Bray Series 70 User manual

The

High

Performance

Company

R

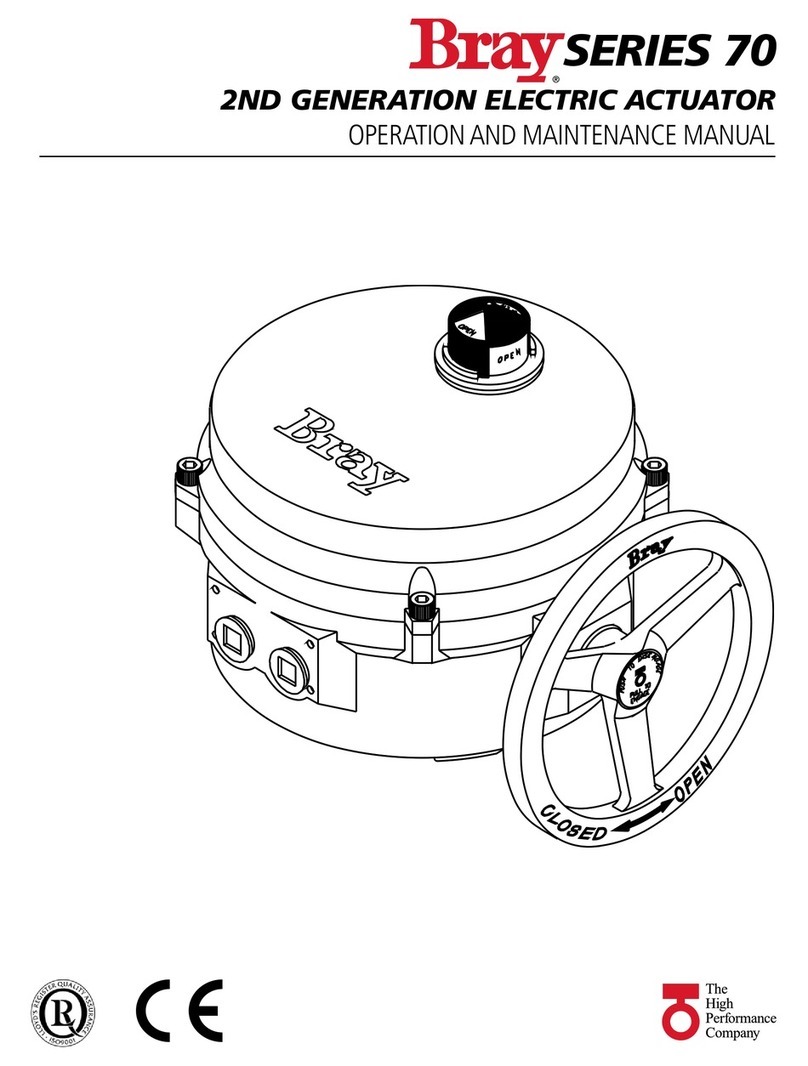

SERIES 70

2ND GENERATION ELECTRIC ACTUATOR

OPERATION AND MAINTENANCE MANUAL

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

Ta b l e OfCO n T e n T s :

p a g e

sa f e T y i n s T r u C T i O n s : d e f i n i T i O n O f T e r m s .................................................................... 2

i n T r O d u C T i O n ............................................................................................................. 3

p r i n C i p l e O f O p e r a T i O n .............................................................................................. 3

e l e C T r i C a l O p e r a T i O n ................................................................................................ 3

m e C h a n i C a l O p e r a T i O n .............................................................................................. 3

m a n u a l O v e r r i d e O p e r a T i O n ..................................................................................... 4

p r e -i n s T a l l a T i O n s T O r a g e ......................................................................................... 4

in s T a l l a T i O n 4

m O u n T i n g T O av a l v e ................................................................................................. 4

f i e l d w i r i n g ............................................................................................................... 4

m u l T i p l e a C T u a T O r w i r i n g ......................................................................................... 5

T r a v e l l i m i T s w i T C h a n d m e C h a n i C a l T r a v e l s T O p a d j u s T m e n T ............................... 5

C l O s e a d j u s T m e n T ...................................................................................................... 5

O p e n a d j u s T m e n T s ...................................................................................................... 6

ba s i C di s a s s e m b l y a n d as s e m b l y in s T r u C T i O n s .......................................................... 6

fi e l d O r fa C T O r y in s T a l l a b l e Op T i O n s

T O r q u e s w i T C h e s O p e r a T i O n ....................................................................................... 7

h e a T e r ........................................................................................................................ 8

s e r v O p r O m O d u l e ...................................................................................................... 8

e x T e r n a l f e e d b a C k p O T e n T i O m e T e r ........................................................................... 10

a u x i l i a r y s w i T C h e s .................................................................................................... 10

a u x i l i a r y s w i T C h C O n f i g u r a T i O n C h a r T .................................................................... 11

T y p i C a l w i r i n g d i a g r a m s f O r m C(s p d T ) s w i T C h e s O n /O f f s e r v i C e ............................ 12

T y p i C a l w i r i n g d i a g r a m s m O d u l a T i n g s e r v i C e ......................................................... 13

a d j u s T m e n T s , C a l i b r a T i O n & s T a T u s l e d O f s e r v O p r O ............................................. 14

q u i C k C O n n e C T r e C e p T a C l e s ...................................................................................... 15

s p i n n e r ....................................................................................................................... 16

l O C a l C O n T r O l s T a T i O n .............................................................................................. 16

a p p e n d i x a

b a s i C T O O l s ................................................................................................................ 17

a p p e n d i x b

a C T u a T O r T r O u b l e s h O O T i n g C h a r T ........................................................................... 18

s e r v O T r O u b l e s h O O T i n g C h a r T ................................................................................. 19

a p p e n d i x C

e x p l O d e d v i e w a n d p a r T s l i s T O f s i z e 003 a n d 005................................................. 20

e x p l O d e d v i e w a n d p a r T s l i s T O f s i z e 008, 012 a n d 020......................................... 21

e x p l O d e d v i e w a n d p a r T s l i s T O f s i z e 030, 050 a n d 065......................................... 22

e x p l O d e d v i e w a n d p a r T s l i s T O f s i z e 130 a n d 180 (e l e C T r i C )............................... 23

e x p l O d e d v i e w a n d p a r T s l i s T O f s i z e 130 a n d 180 (g e a r b O x ).............................. 24

f O r i n f O r m a T i O n O n T h i s p r O d u C T a n d O T h e r b r a y p r O d u C T s

p l e a s e v i s i T u s a T O u r w e b p a g e - www.bray.com 1

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

2

Sa f e t y In S t r u c t I o n S - De f I n I t I o n o f te r m S

reaD anD foLLoW tHeSe InStructIonS

SaVe tHeSe InStructIonS

1.1 Ha z a r D -f r e e u S e

This device left the factory in proper condition to be safely

installed and operated in a hazard-free manner. The notes

and warnings in this document must be obeserved by the

user if this safe condition is to be maintained and hazard-

free operation of the device assured.

Take all necessary precautions to prevent damage to the

actuator due to rough handling, impact, or improper storage.

Do not use abrasive compounds to clean the actuator, or

scrape metal surfaces with any objects.

