General safety notes and driving restrictions

The engineering and construction of this wheelchair has been

designed to provide maximum safety. International safety standards

currently in force have either been fulfilled or exceeded in parts.

Nevertheless, users may put themselves at risk by improperly using

their wheelchairs. For your own safety, the following rules must be

strictly observed.

Unprofessional or erroneous changes or adjustments increase the

risk of accident. As a wheelchair user, you are also part of the daily

traffic on streets and pavements, just like anyone else. We would

like to remind you that you are therefore also subject to any and all

traffic laws.

Be careful during your first ride in this wheelchair. Get to know your

wheelchair.

Before each use, the following should be checked:

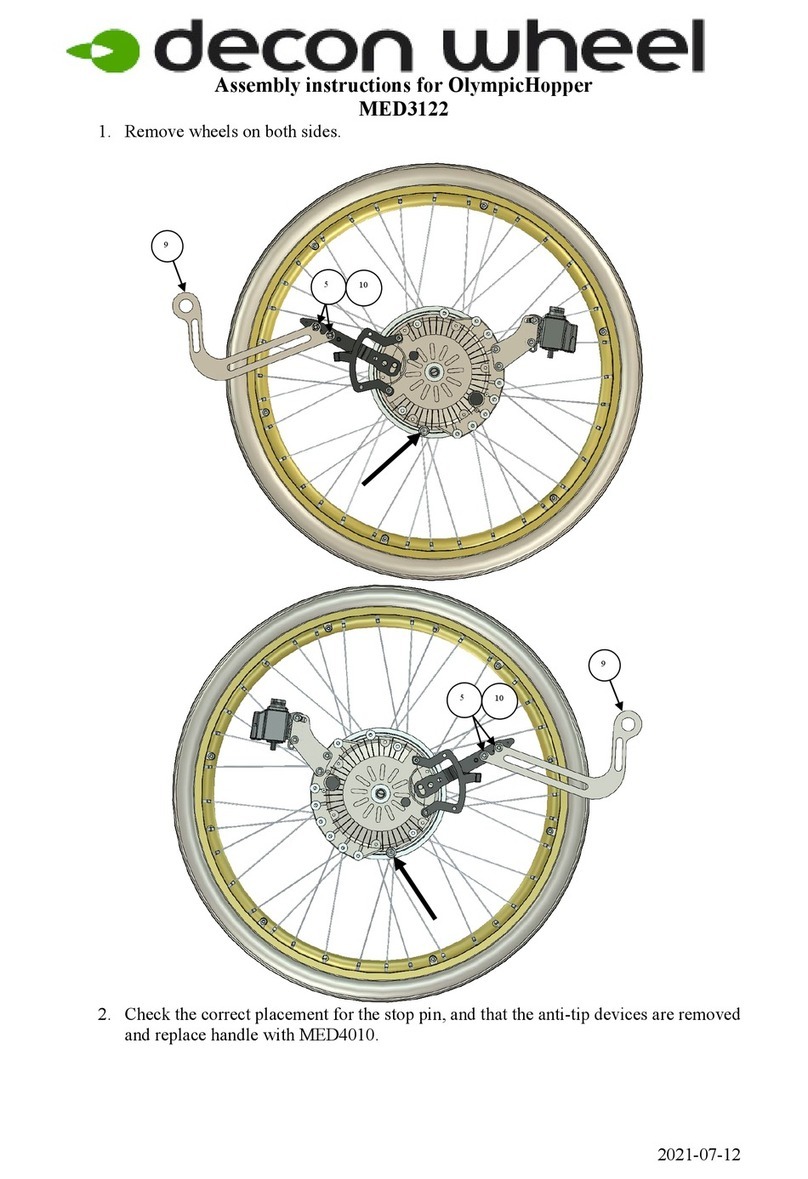

• Fixed axles or Quick-release axles on the rear wheels.

• Velcro on seats and backrests

• Tyres, tyre pressure and wheel locks.

Before changing any of the adjustments of this wheelchair, it is

important to read the corresponding section of the user’s manual.

