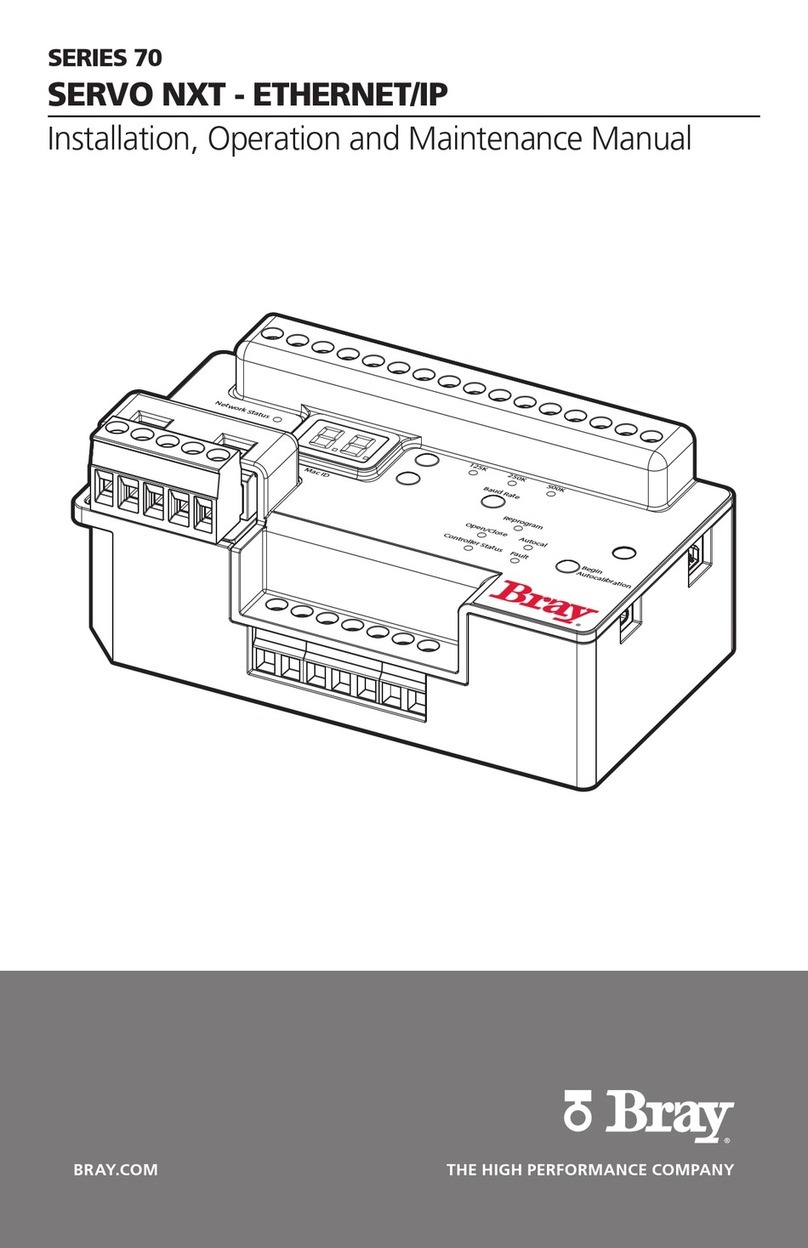

Bray 71 Series User manual

SERIES

ELECTRIC ACTUATOR

Installation Operation and Maintenance Manual

THE HIGH PERFORMANCE COMPANYBRAYCOMMERCIALDIVISION.COM

This Page Intentionally Left Blank

1

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – www.braycommercialdivision.com

Table of Contents

2. DEFINITION OF TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.1. HAZARD-FREE USE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3.2. QUALIFIED PERSONNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

5. PART NUMBERING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. PRINCIPLE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.1. ELECTRICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.2. MECHANICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7. ACTUATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7.1. MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7.2. REMOTE OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

7.2.1. S71 120VAC ON/OFF ACTUATOR WITH INTERPOSING RELAY BOARD . . . . . 6

7.2.2. S71 24V ON/OFF ACTUATOR WITH ON/OFF CONTROLLER . . . . . . . . . . . 8

7.2.3. S71 120VAC MODULATING ACTUATOR WITH S71 SERVO CONTROLLER . . . 10

7.2.4

S71 24V MODULATING ACTUATOR S71 SERVO CONTROLLER. . . . . . . 11

8. STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9. COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.1. MOUNTING THE ACTUATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.2. WIRING THE ACTUATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.3. SETTING TRAVEL LIMIT SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . 14

10. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11. INSTALLABLE OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11.1. HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11.2. SPINNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11.3. RECEPTACLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12. 12.0. APPENDIX A: BASIC TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11. 13.0. APPENDIX B: ACTUATOR TROUBLESHOOTING CHART . . . . . . . . . . . . . 18

12. 14.0. APPENDIX C: ACTUATOR EXPLODED VIEW. . . . . . . . . . . . . . . . . . . . 19

13. 15.0. APPENDIX D: COVER EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . 20

14. 16.0. APPENDIX E: BASE EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . 21

15. 17.0. APPENDIX F: INDICATOR SHAFT EXPLODED VIEW . . . . . . . . . . . . . . . 22

16. 18.0. APPENDIX G: MOTOR EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . 23

2

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

READ AND FOLLOW THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

2.0 DEFINITION OF TERMS

WARNING

Indicates a potentially hazardous situation which if not avoided could result in death

or serious injury

CAUTION

Indicates a potentially hazardous situation which if not avoided may result in minor

or moderate injury

NOTICE

Indicates a potential situation which if not avoided may result in an undesirable result

or state including property damage

3.0 SAFETY

HAZARD FREE USE

This device left the factory in proper condition to be safely installed and

operated in a hazard-free manner. The notes and warnings in this document

must be observed by the user to ensure hazard-free operation of this device.

