions........................................................................................................... 2

2. Transportation and Storage Conditions.........................................................................................2

3 Basic Parameters.............................................................................................................................. 2

4 Basic Performance............................................................................................................................3

5 Software Functions...........................................................................................................................3

Chapter III Preparations........................................................................................................................ 4

1 Structure Diagram............................................................................................................................4

2 Check before Startup....................................................................................................................... 5

3 Placement of 96 deep well plate...................................................................................................... 5

4 Startup............................................................................................................................................... 5

Chapter IV Operation Guide..................................................................................................................6

1 Upper computer operating interface.............................................................................................. 6

Chapter V Fault Analysis and Troubleshooting................................................................................. 17

Operational Manual of

Nucleic Acid Purification System

Hangzhou Bioer Technology Co., Ltd.

1

Chapter I Introduction

This chapter mainly introduces the features and applications of the instrument.

1 Instrument Features

This product adopts a magnetic bead extraction technology to extract and purify nucleic acid

through precision transmission and controlling step motor by single chip microcomputer. It has

features as follows: small volume, light weight, low noise, full-closed workaround; Embedded

real-time operating system; Transparent working chamber facilitating the observation of working

conditions; Large LCD panel, easy to operate. It has powerful functions such like door open protection,

ultra-limit position protection and alarm. It is safer and more reliable for use. It can be used to extract

DNA, RNA from whole blood, cells, and tissues and so on, so as to save time and labor.

2 Instrument Applications

This product can be used for separation and purification of nucleic acid in molecular biology

laboratory and clinical laboratory.

Operation Manual for Automatic Nucleic Acid Purification System

Hangzhou Bioer Technology Co., Ltd.

2

Chapter II Features

This chapter mainly introduces the usage, transportation and storage conditions of the instrument, as

well as its basic parameters, performance and functions.

1. Normal Working Conditions

Ambient temperature: 10C ~ 30C

Relative humidity: 20%-70% without condensation

Power supply: AC100-240V 50-60Hz

Caution:

Before power on, please confirm whether the working conditions meet the above

requirements. Pay special attention to the power line is reliably grounded.

