DS938Z Installation Guide © Bosch Security Systems, Inc. 2011 Page 3

7.2 Sensitivity Mode (S2 and S3)

Sensitivity modes depend on the type of coverage desired and the

installation environment.

•Standard Sensitivity: Tolerates environment extremes on this

setting, but requires the largest amount of intruder motion to

achieve an alarm.

•Intermediate Sensitivity: The recommended setting for most

installations. Use in locations where an intruder is expected to

cover only a small portion of the protected area. Tolerates

normal environments on this setting. The detector is shipped

inIntermediateSensitivity mode.

•High Sensitivity: The setting for fast response to intruder

signals. For use only in extremely quiet environments where

ceiling drafts, and thermal and illumination transients are not

anticipated.

If both switches are in the OFF position, the unit will default to the

Intermediate setting.

NOTE: Although the sensitivity modes provide different degrees of

tolerance to environmentally caused alarms, the installer should

assure peak background noise voltage readings do not exceed

±0.15 VDC. (See Section 8.0 Final Tests).

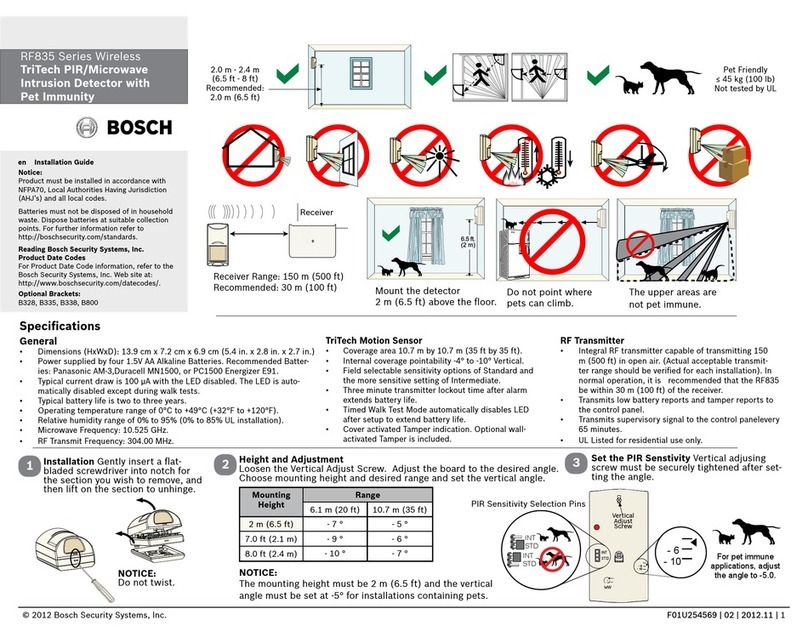

7.3 Motion Monitor (S4 and S5)

Set switches S4 and S5 for the desired Motion Monitor time (see

Section 9.0 Supervision Features). The detector is shipped with

the Motion Monitor feature disabled.