The control systems in which the actuator is installed must

have proper safeguards to prevent injury to personnel, or

damage to equipment, should failure of system components

occur.

1.2 Qu a L I f I e D Pe r S o n e L

A qualied person in terms of this document is one who is

familiar with the installation, commissioning and operation of

the device and who has appropriate qualications, such as:

○ Is trained in the operation and maintenance of electric

equipment and systems in accordance with established

safety practices

○ Is trained or authorized to energize, de-energize, ground,

tag and lock electrical circuits and equipment in

accordance with established safety practices

○ Is trained in the proper use and care of personal

protective equipment (PPE) in accordance with

established safety practices

○ Is trained in rst aid

○ In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in the

operation, commissioning, operation and maintenance of

equipment in hazardous locations

WARNING

The actuator must only be installed, commissioned, oper-

ated and repaired by qualied personnel.

The device generates large mechanical force during normal

operation.

All installation, commissioning, operation and maintenance

must be performed under strict observation of all applicable

codes, standards and safety regulations.

Reference is specically made here to observe all appli-

cable safety regualtions for actuators installed in potentially

explosive (hazardous) locations.

!

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

!

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE used without the safety alert symbol indicates a potential situation which,

if not avoided, may result in an undesirable result or state, including

property damage.

!

In t r o D u c t I o n

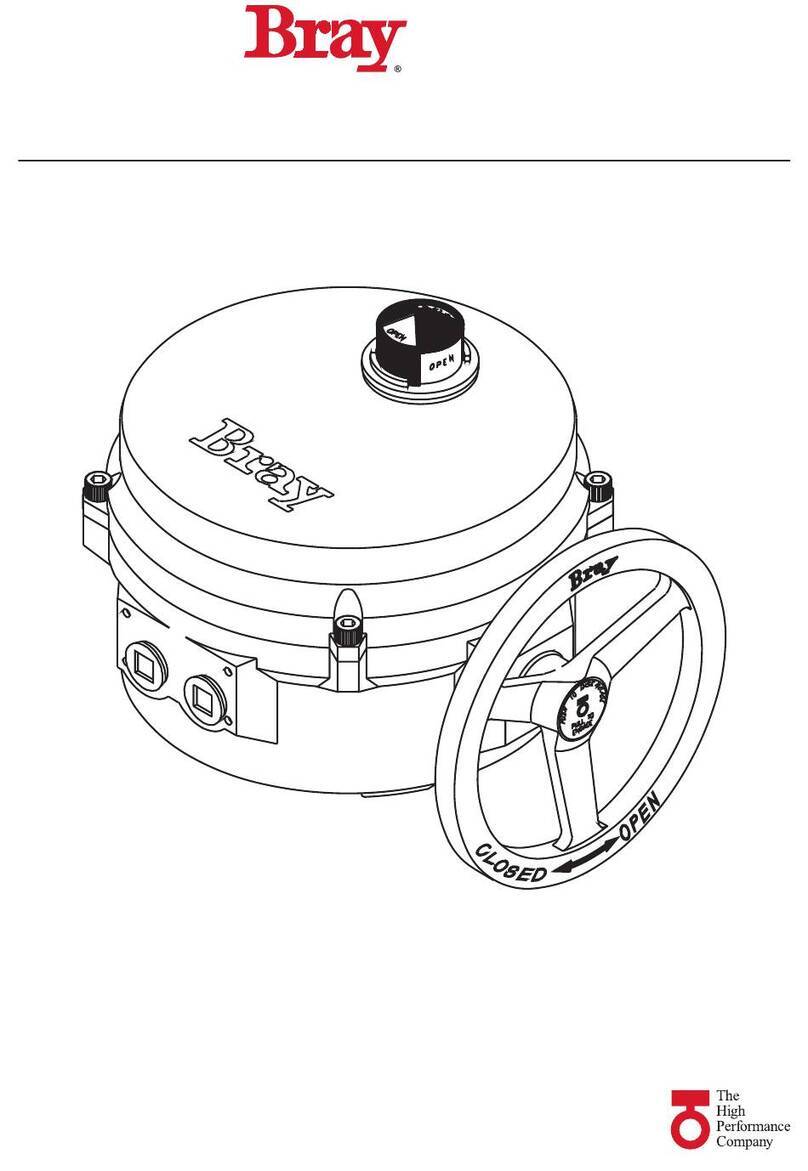

The Bray Series 70 is a quarter turn electric actuator with

manual override for use on any quarter turn valve requiring

up to 18000 in•lb of torque. Operating speeds vary between

6 to 90 seconds.

Pr i n c i P l e OfOP e r a t i O n

The Series 70 actuator is basically divided into two internal

sections; the power center below the switchplate, and the

control center above the switchplate. Below the switchplate

the capacitor and gearmotor with its spur geartrain drive a nal

non-backdriveablewormgearoutput.Theoverridemechanism

for manual operation is also housed here. Above the switch-

plate is where user required, readily accessible components

are placed. The camshaft assembly, limit switches, terminal

strips, torque switches, heater, and servo are all placed here

for easy access. External to the unit are found adjustable me-

chanical travel stops, a large easy to read indicator, the unique

manual override handwheel and dual conduit entry ports. The

external coating is a high quality polyester powder coat which

has exceptional UV as well as chemical resistance.

el e c t r i c a l OP e r a t i O n

The motors used in the Bray Series 70 are either permanent

induction split capacitor design (single phase AC power),

SCI (Three Phase AC Power) or PM (DC Power). Travel limit

switches are mechanical form (SPDT) with contacts rated at

10 amp (0.8 PF), 1/2 HP 125/250 VAC. In cases where the

torque capacity of the unit is exceeded to the point where the

motor stalls and overheats, a thermal protector switch built

into the motor windings will automatically disconnect the motor

power. Once the motor cools sufciently the thermal protector

switch will reset. Optional torque switches are available in all

units to prevent the possibility of stalling the motor, thus reduc-

ing the necessity for an inoperable thermal cooldown period.

Torque switches installed by Bray are factory adjusted to the

output torque rating of the unit using electronic torque testing

equipment.

NOTICE

Field adjustment of the torque switches is not recommended.

General Electrical Schematic

NOTE: this is only a reference. For the actual wiring diagram refer to

the diagram placed inside the actuator cover.

Me c h a n i c a l OP e r a t i O n

Mechanically, the ratio of the gearmotor determines the speed

of the unit. The gearmotor utilizes high efciency spur gears

with various ratios for the different speeds. Initial gear reduction

throughthespurgearsisthentransferredtothewormshaft.The

nal gear reduction and output is through a non-backdriveable

worm gear set. Positioning is determined by an indicator-cam

shaft linked to the output shaft. In the declutchable condition

the manual override drives the worm shaft when engaged.

CAMS

NEUTRAL

OPEN

CLOSE

LIVE

OPEN

CLOSE

MANUAL OVERRIDE SWITCH

TRAVEL LIMIT SWITCHES

CAPACITOR

MOTOR

THERMAL PROTECTOR

TORQUE SWITCHES

FIELD

WIRING

(OPTIONAL)

Single phase power supply.

N.C.

N.O.

COM

COM

N.C.

N.O.

COM

N.O.

N.C.

COM

N.O.

N.C.

N.O.

COM

N.C.