2. Transportation and Storage Conditions

Ambient temperature: -20C+55C

Relative humidity: ≤80%

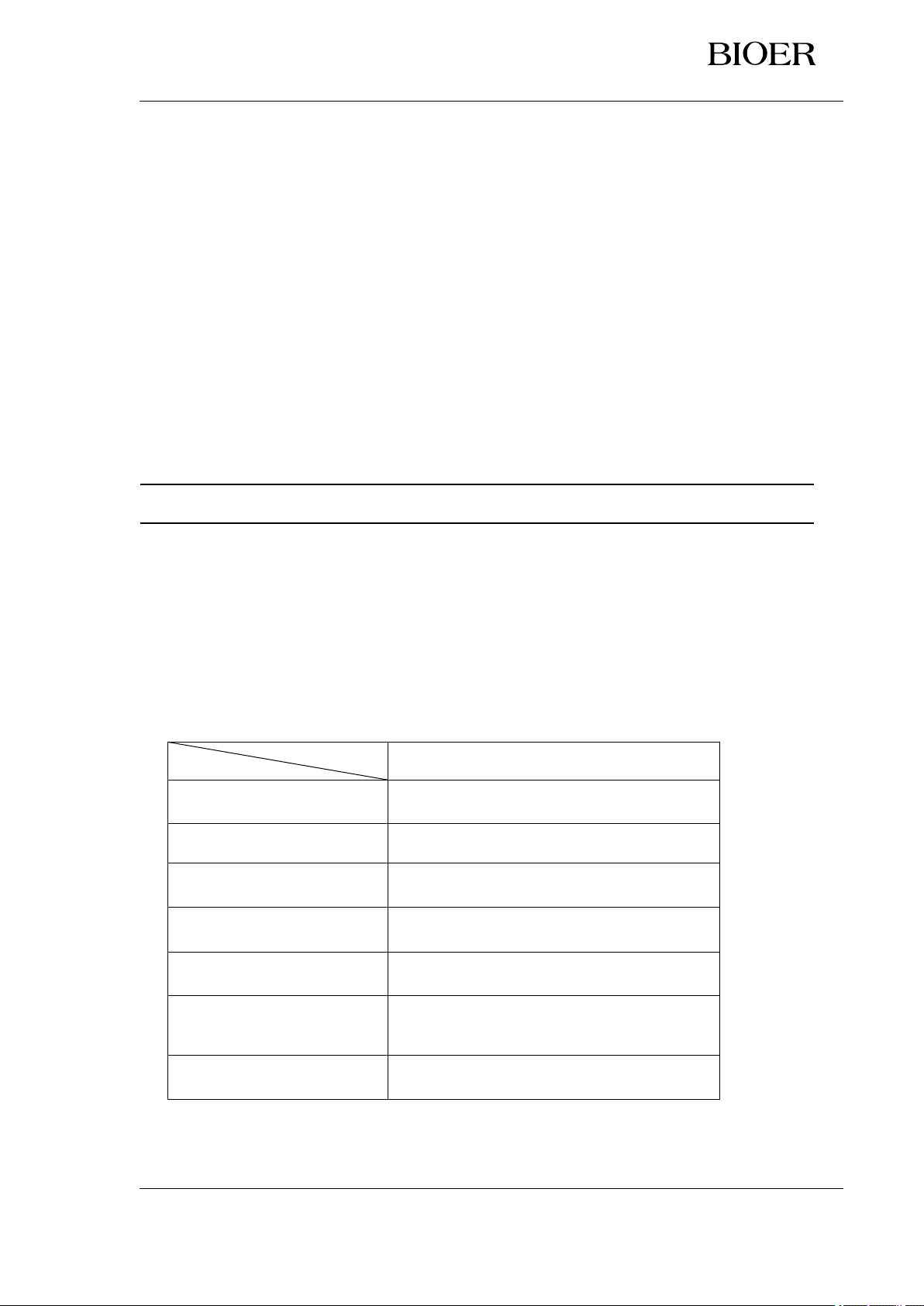

3 Basic Parameters

Model

Parameters

NPA-32P

Sample size

32pcs/time

Magnetic rod (fixed)

4×8 pcs

Sample range

20~1000μl

Magnetic bead collection

efficiency

>98%

Most suitable size of magnetic

beads

0.2~1.0μm

Overall dimensions mm

430*395*435 (L*W*H)

Net weight

32.5Kg

Operation Manual for Automatic Nucleic Acid Purification System

Hangzhou Bioer Technology Co., Ltd.

3

4Basic performance

Operating temperature: room temperature

Program storage: 20

5 Software functions

File edit, view, modify and delete functions

File run, pause, and stop functions

File import & export by U disk

Voice prompt function

Fault protection and alarm function

UV lamp on and timed off

Upgrade by U disk

Caution:

The above software features are for reference only. Bioer reserves the right to change

the software without notice.

Chapter III Preparations

This chapter mainly describes the structure, the functions of screen and keys on the screen, as well as the

preparations before the startup. Before the first operation of this instrument, please read this chapter carefully

and make sure you are familiar with the contents of this chapter.

1 Structure Diagram

Back view of full automatic nucleic acid extraction and purification system

⑤

①

②

③

④

⑥⑦

⑧

⑨

2 Check before Startup

The following contents should be confirmed before power on:

1 Whether the power supply meets the required voltage of the instrument;(see chapter 2 of this

document for power requirements)

2 Confirm that the power cord plug has been reliably inserted into the power socket;

3 Reliable grounding of power cord;

4 Whether the 96 deep well plates is in place.

3 Placement of 96 deep well plate

a)There are four heating blocks placed on each plate with a limit block on each side to assist in

positioning, and a spring plate on each side to help fix the 96 deep well plate.

b)Note: Make sure the 96 deep well plate is placed evenly before starting up.

