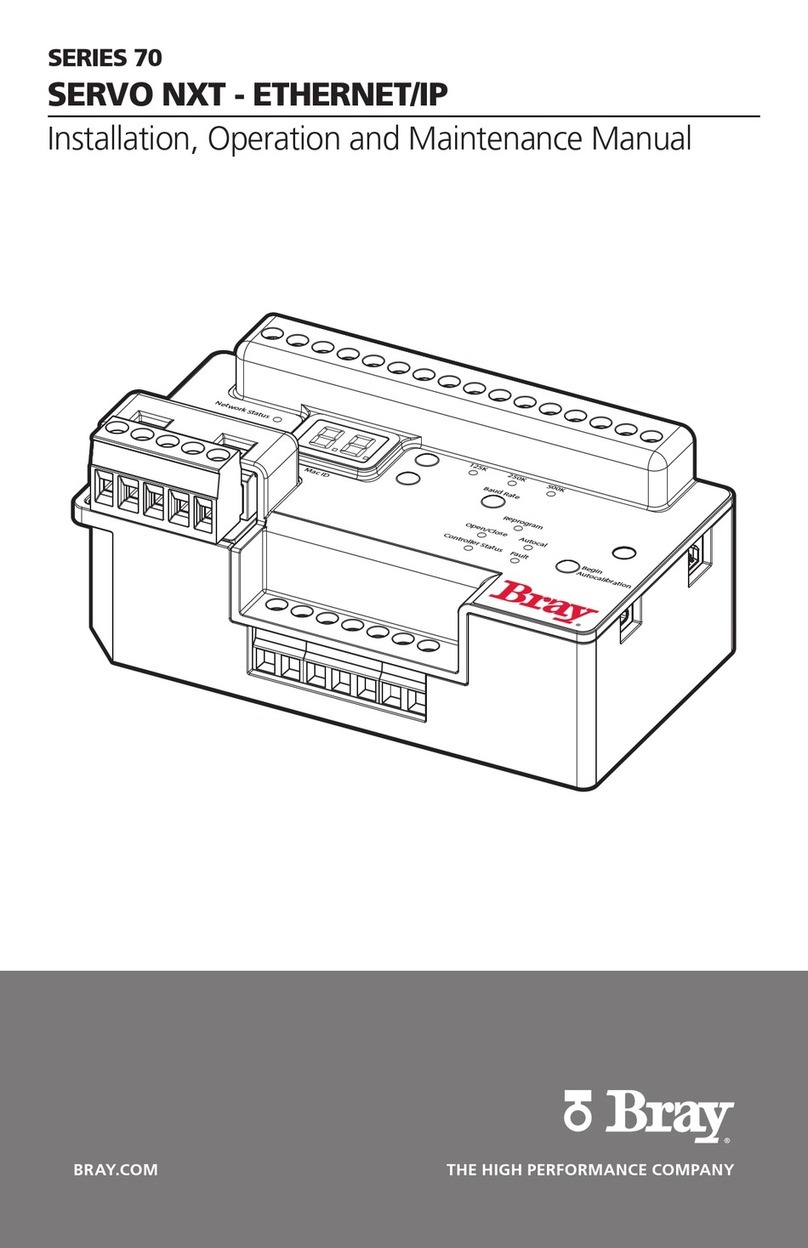

Bray 71 Seires User manual

Series Modulating Controller

ELECTRIC ACTUATOR

Installation Operation and Maintenance Manual

THE HIGH PERFORMANCE COMPANYBRAYCOMMERCIALDIVISION.COM

This Page Intentionally Left Blank

1

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – wwwbraycommercialdivisioncom

Table of Contents

Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hazard Free Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configurable Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Signal Calibration . . . . . . . . . . . . . . . . . . . . . . . .

Autocalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direction Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heartbeat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Signal - Required Connection. . . . . . . . . . . . . . . . . . . . .

Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power - Required Connection . . . . . . . . . . . . . . . . . . . . . . . .

Limit Switch Header - Required Connection . . . . . . . . . . . . . . . .

FB Pot Header - Required Connection . . . . . . . . . . . . . . . . . . .

Heater Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor - Required Connection . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resolving Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

READ AND FOLLOW THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

1.0 DEFINITION OF TERMS

WARNING

Indicates a potentially hazardous situation which if not avoided could result in death

or serious injury

CAUTION

Indicates a potentially hazardous situation which if not avoided may result in minor

or moderate injury

NOTICE

Indicates a potential situation which if not avoided may result in an undesirable result

or state including property damage

3

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

2.0 SAFETY

Hazard Free Use

This device left the factory in proper condition to be safely installed and

operated in a hazard-free manner. The notes and warnings in this document

must be observed by the user to ensure hazard-free operation of this device.