1

2

3

Use this chart as a guide to interpret the S70 electric actuator part number.

Pa r t nu M b e r i n g Sy S t e M re f e r e n c e c h a r t

Pa r t nu M b e r tO r q u e SP e e d , 1/4 tu r n Su P P l y

(In.Lbs) (Seconds) (Z Voltage)

70-003X-113yz-536 300 60/30/15 0/1/2/3/4

70-005X-113yz-536 500 60/30/15 0/1/2/3/4

70-008X-113yz-536 800 30/15/10/6 0/1/2/3/4/5/6/7/8

70-012X-113yz-536 1200 30/15/10/6 0/1/2/3/4/5/6/7/8

70-020X-113yz-536 2000 30/15 0/1/2/3/4/5/6/7/8

70-030X-113yz-536 3000 30/18 0/2/3/4/5/6/7/8

70-050X-113yz-536 5000 30/18 0/2/3/4/5/6/7/8

70-065X-113yz-536 6500 30 0/2/4/5/6/7/8

70-1806-113yz-536 18000 90 0/2/4/5/6/7/8

70-1306-113YZ-536 13000 90 0/2/4/5/6/7/8

Y - DESIGNATES STYLE

A= DECLUTCHABLE

B = NON DECLUTCHABLE 0 1 2 3 4

120VAC 12VDC 24VDC 24VAC 220VAC

X - DESIGNATES THE SPEED

X = 0 1 2 2 3 4 5 6

SEC = 60 30 18 15 10 6 8 90

Z - DESIGNATES THE VOLTAGE

Z=

VOLTAGE=

5 6 7 8

380V 400V 440V 480V

3-PH 3-PH 3-PH 3-PH

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

3

Ma n u a l Ov e r r i d e OP e r a t i O n (de c l u t c h a b l e )

The manual override operates similar to a watch adjusting

knob. To engage the manual override, simply pull the hand-

wheel to its outermost position.Ayellow stripe is revealed for

visual indication that the unit cannot run electrically. The two

handwheel positions, engaged and disengaged, are held in

placewiththeuseof spring plungers.Thehandwheelremains

in position until physically moved. Rotating the handwheel

in the clockwise direction will rotate the output shaft in the

same clockwise (closed) direction and vice-versa.

CAUTION

A label on the handwheel hub warns users not to exceed

a specic rim pull force, for each size of actuator. If the rim

pull force is exceeded, the roll pin securing the handwheel

onto the manual override shaft is designed to shear, thus

preventing more serious internal gearing damage.

Pr e -in S t a l l a t i O n St O r a g e

Units are shipped with two metal screw-in plugs in order to

prevent foreign matter from entering the unit.

NOTICE

To prevent condensation from forming inside these units,

maintain a near constant external temperature and supply

power to the optional heater internal to the unit.

In S t a L L a t I o n

MO u n t i n g t O ava l v e

All Bray Series 70 electric actuators are suitable for direct

mounting on Bray buttery valves. With proper mounting

hardware, the S70 actuator can be installed onto other

quarter-turn valves or devices.

NOTICE

The standard mounting position for the actuator is to orient

the unit with its handwheel in a vertical plane and parallel to

the pipeline. If the actuator is to be mounted on a vertical

pipe, it is recommended that the unit be positioned with the

conduit entries on the bottom to prevent condensation from

entering the actuator by way of the conduit. In all cases, the

conduit should be positioned to prevent drainage into the

actuator.

The actuator should be mounted to the valve as follows:

1. Manually operate the actuator until the output shaft of

the actuator is in line with the valve stem. If possible,

select an intermediate position (i.e. valve disc/stem and

actuator both half open).

2. Place the proper adapter, if required, onto the valve

stem. It is recommended that a small amount of grease

be applied to the adapter to ease assembly.

3. Mount the actuator onto the valve stem. It may be

necessary to swing or manually override the actuator

to align the bolt patterns.

4. Install the furnished mounting studs by threading them

all the way into the actuator base.

5. Fasten in place with the furnished hex nuts and lock

washers.

fi e l d Wi r i n g

WARNING

Turn off all power and lock out service panel before install-

ing or modifying any electrical wiring.

Each actuator is provided with two (2) conduit entries (one

for power and one for control).

1. The motor full load current is noted on the nameplate

of the actuator. The terminal strip will accept wire sizes

ranging from 14 to 22 AWG (14 to 24 AWG for the

servo).

NOTICE

18 AWG minimum wire is recommended for all eld wiring.

Note that the optional heaters use approximately 0.5 amps

at 110 volts.

2. All actuators have their applicable wiring diagram

attached to the inside of the cover. Field wiring

should be terminated at the actuator terminal strip in

accordance with this wiring diagram.

NOTICE

Theconduitconnectionsmustbeproperlysealedtomaintain

the weatherproof integrity of the actuator enclosure.

!

!

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

4

TP TP TP TP

OPEN

MOTOR

CLOSE

CAPACITOR CAPACITOR

CLOSE

MOTOR

OPEN

SPDT

CONTACT

INCORRECT

TWO SPDT

CONTACTS

CAPACITOR

CLOSE

MOTOR

OPEN

CAPACITOR

MOTOR

OPEN

CLOSE

CORRECT

No. 1 No. 2 No. 2No. 1

122 22

33 33

111

CAUTION

Do not reverse motor instantaneously when it is still running-

Reversing direction to actuator motor when it is running can cause

damage to motor, switches and gearing. Directional control switch-

ing can be done by PLC in 20ms or by a small relay in 45ms.

Therefore time delay of 1s has to be incorporated into the control

scheme to avoid damage.*

*

Refer to Technical Bulletin 1176 for more details on Field Wiring.

Mu l t i P l e ac t u a t O r (Pa r a l l e l ) Wi r i n g

CAUTION

DonotconnectmorethanoneS70actuatortoasingleSPDTswitch.

A voltage is present on the opposite winding to the powered one. If

this winding is connected to another as shown in the INCORRECT

diagram it will interfere with the motor performance. Use a multiple

pole switch as shown in the CORRECT diagram.*

tr a v e l li M i t SW i t c h a n d Me c h a n i c a l tr a v e l St O P

ad j u S t M e n t

CAUTION

Theelectrical travel switchesmust besettoactivate(depress)

prior to reaching the mechanical travel stops. The cams are

color coded (green for open, red for closed).

NOTE: Manual travel stops are designed to prevent manual

overtravel from turning the handwheel, not to stop the elec-

tric motor. The travel stops have an adjustment range of

approximately 10-degrees.

cl O S e tr a v e l SW i t c h a d j u S t M e n t

1. Loosen the mechanical stop for the closed position and

back it off so that it does not interfere with actuator travel

(closed stop located on right when viewed from travel

stop side of actuator).

2. Remove the indicator rotor by pulling up it straight up

away from the indicator shaft. This will expose the

machined groove on the end of the cam shaft, which

is the reference to the valve disc position.

NOTE: For Sizes 130 and 180, ignore steps 2 and 6.

The valve position indicator plate on the lower gearbox

is the reference to the valve position.

3. Manually operate the actuator handwheel clockwise until

the valve reaches the desired fully closed position.

4. Rotate the red adjusting knob by hand or with a at head

screwdriveruntilthecamlobejustactivates(depresses)

the switch from a clockwise direction.