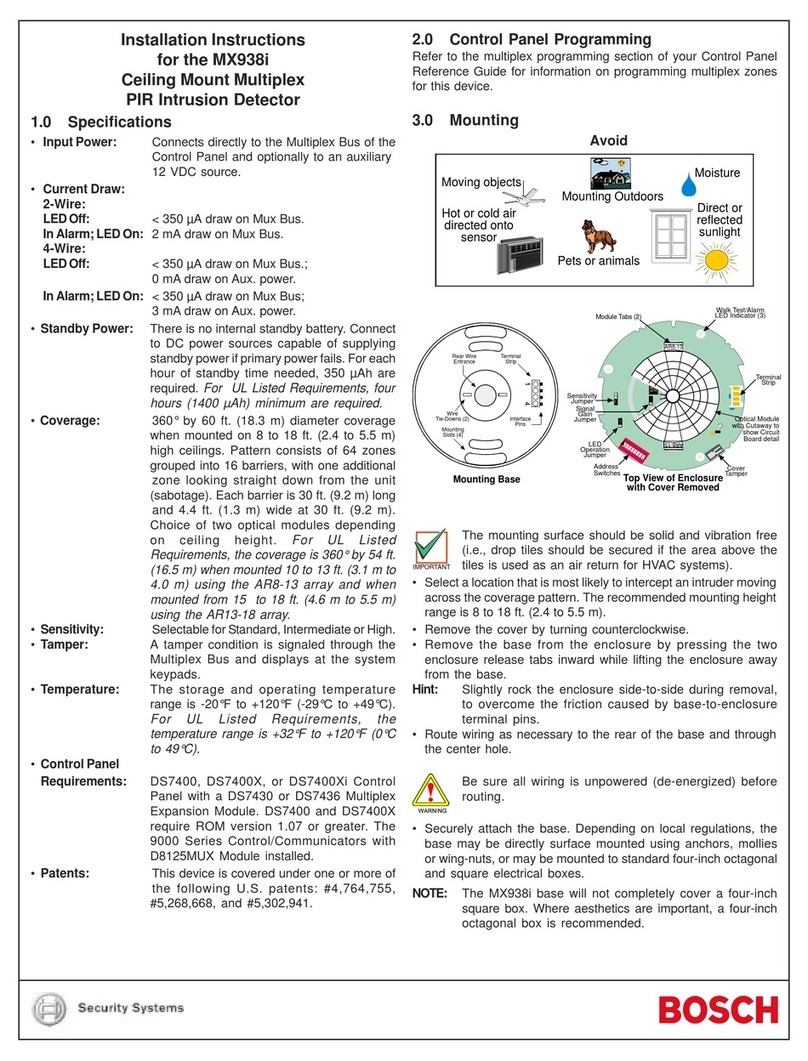

7.4SignalGain

The DS938Z permits selection of the signal gain depending upon

the environment to be protected. The gain select jumper is located

under the optical module.

•High Gain: Recommended for large coverage applications up

to 60 ft. (18.3 m) in diameter. The DS938Z is shipped in this

setting. If the gain select jumper is missing, the unit will default

to High Gain.

•Low Gain: Recommended for applications where the area to

be covered is 40 ft. (12.2 m) or less in diameter and for

applications where High Gain may be too sensitive for

environmental extremes.

NOTE: Setting the DS938Z for Low Gain reduces the coverage area to

40 ft. (12.2 m) in diameter.

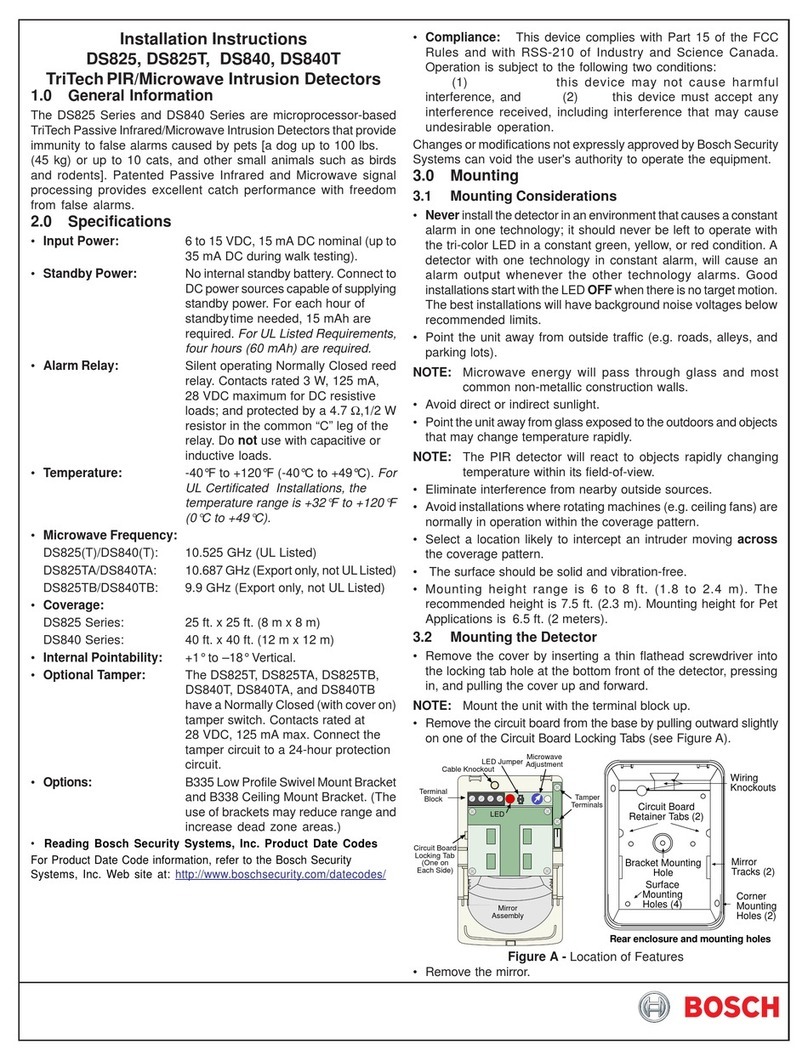

8.0 Setup and Walk Testing

• Attach a TC6000 Test Cord to the Noise Voltage terminals.

Since the outside terminals are common, polarity is not

important and the black lead may be toward or away from the

optical module.

• Attach a Sonalert to the sounder pins at this time if one will be

used during walk testing.

NOTE: The use of a Sonalert type device (sounder) will provide an

audible tone during the time the unit is in alarm. Of the three

available connector pins, the center pin is positive (+) with

respect to either outside pin (outside pins are common (-)).

•Place the cover on the unit, and twist-lock it clockwise into

place.

NOTE: Be sure the TC6000 and Sonalert leads are dressed through the

cutout.

• Apply power to the unit.

•Wait at least two minutes, after applying power, to start walk

tests.