All necessary precautions need to be taken to prevent damage due to rough

handling, impact, or improper storage. Do not use abrasive compounds to

clean the device, or scrape its surfaces with any objects.

Configuration and setup procedures for this device are described in this

manual. Proper configuration and setup are required for the safe operation of

this device.

The control system in which this device is installed must have proper

safeguards to prevent injury to personnel, or damage to equipment, should a

failure of system components occur.

WARNING

The device generates large mechanical force during normal operation

Qualified Personnel

WARNING

The actuator must only be installed commissioned operated and repaired by qualified

personnel

Installation commissioning operation and maintenance must be performed under

strict observation of all applicable codes standards and safety regulations

As per this document, a qualified person is one who is trained in:

1. The operation and maintenance of electric equipment and systems in

accordance with established safety practices.

2. Procedures to energize, de-energize, ground, tag and lock electrical

circuits and equipment in accordance with established safety practices.

3. The proper use and care of personal protective equipment (PPE) in

accordance with established safety practices.

4. First aid.

4

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

3.0 QUICK START GUIDE

WARNING

Turn off all power and lockouttag out service panel before installing or modifying any

electrical wiring

Refer to the actuator manual before adjusting or replacing any actuator

components

Terminate the customer connections at the S Servo terminals in

accordance with the actuator wiring diagram

a To reduce the propagation of noise on the customer cables power

lines and signal lines should not be routed together

b Signal lines should be shielded and the shield line should only be

grounded at one end preferably at the controller

Apply power to the S Servo

a Verify that the Heartbeat LED is illuminated and flashing on and off

Set the Input Command signal type

Set the Feedback (Output) signal type

Verify (or adjust) the travel limits in the actuator

a Bray actuators are shipped with the travel switches in the factory

default position – close travel limit set at degrees and the open

travel limit at degrees

b If the travel limit switch settings are moved from the factory default

position the feedback potentiometer may need to be adjusted for

autocalibration to complete

Perform the Input Signal Calibration routine

Perform the Autocalibration routine

a If autocalibration completes then the product is ready for service

b If autocalibration fails then move to step

Using the Input Command signal command the actuator to the fully

opened position

a Observe the S Servo as it operates and correct any faults that

occur Refer to the Troubleshooting guide for more information

Using the Input Command signal command the actuator to the fully

closed position

a Observe the S Servo as it operates and correct any faults that

occur

Return to Step

5

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

4.0 DESCRIPTION OF OPERATION

The Bray Series Servo provides complete modulating control and

monitoring of the Bray Series Electric Actuator The basic function of the

S Servo is to position the S Actuator in response to a command signal

from a process controller The process controller contains a desired process

set point entered by the user and continually monitors the process variable

(such as flow rate tank level etc) through some type of sensor Varying the

command signal to the S Servo will cause the actuator to change position

which will move the associated control valve to modify the process variable

The process controller continually calculates and transmits the appropriate

command signal to the S Servo to maintain the process at the desired set

point

The command signal to the S Servo can be various DC voltage ranges (-

V -V -V) or a -mA current source The S Servo simultaneously

provides a feedback output signal representing the current actuator

position The retransmission output signal reported by the S Servo can

also be various DC voltage ranges (-V -V) or a -mA current source

These settings along with specific operating modes are enabled by three

simple pushbuttons

6

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Product Settings

The product settings determine how the S Servo will respond to

commands from the process controller These must be defined and verified

before operation begins The settings that can be adjusted on the S Servo

are

• “Input” – InputCommand Signal

• “Output” – OutputFeedback Signal

All units’ ship with default settings from the factory

Feature Setting Configurable?