It is possible that potholes or uneven ground could cause this

wheelchair to tip over, especially when riding uphill or downhill.

When riding forwards over a step or up an incline, the body should

be leaning forward.

DANGER!

• NEVER exceed the maximum load of 125 kg for user plus any

items carried on the wheelchair. If you exceed the maximum

load, this can lead to damage to the chair, or you may fall or tip

over, lose control and may lead to serious injury of the user and

other people.

• When it is dark, please wear light clothing or clothing with

reflectors, so that you can be seen more easily. Make sure that

the reflectors on the side and back of the wheelchair are clearly

visible.

• We would also recommend that you fit an active light.

DANGER!

• To avoid falls and dangerous situations, you should first

practice using your new wheelchair on level ground with

good visibility.

• When getting on or off the wheelchair, do not use the

footboards.

• These should be flipped up beforehand and swung to the

outside as far as possible. Always position yourself as close as

possible to the place where you wish to transfer to.

• Only use your wheelchair with care. For example, avoid

travelling against an obstacle without braking (step, kerb edge)

or dropping down gaps.

• The wheel locks are not intended to stop your wheelchair in

motion. They are only there to ensure that your wheelchair

does not begin rolling unintentionally. When you stop on

uneven ground, you should always use the wheel locks to

prevent unintended movement. Always apply both wheel locks;

otherwise, your wheelchair could tip over.

• Explore the effects of changing the centre of gravity on the

behaviour of the wheelchair in use, for example on inclines,

slopes, all gradients or when overcoming obstacles. Do this

with the secure aid of a helper.

• With extreme settings (e.g. rear wheels in the most forward

position) and less than perfect posture, the wheelchair may tip

over even on a level surface.

• Lean your upper body further forward when going up slopes

and steps.

• Lean your upper body further back when going down slopes

and steps. Never try to climb and descend a slope diagonally.

• Avoid using an escalator which may lead to serious injury in the

event of a fall.

• Do not use the wheelchair on slopes more than 10°. The

Dynamic safe slope is dependant on the chair configuration,

the users abilities and the style of riding. As the users abilities

and style of riding cannot be predetermined then the max safe

slope cannot be determined. Therefore this must be determined

by the user with the assistance of an attendant to prevent

tipping. It is strongly recommended that inexperienced users

have Anti-tips fitted.

• It is possible that potholes or uneven ground could cause this

wheelchair to tip over, especially when riding uphill or downhill.

• Do not use your wheelchair on muddy or icy ground.

• Do not use your wheelchair where pedestrians are not allowed.

• To avoid hand injuries do not grab in between the spokes or

between the rear wheel and wheel lock when driving the

wheelchair.

• In particular when using lightweight metal handrims, fingers will

easily become hot when braking from a high speed or on long

inclines.

• Only attempt stairs with the help of an attendant. There is

equipment available to help you, e.g. climbing ramps or lifts,

please use them. If there is no such equipment available, then

the wheelchair must be tipped and pushed, never carried, over

the steps (2 helpers). We recommend that users over 100 kg in

weight are not transferred in this way. In general, any anti-tip

tubes fitted must be set beforehand, so that they cannot touch

the steps, as otherwise this could lead to a serious tumble.

Afterwards the anti-tip tubes must be set back to their correct

position.

• Make sure that the attendant only holds the wheelchair using

securely mounted parts. Do not use removable parts (e.g. not

on the footrests or the side guards).

• When using the lifting ramp make sure that the anti-tip tubes

fitted are positioned outside the danger area.

• Secure your wheelchair on uneven ground or when

transferring, e.g. into a car, by using the brakes.

• If and whenever possible, during a journey in a specially fitted

vehicle for disabled people, vehicle occupants should use the

seats in the vehicle and the appropriate restraint system. This

is the only way to ensure that occupants will have the

maximum protection if there is an accident.

• Depending on the diameter and setting of the castors, as well

as the centre of gravity setting of the wheelchair, the castors

may begin to wobble at high speeds. This can lead to castor

seizure and the wheelchair may tip over. Therefore, please

make sure that the castors are adjusted correctly (see the

Chapter “Castors”).

10°

10°