All necessary precautions need to be taken to prevent damage due to rough

handling, impact, or improper storage. Do not use abrasive compounds to

clean the device, or scrape its surfaces with any objects.

Configuration and setup procedures for this device are described in this

manual. Proper configuration and setup are required for the safe operation of

this device.

The control system in which this device is installed must have proper

safeguards to prevent injury to personnel, or damage to equipment, should a

failure of system components occur.

WARNING

The device generates large mechanical force during normal operation

3

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

3.2 QUALIFIED PERSONNEL

WARNING

The actuator must only be installed commissioned operated and repaired by qualified

personnel

Installation commissioning operation and maintenance must be performed under

strict observation of all applicable codes standards and safety regulations

As per this document, a qualified person is one who is trained in:

The operation and maintenance of electric equipment and systems in

accordance with established safety practices.

Procedures to energize, de-energize, ground, tag and lock electrical circuits

and equipment in accordance with established safety practices.

The proper use and care of personal protective equipment (PPE) in

accordance with established safety practices.

First aid.

4.0 INTRODUCTION

The Bray Series 71 is a quarter turn electric actuator with manual

declutchable override for use on any quarter turn valve or device requiring up

to 531 lbs-in (60 Nm) of torque. Standard operating speed is 30 seconds for

single phase line powered units. Operational speed of 24VAC/DC units are

dependent on torque and supply voltage. All units are rated for 50% duty, 5

minutes max on time.

25

30

35

40

45

50

55

60

21 22 23 24 25 26 27

Quarter Turn Speed [s]

Supply Voltage [V]

24V Speed versus Supply at 531 lb-in [60Nm]

24VAC

24VDC

4

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

5.0 PART NUMBERING SYSTEM - REFERENCE CHART

6.0 PRINCIPLE OF OPERATION

The Series actuator is divided into two internal sections the drive train

below the switch plate and the motor and control center above the switch

plate Below the switch plate the motor drives a system of spur gears

The manual declutch override for manual operation is housed here as well

Above the switch plate is where user required readily accessible components

are placed The indicator shaft assembly limit switches terminals heater

and electronic controllers are all placed here for easy access

External to the unit is a large and easy to read indicator manual declutch

override and dual conduit entry ports The external coating is a high-quality

polyester powder coat which has exceptional UV protection and chemical

resistance

Series – Torque Options – Actuator Control Voltage – Trim

– – D –

Series

Series - QTR Turn

Torque

lbf-in Nm

Options

Standard - Aux Switches

Aux Switches Heater

Mounting and Conduit Control Type Notes

D Imperial ONOFF IRB or Controller

G Imperial Modulating S Servo

N Metric ONOFF IRB or Controller

R Metric Modulating S Servo

Voltage

VAC

VACVDC

VAC

Coating

Red Polyester

5

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

ELECTRICAL OPERATION

The motors used in the Bray Series are of either permanent split capacitor

(PSC) design for single phase line applications or permanent magnet (PM)

design for ACDC power Travel limit switches are mechanical form

(SPDT) with contact rated at A VAC

The PSC motor is designed for impedance protection such that the current

and self-heating will be limited in cases where the torque capacity of

the unit is exceeded to the point where the motor stalls The PM motor

controllers implement self-resetting over-current protection which will also

limit the current and torque capacity of the motor

MECHANICAL OPERATION

Mechanically the ratio of the gearing determines the output speed of

the unit The actuator utilizes high efficiency spur gears Positioning is

determined by an indicatorcam shaft which is linked to the output shaft In

the declutched position the manual override drives the output

7.0 ACTUATION

MANUAL OPERATION

The Bray Series actuators are provided with a declutchable manual

override system To manually operate the actuator push in the manual

override button and rotate the declutchable lever counter-clockwise until it

reaches the o’clock position Once the declutchable lever is in position

turn the handwheel until the valve reaches the required position The motor

does not shutoff during manual operation and will continue to rotate the

upper gearing if being commanded by the process Push in the manual

override button and rotate the declutchable lever clockwise until it reaches

the o’clock position to re-engage the upper gearing and motor drive

Manual Override Button

Manual Override Lever

REMOTE OPERATION

CAUTION

Verify that the main electric power supplied to the actuator is in compliance with