4 Startup

Switch on the automatic nucleic acid purification system, and the instrument will conduct self-test.

Self-test takes about 10 seconds. Please wait patiently. If no problem is found in the self-test, the main

menu will appear on the screen, and then the user can edit, review, modify and delete files.

①Case Body

②Display

③Operating room

④Where 96 deep well

plate is placed

⑤Closing cover

⑥Power switch

⑦Standard power

outlet

⑧USB interface

⑨Sticker

Caution: The fuse seat is fitted with a fuse for which the requirement is: F 250V 6A 520.

Fuses must be replaced using products that meet the requirements. Contact the supplier or

manufacturer for fuses.

Chapter IV Operation Guide

This chapter explains in detail how to edit/review/modify/delete files, and how to run/stop files. It also

introduces the meaning of protection interface in the process of file running.

Warning!

If there is any abnormal sound or display after the instrument is switched on, or there is a

fault alarm during the instrument self-testing, please switch off the power immediately

and contact Bioer.

Ready? Let's get started!

1 Upper computer operating interface

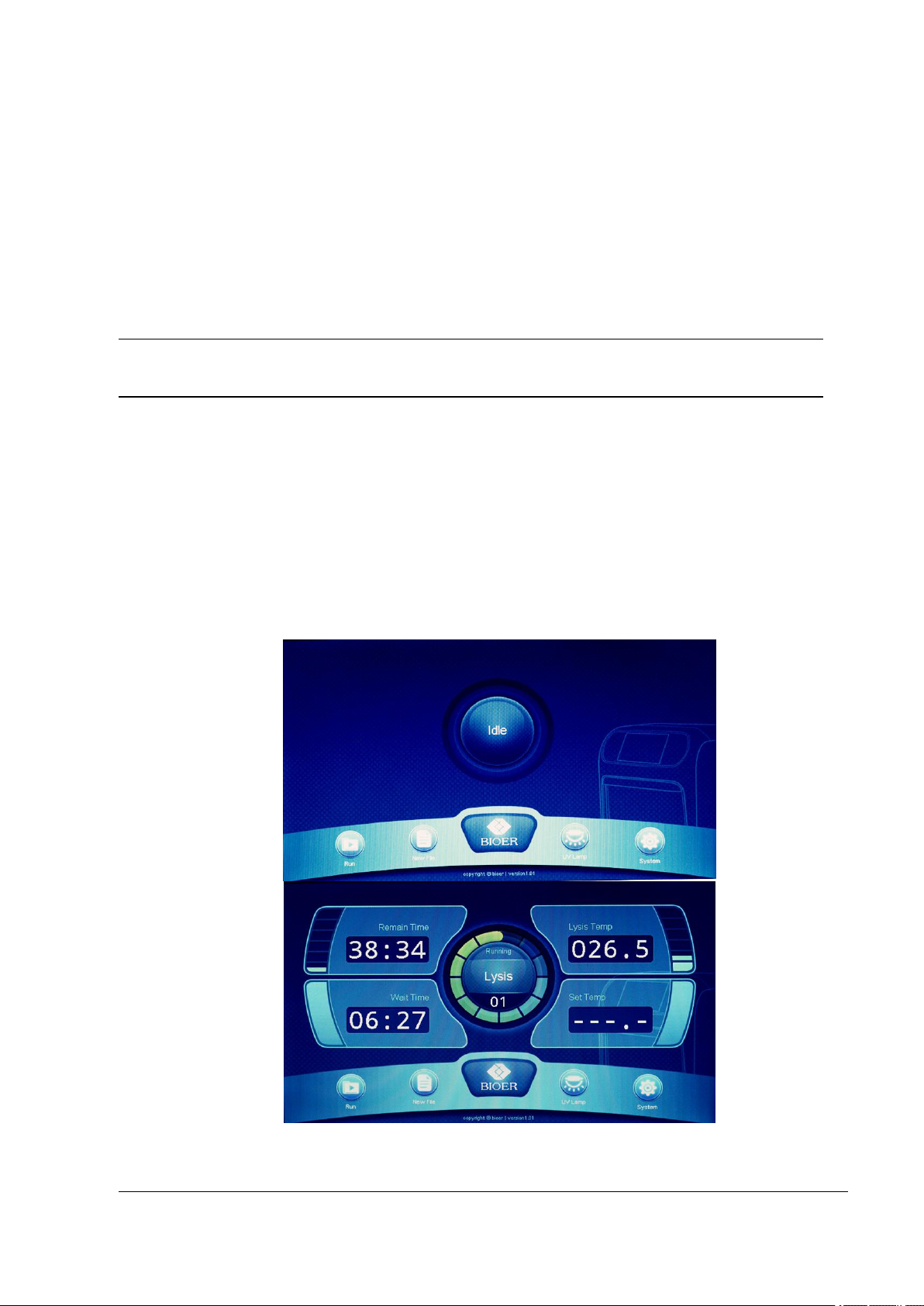

a. Operation main interface

After the system is started, enter the main interface of nucleic acid purification operation, which mainly

has the following functions: Run, New File, Ultraviolet Lamp and System Setting. The interface center displays

the operation state of the instrument. If the instrument is in operation state, click the icon of the center to further

check the detailed operation information. The followings are the idle and runtime main interfaces, respectively.

The bottom four function buttons from left to right are: Run, New File, UV Lamp, and

System Setting.

The middle operation status button and status information are displayed only when the

equipment is in running status. Press the Running button to enter the running state interface to

view the detailed information of the running state.

b. Run

Click run icon on the main interface to enter the file browsing interface. You will see buttons for browsing

menu selection on the left to select files, history or U disk files, information browsing in the middle, function

buttons in the bottom, and main interface icons in the upper left corner to return to the main interface. Select

different browsing menu items, the bottom function button and browsing information will be different.

