Bray 75 Series User manual

The

High

Performance

Compan

y

R

SERIES 74

ELECTRIC ACTUATOR

OPERATION AND MAINTENANCE MANUAL

204450

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

1

TABLE OFCONTENTS PAGE

SPECIFICATION ---------------------------------------------------------------------------------- 2

TRAVEL CAM & LIMIT SWITCHES ADJUSTMENT ------------------------------------------------- 3

MECHANICAL STOPS ---------------------------------------------------------------------------- 4

POTENTIOMETER -------------------------------------------------------------------------------- 4

MODULATING CONTROL BOARD ----------------------------------------------------------------- 5

TROUBLE SHOOTING ---------------------------------------------------------------------------- 6

LUBRICATION, NOTICE & STORAGE ------------------------------------------------------------ 6

PARTS FOR S74 –0890 & 1330 -------------------------------------------------------------- 7,8

PARTS FOR S74 –2210 & 3100 ------------------------------------------------------------- 9,10

WIRING DIAGRAM FOR 110V/220V AC 1-PH / ON/OFF ------------------------------------ 11

WIRING DIAGRAM FOR 110V/220V AC 1-PH / MODULATING ------------------------------ 12

WIRING DIAGRAM FOR 110V/220V AC 1-PH / MODULATING

LOCAL/REMOTE SELECTION SWITCH ----------------------------------------------------- 13

WIRING DIAGRAM FOR 110V/220V AC 1-PH / ON/OFF

LOCAL/REMOTE SELECTION SWITCH ----------------------------------------------------- 14

WIRING DIAGRAM FOR 110V/220V AC 1-PH / 4-20MA OUTPUT SIGNAL ------------------ 15

WIRING DIAGRAM FOR 110V/220V

SAME SWITCH PARALLEL WIRING -------------------------------------------------------- 16

WIRING DIAGRAM FOR 220V/380V/440V 3-PH /WITH REV. STARTER / ON/OFF ----------- 17

WIRING DIAGRAM FOR 220V/380V/440V 3-PH /WITH REV. STARTER / MODULATING ----- 18

WIRING DIAGRAM FOR 220V/380V/440V 3-PH /WITH REV. STARTER

4-20MA OUTPUT / ON/OFF -------------------------------------------------------------- 19

WIRING DIAGRAM FOR 220V/380V/440V 3-PH / 4-20MA

OUTPUT SIGNAL (NOSTARTER) ---------------------------------------------------------- 20

WIRING DIAGRAM FOR 24V DC ON/OFF ----------------------------------------------------- 21

WIRING DIAGRAM FOR 24V AC ON/OFF ----------------------------------------------------- 22

WIRING DIAGRAM FOR 220V/380V/440V 3-PH ON/OFF ----------------------------------- 23

WIRING DIAGRAM FOR 24V DC / MODULATING ---------------------------------------------- 24

WIRING DIAGRAM FOR 24V AC / MODULATING ---------------------------------------------- 25

FOR INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT US AT OUR WEBPAGE - www.bray.com

Model Max Torque Speed (90°) Motor

Motor Speed RPM

220V 380V 440V

No. In/Lbs (Nm) 60 Hz 50 Hz Power 60 Hz 50 Hz Run Start Lock Run Start Lock Run Start Lock