the specifications on the actuator label

Engaging the handwheel before or during the application of a supply voltage will

prevent the actuator motor from driving the valve to the position commanded by

the process

6

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

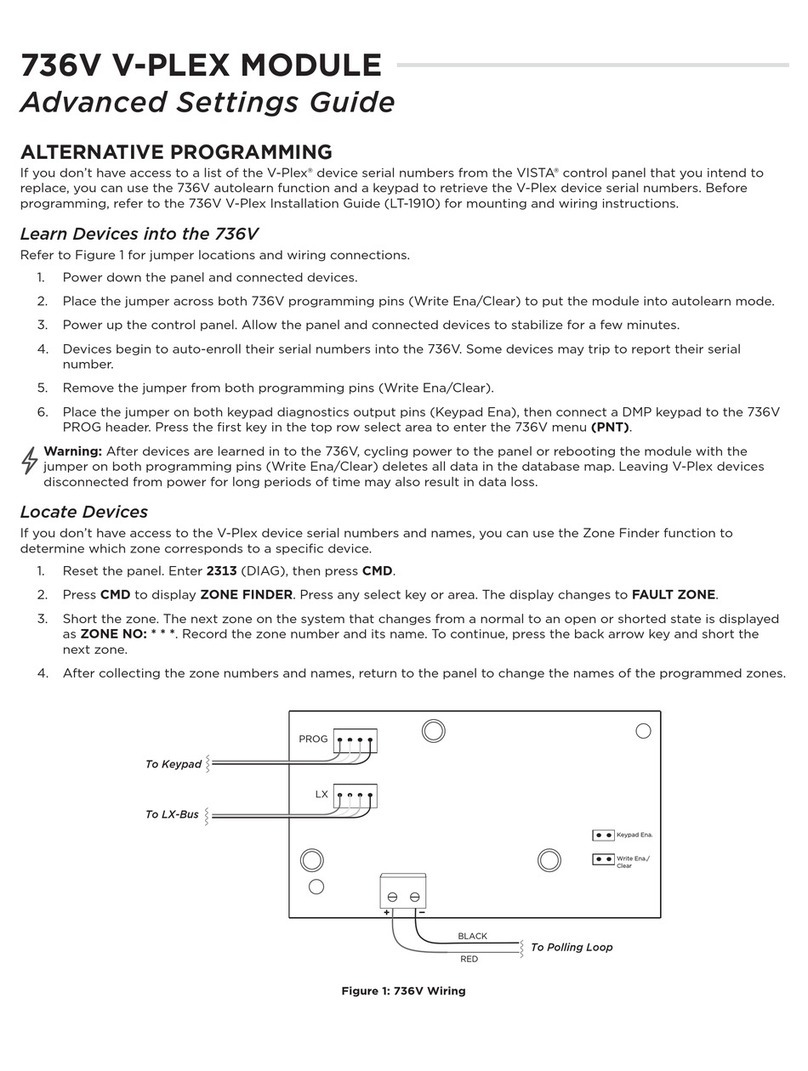

S VAC ONOFF ACTUATOR WITH INTERPOSING RELAY BOARD

The back feeding of one actuator by another one wired in parallel is

eliminated by using the S IRB If the actuator is running Open and the

customer switches “instantaneously” to run Closed the Open relay will take

time to “drop-out” and the Close relay will take time to “pull-in” This time

lapse is ~ms The time delay provided by the S IRB will protect the

switches and gears from the controller’s instantaneous command signal

reversal Current draw and field wiring are not affected by the IRB

NOTE The host controller should use a one second time delay for command

signal reversal

CAUTION

Apply voltage to only one direction terminal at a time

WD-000545

NOTES:

1. HEATER IS OPTIONAL.

2. HEATER LIVE CONNECTION IS REQUIRED WHEN A HEATER IS INSTALLED.

3. AUXILIARY SWITCHES ARE VOLTAGE FREE, RATED FOR 3A, 125/250VAC.

4. AUXILIARY SIGNAL OUT IS SAME VOLTAGE AS AUXILIARY SIGNAL IN.

5. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

6. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

FIELD TERMINALS

·14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·PUSH BUTTON CLAMP

·105 °C, 300V MIN RATED WIRE

·STRIP WIRE: .39"-.43" [10-11mm]

·GROUND WIRE GAUGE TO BE EQUAL TO LARGEST SUPPLY CONDUCTOR.

