ULTRAVUE FACEPIECE REPAIR

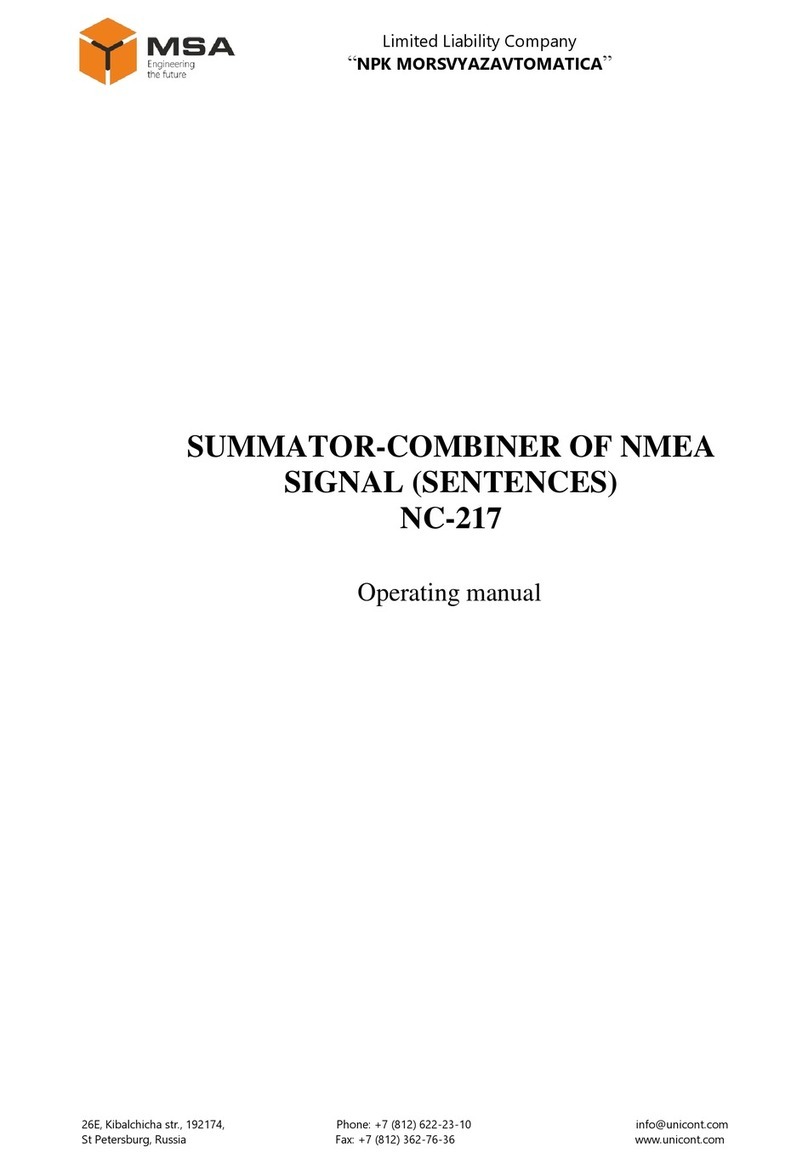

d. The band clamp

must be positioned

so that the screw is

at the 5 or 7 o'clock

position. The screw-

head must be to the

left so that it will not

rub the facepiece

rubber.

e. Tighten the band clamp until the inlet is secured. Be

sure that the band clamp will not pull the facepiece

rubber away from the assembly. Do not over-tight-

en. If the facepiece rubber "bulges" out through the

slots in the clamp, the clamp is too tight and must

be loosened and re-tightened.

3. Don the facepiece and check the face-to-facepiece

seal. Follow the steps in the Facepiece Fit Check.