S74-0890 8850 (1000) 46s 55s 180W 1720 1450 0.6A 0.8A 1.8A 0.4A 0.6A 1.0A 0.4A 0.6A 1.0A

S74-1330 13,300 (1500) 46s 55s 220W 1720 1450 0.8A 1.0A 2.8A 0.6A 0.8A 1.6A 0.6A 0.8A 1.2A

S74-2210 22,100 (2500) 58s 70s 220W 1720 1450 0.8A 1.0A 1.5A 0.4A 0.6A 1.0A 0.4A 0.6A 1.0A

S74-3100 31,000 (3500) 58s 70s 300W 1720 1420 1.2A 1.4A 2.5A 0.6A 0.8A 1.5A 0.6A 0.8A 1.5A

Three Phase

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

2

SPECIFICATIONS

Model Max Torque Speed Motor Motor Speed RPM 12V DC/AC 24V DC/AC

No. In/Lbs (Nm) (90°) Power 12V 24V Run Start Lock Run Start Lock

S74-0890 8850 (1000) 46s 220W — 1800 — — — 7.0A 8.0A 30.0A

S74-1330 13,300 (1500) 46s 220W — 1800 — — — 7.5A 8.0A 30.0A

S74-2210 22,100 (2500) 58s 220W — 1800 — — — 7.5A 8.0A 30.0A

S74-3100 31,000 (3500) 58s 300W — 1800 — — — 15.0A 15.0A 26.0A

12V / 24V

RUN - Full load running current

START - Initial start-up/surge current

LOCK - Locked rotor/stalled current

Model Max Torque Speed (90°) Motor

Motor Speed RPM

110V AC 220 - 240V AC

No. In/Lbs (Nm) 60 Hz 50 Hz Power 60 Hz 50 Hz Run Start Lock Run Start Lock

S74-0890 8850 (1000) 46s 55s 180W 1720 1450 3.2A 12.0A 10.0A 1.6A 4.0A 4.0A

S74-1330 13,300 (1500) 46s 55s 220W 1720 1450 4.0A 14.0A 10.0A 2.0A 3.6A 5.0A

S74-2210 22,100 (2500) 58s 70s 220W 1720 1450 4.0A 12.0A 6.0A 2.0A 4.0A 3.0A

S74-3100 31,000 (3500) 58s 70s 300W 1720 1420 4.0A 14.0A 5.0A 2.2A 4.0A 3.0A

Single Phase

DUTY CYCLE RATINGS

ALL SIZES ON/OFF DUTY 30%

S74-0890 & 1330 MOD. DUTY 75%

S74-2210 & 3100 MOD. DUTY 50%

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

3

LS4 - Aux. switch cam factory set at full closed position.

Can be set at an intermediate position if required.

LS3 - Aux. switch cam factory set at full open position.

Can be set at an intermediate position if required.

LS2 - Close travel switch cam.

Rotate cam clockwise to decrease closed

position and vice versa.

LS1 - Open travel switch cam.

Rotate cam clockwise to increase full open

position and vice versa.

LS4

LS3

LS2

LS1

LS4

LS3

LS2

LS1

TORQUE CAM ADJUSTMENT (FACTORY SET)

S74-0890 & 1330

TS1 - Counter-clockwise: Lowers torque value trip setting.

Clockwise: Increases torque value trip setting.

TS2

TS1 TS1 - Counter-clockwise: Lowers torque value trip setting.

Clockwise: Increases torque value trip setting.

TORQUE CAM ADJUSTMENT (FACTORY SET)

S74-2210 & 3100

TS1 - Counter-clockwise: Increases torque value trip setting.

Clockwise: Lowers torque value trip setting.

TS1 - Counter-clockwise: Increases torque value trip setting.

Clockwise: Lowers torque value trip setting.

TS2

TS1

TRAVEL CAM & LIMIT SWITCH ADJUSTMENT

(ALL SIZES)

LS1 & LS2 - Open and Close travel switch cams can be

set to users preferred Open & Close valve positions.

The motor is powered via the travel switches normally

open (N.O.) contacts the cam depresses the switch lever

Closed

Direction

Open

Direction

Closed

Direction

Open

Direction

to allow motor to run. Adjusting cam so that switch lever

is not depressed will stop motor.

LS3 & LS4 - Are voltage free aux. travel indication switch

cams and can be set at any position between 0 and 90

degrees to provide remote position indication. Travel

cams can be adjusted with a 2.5mm hex key.

4

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

MECHANICAL STOPS

FOR ELECTRIC OPERATION:

Please refer to “Travel Cam & Limit Switch Adjustment”

The motor should be stopped by the end of travel limit

switches (LS1 & 2) being activated by their respective

cams.

FOR MANUAL OPERATION:

1) Slacken the locknuts & back-out the socket head

travel stop bolts.

2) Adjust open (LS1) & close (LS2) travel limit switch

cams to desired end of travel positions.

