12

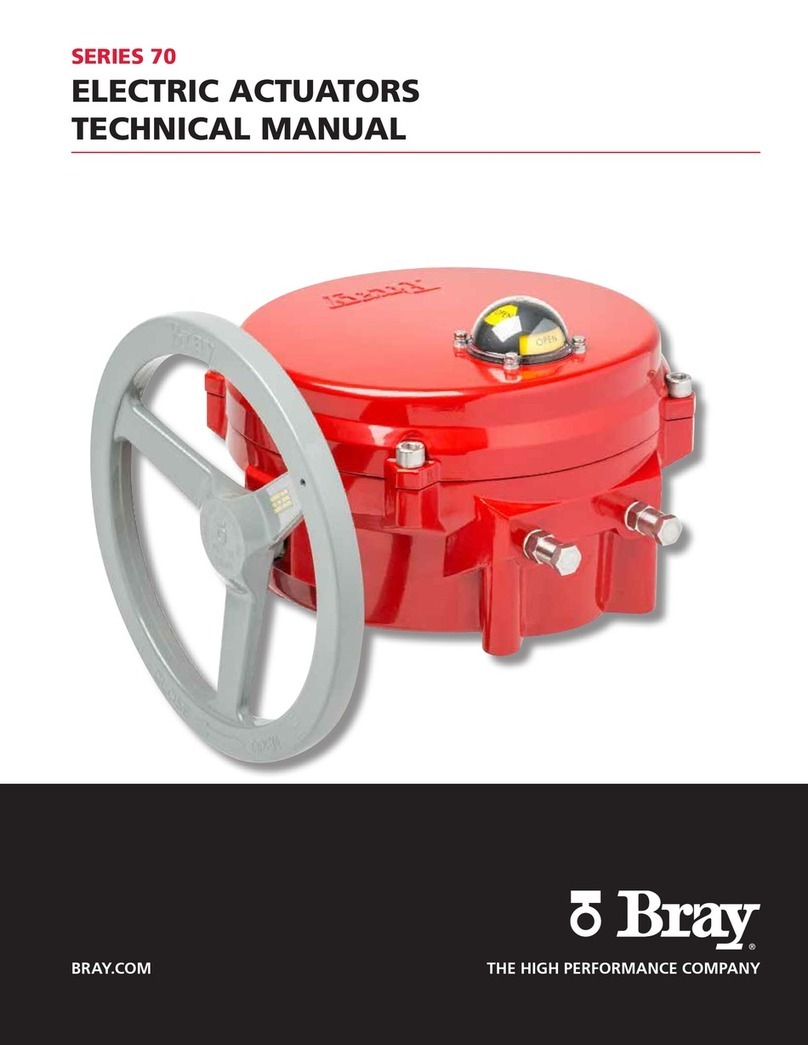

Series 70

Servo NXT - DeviceNet™

Installation, Operation and Maintenance Manual

4.1.2 Network Grounding and Isolation

DeviceNet™ should be grounded at ONE location.

Grounding at more than one location may produce

ground loops, while not grounding the network

will increase sensitivity to ESD and outside noise

sources. Grounding near the physical center of the

network is desired.

The trunk drain/shield should be attached to the

power supply ground or V with a copper conductor

that is either solid, stranded, or braided. Use a 1”

copper braid or a #8 AWG wire that is less than

3 meters/10 feet in length. This should then be

attached to a good earth or building ground (such

as an 8 foot stake driven into the ground, attached

to building iron or to the cold water plumbing).

If the network is already grounded, do NOT connect

the grounding terminal of the tap or ground of the

supply to earth. If more than one supply is on the

network, then connect the drain wire/shield at ONE

supply only, preferably near the physical center of

the network.

4.1.3 Network Power

DeviceNet™ has a single supply current capability

of up to 16 amps using a thick cable trunk line,

and up to 6 amps using a thin cable trunk line,

which makes the network highly functional and

cost effective.

Power configuration is adjustable based on your

system requirements. The DeviceNet™ power bus

is supplied by a nominal 24 volt source and can

support up to 8 amps on any section of thick cable

trunk line or up to 3 amps on any section of thin

cable trunk line. Since this much current can be

drawn from each sideof a powertap, a singlesupply

network can possibly provide twice these current

levels. If the system has even greater requirements,

DeviceNetÔ can support multiple power supplies.

The network power supply can be placed at the end

or at the center of the network. By examining the

current requirements of the network, the power

supply should be placed such that the maximum

current specification is not exceeded.

The selection of the power supply should ensure a

tolerance of +24 VDC +/ 1% and current capability

of 016 amps.