SPEAKING DIAPHRAGM

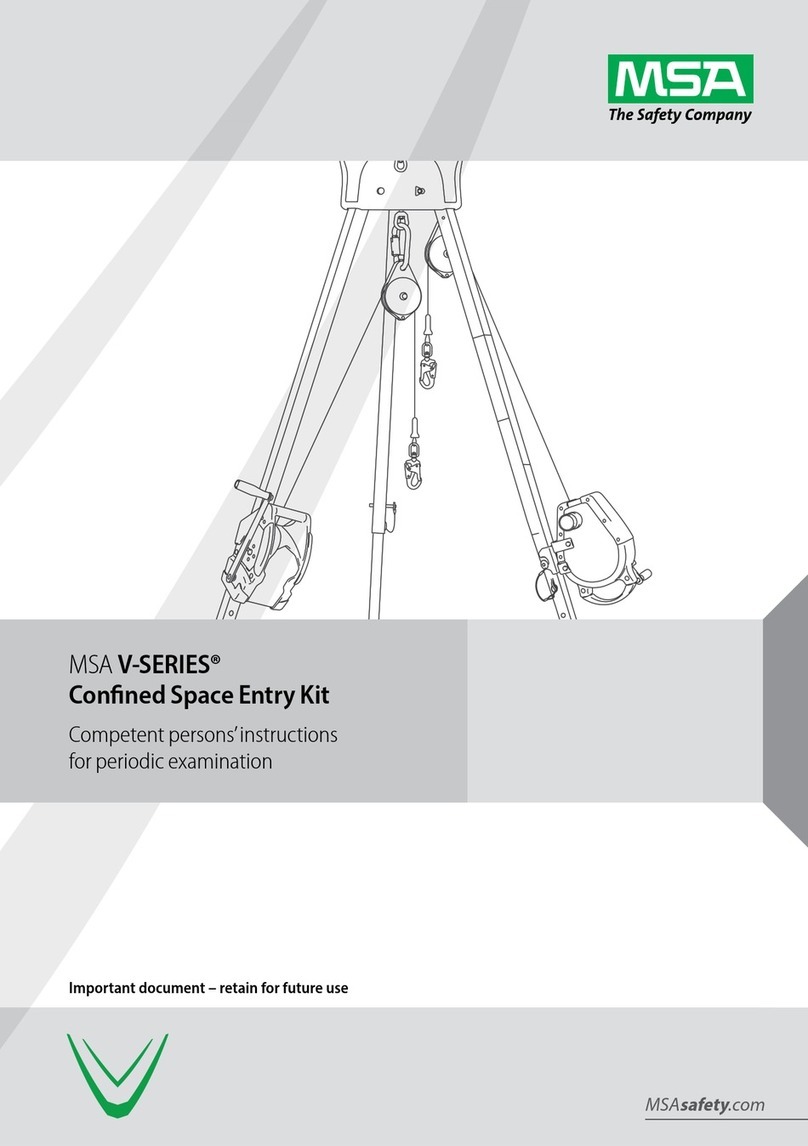

1. Unscrew the retainer

ring, using the face-

piece spanner wrench

(P/N 461828).

2. Turnthe facepiece upside down and shake out the

metal speaking diaphragm.

3. Check the speaking diaphragm for damage. Replace it

if it is wornor damaged.

4. Check the speaking diaphragm gasket or O-ring.

Replace the gasket or O-ring if either is wornor dam-

aged.

The flat gasket (used on old-style facepieces) and the

O-ring (used on the new design) are not interchange-

able. Replace the gasket with the P/N 83630 gasket

only. Replace the O-ring with the P/N 629935 O-ring

only.Failureto follow this warning may cause inhala-

tion of contaminant and result in serious respiratory

injury or death.

5. To reassemble the speaking diaphragm, place the

gasket or o-ring in the groove of the speaking

diaphragm housing.