3) Using handwheel drive actuator to it’s fully open

position (confirm that open travel position switch is

activated). Turn handwheel one half turn opening

actuator more. With hex key, screw open travel bolt

in until it comes to a stop against internal stop pad.

4) Secure bolt by tightening locknut against housing.

5) Repeat steps 1 to 4 for close travel bolt.

POTENTIOMETER

Potentiometers turn with transmission shafts, and can

provide a feedback signal for position indication.

Potentiometer terminals 1, 2, 3 are wired to terminal

blocks 5, 6, 7.

When a valve is closed: 5,6 — 1K Ohm

6,7 — 0K Ohm

When a valve is opened: 5,6 — 0K Ohm

6,7 — 1K Ohm

For modulating controllers, potentiometer terminals 1, 2,

3 are wired to terminal blocks 8, 9, 10.

When a valve is closed: 8,9 — 5K Ohm

9,10 — 0K Ohm

When a valve is opened: 8,9 — 0K Ohm

9,10 — 5K Ohm

CLOSE

OPEN

5

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

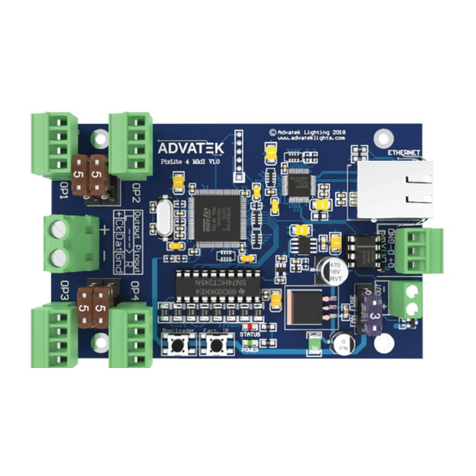

MODULATING CONTROL BOARD: INTERFACE

A

Terminal Block

Green Lamp (Open Indicator)

Red Lamp (Closed Indicator)

Sensitivity Switch is set in

position 3 at factory.

Pos. 1 being most sensitive

Pos. 0 being least sensitive

(Closed angle trim pot)

Output

B

1

2

3

4

5

6

7

8

VR2

9

10

11

12

Input

Power

N

L

0

1

2

3

4

5

6

7

8

9

(Open angle trim pot)

Standard factory

setting is #1,4,& 8 ON

#2,3,5,6 &7 OFF.

87654321

ON

Yellow Lamp

(Power Light)

*

S1 ~ S8 D.I.P. Switch

VR1

Input Signal

4~20mA

1~5V DC

2~10V DC

Output Signal

4~20mA

2~10V DC

Comparison

Part

Control Part

Driving Part

Control Object

AC Motor

Control Volume

Valve 90°

270°VR

(5K Ohm)

Feedback

Signal

*D.I.P.SWITCH S ETTINGS (WARNING:Disconnect power

supply prior to changing settings)

S1,2 Select Input Signal:

4-20mA, 1-ON, 2-OFF

1-5VDC, 1-OFF, 2-OFF

2-10VDC, 1-OFF, 2-ON

S3,4,5 Select Output Signal:

2-10VDC, 3-ON, 4-OFF. 5-ON

4-20mA, 3-OFF, 4-ON, 5-OFF

S6 Valve fully closed on 4mA or 1V or 2V Input

Signal and full open on 20mA or 5V or 10V

Input Signal, 6-OFF (for reverse operation

switch 6-ON)

S7,8 Position on loss of incoming control signal:

Valve will fully close –7-ON, 8-OFF

Valve will fully open –7-OFF, 8-ON

Valve will stop where it is –7-ON, 8-ON

If reverse operation (4mA to open, 20mA

to close) reverse 7 & 8 positions.

VR TRIM POT ADJUSTMENT

VR2 (Close Travel) Turn fully clockwise, provide

close signal, then turn pot. counter clockwise 3 to 6

turns until red light stays on.

VR1 (Open Travel) Turn fully counter clockwise,

provide open signal, then turn pot. clockwise 3 to 6

turns until green light stays on.

6

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

Problem Possible cause Solutions

Motor does not operate

Check supply power and voltage are correct.