7

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

S VAC ONOFF ACTUATOR WITH INTERPOSING RELAY BOARD

S VAC ONOFF ACTUATOR WITH INTERPOSING RELAY ASSEMBLY

8

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

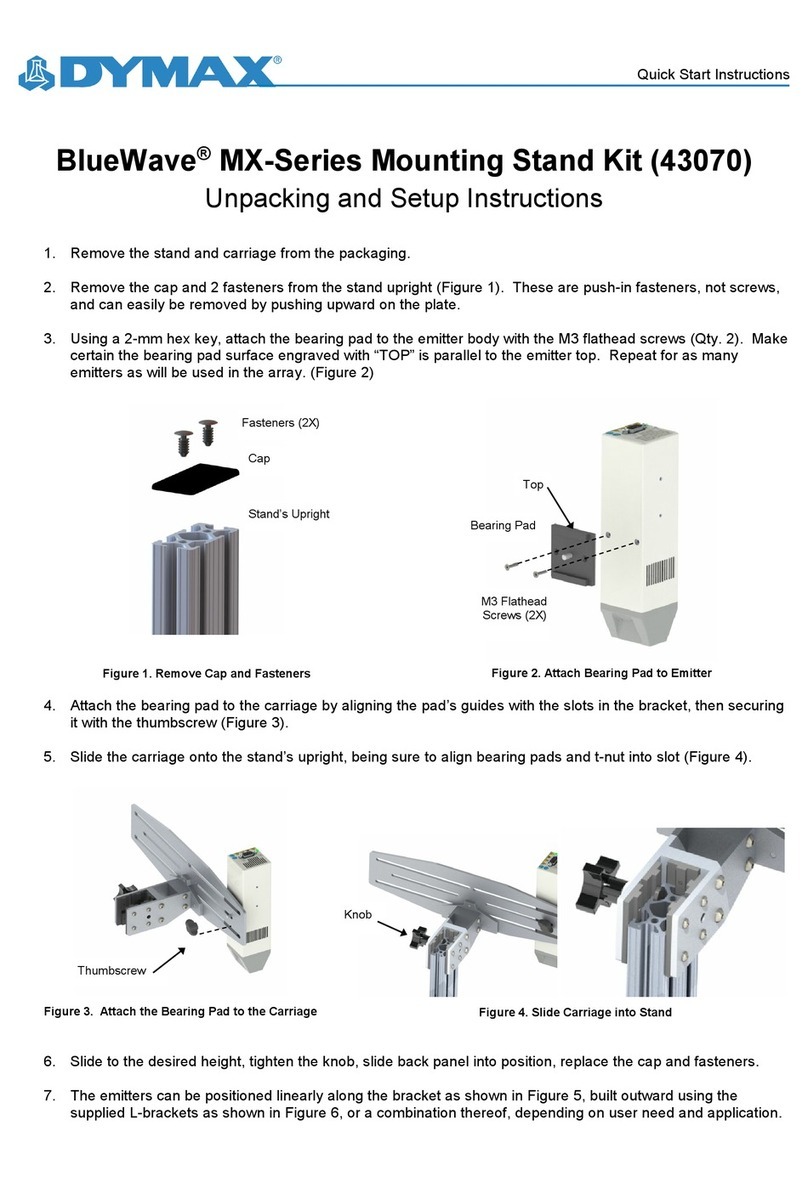

S V ONOFF ACTUATOR WITH ONOFF CONTROLLER

Whether supplying AC or DC power the V OnOff Controller provides

a reference direction signal and DC power to an H-bridge to power and

control motor direction The controller will handle instantaneous switching

of the command signal and enforce a short timing delay In the case of a

control fault where both directions are commanded at once the controller

will stop actuator movement In the case of an over torque fault the

H-bridge is also configured to limit max current which will effectively lock

the rotor

CAUTION

Apply voltage to only one direction terminal at a time

WD-000544

NOTES: FIELD TERMINALS

·14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·PUSH BUTTON CLAMP

·105 °C, 300V MIN RATED WIRE

·STRIP WIRE: .39"-.43" [10-11mm]

·

GROUND WIRE GAUGE TO BE EQUAL TO LARGEST SUPPLY CONDUCTOR.