NOTICE: All continuous duty actuators have a cam

locking screw. Cam locking screw must be slackened

before cam adjustments and re-tightened after cam

adjustments.

*Refer to SK-081149 for more details

NOTE: It is possible that the rotation of one cam will

move the other cam. If this occurs, hold the other knobs

or cams during adjustment.

5. With the travel switch in the closed position, rotate the

handwheelclockwise1/4to1/2aturn.Adjust the closed

travel stop bolt until it bottoms against the output gear

and lock it in position with the locknut.

6. Afteralltravelswitchadjustmentshavebeencompleted,

replace the indicator rotor and secure the actuator

cover.

!

!

!

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

5

OP e n tr a v e l SW i t c h a d j u S t M e n t

1. Loosen the mechanical stop for the open position and

backitoff,sothatitdoesnotinterferewithactuatortravel.

The open stop is located on the left, when viewed from

travel stop side of actuator.

2. Remove the indicator rotor by pulling it straight up away

from the indicator shaft. This will expose the machined

groove on the end of the cam shaft, which is the refer-

ence to the valve disc position.

NOTE: For Sizes 130 and 180, ignore steps 2 and 6.

The valve position indicator plate on the lower gearbox

is the reference to the valve position.

3. Manually operate the actuator handwheel counter-

clockwise until the valve reaches the desired open

position.

4. Rotate the green adjusting knob until the cam lobe just

activates(depresses)theswitchfromacounterclockwise

direction.

NOTICE: All continuous duty actuators have a cam

locking screw. Cam locking screw must be slackened

before cam adjustments and re-rightened after cam

adjustments.

*Refer to SK-081149 for more details

NOTE: It is possible that the rotation of one cam will

move the other cam. If this occurs, hold the other knobs

or cams during adjustment.

5. With the travel switch in the open position, rotate the

handwheel counterclockwise 1/4 to 1/2 a turn. Adjust

the open travel stop bolt until it bottoms against the

output gear and lock in position with the locknut.

6. After all travel stop adjustments have been completed,

replace indicator rotor and secure the actuator cover.

DI S a S S e m b L y a n D aS S e m b L y

tO O l S r e q u i r e d :

See Appendix A for a complete list of basic tools

Pr O c e d u r e :

WARNING

Turn off all power and lock out service panel before installing

or modifying any electrical wiring.

1. Disconnect motor wires from the main terminal strip

(motor neutral, open, and close).

2. Remove the switchplate by unscrewing the seven phil-

lips head mounting screws. The switchplate should lift

out as an assembly with the camshaft attached.

3. The switchplate can be independently disassembled.

4. To remove the Gearmotor, rst disconnect the motor

leadswhichruntothe capacitor, and unscrew the mount-

ing screws for size 003-005 (two lower, one upper) for

size 008-180 (four lower, one upper). The motor can

now be removed vertically out of the unit. Note: do not

misplace the alignment pin.

5. To remove the worm shaft spur gear, remove the spring

pin using a 3/32”punch, then slide the gear off the end of

the worm shaft for size 003-020. Remove bowed E-clip

retainer for size 030-180.

6. To remove the output drive worm gear, back off both

mechanical travel stops. Remove the retaining ring and

thrust washer, then lift the output drive worm gear out

of its base.

7. The handwheel is held by a spring pin.

NOTE 1: Assembly is

the opposite of removal

NOTE 2: Pictures shown

for size 003-005 are typi-

cal for all sizes

!

6

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

7

fI e L D orfa c t o r y In S t a L L a b L e oP t I o n S

tO r q u e SW i t c h e S

Torque switches are a factory installed and calibrated option

available for all Series 70 units. Installation is simple, but

due to the requirement for special calibration equipment, it

is not recommended for eld installation. In fact, modifying

the factory torque setting voids the actuator warranty. The

unique mechanism is extremely accurate and has excellent

repeatability. The worm is pinned to the worm shaft, which

is held in position with a stack of disc springs at both ends.

The torque transmitted through the worm to the output worm

gear acts directly against the disc springs, which compress

proportionately.Thewormandwormshaftshiftlongitudinally

as a result. A specially designed drive lever and pin is incor-

porated into the worm, providing the prole for the torque

switching mechanism. A

drive lever & pin rides in the

worm gear torque sensor

groove, and in turn drives

a cam. The cam then actu-

ates its electrical switch,

which interrupts the power

to the motor winding when

the torque exceeds the

setting. The motor can still

be powered to run in the

opposite direction, or if the torque diminishes, the switch

will release automatically.

tO r q u e SW i t c h Me c h a n i S M

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

TORQUE SWITCH MECHANISM

CAUTION

8. Further disassembly of the unit requires special tools

and procedures, and thus will not be covered in this

manual.

!

8

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

he a t e r

To prevent condensation from forming inside the actuator,

Bray offers an optional heater. The heater is a PTC (Positive

Temperature Coefcient) style which has a unique tempera-

ture - resistance characteristic. The heater self-regulates by

increasing its electrical resistance relative to its temperature.

The heater does not require external thermostats or switches

to control its heat output. It is constructed of a polycrystalline

ceramic,sandwichedbetweentwoconductors,andwrapped

inside a thermally conductive electrical insulator.

Connect the heater wires to the terminal strip as indicated

on the wiring diagram.

NOTE: The heater must have a constant power supply to

be effective.

WARNING

The heater surface can reach temperatures in excess of

200 degrees Celsius

he a t e r Ki t cO n S i S t S O f :

1 Heater with ying leads

2 Heater Mounting Bracket

3 #10 pan head screw, phillips drive

tO O l S r e q u i r e d :

• For terminal wiring: Screwdriver, 3/16” tip at blade

• For heater mounting screw: Screwdriver, No.1 phillips

in S t a l l a t i O n P r O c e d u r e :

The heater is mounted through a hole provided in the

switchplate.

Before servicing unit, switch all power off at the service

panel and lock the service disconnecting means to pre-

vent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the

service panel.

Disconnect all power to the unit.

1 Place the heater snugly into its mounting bracket until

approx. 1/2 to 1”is left above the bracket as shown in

diagram.

2 Slip the heater into its mounting hole.

3 Align the fastening hole in the bracket with the

threaded screw hole in the plate. Fasten the heater to

the switchplate.

4 Connect the heater wires to the terminal strip as

indicated on the wiring diagram.

Se r v O -Pr O MO d u l e

Servo kits can be eld installed on any continuous duty actua-

tor (30 or 60 sec. operation speed) to provide proportional

positioning in response to a control signal. Intermittent duty

actuators are not adaptable for servo control.

Se r v O Ki t cO n S i S t S O f :

1 One servo module

2 Four #6 cross drive pan head screw (two for servo,

two for pot)

3 One potentiometer assembly

4 Two #6 type A internal lockwashers (for pot)

5 One wiring diagram sticker for attaching to inside

of actuator’s cover

6 One wiring diagram sticker for servo units with

torque switches

tO O l S r e q u i r e d :

• For actuator terminals wiring Screwdriver, 3/16” atblade

• For servo terminals Screwdriver, No.1 phillips

• For servo and pot mounting screws Screwdriver,

No.2 phillips

in S t a l l a t i O n Pr O c e d u r e :

!