Check by meter.

Any blisters on the capacitor? If so replace.

Is the gear train locked-up? Remove motor to check.

Motor stops running Is power supply short circuited? Check wiring.

Any foreign objects in pipeline? Check for obstructions.

Unable to fully open/close Loose/Misaligned cam? Adjust/Tighten using wrench.

Bent valve stem? Replace valve stem.

Mechanical stop adjustment incorrect?

Check position of stops.

Valve stops operating when motor Gear worn out? Replace gear.

is running. Sleeve adapter worn out or broken? Replace sleeve adapter.

Broken valve stem or actuator Replace valve stem or actuator

transmission shaft. transmission shaft?

Abnormal control for operating two or Controlling circuit connected in Refer to the wiring diagram.

more actuators simultaneously. tandem or parallel?

Motor overheats. Incorrect voltage? Check by meter.

Valve torque too high? Replace with larger actuator.

High working frequency? Check duty cycle.

Is motor stem or bearing binding? Replace the binding parts.

Occasional on/off actuator failure. Simultaneous input power on/off. Check if the selection switch is

normal.

Vibration when valve is closed. Motor brake spring fatigued or Replace spring or Teflon.

Teflon worn?

ACTUATOR TROUBLESHOOTING CHART

LUBRICATION

The gearbox of the Bray actuator is enclosed, and it has

already been lubricated sufficiently with high tempera-

ture lubricant at the factory sufficient for use for up to two

years.

IMPORTANT NOTICES & MAINTENANCE

Notices:

1. Make sure the voltage is correct before power-up.

2. Turn power off before conducting any mainte-

nance.

3. Seal the casing and conduit entrance after wiring

to prevent dust or water contamination.

4. The angle of electric actuator installation must

between 0~180 degree. Do not install upside

down or below the horizontal.

5. Do not install when hazardous or explosive gases

may be present.

6. The frequency of open and close operation is

restricted to every 5 minutes. Avoid too high a

cycle frequency.

7. When more than one electric actuator needs to

operate simultaneously, please connect with

individual cables & not in parallel.

8. Connect the ground wire to PE inside the electric

actuator.

9. The warranty period of our product is one year.

Storage:

1. The actuator should be placed in a clean and dry

place, and protected from the weather and

extreme vibration.

2. If actuator needs be stored outside, it must be

protected from excess moisture, dust, and

weather.

7

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

SERIES 74

SIZE: 0890 & 1330 (1 OF 2)

1 SCREW

2 MOUNTING PLATE

3 WINDOW PROTECTION COVER

4 HOUSING COVER

5 WINDOW

6 SCREW

7 SCREW

8 BRAKE SPRING COVER

9 BRAKE SPRING

10 MOTOR BRAKE (PTFE)

11 MOTOR

12 SCREW

13 CAPACITOR

14 MOUNTING BRACKET

15 SCREW

16 SCREW

17 FIXED PLATE

18 MOUNTING BRACKET

19 TERMINAL BLOCK

20 SCREW

21 LIMIT SWITCH

22 MOUNTING BRACKET

23 SCREW

24 SET SCREW

25 TRAVEL CAM

26 BEARING

27 1st GEAR

28 DRIVE KEY

29 2nd GEAR

30 BEARING

31 BEARING

32 SNAP RING (C TYPE)

33 DRIVE KEY

34 3rd GEAR

35 BEARING

36 SCREW

37 MOUNTING PLATE

38 SCREW

39 4th GEAR

40 BEARING

41 SNAP RING (C TYPE)

42 5th GEAR

43 BEARING

44 DRIVE KEY

45 SHAFT

46 BEARING

47 BEARING

48 INNER GEAR

49 SCREW

50 POSITION INDICATOR

51 BEARING

52 PLANET GEAR

53 POSITION INDICATOR SHAFT

54 BEARING

55 SNAP RING (C TYPE)

56 BEARING

57 OUTPUT DRIVE

58 SPRING PIN

59 O-RING

60 BEARING

61 BEARING

62 NUT

63 WASHER

64 SOCKET END SET SCREW

65 0-RING

66 BEARING

67 WORM WHEEL SHAFT

68 HAND WHEEL

69 DRIVE KEY

70 SCREW + WASHER

71 COVER PLATE

72 OIL SEAL

73 SOCKET HEAD SCREW

74 HOUSING BASE

75 OIL SEAL

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

SERIES 74

SIZE: 0890 & 1330 (2 OF 2)