The following figure shows the file browsing interface.

A list of stored files is in the middle, showing up to 9 files per page and totally 250 files. The current

selected file is displayed in white. Click the current selected file to enter the file editing interface.The page

information and page forward/back button is in the right; the function button is in the bottom, including Export,

Delete, New, Edit, and Run.

Export: Copy the selected file to the default u-disk directory (under the \pcrex\Bioer of u-disk directory).

Delete: Delete the selected file from the instrument.

New: After creating the default file, go to the file editing interface to edit the new file.

Edit: Go to the File Editing Interface to edit the current selected file.

Run: Run the selected file.

The following image shows the history browsing interface.

A list of 9 files that were last edited and run is in the middle. The current selected file is displayed in white.

Click the current selected file to enter the file editing interface. T the function button is in the bottom, including

Clear Record, Edit, and Run.

Clear: Clear history

Edit: Go to the file edit interface to edit the selected file

Run: Run the selected file

The following figure shows the U disk file browsing interface, which can only be displayed when the U

disk is inserted. If the U disk is not inserted, it prompts failure to detect the U disk.

In the center is the ".ebr "file list that conforms to the file name standard in the default directory of U disk

(under the \pcrex\Bioer of u-disk directory) (a legal filename consists of an English letter, a number, and an

underscore, and a filename that does not include a suffix is no longer than 12 characters long). The current

selected file is displayed in white. The page information and page forward/back button are in the right; the

function button is in the bottom, including the import.

Import: Copy the selected file to the instrument

c. New/edit file

User can create new file and edit file the following ways:

Click on the new file on the main interface.

Click on currently selected file of the device file browsing interface.

Click on New button of the device file browsing interface.

Click on Edit button of the device file browsing interface.

Click on the currently selected file on the history browsing interface.

Click on the Edit button in the history browsing interface.