9

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

Disconnect all power to the unit.

Remove the on/off duty, 9 point terminal strip

and its marker

1 Disconnect all wiring to the terminal strip.

2 All wiring in the actuator is color coded to facilitate

wiring, and does not need to be tagged or marked.

3 Field wiring should be marked if it is not already

color coded.

Mount the servo module

4 Secure the servo card module onto switchplate

with the 2X #6 screws.

Install the potentiometer assembly

5 The potentiometer installs next to the camshaft

where there are two threaded holes provided.

6 The potentiometer assembly must be mounted in the

correct orientation, with the actuator in its fully open

(counter clockwise) position, the indicator shaft should

be in-line with raised green rib on pot gear.

7 Push the assembly towards the cam to mesh the pot

gears. Then tighten the mounting screws.

Note: Sizes 130 and 180, the raised green rib on

pot gear should be aligned with arrow on lower gear

box’s position indicator plate.

Wire the pot to the servo

8 Connect the pot wires into the terminal strip on the servo

module.

9 Wire according to the wiring diagram provided.

Wire the servo to the actuator

10 Wire according to the wiring diagram provided.

11 See the servo calibration instructions.

Se r v O ca l i b r a t i O n

The calibration procedure denes the limits of operation of

the Series 70 Actuator between the fully open valve position

and the fully closed valve position. The cams on the Series

70 Actuator dene the fully open and closed positions of the

valve and may be set at any degree of opening. The only

requirement is that the open cam limit setting must set at a

higher degree of opening than the closed cam limit setting.

In other words, the “Open”position must be more open than

the “Closed”position.

Calibration is performed as follows:

1 Adjust the Open and Closed limit switch cams

on the Series 70 Actuator to the desired position.

2 Engage the handwheel and move the Series 70

Actuator to its mid position.

NOTE:

An analog signal source is not required for calibration.

Press and hold the “Calibrate”Set pushbutton for a

minimum of 2 seconds. When the servo begins to drive

the actuator closed, release the button. The servo will

now seek both travel limits and record these values to its

nonvolatile memory. Following a successful calibration,

the status LED will begin to ash a steady single green

ash. If the calibration is unsuccessful the status LED

will ash two green ashes. If this occurs, make sure

the cams and the potentiometer are set correctly.

This completes the “Self Calibration”procedure.

After completingthecalibrationprocedure,itisgood practice

toapplythefullyclosedandfullyopenCommandSignals,and

verify that the S70 Actuator moves to the proper positions.

*

Refer to Servo Pro Manual for more details

MOTOR

OPEN

1

ON

MOTOR

CLOSE

FUSE

NEUTRAL

NEUTRAL

LINE Power

OUTPUT (+)

OUTPUT (-)

+5 VDC

INPUT (+)

INPUT (-)

OPEN

LIMIT

CLOSE

LIMIT

COMMON

COMMON

HANDWHEEL

CALIBRA T ESTATUS

+5 VDC

COMMON

FB POT

HIGH

VOLT A GE

SERVO

210987

6543

PRO

HEATER

DEAD BAND

CLOSE

SPEED

OPEN

SPEED

CLOSE

OPEN

COMMON

TORQUE LIMIT

CLOSE

OPEN

COMMON

CONTROL BOX

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

Green Rib

10

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

ex t e r n a l Si g n a l fe e d b a c K PO t e n t i O M e t e r

Potentiometers for external feedback can be eld installed

on all continuous duty actuators. Actuators which are not

continuous duty do not have a pot gear tted on their indicator

shafts & must be tted with a new shaft which has a pot drive

gear for feedback pot (see Options: Auxiliary Switches).

fe e d b a c K PO t e n t i O M e t e r Ki t c O n S i S t S O f :

1 One potentiometer assembly

2 Two #6 cross drive pan head screws

3 Two #6 internal lockwashers

4 One 4 point terminal strip

5 One terminal strip marker for feedback pot

6 One small wiring diagram sticker for the

additional potentiometer

tO O l S r e q u i r e d :

• For terminal wiring Screwdriver, 3/16” tip at blade

• For pot mounting screws Screwdriver, No.2 phillips

in S t a l l a t i O n P r O c e d u r e :

1 The potentiometer installs next to the camshaft where

there are two threaded holes provided for it.

2 The potentiometer assembly must be mounted in the

correct orientation, with the actuator in its fully open

(counter clockwise) position, the indicator shaft should

be in-line with raised green rib on pot gear.

3 Push the assembly towards the cam to mesh the pot

gears. Then tighten the mounting screws.

4 Fit the 4 point terminal strip and marker in the kit. Before

laying down the marker, cut it to obtain a marker as il-

lustrated: opposite

5 Wire the pot to the terminal strip using the small stick-on

wiring diagram provided.

6 Adhere the wiring diagram sticker to the inside of

the cover.

Se t t h e PO t e n t i O M e t e r :

1 Manually operate the actuator handwheel until the unit

is in the fully closed position.

2 Rotate the black potentiometer drive gear adjustment

knob, to engage the potentiometer gear at the

closed position.

3

Manually operate the actuator to the fully open position.

au x i l i a r y S W i t c h e S

Auxiliary switches are available / refer to chart on next page.

NOTES:

1 All auxiliary switches have voltage -free contacts.

2 Size 6, 12, and 30 have double lobe cams. Sizes 130

and 180 has single lobe cams.

3 Main switches are one OPEN and one CLOSE switch.

4 Auxiliary switches are one OPEN and one CLOSE

switch, which are xed to activate 3°before the

main switches.

5 Adjustable auxiliary switches are adjustable to

any position.

in S t a l l a t i O n P r O c e d u r e

1 Cut terminal strip marker to length needed with letters

facing up.

2 Mount terminal strip and marker to switchplate using

two #4-40 screws.

Aux Terminal Strip

178 9

2 3 4 5 6

D

C

B

A

Cut marker as

needed (4-way

shown as example)

and mount to

switchplate as

shown.

