2

PA24-27 Series - Installation, Operation & Maintenance Manual Continued

For Simple Set PIC Valves

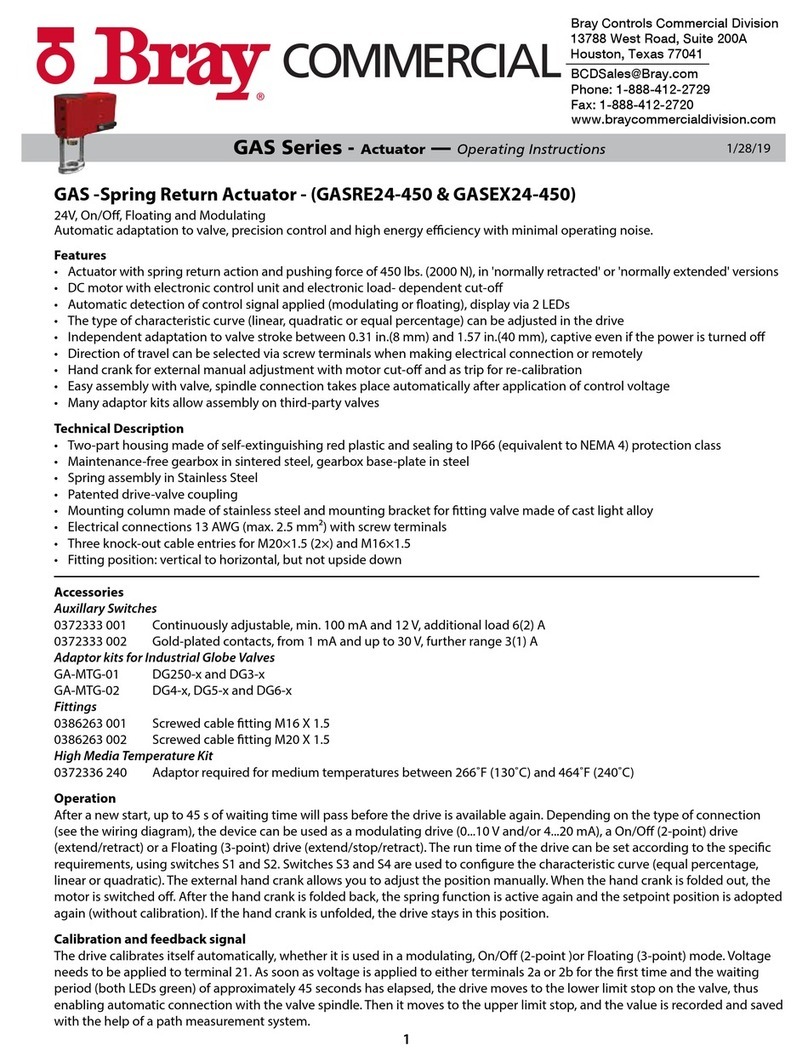

Application

The PA(M) Series is a line of linear motor actuators to be used primarily

on Bray PIC Valves utilized in Building Automation Systems. These

actuators are available with a multitude of options for On/O/Floating or

Modulating with or without electronic Failsafe.

These actuators automatically calibrate to the stroke of the valve as soon

as power is applied and are field selectable direct or reverse acting.

A simple, reliable, versatile solution for your Bray Commercial Simple Set

pressure Independent control valves!

PA Series Actuators - Model Number Matrix

PA Series Actuators - Dimensions

PA Series Actuators - Function

PA24-27 24V On/O & Floating - Non-Fail Safe

PA24-27-FS 24V On/O & Floating - Fail Safe

PAM24-27 24V Modulating - Non-Fail Safe

PAM24-27-FS 24V Modulating - Fail Safe

4.09"

3.62"

2.08"

Unlike conventional control valve sizing where valves are sized to a Cv, the Simple Set valves are simply sized for flow and pipe

size. Refer to the ordering table for the wide range of flow values available.

IMPORTANT: Valve diameter should NEVER exceed pipe diameter!

The design of Simple Set combines high performance with small size and compact construction.

The main components of the valve are:

Actuator

Reacts to building controller

call for more or less flow.

Modulating Control Component

1. Rotates laterally to limit max flow

through the valve per the Pre-Setting

Scale

2. Moves vertically in response to the

actuator vcall for more or less flow.

P/T Plugs

Allows for measurement of

water flow and temperature.

Pressure Control Cartridge

Ensures constant flow rate is achieved under

fluctuating system pressures. As the system

dierential pressure increases and decreases,

the Dp controller absorbs and releases pressure

through an internal capillary tube maintaining

a constant Dp across the valve.

Pre-Setting Scale

Sets maximum flow

allowed through the valve.

Pre-Setting Scale (Detail)

3

5

4

1

2

4

3

2

1

0

5

.

5

m

m

3