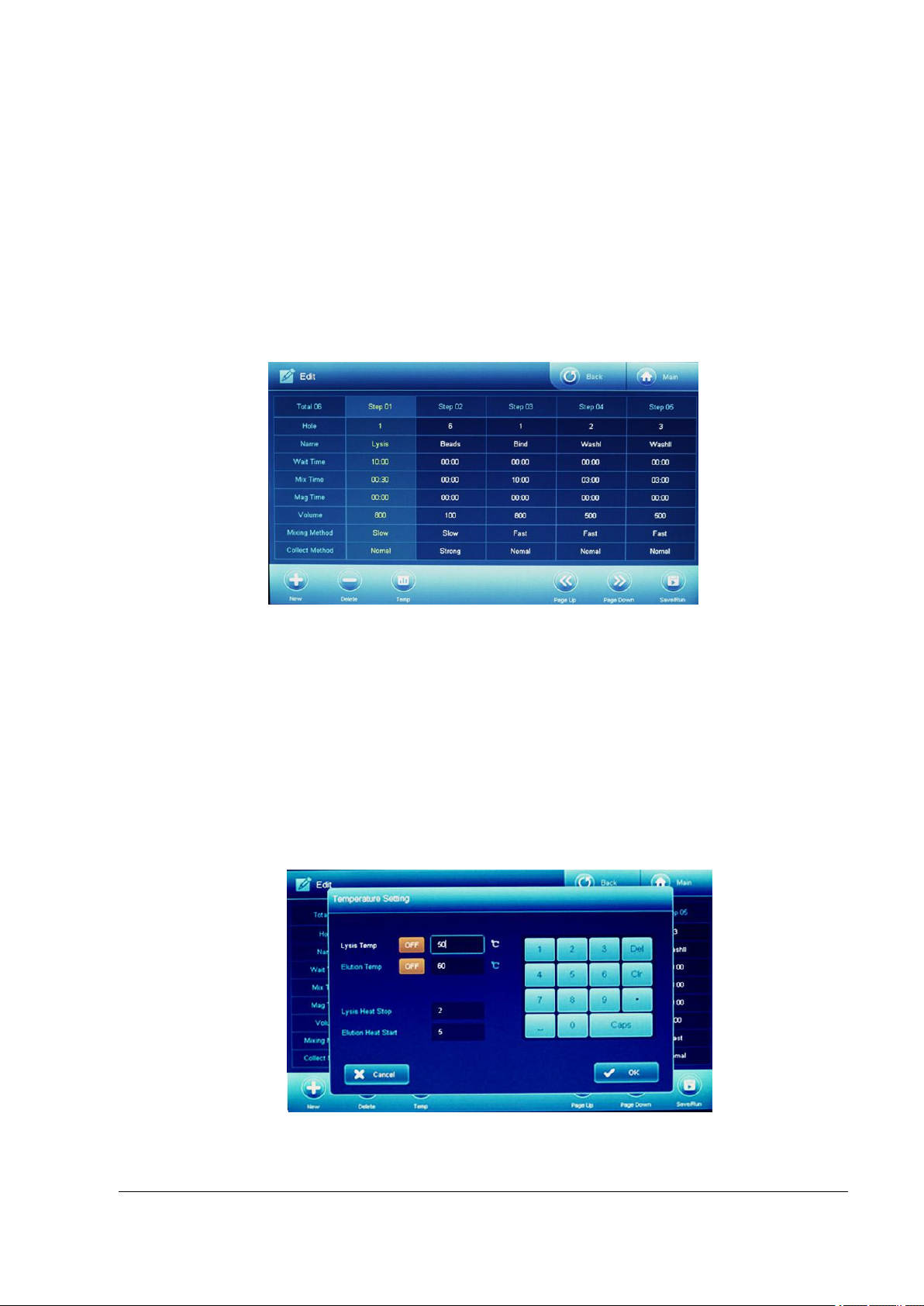

In the center of the interface, all steps of the program are displayed, including well location, step name,

waiting time, mixing time, binding time, volume, mixing mode and binding mode.