Green Rib

11

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

cO n f i g u r a t i O n Si z e 6 Si z e 12 & 30

1 ON/OFF (Intermittent Duty Motor) with Main 2 Switch 2 Switch

Switches (Standard OPEN and CLOSE switches) 2 Cams 2 Cams N/A

Standard Assembly P/N Standard Assembly P/N

2ON/OFF (Continuous Duty Motor) with Main 2 Switch 2 Switch 2 Switch

Switches (Standard OPEN and CLOSE switches) 2 Cams 2 Cams 2 Cams

& Pot Gear & Pot Gear & Pot Gear

Standard Assembly P/N Standard Assembly P/N Standard Assembly P/N

3ON/OFF (Intermittent Duty Motor) with Main 4 Switch 4 Switch

and 1 set of Auxiliary Switches 2 Cams 2 Cams N/A

Kit P/N 70-0006-22980-536 Kit P/N 70-0012-22960-536

4ON/OFF (Continuous Duty Motor) with Main 4 Switch 4 Switch 4 Switch

and 1 set of Auxiliary Switches 2 Cams 2 Cams 4 Cams

& Pot Gear & Pot Gear

Kit P/N 70-0006-22980-536 Kit P/N 70-0012-22960-536

5ON/OFF with Main, 1 set of Auxiliary, and 5 Switch 5 Switch

1 Adjustable Auxiliary Switches 3 Cams 3 Cams N/A

Kit P/N 70-0006-22983-536 Kit P/N 70-0012-22963-536

6ON/OFF with Main, 1 set of Auxiliary, and 6 Switch 6 Switch

1 set of Adjustable Auxiliary Switches 3 Cams 3 Cams N/A

Kit P/N 70-0006-22984-536 Kit P/N 70-0012-22964-536

7ON/OFF with Main, 1 set of Auxiliary, and 6 Switch

2 Adjustable Auxiliary Switches N/A 4 Cams N/A

Kit P/N 70-0012-22961-536

8ON/OFF with Main, 1 set of Auxiliary, and 8 Switch

2 sets of Adjustable Auxiliary Switches N/A 4 Cams N/A

Kit P/N 70-0012-22962-536

9Servo with Main, 1 set of Auxiliary, and 5 Switch

1 Adjustable Auxiliary Switches N/A 3 Cams & 1 Pot Gear N/A

Kit P/N 70-0012-22966-536

10 Servo with Main, 1 set of Auxiliary, and 6 Switch

1 set of Adjustable Auxiliary Switches N/A 3 Cams & 1 Pot Gear N/A

Kit P/N 70-0012-22967-536

11 ON/OFF with Main and 1 Adjustable 3 Switch 3 Switch 3 Switch

Auxiliary Switches 3 Cams 3 Cams 3 Cams

Kit P/N 70-0006-22988-536 Kit P/N 70-0012-22968-536

12 Servo with Main and 1 Adjustable 3 Switch 3 Switch

Auxiliary Switches N/A 3 Cams & 1 Pot Gear 3 Cams

Kit P/N 70-0012-22971-536 1 Pot Gear

Si z e 180

12

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

Wiring diagram for basic unit with C-Form (SPDT) travel switches. (Drawn

for actuator in its fully closed condition.)

Wiring diagram for unit with one set of “Voltage Free” C-Form (SPDT) open/close travel switches.

(Drawn for actuator in its fully closed condition.)

Actuator ‘C’-Form Switches, SPDT

Field Wiring Actuator

Field Wiring Actuator

Size-12 & 30

V3-Sw with

Lever

COM.

N.C.

N.O.

Size-6

V3-Sw

N.C.

N.O.

COM.

NOT TO EXCEED

500 OHMS

FIELD WIRING

5 VDC AT 50mA (IF REQUIRED)

POSITION

FEEDBACK

DEVICE

LOAD DEVICE

INCOMING COMMAND SIGNAL

+

OUTGOING FEEDBACK SIGNAL

-

+

NEUTRAL

LIVE

MOTOR

N

C

OR BLACK

YELLOW

O

ACTUATOR

RED

BLUE

POTENTIOMETER

GREY +

OVERRIDE SW

WHITE

ORANGE

-

YELLOW

YELLOW

FEEDBACK

COM

N.O.

N.C.

MANUAL

AUX CLOSE

COM

N.O.

CLOSE

N.C.

N.O.

AUX OPEN

GREEN

CAM

COM

RED

CAM

N.C.

OPEN

COM

N.C.

N.O.

N.C.

COM

N.O.

BLUE

C

BLUE

D

B

A

RED

RED

(VOLTAGE FREE)

(VOLTAGE FREE)

CLOSE N.O.

OPEN N.O.

BLUE

BLUE

RED

RED

HEATER

(OPTIONAL)

(SEE NOTE 3)

(SEE NOTE 4)

MOTOR

OPEN

1

ON

MOTOR

CLOSE

FUSE

NEUTRAL

NEUTRAL

LINE Power

OUTPUT (+)

OUTPUT (-)

+5 VDC

INPUT (+)

INPUT (-)

OPEN

LIMIT

CLOSE

LIMIT

COMMON

COMMON

HANDWHEEL

CALIBRAT ESTATUS

+5 VDC

COMMON

FB POT

HIGH

VOLTAGE

SERVO

210987

6543

PRO

HEATER

DEAD BAND

CLOSE

SPEED

OPEN

SPEED

CLOSE

OPEN

COMMON

TORQUE LIMIT

CLOSE

OPEN

COMMON

CONTROL BOX

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

*

E

F

GROUND

SINGLE PHASE

POWER SUPPLY

WHITE

BLACK

-

+

CALIBRATION SEQUENCE:

1. SET TRAVEL LIMIT SWITCHES

TO DESIRED END OF TRAVEL POSITIONS.

2. CONNECT POWER SUPPLY.

3. WITH ACTUATOR AT MID TRAVEL

PRESS "CALIBRATE" BUTTON FOR TWO SECONDS.

4. ACTUATOR WILL SELF-CALIBRATE.

13

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

NOT TO EXCEED

500 OHMS

FIELD WIRING

5 VDC AT 50mA (IF REQUIRED)

POSITION

FEEDBACK

DEVICE

LOAD DEVICE

INCOMING COMMAND SIGNAL

+

OUTGOING FEEDBACK SIGNAL

-

+

NEUTRAL

LIVE

MOTOR

N

C

OR BLACK

YELLOW

O

ACTUATOR

RED

BLUE

POTENTIOMETER

GREY +

OVERRIDE SW

WHITE

ORANGE

-

YELLOW

YELLOW

FEEDBACK

COM

N.O.

N.C.

MANUAL

AUX CLOSE

COM

N.O.

CLOSE

N.C.

N.O.

AUX OPEN

GREEN

CAM

COM

RED

CAM

N.C.

OPEN

COM

N.C.

N.O.

N.C.

COM

N.O.

BLUE

C

BLUE

D

B

A

RED

RED

(VOLTAGE FREE)

(VOLTAGE FREE)

CLOSE N.O.

OPEN N.O.

BLUE

BLUE

RED

RED

HEATER

(OPTIONAL)

(SEE NOTE 3)

(SEE NOTE 4)

MOTOR

OPEN

1

ON

MOTOR

CLOSE

FUSE

NEUTRAL

NEUTRAL

LINE Power

OUTPUT (+)

OUTPUT (-)

+5 VDC

INPUT (+)

INPUT (-)

OPEN

LIMIT

CLOSE

LIMIT

COMMON

COMMON

HANDWHEEL

CALIBRAT ESTATUS

+5 VDC

COMMON

FB POT

HIGH

VOLTAGE

SERVO

210987

6543

PRO

HEATER

DEAD BAND

CLOSE

SPEED

OPEN

SPEED

CLOSE

OPEN

COMMON

TORQUE LIMIT

CLOSE

OPEN

COMMON

CONTROL BOX

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

*

E

F

GROUND

SINGLE PHASE

POWER SUPPLY

WHITE

BLACK

-

+

CALIBRATION SEQUENCE:

1. SET TRAVEL LIMIT SWITCHES

TO DESIRED END OF TRAVEL POSITIONS.

2. CONNECT POWER SUPPLY.

3. WITH ACTUATOR AT MID TRAVEL

PRESS "CALIBRATE" BUTTON FOR TWO SECONDS.

4. ACTUATOR WILL SELF-CALIBRATE.

Wa r n i n g : Tu r n aLL Po W e r of f P r i o r T o a d j u s T i n g diP s W i T c h e s .