1. HEATER IS OPTIONAL.

2. AUXILIARY SWITCHES ARE VOLTAGE FREE, RATED FOR 3A, 125/250VAC.

3. AUXILIARY SIGNAL OUT IS SAME VOLTAGE AS AUXILIARY SIGNAL IN.

4. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

5. IF USING VAC POWER SUPPLY, SUPPLY TO BE RATED 100VA, CLASS 2

6. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

SERIES 71

9

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

S VAC ONOFF ACTUATOR WITH ONOFF CONTROLLER BOARD

S VAC ONOFF ACTUATOR WITH ONOFF CONTROLLER ASSEMBLY

10

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

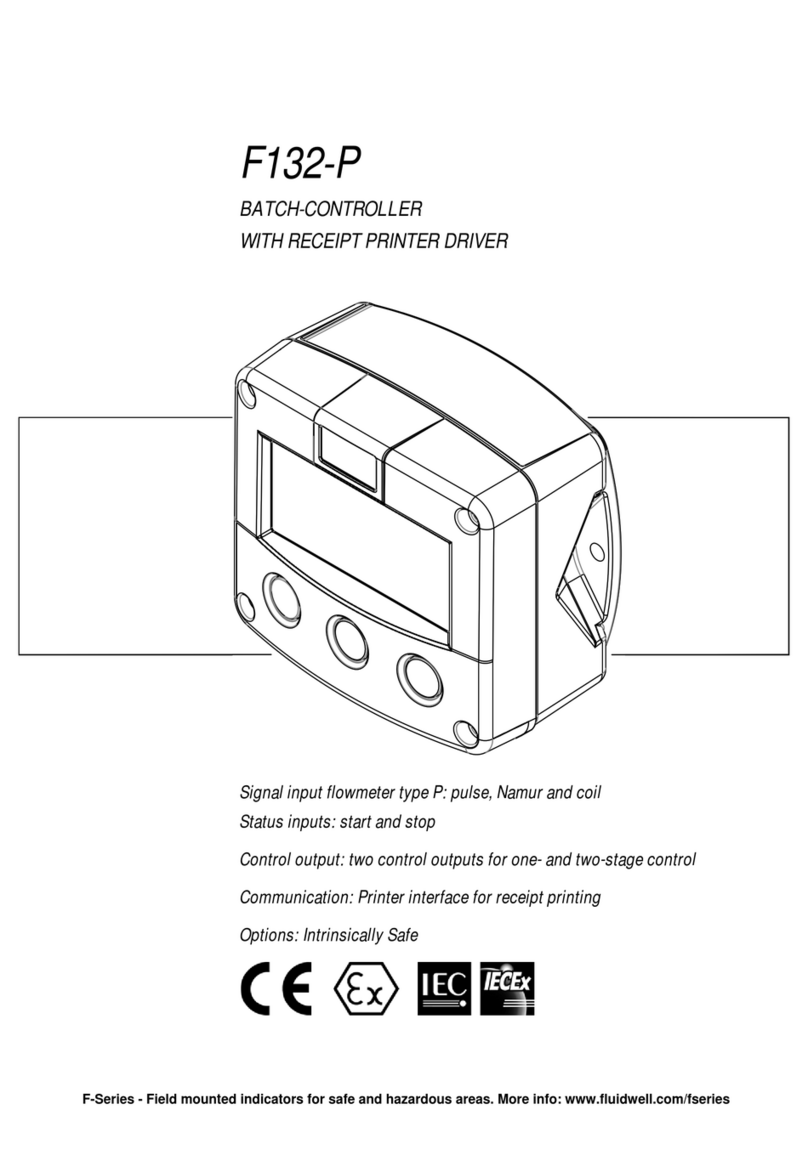

S VAC MODULATING ACTUATOR S SERVO CONTROLLER

Power connection that energizes the S Servo and powers the actuator

under control The voltage supplied should be based on the actuator

nameplate voltage and the voltage listed on the S Servo label

The S Servo has an onboard protective fuse that is in line with the input

power connection This protective fuse is rated for A

See S Servo Manual at braycommercialcom for more details

To control the actuator remotely from a process controller in a modulating

application the user must apply the proper supply voltage and the

configured control signal to the S Servo electronics package The control

signal may be applied locally from a hand-held signal generator or remotely

from a process controller

In the case of an over torque fault the electronics are configured to limit

max current which will effectively lock the rotor

For more information please refer to the S S Servo Manual This manual

is available on the company website (wwwbraycommercialdivisioncom)

Xref C:\BII_Vault\Global\Templates\ACAD\LogoBrayControls1.dwg Xref C:\BII_Vault\Global\Templates\ACAD\LogoBrayControls1.dwg

WD-000579

------

BUSA

S71

120/230V S71 SERVO

AND HEATER (OPTIONAL)

1

NOT RELEASED - DO NOT MANUFACTURE

WD-000579

------

BUSA

S71

120/230V S71 SERVO

AND HEATER (OPTIONAL)

1

NOT RELEASED - DO NOT MANUFACTURE

120/230V

S71 SERVO

(SEE NOTES 7-9)

(SEE NOTES 8-11)

INPUT (+)

INPUT (-)

OUTPUT(+)

OUTPUT(-)

SIGNAL

LIVE

NEUTRAL

POWER

120/230V S71

SERVO

(SEE NOTES 7-9)

(SEE NOTES 8-11)

INPUT (+)

INPUT (-)

OUTPUT(+)

OUTPUT(-)

SIGNAL

LIVE

NEUTRAL

POWER

LIMIT

OPEN

LIMIT

CLOSE

LIMIT CLOSE

POT WIPER

POT COM

LIMIT

OPEN

POT V+

LIVE

NEUTRAL

MOTOR

MOTOR CL

NEUTRAL

CAP

CLOSE

MOTOR OP

CAPACITOR

CAP

OPEN

HEATER

NOTES:

1. HEATER IS OPTIONAL.

2. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

3. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

4. WHEN USING 0-10VDC MODE,THE COMMON OF THE COMMAND SIGNAL

SHOULD NOT BE GROUND/EARTH REFERENCED.

5. COMMAND SIGNAL AND FEEDBACK SIGNAL MUST BE ISOLATED FROM EACH

OTHER AND ANY OTHER CIRCUITS.

6. COMMAND SIGNAL & FEEDBACK SIGNAL WIRES SHOULD BE SHIELDED

PROPERLY & SHIELD SHOULD BE GROUNDED/EARTHED ON ONE END ONLY,

PREFERABLYTHE CONTROLLER END.

7. FEEDBACK LOOP IS POWERED BY THE SERVO, DO NOT SUPPLY

EXTERNAL POWER.

8. POSITION FEEDBACK DEVICE LOAD IS NOT TO EXCEED 400 OHMS IN

THE 4-20mA CONFIGURATION.

HEATER

(OPTIONAL)

CAM

#4

N.O.

COM N.C.

CAM

#3

N.O.

COM N.C.

CAM

#2

N.O.

COM N.C.

CLOSE

CAM

#1

N.O.

COM N.C.

OPEN

AUX

CLOSE

AUX

OPEN

SWITCH PCB

ACTUATOR

FIELD WIRING

GROUND

NEUTRAL

LIVE

-

+

-

+

POSITION

FEEDBACK

DEVICE

OUTGOING FEEDBACK

SIGNAL (SHIELDED)

COMMAND

SIGNAL

DEVICE

INCOMING COMMAND

SIGNAL (SHIELDED)

CALIBRATION SEQUENCE:

1. CONNECT POWER SUPPLY.

2. SET INPUT AND OUTPUT SIGNAL MODES.

3. CALIBRATETHE INPUT SIGNAL.

·DISCONNECT ALL SIGNAL WIRES FROM INPUT(+)/(-).

·FOR 0-10V, 0-5V, AND 2-10V MODES, SHORT INPUT

(+) TO INPUT (-).

·PRESS THE "CALIBRATE" BUTTON FOR 2 SECONDS.

·IMMEDIATELY PRESS THE INPUT SIGNAL BUTTON.