76 SCREW*

77 TORQUE LIMIT SWITCH*

78 MOUNTING PLATE*

79 SPACER*

80 TORQUE CAM*

81 SCREW*

82 SNAP RING (E TYPE)*

83 WASHER*

84 SCREW*

85 MOUNTING PLATE*

86 BEARING*

87 BEARING*

88 TORQUE DRIVE SHAFT*

* OPTIONAL

89 WORM SHAFT

90 BEARING

91 SPRING WASHER*

92 BEARING*

93 BUSHING*

94 WASHER*

95 NUT*

96 0-RING*

97 FIXED SEAT*

98 OIL SEAL*

99 SNAP RING (C TYPE)*

100 SOCKET HEAD SCREW*

8

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

SERIES 74

SIZE: 2210 & 3100 (1 OF 2)

1 SCREW

2 MOUNTING PLATE

3 WINDOW PROTECTION COVER

4 WINDOW

5 HOUSING COVER

6 SCREW

7 MOTOR

8 SCREW

9 MOTOR BRAKE (PTFE)

10 BRAKE SPRING

11 BRAKE SPRING COVER

12 SCREW

13 SCREW

14 POSITION INDICATOR

15 CAPACITOR

16 SCREW

17 MOUNTING BRACKET

18 SCREW

19 MOUNTING PLATE

20 SHAFT

21 BEARING

22 BEARING

23 GEAR

24 GEAR

25 SCREW

26 SHAFT

27 MOUNTING PLATE

28 TRAVEL CAM

29 SET SCREW

30 LIMIT SWITCH

31 SCREW

32 MOUNTING PLATE

33 MOUNTING BRACKET

34 SCREW

35 TERMINAL BLOCK

36 DRIVE KEY

37 BEARING

38 1st GEAR

39 BEARING

40 SHAFT

41 MOUNTING PLATE

42 SCREW

43 BEARING

44 SNAP RING (C TYPE)

45 2nd GEAR

46 BEARING

47 DRIVE KEY

48 BEARING SHAFT

49 BEARING

50 BEARING

51 INNER GEAR

52 BEARING

53 PLANET GEAR

54 BEARING

55 SNAP RING (C TYPE)

56 BEARING

57 OUTPUT GEAR

58 O-RING

59 BEARING

60 SCREW

61 GEAR

62 POSITION INDICATOR SHAFT

63 PIN

64 SCREW

65 COVER PLATE

66 BEARING

67 O-RING

68 BEARINGS

69 HOUSING BASE

70 BEARING

71 WORM WHEEL SHAFT

72 O-RING

73 BEARING

74 MOUNTING PLATE

75 OIL SEAL

76 HAND WHEEL

77 DRIVE KEY

78 SCREW + WASHER

79 SCREW

80 NUT

81 OUTPUT BASE

82 WASHER

83 SCREW

84 BEARING

85 BUSHING

86 SCREW

87 SCREW

88 BEARING

89 OUTPUT WORM GEAR

90 BEARING

91 O-RING

92 OUTPUT BASE FLANGE

93 SCREW

94 OIL SEAL

9

10

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

SERIES 74

SIZE: 2210 & 3100 (2 OF 2)

95 SCREW*

96 TORQUE LIMIT SWITCH*

97 MOUNTING PLATE*

98 SPACER*

99 TORQUE CAM*

100 SET SCREW*

101 SNAP RING (E TYPE)*

102 WASHER*

103 SCREW*

104 MOUNTING PLATE*

105 BEARING*

106 BEARING*

107 TORQUE DRIVE SHAFT*

108 SPRING*

109 BEARING*

* OPTIONAL

110 BUSHING*

111 O-RING*

112 MOUNTING PLATE*

113 SCREW

114 O-RING

115 WASHER

116 WASHER

117 OIL SEAL*

118 WORM WHEEL

119 COVER PLATE

120 BUSHING

121 BEARING

122 SPRING

123 SCREW*

11

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

DIAGRAM ABBREVIATIONS

1. MC1 and MC2: Electromagnetic Contactor

2. C.S.: Control Switch

3. Duty Cycle: our standard modulating type S74-1330

is 75% duty cycle and S74-3100 is 50% duty cycle.