Input Signal -mA Yes

Output Signal -mA Yes

Failure Position Last No

Dead Band Control No

Heater Setpoint C No

Figure S Servo Default Settings

5.0 USER INTERFACE

The S Servo features a rich LED-based menu that displays both

configurable settings and operational status Indicators are grouped

together based on function shown by their respective label(s) Without

any user interaction the S Servo will display the factory default product

settings valve status and fault status

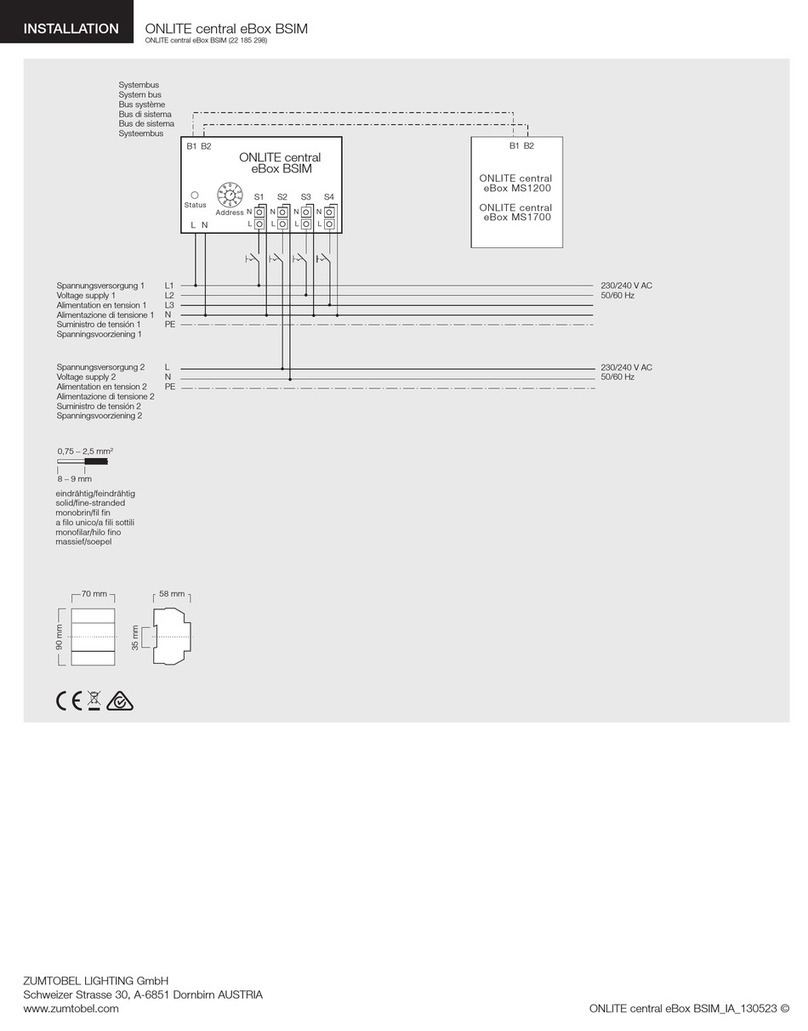

Figure V S Servo

7

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Configurable Settings

Settings can be changed locally by utilizing the push-button associated with

each product setting Each push-button is labeled and placed below a set

of LEDs with individual labels corresponding to the setting Settings are

changed using the push-button The next LED in the sequence will illuminate

once the push-button is pressed

4-20mA

0-10V

0-5V

INPUT SIGNAL

4-20mA

0-10V

0-5V

OUTPUT SIGNAL

2-10V

Figure Servo Push Button Menu Flow

Description of Settings

Input Signal Type - Configurable

Input signals position the valve under control based on the magnitude of

the signal The minimum value corresponds to the closed position and the

maximum value to the open position Only one input signal can be active at

a time

Input Setting Description

-mA (default)

Analog Current Range

Minimum mA

Maximum mA

-V

Analog Voltage Range

Minimum V

Maximum V

-V

Analog Voltage Range

Minimum V

Maximum V

-V

Analog Voltage Range

Minimum V

Maximum V

Figure Servo Input Settings

8

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Output Signal Type - Configurable