SW i t c h cO M M a n d in P u t

4-20 mA DC 0-5 vdc * 0-10 vdc 2-10 vdc

1 Off On On On

2 Off Off On On

3Off Off Off On

Ou t P u t

4-20 mA DC 0-5 VDC 0-10 VDC 2-10 VDC

4 Off On On N/A

5 On Off Off N/A

6Off On Off N/A

fO r W a r d ac t i n g re v e r S e ac t i n g

7 Off On

fa i l i n

la S t PO S i t i O n fa i l en a b l e **

8 Off On

fa i l cl O S e fa i l OP e n

9 Off On

tO r q u e tO r q u e

SW i t c h en a b l e SW i t c h di S a b l e

10 Off On

*To control servo with a remote potentiometer, set the Command Input to 0-5VDC (see Command Signal Con-

nector section; page 8 Servo Pro Manual).

**Fail position is the position that the servo will travel to when the control signal is removed. It does not apply

to 0-5VDC or 0-10VDC Command Signals.

14

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

i. ad j u S t t h e OP e n a n d cl O S e SP e e d O f y O u r a c t u a t O r (th e f a S t e S t c l O S i n g S P e e d O f y O u r

a c t u a t O r i S P r i n t e d O n t h e l a b e l O f t h e u n i t ):

1. Use the Close Speed trim pot to adjust the closing speed of your actuator (pot in the fully

CCW position = fastest close speed).

2. Use the Open Speed trim pot to adjust the opening speed of your actuator (pot in

the fully CCW position = fastest open speed).

ii. ca l i b r a t e t h e S e r v O :

1. Manually position your actuator somewhere in mid position; away from the travel limits.

2. Disengage your handwheel (push it back in towards the actuator), hold down the Calibration push

button for two seconds and release, the servo will begin to drive the actuator in the close

direction and then in the open direction in order to save these limits to memory.

3. Following a successful calibration the servo’s Status LED will begin to ash the normal operation code, an

unsuccessful calibration will yield a Red-Green-Red-Green ash immediately following the attempted calibration

(for more information on the Status LED ash codes see the Status LED Flash Code Table).

St a t u S led

The “Status LED” is a bi-color LED which provides detailed information regarding the operation of the S70 Servo Pro.

Table 2 below illustrates the different combinations of LED ash codes and their corresponding conditions. Following the

table is a more descriptive explanation of the Flash Code. Whenever the LED is ashing green, regardless of the ash

code, the servo will operate, but not necessarily optimally. Whenever the LED ash codes are RED, the servo will not

operate. An example is an engaged handwheel, the Status LED will ash a single red ash code and will not operate.

ta b l e 2: St a t u S led f l a S h c O d e S

gr e e n St a t u S led W a r n i n g a n d i n f O r M a t i O n fl a S h cO d e S :

#in d i c a t i O n re a S O n SO l u t i O n

1 Steady Green Flash Normal Operation Servo Functioning Ok

2 2 Green Flashes Calibration Defaults Loaded Adjust travel limits, push autocalibration PB

3 3 Green Flashes Reverse Acting Mode If you would like your servo to not operate in reverse

acting mode, set DIP switch 7 accordingly

4 4 Green Flashes 2-10VDC Input Command Signal Selected If you require a different configuration, set DIP

switches 1, 2, and 3 accordingly

5 1 Red Flashes Handwheel engaged Push the Handwheel in towards the actuator

6 2 Red Flashes Command Signal Failure Set DIP switches accordingly, send servo ap-

propriate signal

7 3 Red Flashes Feedback Pot Fault Position the feedback Pot correctly, see Feedback

Pot calibration

8 4 Red Flashes Limit Switch Fault Check wiring of limit switches, ensure that both

switches are not tripped simultaneously

9 5 Red Flashes Torque Switch Fault

Ensure that DIP switch 10 is positioned correct,

check wiring of torque switches, reverse direction

of actuator, correct over torque condition

10 6 Red Flashes Feedback Pot Wired In Reverse Correctly wire the Feedback Pot

Note: A ashing green LED provides status and warning information. The servo will operate normally in this state. Some

ash codes indicate a warning, where the servo has recovered automatically such as the detection of an invalid cali-

bration. In this case, a default calibration is automatically loaded that will allow the Servo to operate, but may not be a

perfect match to the actuator. The servo should be re-calibrated as soon as possible.

15

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

re c e P t a c l e S (qu i c K cO n n e c t O r S )

Unless otherwise specied, power receptacles will be

5-pin mini style standard duty with a black anodized

aluminum nish. They conform to ANSI B93.55M except

in wire color. Euro receptacles will be used for low power

instrument and signal cable since they can be supplied

shielded. Wiring diagrams for plug-in receptacles for

either the Bray Series 70 or the local control station will

be provided as a separate diagram. Units ordered with

pin connector receptacles factory installed are wired

and tested. Cordsets which t these receptacles may be

ordered in several lengths.

re c e P t a c l e Ki t c O n S i S t S O f :

1) Receptacle(s), male pin and male thread 1/2”-NPT, in

the qty., style and number of pins ordered

Wi r i n g S c h e M a t i c f O r O P t i O n a l Pi n cO n n e c t O r re c e P t a c l e S

nO l.c.S.1With l.c.S.1

requireMentS recePtacleS req’d diagraM diagraM

On - Off unitS (i n t e r M i t t e n t O r c O n t i n u O u S )

PO W e r O n e M i n i SK-960517 SK-960515

PO W e r PO S i t i O n i n d i c a t i O n 2O n e M i n i O n e e u r O SK-960717 SK-960513

PO W e r PO S i t i O n i n d i c a t i O n 3O n e M i n i O n e e u r O SK-960516 SK-9607165

PO W e r fe e d b a c K P O t e n t i O M e t e r O n e M i n i O n e e u r O SK-960718 SK-960720

PO W e r PO S i t i O n i n d i c a t i O n 3fe e d b a c K P O t e n t i O M e t e r O n e M i n i 6-P i n e u r O 4SK-960719 n/a

Custom congurations are possible - consult the factory.

1 L.C.S.: Local Control Station , WHICH implies

mounted to the actuator

2Travel indication is wired to the supply voltage

3 Travel indication wiring is voltage free

4

A 6-pin EURO connector is required for this application,

consult factory for price and availability.

2) Reducing bushing 3/4”to 1/2” NPT for installation in

size 12 - 180 and control stations

3) Wiring diagram (SK-# below)

tO O l S r e q u i r e d :

• For terminal wiring Screwdriver, 3/16” tip at blade

• For Mini or Euro receptacle Wrench, 1”

in S t a l l a t i O n P r O c e d u r e :

1) Screw the receptacle into the actuator conduit entry

using teon tape or similar.

2) Wire to the terminal strip according to the wiring

diagram or the eld wiring requirements.

5 The Local Control Station comes standard with 120 Volt

lamp bulbs, for other voltages consult factory.

Note: the Control Station lights must be wired to the same

voltage as the remote end of travel indication.

Euro receptacles use 22 AWG wire rated at 250V, 4 Amp.

Pin conguration interfaces with European standards.

Mini receptacles use 18 AWG wire rated at 300 V, 9 Amp.