4. PE - Actuator grounding connection.

5. LS1 & 2 - Open & Close travel limit switches.

LS3 & 4 - Aux travel indication swithes (voltage free

contacts)

6. TS1 & 2 -

Open & Close overtorque switches (optional)

WIRING DIAGRAM S74 - 890 & 1330 SIZES 110V / 220V AC 1-PH / ON-OFF SERVICE

134567ABCDEF

NL

Power Supply

110/220V

1-PH

LS1 LS2

ACTUATOR

CS

Note: Typical field wiring shown

with dashed lines.

PE

TS1 TS2

LS3 LS4

NC

COM

OPEN CLOSE

COM

NO

NC

COM

NO NC

COM

NO

NCNO

COM

NCNO

COM

NCNO

M

C

Heater

Fully closed ind. Lamp

Fully open ind. Lamp

G

(optional)

(optional)

Actuator drawn for it's fully

closed postion (close travel

switch "LS2" has been

tripped.)

Connect to remote position

indication circuit, if required.

12

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 - 890 & 1330 SIZES 110V / 220V AC 1-PH / MODULATING SERVICE

1234567

8910 11 12

N

L

+

-

5K

AB

CDE

Modulating Control Board

110/220V AC

LS4

LS3

Note:

(1) Input Signal :

4-20mA or

1-5V or

2-10V.

(2) Output Signal :

4-20mA or

2-10V.

LS2

LS1

TS2

TS1

F

4321

M

90/180 DC

F

BA

Position Feedback Signal

-

+

INT POT

NO NC

COM

NO NC

COM

NO NC

NO NC

COM

NO NC

COM

NO NC

COM

COM

Connect to remote position

indication circuit if required.

Heater

Input Signal

(Use shielded wire &

ground shield on one

end only.)

Power Supply

(optional)

(optional)

13

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 110V / 220V AC 1-PH / MODULATING SERVICE

LOCAL / REMOTE SELECTOR SWITCH

5K

Modulating Control Board

TS1

Pot.

LS1 LS2

7

N

L

6

5

4Heater

Switch (1)

Switch (2)

Remote

Local

Close

Open

GRO

Lamp

(open)

Lamp

(close)

Lamp

(power)

_

A

D

C

B

F

E

12111098

TS2

M

C

123

RY1

-

+

-

+

(Optional)

(Optional)

Input Signal

4-20mA or

2-10V or 1-5V.

Output Signal

4-20mA or 2-10V.

Power Supply

110/120V

1-PH.

+

Connect

to remote

position

indication

circuit if

required.

LS3

LS4

14

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 110V / 220V AC 1-PH / ON-OFF SERVICE

LOCAL / REMOTE SELECTOR SWITCH

134567

PE

RG

O

M

C

S2

S1

Remote

Open Close

Close Open

LS1LS2

Lamp (power)

Heater

Lamp (open)

Lamp (closed)

(optional)

TS2

(optional)

TS1

B

LS3

A

LS4

F

E

D

C

Local

GLN

Power Supply

110V/220V

Customer's

remote control

switch.

Connect to remote position

indication circuit, if required.

15

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 110V / 220V AC 1-PH / 4-20MA OUTPUT SIGNAL

134567ABCDEF

NG L

Power Supply

110V/220V

1-PH

TS1 TS2

LS3 LS4

ACTUATOR

Fully open indicator (Lamp)

Fully closed indicator (Lamp)

PE

LS1 LS2

89

4-20mA

Output Signal

(optional)

M

(optional)

R13

R14

*R14 adjusts 4mA

*R13 adjusts 20mA

(optional)

Heater

Customer's

remote control

switch.

Open Close

Connect to remote position

indication circuit, if required.