4. RE-ATTACH THE INPUT SIGNAL WIRES.

5. PRESS THE "CALIBRATE" BUTTON FOR TWO SECONDS.

6. ACTUATOR WILL SELF-CALIBRATE.

TERMINALS - ELECTRONICS

·14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·PUSH BUTTON CLAMP

·105 °C, 300V MIN RATEDWIRE

·STRIP WIRE: .39"-.43" [10-11mm]

·GROUND WIRE GAUGETO BE EQUALTO LARGEST

SUPPLY CONDUCTOR.

FEEDBACK

POTENTIOMETER

POT PCB

GROUND

NEUTRAL

LIVE

-

+

-

+

POSITION

FEEDBACK

DEVICE

COMMAND

SIGNAL

DEVICE

ACTUATOR

WD-000579 REV 1

FIELD

WIRING

CALIBRATION SEQUENCE:

1. CONNECT POWER SUPPLY.

2. SET INPUT AND OUTPUT SIGNAL MODES.

3. CALIBRATETHE INPUT SIGNAL.

·DISCONNECT ALL SIGNAL WIRES FROM INPUT(+)/(-).

·FOR 0-10V, 0-5V, AND 2-10V MODES, SHORT INPUT

(+) TO INPUT (-).

·PRESS THE "CALIBRATE" BUTTON FOR 2 SECONDS.

·IMMEDIATELY PRESS THE INPUT SIGNAL BUTTON.

4. RE-ATTACH THE INPUT SIGNAL WIRES.

5. PRESS THE "CALIBRATE" BUTTON FOR TWO SECONDS.

6. ACTUATOR WILL AUTOMATICALLY COMPLETE

SELF-CALIBRATION.

FIELD CONNECTIONS:

14-24 AWG, 18 AWG

RECOMMENDED

105 °C, 300V MIN

RATED WIRE.

STRIP WIRE: .39"-

.43" [10-11mm]

GROUND WIRE GAUGE

TO BE EQUALTO

LARGEST SUPPLY

CONDUCTOR.

O C

BLACK

BLACK

BLACK

RED

GREY

BLUE

RED

WHITE

BLACK

NOTES:

1. HEATER IS OPTIONAL.

2. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

3. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

4. WHEN USING 0-10VDC MODE,THE COMMON OF THE COMMAND SIGNAL

SHOULD NOT BE GROUND/EARTH REFERENCED.

5. COMMAND SIGNAL AND FEEDBACK SIGNAL MUST BE ISOLATED FROM EACH

OTHER AND ANY OTHER CIRCUITS.

6. COMMAND SIGNAL & FEEDBACK SIGNAL WIRES SHOULD BE SHIELDED

PROPERLY & SHIELD SHOULD BE GROUNDED/EARTHED ON ONE END ONLY,

PREFERABLYTHE CONTROLLER END.

7. FEEDBACK LOOP IS POWERED BY THE SERVO, DO NOT SUPPLY

EXTERNAL POWER.

8. POSITION FEEDBACK DEVICE LOAD IS NOT TO EXCEED 400 OHMS IN

THE 4-20mA CONFIGURATION.

N

OC

GREY

BLACK

WHITE

MOTOR

6W

2

3

1

4

TERMINALS - AUX

·12-22 AWG MAX RANGE, 18

AWG RECOMMENDED

·SCREW CLAMP WITH WIRE

PROTECTOR

·105 °C, 300V MIN RATEDWIRE

·TORQUE SCREW TO 5.5 IN-LBS

·STRIP WIRE: .177"-.217"

[4.5-5.5mm]

TERMINALS - ELECTRONICS

·14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·PUSH BUTTON CLAMP

·105 °C, 300V MIN RATEDWIRE

·STRIP WIRE: .39"-.43" [10-11mm]

·GROUND WIRE GAUGETO BE EQUALTO LARGEST

SUPPLY CONDUCTOR.

TERMINALS - AUX

·12-22 AWG MAX RANGE, 18

AWG RECOMMENDED

·SCREW CLAMP WITH WIRE

PROTECTOR

·105 °C, 300V MIN RATEDWIRE

·TORQUE SCREW TO 5.5 IN-LBS

·STRIP WIRE: .177"-.217"

[4.5-5.5mm]

AUX OPEN

AUX CLOSE

AUX COM

11

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

WD-000543

NOTES:

1. HEATER IS OPTIONAL.

2. AUXILIARY SWITCHES ARE VOLTAGE FREE, RATED FOR 3A, 125/250VAC.

3. AUXILIARY SIGNAL OUT IS SAME VOLTAGE AS AUXILIARY SIGNAL IN.

4. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

5. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

6. IF USING VAC POWER SUPPLY, TO BE RATED 100VA, CLASS 2.

7. WHEN USING 0-10VDC MODE, THE COMMON OF THE COMMAND SIGNAL

SHOULD NOT BE GROUND/EARTH REFERENCED.

8. COMMAND SIGNAL AND FEEDBACK SIGNAL MUST BE ISOLATED FROM EACH

OTHER AND ANY OTHER CIRCUITS.

9. COMMAND SIGNAL & FEEDBACK SIGNAL WIRES SHOULD BE SHIELDED

PROPERLY & SHIELD SHOULD BE GROUNDED/EARTHED ON ONE END ONLY,

PREFERABLY THE CONTROLLER END.

10. FEEDBACK LOOP IS POWERED BY THE SERVO, DO NOT SUPPLY

EXTERNAL POWER.