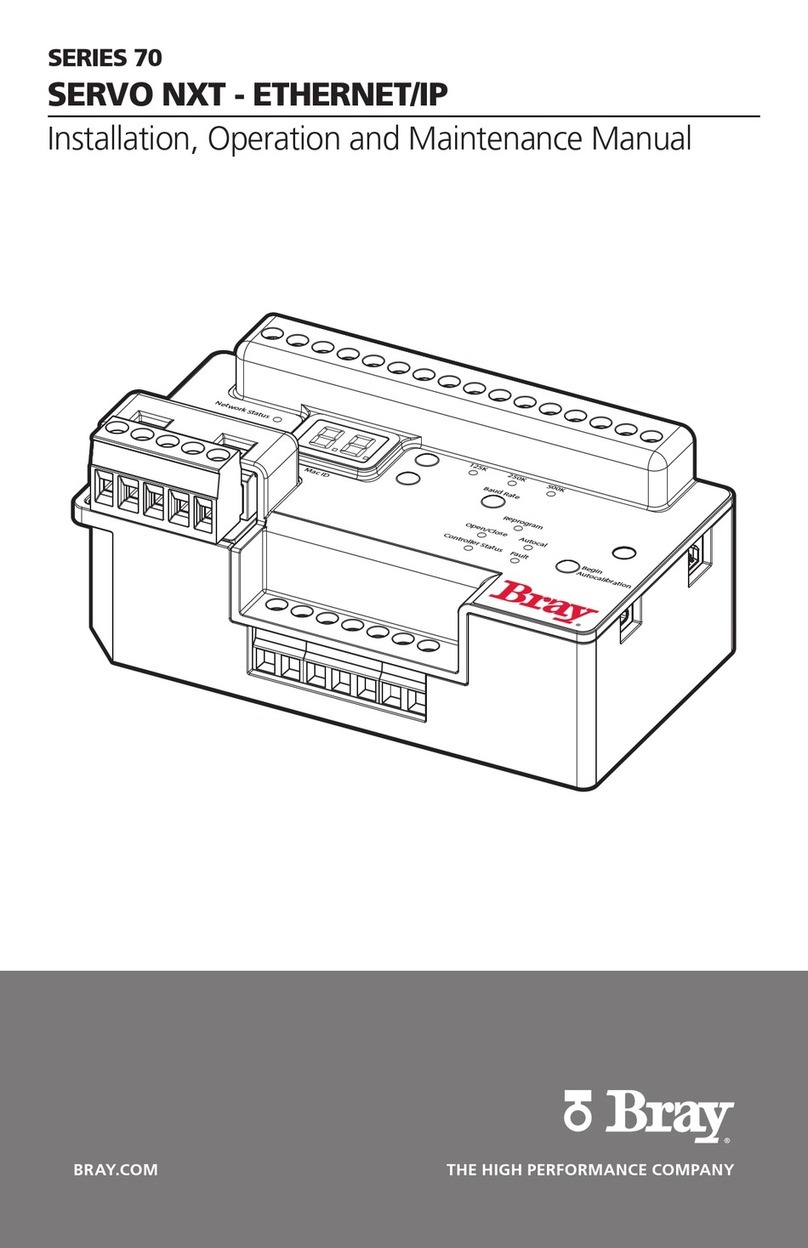

4.2 Configuration

When adding the Actuator Controller to a

DeviceNet™ network, it must be configured with

the correct network Baud Rate and it must also

have a unique Mac ID. The Actuator Controller

should not be added to an existing network until

the MAC ID and Baud rate have been properly set.

If the Actuator Controlleris added toa network with

either a conflicting MAC ID or incorrect Baud rate,

the network will not be effected, but the Actuator

Controller will be taken offline as indicated by a

solid red color on the Network LED. The unit must

then be removed from the network and then added

after the conflicts have been resolved.

If the MAC ID or Baud Rate needs to be changed,

then the unit should be powered on with AC power,

allowing the necessary changes to be made before

connecting the device to the DeviceNet™ network.

4.3 Commissioning

Commissioning is the process of taking the Actuator

Controller from the on-line state to establishing

a dedicated connection with a master on the

network. The controller supports a Polled network

connection and an Explicit message connection.

These connections are supported simultaneously

but only one connection of each type is supported

at a time.

When the controller transitions from the On-line

state to the Commissioned state, the Network LED

will change from flashing green to a solid green.

When the Master / Slave relationship is released,

the Network Led will return to a flashing green.

The Process Controller needstohavetheinformation

contained in the EDS file of the Actuator Controller

referenced before commissioning will occur.

4.3.1 EDS (Electronic Data Sheet)

An EDS (Electronic Data Sheet) is an external file

that contains information about configurable

attributes for a device, including object addresses

of each parameter. The EDS provides the user

with a simple to use interface for configuring and

monitoring a device.

The EDS file is included with the Actuator Controller

to aide in commissioning. Products such as the

Process Controller will use the EDS to automatically

obtain the data that is required for configuration.

When the Actuator Controller EDS file is accessed

through an application, all of the parameters

available for monitoring and configuration are

displayed. EDS parameters which are settable can

be modified and saved to the Actuator Controller.

Depending upon the EDS enabled application that

is used, features such as monitoring are available