Output signals report the position of the valve under control based on the

magnitude of the signal The minimum value corresponds to the closed

position and the maximum value to the open position Only one output

signal can be active at a time

Output Setting Description

-mA (default) Analog Current Range

Minimum mA

Maximum mA

-V Analog Voltage Range

Minimum V

Maximum V

-V Analog Voltage Range

Minimum V

Maximum V

Figure S Servo Input Settings

Failure Position Last

The Failure Position determines how the S Servo positions the valve

upon loss of input signal Loss of input signal occurs when the input signal

received is outside the valid range of the selected Input Signal Type eg

an input signal of less than mA for the -mA input The S Servo will

position the valve at the last valid commanded position before loss of signal

Dead Band Control

Dead Band Control determines the acceptable offset between the position

command provided by the input command and the current position

of the actuator determined from the feedback signal provided by the

potentiometer This value is a percentage of the full input range and creates

an inactive area centered around the desired set point For example for

a -V input command the Dead Band setting allows the actuator

position to be offset from the desired set point by up to V in either

direction creating a dead band with a span of V

Heater Setpoint

The S Servo maintains surveillance of the internal temperature of the

actuator If the internal temperature rises above F (C) the S Servo

will automatically turn off the W anti-condensation heater

Operating Modes

Remote Operation

By default the operating mode of the S Servo is remote mode where

the valve is positioned based on input signals Exiting another mode of

operation generally results in the S Servo returning to remote mode

9

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Manual Operation

Manual operation of the actuator is performed via declutchable handwheel

The S Servo will continue to operate as if in remote mode though it

will not be able to actuate to a new setpoint until the manual mode is

disengaged See the S IOM for additional details

Command Signal Calibration

A command signal calibration routine is provided to increase accuracy by

accounting for small static defaults associated with the input circuitry It is

suggested to perform this once at commissioning prior to performing the

autocalibration routine

First select the desired input signal mode using the input pushbutton until

the appropriate LED is highlighted If -mA mode is selected disconnect

wiring from the command signal terminals If a voltage mode is selected

disconnect wiring from the command signal terminals and attached a wire

jumper between the command () and command (-) terminals

Press and release the calibration (Cal) button once the calibration LED

begins to flash rapidly Within second press and release the Input mode

button Most LEDs will turn off The Heartbeat LED will continue to operate

and the Fault LED may continue to flash

Once the LEDs turn back on the calibration is complete and the calibration

will be stored in the non-volatile memory Reconnect the command signal

wiring to the command signal terminals

WARNING

The input signal calibration routine must be run if the input signal type is changed

from a voltage mode to a current mode or vice versa

Autocalibration

Autocalibration mode is entered by pressing and holding the Autocalibration

(Cal) button for at least second Entering Autocalibration mode starts the

autocalibration sequence a series of commands performed by S Servo on

the actuator to determine the operating points During the autocalibration

sequence the S Servo should be monitored to ensure it operates

correctly The calibration LED will flash slowly to show that autocalibration

has been entered and will continue to flash at the end of travel until

autocalibration completes Upon completion of the autocalibration

sequence calibration LED will turn off

If the fault indication lights illuminate during autocalibration then the

autocalibration sequence could not be successfully completed Refer to the

troubleshooting section for more information

No other operating modes can be entered during autocalibration and

entering autocalibration mode will override any previous mode of operation

10

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Status Indication

These are all indicators that report key information on the operation and

functional status of the S Servo and actuator

Figure - S Servo Setting Buttons and Status Indication LEDs

Direction Indicators

The Open (green) and Close (red) indicators located at the top left of the

display show the current direction of travel When the actuator is energized

the corresponding indicator will flash to indicate travel The green indicator

will be lit if the open travel limit is reached The red indicator will remain lit if

the close travel limit is reached

OPEN (Green LED) CLOSE (Red LED) DESCRIPTION OF ACTIVITY

OFF OFF No power or actuator is stopped

mid-travel

ON (solid) OFF Stopped at fully open position

ON (solid) ON (flashing) At fully open position moving in

the closed direction

OFF ON (flashing) Moving in the closed direction

OFF ON (solid) Stopped at full closed position

ON (flashing) ON (solid) At full closed position moving in

the open direction

ON (flashing) OFF Moving in the open direction

ON (flashing) ON (flashing) Fault condition where both limit

switches are activated Fault LED

is also ON (flashing)

ON ON Motor Braking – Both LEDs may

momentarily activate during

motor braking The Fault LED will

not turn on during this operation

Figure – Direction Indication LED Status Description

11

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Fault Status

The Fault LED located at the bottom left will turn on during a fault

condition The occurrence of a fault indicates that user intervention is

required to restore operation and these indicators attempt to provide the

diagnostic information needed to accomplish this

Fault LED (flashing) Other LED Fault Condition

-mA Input LED flashing Command Signal Fault Input signal is

-mA mode and the input signal is less

than mA or greater than mA

-V Input LED flashing Command Signal Fault Input signal

is -V mode and the input signal is

greater than V

-V Input LED flashing Command Signal Fault Input signal is

-V mode and the input signal is greater

than V

-V Input LED flashing Command Signal Fault Input signal is

-V mode and the input signal is less

than V or greater than V

Output LED flashing

(selected output mode)