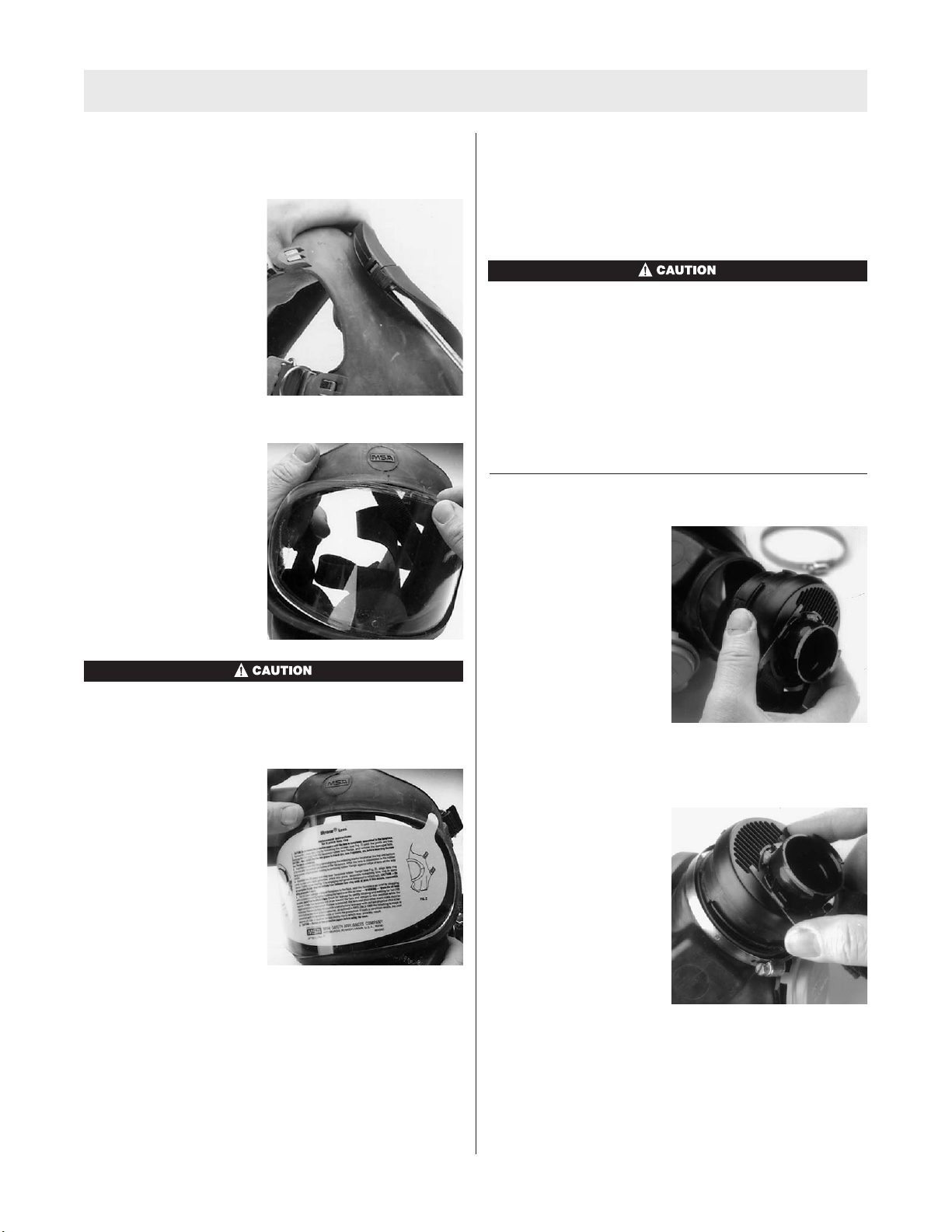

6. Place the speaking

diaphragm in the hous-

ing so that the rolled lip

rests on the gasket or

o-ring.

Be sure that the crimped side of the speaking diaphragm

is facing up (away from the gasket or o-ring).

7. Replace the retainer ring and tighten, using the span-

ner wrench.

8. Don the facepiece and check the face-to-facepiece

seal. Follow the steps in the Facepiece Fit Check.

INHALATION DISC VALVE

1. Use the spanner

wrench (P/N 496317).

Press the adapter slip

nut in. Turnthe wrench

counter-clockwise (left)

to unthread the

adapter.

2. Lift the neckstrap retaining ring off the housing. Note

how the "fingers’’ line up in the housing.