Below steps interface are function buttons, including Add, Delete, Temperature, Previous Page, Next Page,

Save/Run; Upper left return and main interface icon are used to return to the previous interface or main

interface.

The currently selected step is displayed in a different color. Click on the unselected step column to select

the specified step. It can save up to 30 steps program, if there are more than 5 steps, the rest of steps are to be

paged by pressing the up/down button. Add or remove steps by clicking on Add or Remove buttons.

Click on the temperature button to display the temperature setting interface.

Set up the lysis temperature, temperature, lysis heating termination step and elution heating termination

step. After setting, click on ok to return to the file editing interface. If the change is to be waived, click on

Cancel.

By clicking on the selected step area, you will enter the step editing interface, as shown in the following

figure.

Set up well positions (1~6), liquid volume, waiting time, mixing mode and binding mode.

Click on the list box beside the name, and the name selection list will pop up.

It allows users to select the appropriate name in a pre-set list of step names to describe the action that the

step performs. See step name management section for how to add or remove preset step names.

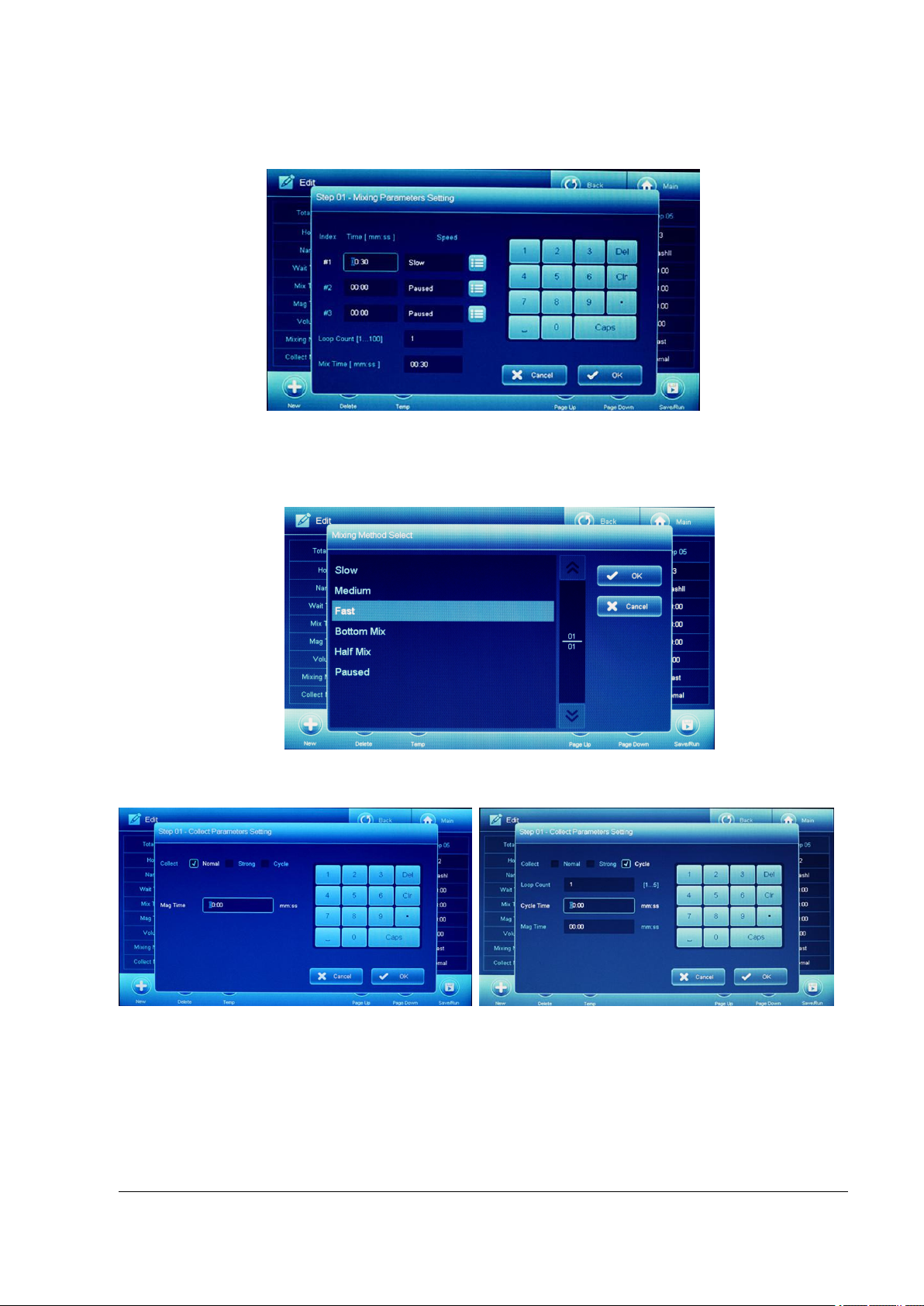

Click on the list box of mixing mode, and the mixing parameter setting will pop up.

The mixing parameter allows user to set up a mixing step for up to three periods. If the mixing step is not

to be used, set the time to 00:00. The mixing speed can be selected from the option list by clicking on the

mixing steps list. See the figure below.