Feedback Potentiometer Fault

potentiometer voltage is outside of the

V-V range when near limits

Calibration LED Calibration Fault Calibration failed due

to Feedback Potentiometer Fault or the

motor was not able to reach end of travel

in expected time

Open LED & Close LED

both flashing

Limit Switch Fault Both limit switches

activated at the same time

Figure – Fault Indication LED Status Description

Refer to the Troubleshooting section for the actions required to clear a fault

Calibration

The calibration (CAL STATUS) LED indicator located at the bottom right

serves as a calibration status indicator for the S Servo

Calibration (CAL STATUS) LED Description

OFF Autocalibration routine previously

completed successfully

ON (slowly flashing) S Servo operating using default factory

calibration settings

ON (quickly flashing) Calibration routine in progress

Figure – Calibration Status LED Status Description

12

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

CAUTION

If cams or potentiometer are adjusted the previous calibration settings will not apply

to the new setup Re-run the calibration routine to avoid unexpected behavior

Heartbeat

The heartbeat indicator at the top right serves as status indicators for the

S Servo No matter what operation is performed these indicators should

be flashing on and off If they are not flashing refer to the Troubleshooting

section

13

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

6.0 HARDWARE DESCRIPTION

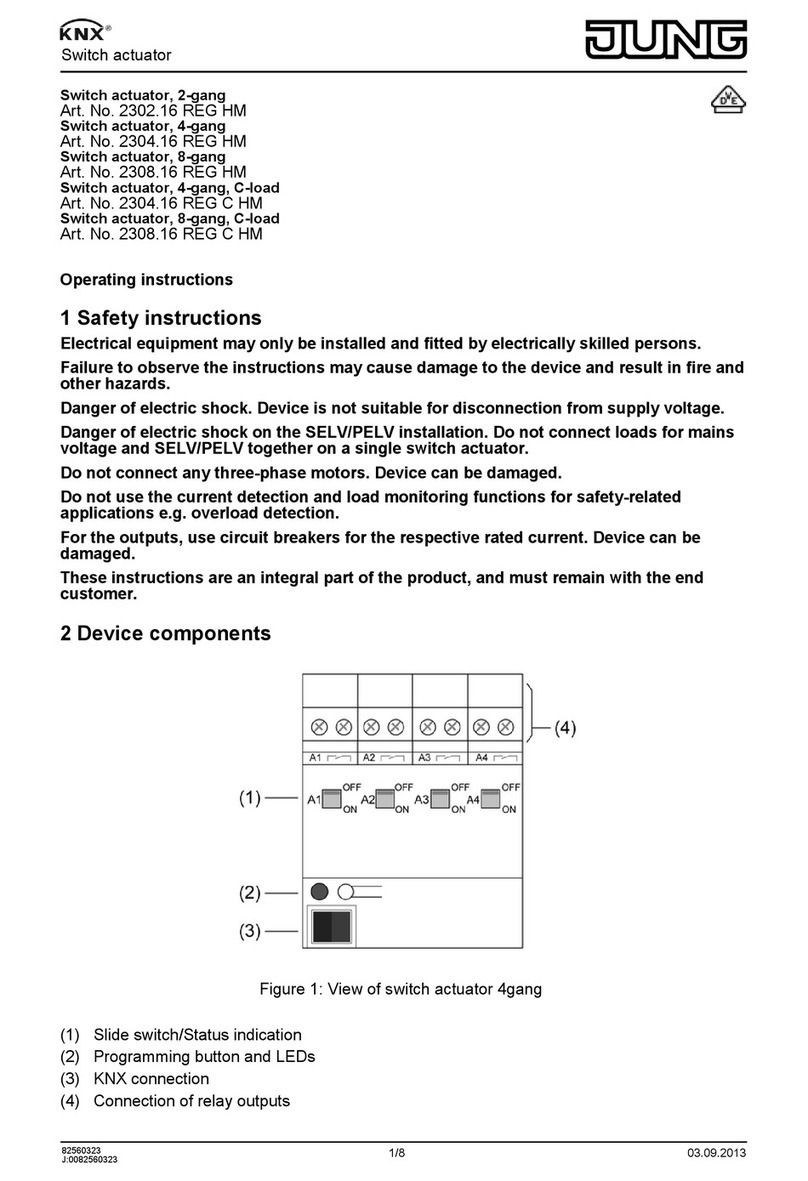

Terminal Connections

WARNING

Turn off all power and lockouttag out service panel before installing or modifying any

electrical wiring

There are two categories of connections voltage level and connection type

Field terminals are provided on the unit for the landing of stripped wires

connecting the S Servo to the field wiring needed for it successfully

operate All field terminals are positioned on the left side of the controller

easily accessible facing the conduit entries Internal actuator connections

are made at the factory and should not require any customer adjustment

Auxiliary switches are provided voltage free and rated for operation up to

A at VAC

Field Terminals Internal Connections

High voltage ( V) Power (Live Neutral) Motor Terminals

Heater Header

Low voltage ( V) Input Signal

(Input Input-)

Output Signal

(Output Output-)

FB Pot Header

Limit Switch Header

Voltage Free Auxiliary Switch

(Com Close Open)

Auxiliary Switch Header

Figure Terminal Connection Categories

A Division of BRAY INTERNATIONAL, Inc.