Pin conguration conforms to ANSI B93.55M.

* For requirements beyond these ratings consult

the factory.

16

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

SP i n n e r

A spinner is available to ease and speed the manual over-

ride of the Bray Series 70 actuator. The 300 and 500 in.lb.

units mount the spinner on a lever which screws onto the

back of the handwheel. The 800 through 18000 in.lb. units

mount the spinner on the rim of the handwheel. Note that

care should be exercised in the use of spinner equipped

handwheels. Rapid operation of the handwheel to close

the valve may cause water hammer. Also, rapid travel into

a travel stop may cause damage.

SP i n n e r Ki t c O n S i S t S O f :

For 300 and 500 in.lb. For 800 to 18000 in.lb. units

Spinner and lever assembly Socket head shoulder bolt,

Flat head socket cap screw, 1/4-20UNC x .75

#10-32UNF x 3/8 Spinner handle

tO O l S r e q u i r e d :

• For socket head shoulder bolt and at head capscrew

Hex key, 1/8” for 300 and 500 in.lb.

Hex key, 3/16” for 800 to 18000 in.lb.

in S t a l l a t i O n P r O c e d u r e :

• For 300 and 500 in.lb. units simply position the lever onto

the back of the handwheel then screw the at head cap

screw in to place from behind.

•For 800 up to 18000 in.lb. units, put the socket head

shoulder bolt through the spinner handle and screw it

rmly into the handwheel rim.

can be used on the on - off units and the servo controlled

modulating units. Optional key operated locking switches

are available.

Note: The control station used with On - Off S70 and that

used with modulating S70 have different contact blocks

internally, the correct part number must be used to ensure

you order the correct unit (see price sheet).

lO c a l cO n t r O l St a t i O n Ki t c O n S i S t S O f :

1 Local control station assembly

2 Four socket head cap screws, #10-24UNC x 4.50 long,

for mounting the station to the actuator

3 A gasket for sealing the station to the actuator

4 Wiring diagram

tO O l S r e q u i r e d :

• For tapping control station mounting holes on actuator,

#10-24UNC Tap.

• For wiring Screwdriver, 3/16” at blade.

• For mounting and cover screws Hex key, 5/32”

in S t a l l a t i O n P r O c e d u r e :

1.

Tap #10-24UNC holes

using the cored holes

on the side of actuator.

2. Adhere the gasket tothe

control box.

3. Mount the control box

to the actuator using

the 4 long socket head

capscrews.

4. Wire the control box to the actuator in accordance to

the wiring diagram provided. The local control station

contains no terminal strips, and all wiring is direct to the

switches and lights via 2” x 3/4” NPT holes in bottom of

housing.

Ordering the control station with optional pin

connectorrecep-

tacles will elimi-

nate the neces-

sity of eld wiring.

The units will be

completely fac-

tory wired and

tested.

Note: The inclined

cover of the local

controlstationcanbe

mounted in any of its

four symmetrical po-

sitions. If eld wiring is required , rst mount the base to the

actuator, then remove the cover to gain access for wiring.

lO c a l cO n t r O l St a t i O n (Si n g l e Ph a S e PO W e r e d

ac t u a t O r S )

Bray’s local control station gives the user the ability to locally

override the actuator electrically. The station is open / stop /

close operation in the local control mode. Red and green end

of travel indication lights are also provided. Depending on how

it is wired the control station

17

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

aP P e n D I x a

ba S i c tO O l S

cO M M O n tOal l un i t S

Terminal connections, cam adjustment Screwdriver, 1/4” tip at tip blade

All switches, terminal strip, torque switch plate Screwdriver, No.1 phillips

Switchplate screws, capacitor Screwdriver, No.2 phillips

Servo trimmer pots Screwdriver, 1/8” at tip for trim pots

300-500 i n •l b u n i t S

Mounting nuts Wrench, 1/2”

Cover captivated capscrews Hex key, 1/4”

Travel stop adjusting bolts Wrench, 7/16”

Travel stop jam nuts Wrench, 7/16”

Motor mount socket at head capscrew Hex key, 3/32”

Motor mount socket head capscrew Hex key, 9/64”

800-1200 i n •l b u n i t S

Mounting nuts (small pattern) Wrench, 1/2”

Mounting nuts (large pattern) Wrench, 3/4”

Cover captivated capscrews Hex key, 5/16”

Travel stop adjusting bolts Wrench, 9/16”

Travel stop nuts Wrench, 9/16”

Motor mount socket head capscrew Hex key, 5/32”

3000-6500 i n •l b u n i t S

Mounting nuts, travel stop jam nuts Wrench, 3/4”

Cover captivated capscrews Hex key, 3/8”

Travel stop adjusting studs Wrench, 3/4”

Motor mount socket head shoulder bolt Hex key, 5/32”

Motor mount socket head cap screws Hex key, 3/16”

13000-18000 i n •l b u n i t S

Mounting nuts, travel stop jam nuts Wrench, 3/4”

Cover captivated capscrews Hex key, 3/8”

Travel stop adjusting studs Wrench, 15/16”

Motor mount socket head shoulder bolt Hex key, 5/32”

Motor mount socket head cap screws Hex key, 3/16”

18

BRAY Series 70 Electric Actuator

Operation and Maintenance Manual

aP P e n D I x b

ac t u a t O r tr O u b l e S h O O t i n g ch a r t

Pr O b l e M PO S S i b l e c a u S e SO l u t i O n S

Actuator does not operate Override is engaged Push handwheel in all the way

Wiring is incorrect Check wiring and power supply

Actuator motor has reached its Allow time to cool

thermal shutdown temperature

Actuator operates in reverse directions Field wiring is reversed Rewire eld wiring

Actuator does not fully close valve Limit switches are depressed Readjust travel limit switches

(or open valve) Mechanical travel stop is Adjust mechanical travel stops

stopping actuator

Valve torque requirement is Manually override out of seat, try

higher than actuator output angle seating or larger actuator

Optional torque switches Valve torque exceeds actuator are activating

torque rating - consult factory

Voltage power supply is low Check power source.

Engaging override handwheel does Override pin is corroded or Clean and check for smooth

not shut off motor damaged operation of the override switch pin

Override switch is damaged Replace switch

Disengaging override handwheel Not completely disengaged Push handwheel in as far as

does not restart motor possible (no yellow showing)

Override pin is damaged or Replace override pin

and does not activate switch

Incorrect wiring of override Check wiring

switch

Motor runs but worm and gear Worm gear segment is not Remove switchplate and inspect,

segment do not meshing with worm adjust travel stops to prevent gear

disengaging

Pin/Key on Worm/Motor Replace Pin/Key on drive gear

drive gear sheared

Corrosion inside unit Condensation forming Test heater wiring, should have

constant power

Water leaking in Check all seals and possible water

entry through conduit

Other manuals for Series 70

9

This manual suits for next models

1

Table of contents

Other Bray Controllers manuals

Bray

Bray Series 70 User manual

Bray

Bray 71 Series User manual

Bray

Bray 71 Seires User manual

Bray

Bray 70-003-113-536 Series User manual

Bray

Bray 75 Series User manual

Bray

Bray PA(M)24-27 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 92 Series User manual

Bray

Bray Series 70 User manual