NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

Sole UK Distributor, Sealey Group.

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk.

IP32 7AR

www.sealey.co.uk

sales@sealey.co.uk

01284 757500

01284 703534

Web

5. OPERATION

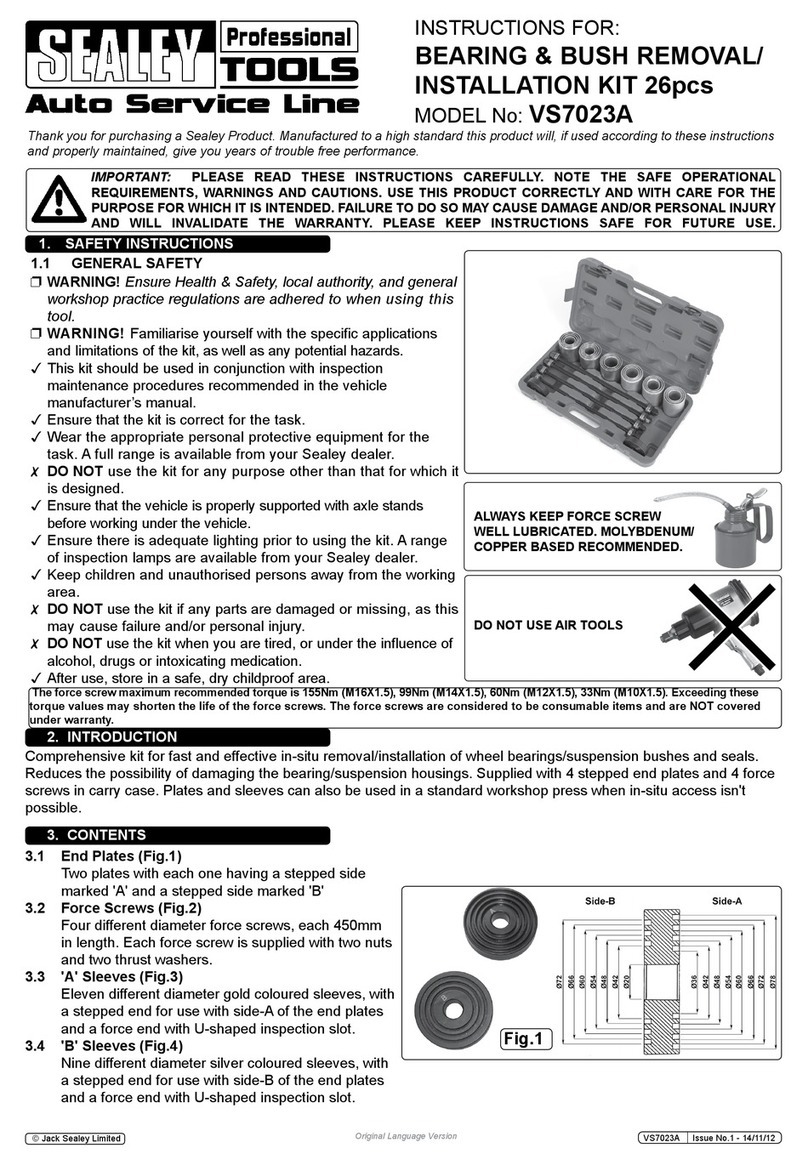

5.1. It is necessary to pretension self adjusting clutches before removal or installation. This prevents plate distortion which can lead to

the clutch disengaing or dragging.

5.2. Follow the instructions below in conjunction with the assembly illustration in g.3.

5.3. FITTING

5.3.1. Before tting make sure all vehicle compnents are clean and that the clutch splines have been lightly greased before tting.

5.3.2. Select the required alignment plate ,3 slot (8) or 4 slot (7) see g.2.

5.3.3. Screw in the pressure screw (6) all the way through the required alignment plate, and put to one side for later use, see g.3.

Note: The selection of either the 3 or 4 slotted plate will depend on whether the ywheel has an even or odd number of clutch

assembly retaining bolts.

5.3.4. Select the required adaptor studs, see g.1 (1 to 5) from the kit which depends on the thread size and pitch in the ywheel’s screw

holes.

5.3.5. Select the required adaptor, see g.2 (10 to 29) for the vehicle’s spigot bearing and clutch plate.

5.3.6. Offer up the clutch plate with the adaptor to the engine (making sure the clutch plate is the correct way round).

5.3.7. Offer up the clutch cover assembly, locating it onto the clutch cover dowels. Keep one hand on the assembly because it will be

loose and could fall off.

5.3.8. Fit the adaptor studs from the kit, see g.1 (1 to 5) into the ywheel through the clutch cover retaining holes, alternate holes only

and tighten with a spanner.

5.3.9. The clutch cover should now be secure and aligned onto the ywheel.

5.3.10. Fit the alignment plate (7 or 8) over the adaptor studs and secure using the adaptor stud retainer nuts (9) see gs 2 and 3.

5.3.11. Rotate the pressure screw (6) until it comes into contact with the clutch assembly diaphagm (by hand only).

5.3.12. Double check to make sure all the components are still correctly aligned.

5.3.13. Carefully rotate the pressure screw clockwise (using a socket and ratchet or spanner) to compress the diaphragm on to the clutch

which will pull the clutch cover assembly onto the ywheel.

5.3.14. Once the clutch cover assembly has butted to the ywheel, t the vehicle’s original clutch assembly retaining bolts hand tight.

Once the bolts have been tted, tighten to the manufacturer’s torque.

5.3.15. Unwind the pressure screw (6) anticlockwise which will release the tension.

5.3.16. Once the tension is released, remove the stud retainer nuts (9), alignment plate (7 or 8) and adaptor studs (1 to 5).

5.3.17. Once these have been removed, t the rest of the clutch cover’s retaining bolts and torque to the required setting.

5.3.18. Remove the spigot/clutch adaptor from the centre of the clutch plate. There is a thread in the centre of the adaptor and it may be

necessary to screw a T handle adapter (34) or bolt (32) into the adaptor to be able to remove it. Both are supplied in the kit.

5.4. REMOVAL

5.4.1. To remove the clutch it is the reverse sequence of tting and needs to be done if the clutch assembly is to be reused.

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

VS011A.V3 | Issue 1 19/05/15

Original Language Version

© Jack Sealey Limited