Click on the list box beside the binding mode, and the binding parameter setting will pop up.

Click on the save/run icon to display the file save interface, as shown in the figure below.

A soft keyboard is available for inputting the file name. If the file does not want to be viewed, modified, or

run, you can enter a password.

Run: Run the current edited file.

Save: Save the current edited file.

d. Running files

After editing and saving the program, you can run the it in the following ways:

Click on Run button on the file browsing interface;

Click on Run button in the history browsing interface;

Click on Run button in the file save interface.

The lysis and elution temperatures are displayed on top of the running interface. The lower left side of the

interface shows the steps undergoing, including waiting time, mixing time, binding time, and remaining time.

The bottom right side of the interface shows the number of columns being heated. At the bottom is the function

button, including: Stop, Pause, Pause/Reset.

Stop: Stop the experiment.

Pause: Suspend the experiment.

Pause/Reset: Suspend the experiment and Raise the magnetic rods.

e. UV light setting

In the operation main interface, click ultraviolet lamp setting to enter the ultraviolet lamp setting interface.

After setting ultraviolet lamp turn-on time, click ok to turn to the ultraviolet lamp turn-on time set state

interface or click cancel button to return to the main interface.

f. System setting

Click on the system settings to enter the system settings interface in the operation main interface.

The 8 buttons in the middle correspond to 8 Settings entries. Click the button in the upper right corner to return

to the main interface.