A Division of BRAY INTERNATIONAL, Inc.

·

·

·

·

·

·

·

·

·

·

·

·

·

·

Figure S Servo Field Wiring

14

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

NOTICE

Refer to the actuator wiring diagram for wire gauge voltage and temperature limits

of the terminal blocks

All actuator connections should match the actuator wiring diagram

Figure V S Servo wiring diagram

15

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Xref C:\BII_Vault\Global\Templates\ACAD\LogoBrayControls1.dwg Xref C:\BII_Vault\Global\Templates\ACAD\LogoBrayControls1.dwg

WD-000579

------

BUSA

S71

120/230V S71 SERVO

AND HEATER (OPTIONAL)

1

NOT RELEASED - DO NOT MANUFACTURE

WD-000579

------

BUSA

S71

120/230V S71 SERVO

AND HEATER (OPTIONAL)

1

NOT RELEASED - DO NOT MANUFACTURE

120/230V

S71 SERVO

(SEE NOTES 7-9)

(SEE NOTES 8-11)

INPUT (+)

INPUT (-)

OUTPUT(+)

OUTPUT(-)

SIGNAL

LIVE

NEUTRAL

POWER

120/230V S71

SERVO

(SEE NOTES 7-9)

(SEE NOTES 8-11)

INPUT (+)

INPUT (-)

OUTPUT(+)

OUTPUT(-)

SIGNAL

LIVE

NEUTRAL

POWER

LIMIT

OPEN

LIMIT

CLOSE

LIMIT CLOSE

POT WIPER

POT COM

LIMIT

OPEN

POT V+

LIVE

NEUTRAL

MOTOR

MOTOR CL

NEUTRAL

CAP

CLOSE

MOTOR OP

CAPACITOR

CAP

OPEN

HEATER

NOTES:

1. HEATER IS OPTIONAL.

2. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

3. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

4. WHEN USING 0-10VDC MODE, THE COMMON OF THE COMMAND SIGNAL

SHOULD NOT BE GROUND/EARTH REFERENCED.

5. COMMAND SIGNAL AND FEEDBACK SIGNAL MUST BE ISOLATED FROM EACH

OTHER AND ANY OTHER CIRCUITS.

6. COMMAND SIGNAL & FEEDBACK SIGNAL WIRES SHOULD BE SHIELDED

PROPERLY & SHIELD SHOULD BE GROUNDED/EARTHED ON ONE END ONLY,

PREFERABLYTHE CONTROLLER END.

7. FEEDBACK LOOP IS POWERED BY THE SERVO, DO NOT SUPPLY

EXTERNAL POWER.

8. POSITION FEEDBACK DEVICE LOAD IS NOTTO EXCEED 400 OHMS IN

THE 4-20mA CONFIGURATION.

HEATER

(OPTIONAL)

CAM

#4

N.O.

COM N.C.

CAM

#3

N.O.

COM N.C.

CAM

#2

N.O.

COM N.C.

CLOSE

CAM

#1

N.O.

COM N.C.

OPEN

AUX

CLOSE

AUX

OPEN

SWITCH PCB

ACTUATOR

FIELD WIRING

GROUND

NEUTRAL

LIVE

-

+

-

+

POSITION

FEEDBACK

DEVICE

OUTGOING FEEDBACK

SIGNAL (SHIELDED)

COMMAND

SIGNAL

DEVICE

INCOMING COMMAND

SIGNAL (SHIELDED)

CALIBRATION SEQUENCE:

1. CONNECT POWER SUPPLY.

2. SET INPUT AND OUTPUT SIGNAL MODES.

3. CALIBRATE THE INPUT SIGNAL.

·DISCONNECT ALL SIGNAL WIRES FROM INPUT(+)/(-).

·FOR 0-10V, 0-5V, AND 2-10V MODES, SHORT INPUT

(+) TO INPUT (-).

·PRESS THE "CALIBRATE" BUTTON FOR 2 SECONDS.

·IMMEDIATELY PRESS THE INPUT SIGNAL BUTTON.