16

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 110V / 220V SAME SWITCH CONNECTION WIRING

1

3

4

5

6

C

1

5

4

3

6

B

1

5

4

3

6

A

Full close

close

open

Full open

close

open

close

open

Ra1

Rb1

Rb2

Ra2

Rb3

Ra3

close

open

R

110V/220V

Power

L

N

Single phase

7

7

7

WARNING - Do not wire multiple

single phase on/off duty actuators

in parallel with common contacts.

Example shown for three single

phase actuators, two (A & B) being

in their closed position & the third

one (C) being fully open.

NOTE: Three sets of relay contacts

are used, if they were all connected

to one set of contacts the resultant

parallel configuration would cross

feed the motors and damage them.

Ra-1 to 3 N.O. contacts on R

Rb-1 to 3 N.C. contacts on R

Full close

Full open

Full close

Full open

Actuator "A"

Actuator "B"

Actuator "C"

Relay

Coil

17

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 220V / 380V / 440V 3-PH / ON-OFF SERVICE

LOCAL / REMOTE SELECTOR SWITCH

A

B

C

E

F

LS1 LS2

D

W

V

U

Heater

Switch (1)

Switch (2)

Remote

Local

Close

Open

GRO

Lamp

(open)

Lamp

(close)

Lamp

(power)

110V

1

3

4

TS1 TS2

M

MC1-a

MC2-a

MC2-a

MC2-a

MC1-a

MC1-a

MC2-b MC1-b

MC1 MC2

open

close

LS4

LS3

Power Supply

220V/380V

440V 3-PH

L1

L2

L3

Customer's

remote

control

switch.

Connect

to remote

position

indication

circuit if

required.

18

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 220V / 380V / 440V 3-PH / MODULATING SERVICE

67 11

12

+

-

5K

Modulating Control Board

LS1

Potentiometer

Output Signal

4-20mA

or 2-10V.

TS1 TS2

LS2

W

V

U

Heater

Switch (1)

Switch (2)

Remote

Local

Close

Open

M

GRO

Lamp

(open)

Lamp

(close)

Lamp

(power)

Power Supply

220V/380V

Note:

1. Change over any two lines of three phase lines power supply when the power lamp is off.

2. When you select the local control, you need to control the actuator by switch (2).

3. Input Signal: 4-20mA, or 2-10V, or 1-5V

4. Output Signal: 4-20mA or 2-10V

440V 3-PH

110V

-

+

MC2-a

MC1-a

MC2-a

MC2-a

MC1-a

L1

L2

L3

MC1-a

MC1-b

MC2-b

MC1 MC2

C

B

A

F

E

D

Input Signal

(Use shielded wire &

ground shield on one

end only.)

Connect

to remote

position

indication

circuit if

required.

LS3

LS4

19

BRAY Series 74 Electric Actuator

Operation and Maintenance Manual

WIRING DIAGRAM S74 220V / 380V / 440V 3-PH / ON-OFF SERVICE

LOCAL / REMOTE SELECTION SWITCH / 4-20mA OUTPUT SIGNAL

A

B

C

E

F

(optional)

(optional)

LS1 LS2

D

W

V

U

Heater

Switch (1)

Switch (2)

Remote

Local

Close

Open

GRO

Lamp

(open)

Lamp

(close)

Lamp

(power)

110V

1

3

4

TS1 TS2

M

MC1-a

MC2-a

MC2-a

MC2-a

MC1-a

MC1-a

MC2-b MC1-b

MC1 MC2

R13

R14

*R13 adjusts 20mA

*R14 adjusts 4mA

8

9

4-20mA

output

signal

(optional)

open

close

Customer's

remote

control

switch.

Connect

to remote

position

indication

circuit if

required.

Position

feedback

signal

card.

LS3

LS4

Power Supply

220V/380V

440V 3-PH

L1

L2

L3

This manual suits for next models

4

Table of contents

Other Bray Controllers manuals

Bray

Bray Series 70 User manual

Bray

Bray SERVO PRO 70 Series User manual

Bray

Bray 71 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray PA(M)24-27 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 70-003-113-536 Series User manual