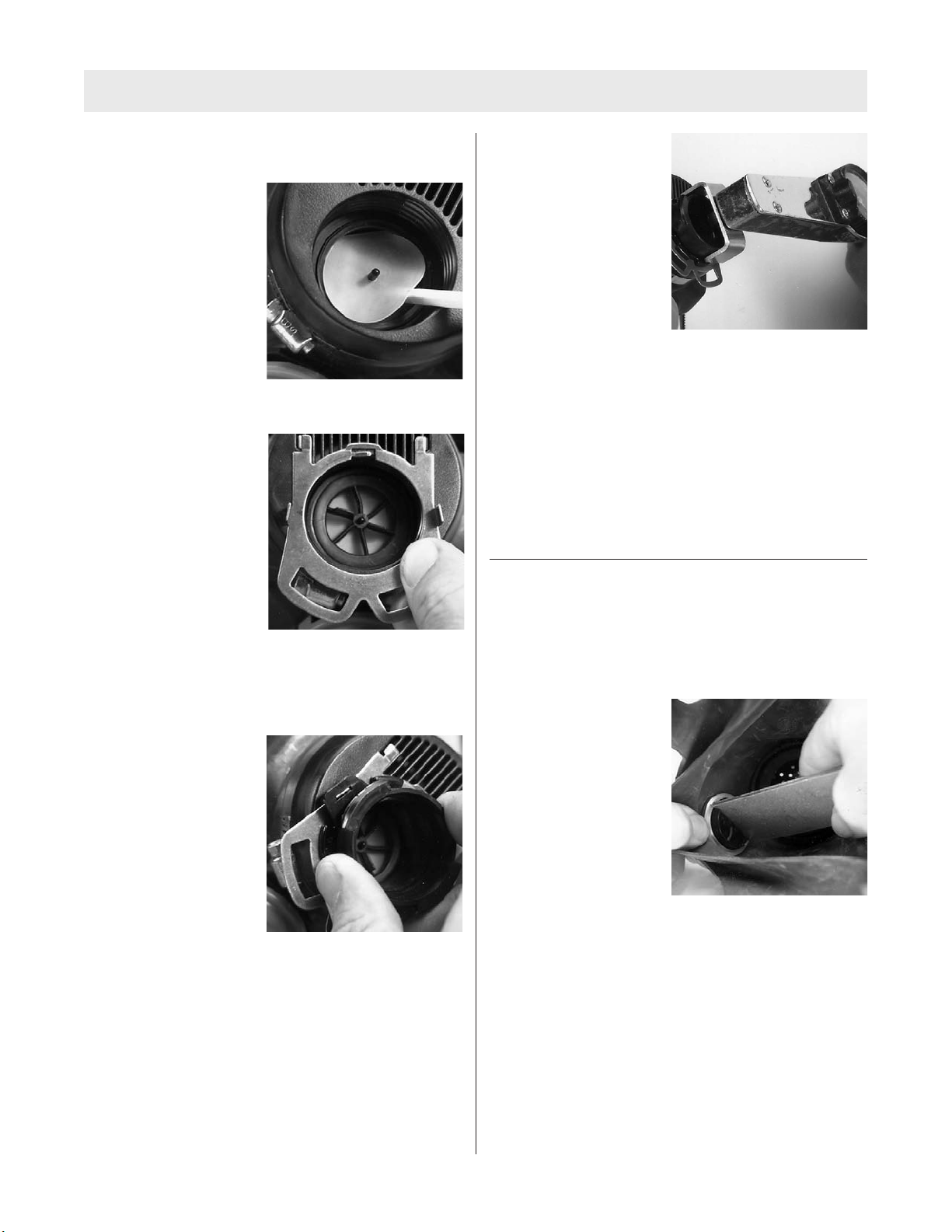

3. Lift the spider gasket

out of the coupling nut

housing by its tab.

4. Remove the valve disc from the coupling nut housing.

If you cannot grasp the disc with your fingers, use a

blunt object, such as a ballpoint pen to lift one edge,

then remove the disc. Be careful not to tear the soft

disc.

5. Inspect the disc for tears or punctures. The disc

should be very soft and pliable. Install a new disc if it

is damaged or hardened.

9TAL 502 (L) Rev. 0 - 10064385