4. RE-ATTACHTHE INPUT SIGNAL WIRES.

5. PRESS THE "CALIBRATE" BUTTON FOR TWO SECONDS.

6. ACTUATOR WILL SELF-CALIBRATE.

TERMINALS - ELECTRONICS

·

14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·

PUSH BUTTON CLAMP

·

105 °C, 300V MIN RATEDWIRE

·

STRIP WIRE: .39"-.43" [10-11mm]

·

GROUND WIRE GAUGETO BE EQUALTO LARGEST

SUPPLY CONDUCTOR.

FEEDBACK

POTENTIOMETER

POT PCB

GROUND

NEUTRAL

LIVE

-

+

-

+

POSITION

FEEDBACK

DEVICE

COMMAND

SIGNAL

DEVICE

ACTUATOR

WD-000579 REV 1

FIELD

WIRING

CALIBRATION SEQUENCE:

1. CONNECT POWER SUPPLY.

2. SET INPUT AND OUTPUT SIGNAL MODES.

3. CALIBRATE THE INPUT SIGNAL.

·DISCONNECT ALL SIGNAL WIRES FROM INPUT(+)/(-).

·FOR 0-10V, 0-5V, AND 2-10V MODES, SHORT INPUT

(+) TO INPUT (-).

·PRESS THE "CALIBRATE" BUTTON FOR 2 SECONDS.

·IMMEDIATELY PRESS THE INPUT SIGNAL BUTTON.

4. RE-ATTACHTHE INPUT SIGNAL WIRES.

5. PRESS THE "CALIBRATE" BUTTON FOR TWO SECONDS.

6. ACTUATOR WILL AUTOMATICALLY COMPLETE

SELF-CALIBRATION.

FIELD CONNECTIONS:

14-24 AWG, 18 AWG

RECOMMENDED

105 °C, 300V MIN

RATED WIRE.

STRIP WIRE: .39"-

.43" [10-11mm]

GROUND WIRE GAUGE

TO BE EQUALTO

LARGEST SUPPLY

CONDUCTOR.

O C

BLACK

BLACK

BLACK

RED

GREY

BLUE

RED

WHITE

BLACK

NOTES:

1. HEATER IS OPTIONAL.

2. LIVE, NEUTRAL, & GROUND ARE A SINGLE PHASE POWER SUPPLY.

3. ALL SWITCHES SHOWN IN DEACTIVATED STATE.

4. WHEN USING 0-10VDC MODE, THE COMMON OF THE COMMAND SIGNAL

SHOULD NOT BE GROUND/EARTH REFERENCED.

5. COMMAND SIGNAL AND FEEDBACK SIGNAL MUST BE ISOLATED FROM EACH

OTHER AND ANY OTHER CIRCUITS.

6. COMMAND SIGNAL & FEEDBACK SIGNAL WIRES SHOULD BE SHIELDED

PROPERLY & SHIELD SHOULD BE GROUNDED/EARTHED ON ONE END ONLY,

PREFERABLYTHE CONTROLLER END.

7. FEEDBACK LOOP IS POWERED BY THE SERVO, DO NOT SUPPLY

EXTERNAL POWER.

8. POSITION FEEDBACK DEVICE LOAD IS NOTTO EXCEED 400 OHMS IN

THE 4-20mA CONFIGURATION.

N

OC

GREY

BLACK

WHITE

MOTOR

6W

2

3

1

4

TERMINALS - AUX

·

12-22 AWG MAX RANGE, 18

AWG RECOMMENDED

·

SCREW CLAMP WITH WIRE

PROTECTOR

·

105 °C, 300V MIN RATEDWIRE

·

TORQUE SCREW TO 5.5 IN-LBS

·

STRIP WIRE: .177"-.217"

[4.5-5.5mm]

TERMINALS - ELECTRONICS

·14-24 AWG MAX RANGE, 18 AWG RECOMMENDED

·PUSH BUTTON CLAMP

·105 °C, 300V MIN RATEDWIRE

·STRIP WIRE: .39"-.43" [10-11mm]

·GROUND WIRE GAUGETO BE EQUALTO LARGEST

SUPPLY CONDUCTOR.