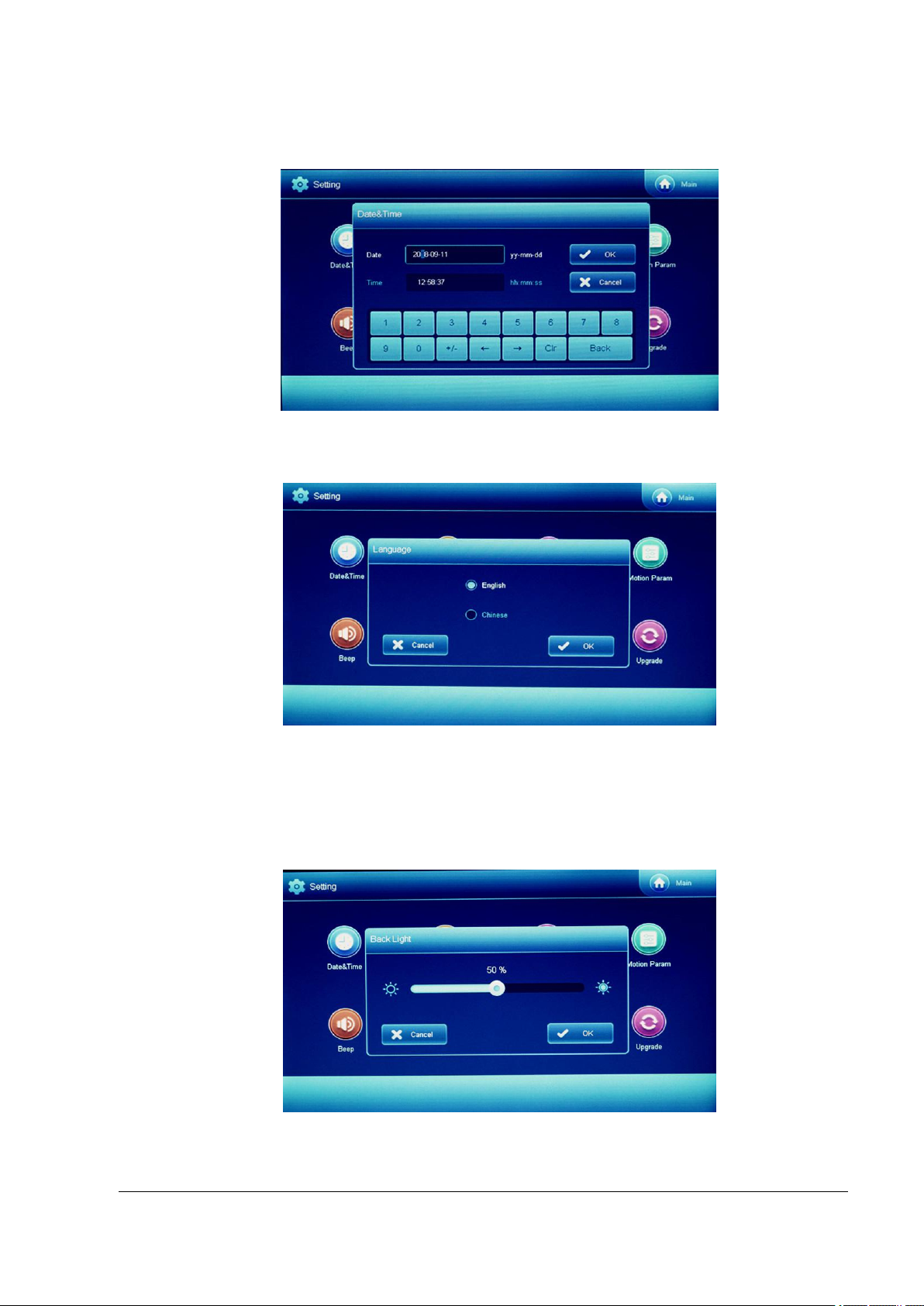

g. Date &Time

Click the Date & Time button in the system setting interface, enter the Date & Time setting interface, and

click ok or cancel button after setting time or date to return to the system setting interface.

h. Language selection

In the system settings interface click language into the language settings interface, select Chinese or

English, click OK or cancel button to return to the system settings interface.

i. Backlight adjustment

Click backlight adjustment on the system setting interface to enter the backlight adjustment interface.

Turn up/down screen brightness by clicking and dragging the scroll bar, or by clicking certain spot in the

horizontal column to modify the position of the indicator sign, and then click ok or cancel to return to the

system setting interface.

Table of contents

Other Bioer Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

PolyScience

PolyScience MX07R-20 Operator's manual

Wassermann

Wassermann Polyquick 160-T120 user manual

Genetix

Genetix ClonePix FL Quick setup instructions

Thermo Scientific

Thermo Scientific Sorvall RC6 Plus instruction manual

Funke Gerber

Funke Gerber ColonyStar manual

NoiseKen

NoiseKen ESS-2000AX instruction manual