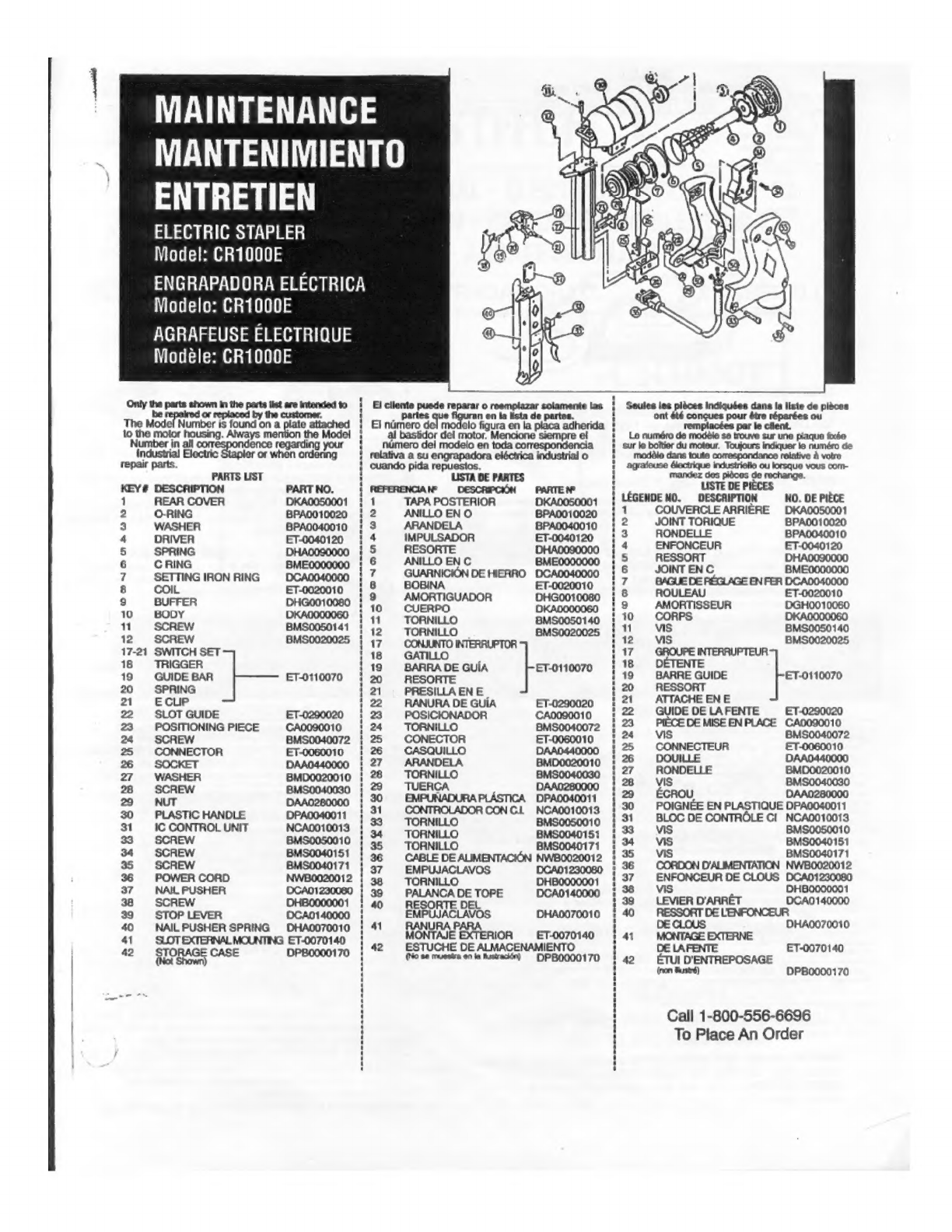

Bostitch CR1000E User manual

Other Bostitch Tools manuals

Bostitch

Bostitch T40 User manual

Bostitch

Bostitch FS32C User manual

Bostitch

Bostitch SB156SX-1-E User manual

Bostitch

Bostitch 216 series User manual

Bostitch

Bostitch 750S4 User manual

Bostitch

Bostitch BT1855SP-A Maintenance and service guide

Bostitch

Bostitch MARK III User manual

Bostitch

Bostitch BT1855 User manual

Bostitch

Bostitch IC50-1-E User manual

Bostitch

Bostitch BTMT72394 User manual

Bostitch

Bostitch BTMT72391 User manual

Bostitch

Bostitch SB-150SX User manual

Bostitch

Bostitch MFN201, MIIIFS, MIIIFN Instruction manual

Bostitch

Bostitch SC73462 Instruction manual

Bostitch

Bostitch D62ADC User manual

Bostitch

Bostitch BTFP71875 User manual

Bostitch

Bostitch SC50HPB-E User manual

Bostitch

Bostitch 438 User manual

Bostitch

Bostitch MCN-KIT2 User manual

Bostitch

Bostitch 750S5 User manual