TERMINALS - AUX

·12-22 AWG MAX RANGE, 18

AWG RECOMMENDED

·SCREW CLAMP WITH WIRE

PROTECTOR

·105 °C, 300V MIN RATEDWIRE

·TORQUE SCREW TO 5.5 IN-LBS

·STRIP WIRE: .177"-.217"

[4.5-5.5mm]

AUX OPEN

AUX CLOSE

AUX COM

Figure V S Servo wiring diagram

Input Signal - Required Connection

Connection for the input signal that positions the valve under control based

on the magnitude of the signal The signal that is present at this connection

should be based on the input setting (see Product Settings)

Input signals are polarized so that miswiring may result in unexpected

behavior Ensure that the wiring diagram is followed when making this

connection

Output Signal

Connection for the output signal that reports the position of the valve under

control based on the magnitude of the signal The signal that is present at

this connection is based on the output setting (see Product Settings)

Output signals are polarized so that miswiring may result in unexpected

behavior Ensure that the wiring diagram is followed when making this

connection

16

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Auxiliary Signals

Connection for the auxiliary switches which indicate to the customer when

an end of travel set point has been reached Auxiliary switches are voltage-

free contacts and powered by the customer Signal power is applied via the

auxiliary common terminal and the customer reads a switched voltage signal

from the auxiliary closed or auxiliary open terminal There are no interposing

electronics systems and the associated header provides a direct connection

to these switches Signal protection must be provided by the customer

Power - Required Connection

Power connection that energizes the S Servo and powers the actuator

under control The voltage supplied should be based on the actuator

nameplate voltage and the voltage listed on the S Servo label

The S Servo has an onboard protective fuse that is in line with the input

power connection This protective fuse is rated for A

Limit Switch Header - Required Connection

Connections for the travel limit switches which indicate to the S Servo

when an end of travel set point has been reached The S Servo provides

a logic level voltage at the Open and Close terminals of this connection

Once one of the travel limit switches is engaged the switch at the applicable

connection will engage and pull this pin to V signaling the S Servo to

end travel

For proper operation both travel limit switches should not be engaged

at the same time This would prevent the S Servo from operating the

actuator and results in a fault condition

NOTICE

Low voltage actuator connections are powered by the S Servo An external source

should never be connected to these terminals

FB Pot Header - Required Connection

Connections for the feedback potentiometer used by the controller to

determine the position of the valve

The S Servo provides a logic level voltage across the potentiometer and

then monitors the voltage that is returned on the wiper connection The

wiper voltage will change as the potentiometer is turned due to the rotation

of the cam shaft During autocalibration the S Servo can save the wiper

voltage range and use it to position the actuator accurately and precisely

NOTICE

The S Servo has been programmed to monitor within a specific range of feedback

voltage (V-V) Utilizing a potentiometer other than the factory provided

potentiometer may result in unexpected behavior

17

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Heater Header

If the actuator has an internal heater then the heater wires are terminated at

this connection The heater will be powered by the input power connection

Only Bray supplied heaters should be connected to the S Servo

Motor - Required Connection

Connections for the motor that operates the actuator Refer to the actuator

manual for more information on the motor

NOTICE

The output signal is powered by the S Servo An external source should never be

connected to the terminals

18

Series 71 – Modulating Controller - Electric Actuator

Installation, Operation and Maintenance Manual

Refer to the actuator manual before adjusting or replacing any actuator

components Before testing or acting on any issues check for any active

faults

Resolving Issues

Issue Possible Causes Possible Solutions

S Servo does not

turn on when power is

applied Heartbeat is

OFF

Fuse is blown Verify and replace fuse

S Servo is incorrectly

wired

Verify wire connections

against the wiring diagram

S Servo is not receiving

power

Evaluate the Input Power

connection with a multimeter

or oscilloscope

Power is not correct Check the provided power

against the voltage listed for

the S Servo and actuator

Heartbeat is ON and not

flashing Heartbeat is

OFF and not flashing

other LEDs ON

Internal timer fault due to

power surge

Remove and reapply power

Contact Factory

Actuator moves back

and forth near setpoint

(hunting)

Excessive noise on the

signal lines

Use an oscilloscope to

evaluate for the presence of

EMI

Utilize EMI reducing

techniques to mitigate the

issue

S Servo not responding

to command signal

S Servo in

autocalibration mode

Check the indicators for

autocalibration mode

S Servo is incorrectly

wired

Verify wire connections

against the wiring diagram

7.0 TROUBLESHOOTING GUIDE

WARNING

Turn off all power and lockouttag out service panel before installing or modifying any

electrical wiring

This manual suits for next models

1

Table of contents

Other Bray Controllers manuals

Bray

Bray Series 70 User manual

Bray

Bray PA(M)24-27 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray 92 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray 71 Series User manual

Bray

Bray 73 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 98 Series User manual