NOTE: Walk testing should be done across the coverage pattern as

shown.

• The edge of the coverage pattern is determined when the Alarm/

Test LED indicator (and optional Sonalert®, if installed) first turns

on.

• Walk test the unit from all directions to determine the

boundaries.

• After completion of the walk tests, remove the Sonalert®(if

installed).

9.0 Final Tests

9.1 Noise Measurement

NOTE: Meter readings are very important in determining background

disturbance levels and catch margin sensitivity.

• Connect a 20,000 ohm/volt (or greater) DC VOM to the Noise

Voltage connector using the TC6000 as shown. Set meter scale

for about 3.0 VDC.

• The base reference level for reading background noise or target

voltages is approximately 2.0 VDC. Installations in quiet

environments, therefore, will result in a steady meter reading

between 1.9 and 2.1 VDC. Look for areas and sources of thermal

disturbances if the meter fluctuates greatly.

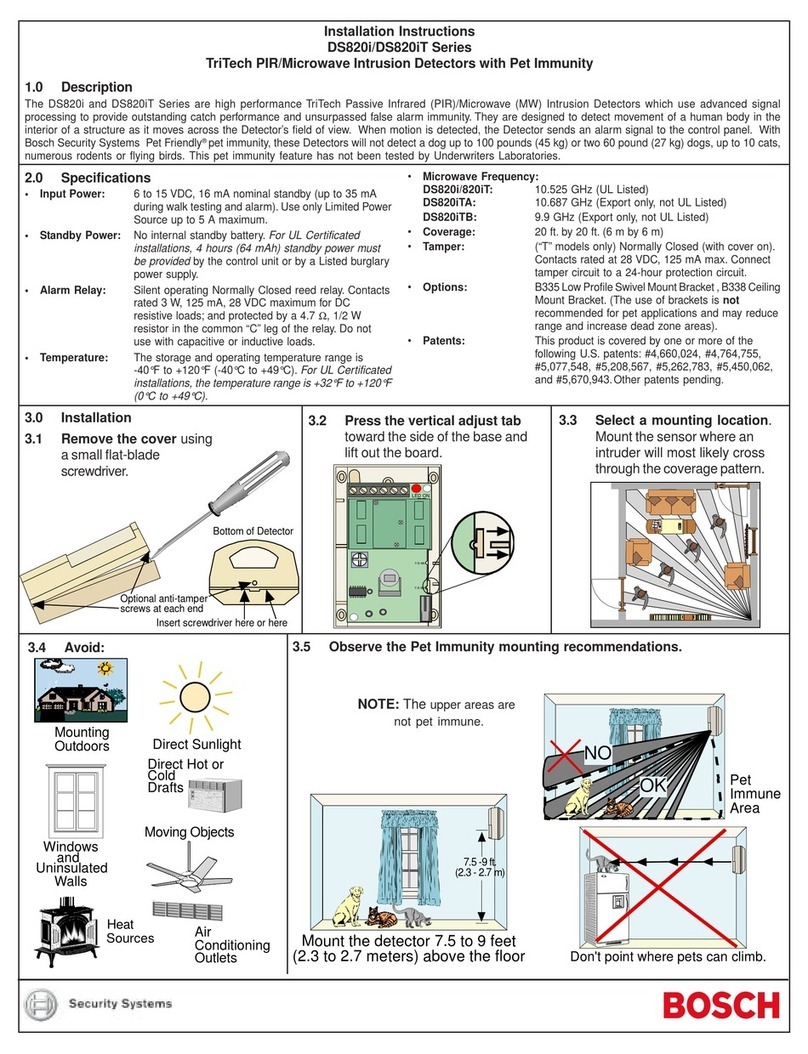

9.2 False Alarm Prevention

• Turn on all heating and cooling sources that would normally be

in operation during times of protection. Stand away from the unit

and outside the coverage pattern, then monitor the background

noise for at least three minutes.

Readings should not deviate from the reference level more than

±0.15 VDC. For readings outside these limits; eliminate the

cause, rotate the unit slightly, or mask out the mirror segment(s)

looking down at the thermal disturbance.

9.3 Coverage Margin

• Again walk across the farthest edge of required coverage.

A minimum voltage change of 1.0 VDC from the reference level is

required in the wintertime when the background temperature is

cool. This will make up for summertime, when the background is

warmer. If testing the unit in the summertime, the minimum

recommended voltage change is 0.75 VDC.

• When testing is completed, remove the TC6000 Test Cord, and

twist-lock the cover into place.

10.0Supervision Features

The DS938Z performs several supervision features that, combined

with the advanced motion detection capabilities of the detector,

provide an extremely high level of security. A supervision trouble

condition is indicated at the detector by the Alarm/Test LED (see

the Supervision Display Chart).

• The LED indicates the cause of the supervision trouble using

coded pulses. The supervision trouble signal activates the

Trouble Output available at terminal 8, which should be

connected to a 24-hour zone.