11. POSITION FEEDBACK DEVICE LOAD IS NOT TO EXCEED 400 OHMS IN

THE 4-20mA CONFIGURATION.

CALIBRATION SEQUENCE:

1. CONNECT POWER SUPPLY.

2. SET INPUT AND OUTPUT SIGNAL MODES.

3. CALIBRATE THE INPUT SIGNAL.

·DISCONNECT ALL SIGNAL WIRES FROM INPUT(+)/(-).

·FOR 0-10V, 0-5V, AND 2-10V MODES, SHORT INPUT

(+) TO INPUT (-).

·PRESS THE "CALIBRATE" BUTTON FOR 2 SECONDS.

·IMMEDIATELY PRESS THE INPUT SIGNAL BUTTON.

4. RE-ATTACH THE INPUT SIGNAL WIRES.

5. PRESS THE "CALIBRATE" BUTTON FOR TWO SECONDS.

6. ACTUATOR WILL SELF-CALIBRATE.

FIELD TERMINALS

·

14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·

PUSH BUTTON CLAMP

·

105 °C, 300V MIN RATED WIRE

·

STRIP WIRE: .39"-.43" [10-11mm]

·

GROUND WIRE GAUGE TO BE EQUAL TO LARGEST

SUPPLY CONDUCTOR.

SERVO 71

S V MODULATING ACTUATOR S SERVO CONTROLLER

Power connection that energizes the S Servo and powers the actuator

under control The voltage supplied should be based on the actuator

nameplate voltage and the voltage listed on the S Servo label

The S Servo has an onboard protective fuse that is in line with the input

power connection This protective fuse is rated for A

See S Servo Manual at braycommercialcom for more details

To control the actuator remotely from a process controller in a modulating

application the user must apply the proper supply voltage and the

configured control signal to the S Servo electronics package The control

signal may be applied locally from a hand-held signal generator or remotely

from a process controller

The V S Servo may be powered from either VDC or a VAC VA

Class power supply In the case of an over torque fault the electronics are

configured to limit max current which will effectively lock the rotor

For more information please refer to the S Servo Manual This manual is

available on the company website (wwwbraycommercialdivisioncom)

12

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

S VAC MODULATING ACTUATOR WITH SEVRO S BOARD

S VAC MODULATING ACTUATOR WITH S SERVO ASSEMBLY

13

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

8.0 STORAGE

WARNING

Actuators are not weatherproof unless they are properly installed on the valve or

prepared for storage Bray cannot accept responsibility for deterioration caused

on-site

Store units on a shelf or wooden pallet in order to protect against floor

dampness

Cover the units to protect against dust and dirt

To prevent condensation from forming inside these units maintain a near

constant external temperature and store in a well-ventilated clean dry room

away from vibration

For units with an internal heater power should be supplied to the heater via

conduit entry with an appropriate sealing gland

9.0 COMMISSIONING

MOUNTING THE ACTUATOR

All Bray Series electric actuators are suitable for direct mounting on Bray

valves With proper mounting hardware the S actuator can be installed

onto other quarter-turn valves or devices

NOTICE

• The standard mounting position for the actuator orients the unit with its handwheel

in a vertical plane and parallel to the pipeline

• If the actuator is mounted on a vertical pipe it is recommended that the unit be

positioned with the conduit entries on the bottom to prevent condensation from

entering the actuator through its conduits

• In all cases the conduit should be positioned to prevent drainage into the actuator

X

X X

Follow the steps below to mount the actuator onto the valve.

•

Manually operate the actuator until the output shaft of the actuator is in line with the

valve stem. If possible, select an intermediate position for both the valve and actuator.

• If required, place the proper adapter onto the valve stem. It is recommended that a

small amount of ‘anti-seize’ lubricant be applied to the adapter to ease assembly.

• Mount the actuator onto the valve stem.

• Install the furnished mounting studs by threading studs all the way into the actuator

base. It may be necessary to manually operate the actuator to align the valve and

actuator bolt patterns.

• Fasten the mounting studs in place with furnished hex nuts and lock washers.

14

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

WIRING THE ACTUATOR

WARNING

Turn off all power and lockouttag out service panel before installing or modifying any

electrical wiring

SETTING TRAVEL LIMIT SWITCHES

WARNING

• Ensure a ground wire is attached to one of the two ground wire locations and

follow proper grounding techniques as required by applicable codes standards and

safety regulations

Standard factory setting of the travel limit switches allows 90° travel between open and

close positions. Cams for each switch are adjustable for applications where less than

90-degree travel is desired between the open and closed positions.

.

•

Manually operate the actuator to the closed position.

• Using a hex key, loosen the set screw on the Close limit switch cam.

• Adjust the cam until it activates the limit switch. The limit switch will “click” when

activated.

• Tighten the set screw.

• Adjust the Closed auxiliary switch such that it advances slightly past the closed limit

switch.

• Repeat in the open position with the open cams.

• Take the actuator cover o. The cover should be kept on hand for reference.

•

Wire the actuator as per the wiring diagram attached to the inside of the actuator cover.

NOTICE

• Power and control wiring should use separate conduit entries

• A minimum of AWG wire is recommended for all field wiring

• Field wiring terminals are push button type with wire clamps and can accept wire

gauge from to AWG

• Wires to be stripped - [-mm]

• The conduit connections must be properly sealed to maintain the weather proof

integrity of the actuator enclosure

• Only one wire is allowed per terminal entry

NOTICE

If the unit came assembled to a valve the switches have been factory-set and

DO NOT need adjustment

15

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

11.0 INSTALLABLE OPTIONS

HEATER

Bray offers an optional heater as a factory installable option for the Series

actuator to prevent condensation from forming inside the actuator

Units with OnOff actuation use a positive temperature coefficient (PTC)

style heater which has a unique temperature – resistance characteristic The

heater self-regulates by increasing its electrical resistance relative to the

internal temperature The heater does not require external thermostats or

switches to control its heat output VACVAC OnOff units require

dedicated live to power the heater

Modulating units use a resistive element controlled by an on-board

thermostat

NOTICE

The heater must have a constant power supply to be effective

WARNING

The heater surface can reach temperatures in excess of F (C)

10.0 MAINTENANCE

While the S has been designed for minimal maintenance requirements it

is suggested that an operator dustclean the unitreview operation every

months cycles or as required by the required site maintenance plan

WARNING

In the case of disassembly ensure that all mechanical forces that could affect

the position of the quarter turn device are removed prior to loosening of the S

mounting bolts

CAUTION

Before re-installing the cover

• Ensure that there is no dirt or debris on the cover seal and mating surfaces

• Ensure that the cover seal is in place and not damaged

16

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

SPINNER

A spinner is field installable attachment to the actuator handwheel to ease

and speed the manual operation of the Series actuator Spinners are

provided with each actuator

RECEPTACLES

Bray offers plug-in receptacles as a field or factory option for quick and easy

field wiring of Series actuators Cord sets to fit these connectors can also

be ordered in several lengths Unless otherwise specified power receptacles

will be -pin mini style standard duty with a black anodized aluminum

finish They conform to ANSI BM except in wire color Euro receptacles

will be used for low power instrument and signal cable since they can be

supplied shielded Wiring diagrams for plug-in receptacles will be provided

as a separate diagram Units ordered with pin connector receptacles factory

installed are wired and tested

Receptacle Kit:

• Receptacle(s), male pin and male thread.

• NPT (M20), in the quantity, style, and number of pins ordered.

Tools Required:

• Wrench, 1" (25mm)

Installation Procedure:

• Screw the receptacle into the activator conduit entry using Teflon tape or similar.

• Wire to the terminal strip according to the wiring diagram or the field wiring requirements.

NOTES:

• Euro receptacles use 22 AWG wire rated at 250V, 4 Amp. Pin configuration interfaces

with European standards.

• Mini Receptacles use 18 AWG wire rated at 300V, 9 Amp. Pin configuration conforms

to ANSI B93.55M.

• Factory will need the model of the existing unit if it is to be retrofit with receptacles.

17

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

12.0 APPENDIX A: BASIC TOOLS

COMPONENT SIZE QTY REFERENCE TOOL TORQUE

Cover Bolt M Appendix D

Item Hex Key mm - in-lbs

[- Nm]

Indicator Dome Screws M Appendix D

Item Hex Socket mm in-lbs

[Nm]

Motor Screws M Appendix G

Item Hex Key mm - in-lbs

[- Nm]

Ground Screw Internal M Appendix E

Item Hex Key mm - in-lbs

[- Nm]

Ground Screw External M Appendix E

Item Hex Key mm - in-lbs

[- Nm]

Switch PCB Mounting

Screws M Appendix F

Item Phillips - in-lbs

[- Nm]

PCB Guard Mounting

Screw M Appendix F

Item Hex Key mm - in-lbs

[- Nm

Capacitor Mounting

Screw M Appendix E

Item Hex Key mm - in-lbs

[- Nm

Cam Set Screws M Appendix E

Item Hex Key mm - in-lbs

[- Nm

Indicator Shaft Gear Set

Screw M Appendix E

Item Hex Key mm - in-lbs

[- Nm

Potentiometer Set Screw M Appendix F

Item Hex Key mm - in-lbs

[- Nm

18

Series 71 – Electric Actuator

Installation, Operation and Maintenance Manual

13.0 APPENDIX B: ACTUATOR TROUBLESHOOTING CHART

Actuator does not operate Wiring is incorrect Check wiring and power

supply

Actuator operates in

reverse directions Field wiring is reversed Rewire field wiring

Actuator does not fully

close valve (or open valve)

Limit switches are

depressed

Readjust travel limit

switches

Valve torque requirement

is higher than actuator

output

Readjust travel limit

switches

Voltage power supply is

low Check power source

Motor runs but output

gear does not rotate Override is engaged Rotate lever CCW to the

oclock position

Corrosion inside unit

Condensation forming Test heater wiring should

have constant power

Water leaking in

Check all seals and

possible water entry

through conduit

No power available to

actuator Tripped circuit breaker Reset circuit breaker after

remove the cause of trip

Manual Override hard to

turn Jammed valve Refer to valve maintenance

Manual Override will not

operate valve

Stripped gearing Replace as necessary

Broken hand wheel shaft Replace as necessary

Broken valve stem Repair or replace as

necessary

Motor runs but will not

operate valve Stripped gearing Replace as necessary

Table of contents

Other Bray Controllers manuals

Bray

Bray 98 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray GAS Series User manual

Bray

Bray PA(M)24-27 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 73 Series User manual

Bray

Bray Series 70 User manual