brewer Assist PRO 7500 User manual

Document #101522 RevBPrinted in USA © 2017

Installation & Operation Manual

Important Information............................................2

Safety Information.................................................3

Component Identication ......................................3

Specications ........................................................4

Installation .............................................................5

Operation ..............................................................8

Table Adjustments...............................................14

Maintenance........................................................19

Warranty..............................................................20

Accessories.........................................................20

The Brewer Company, LLC

N88 W13901 Main Street, Suite 100

Menomonee Falls, WI 53051

P 1.888.Brewer.1

F 262.251.2332

www.brewercompany.com

Model 7500

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 2 Document #101522 RevB

Service

If you require assistance with the installation or operation

of your Brewer

table,

call the Brewer Customer Service

Department at (1-888-Brewer1). Our trained staff will attempt

to assist you in correcting the problem directly over the phone.

If service is required, a factory authorized technician will be

sent to your location.

Please ll in the following information for use when calling the

Brewer Company or your distributor with questions regarding

your unit. See Figure 1 for model and serial number location.

Date of Purchase _________________________

Serial Number ____________________________

Model Number ___________________________

Authorized

Dealer Name ____________________________

Dealer

Phone Number ___________________________

Dealer Address ___________________________

IMPORTANT INFORMATION

General

Read and understand all operating instructions, safety

information, and maintenance requirements contained

in this manual prior to operating the table. Become

familiar with all of the table functions before using it with

a patient.

The Brewer AssistPRO Power Procedure Table is

designed to provide positioning and support of patients

during general examinations conducted by qualied

medical professionals.

The AssistPRO is primarily used in examination rooms

for general examinations and minor procedures. The

wide variety of positions provided by four powered

motions, adjustable legrest, adjustable headrest, stirrups

and treatment pan, create a safe and convenient patient

positioning table for most examinations and procedures

performed in the doctor’s ofce.

The table is easily adjusted to a wide variety of positions

using the convenient foot control or hand pendant

provided with the table. The table height can be

adjusted from 19” to 40”. The table seating surface can

be moved from the normal horizontal position to an angle

of 30°. The backrest can be adjusted from a at lying

down position, to an 85° angle for seating. The legrest

can be adjusted from a vertical position for seating, to a

horizontal position for laying.

The AssistPRO is also capable of storing four preferred

positions into the tables memory. Utilizing an intuitive

two step programming method, the user can recall any

programmed position with the touch of a button.

In addition to the electronically controlled positions

noted above, several manual adjustments are available:

1. The legrest can be manually adjusted from a sitting

to a kneeling position.

2. With the table in the horizontal position, the legrest

can be extended an additional 5” for tall patients.

3. Stirrups may be manually extended and positioned

innitely within the lateral range of travel.

4. A removable treatment pan is stowed beneath the

front of the seat and can be pulled out for use during

examinations.

5. The headrest can be adjusted to a variety of patient

positions using three clamp action locking levers.

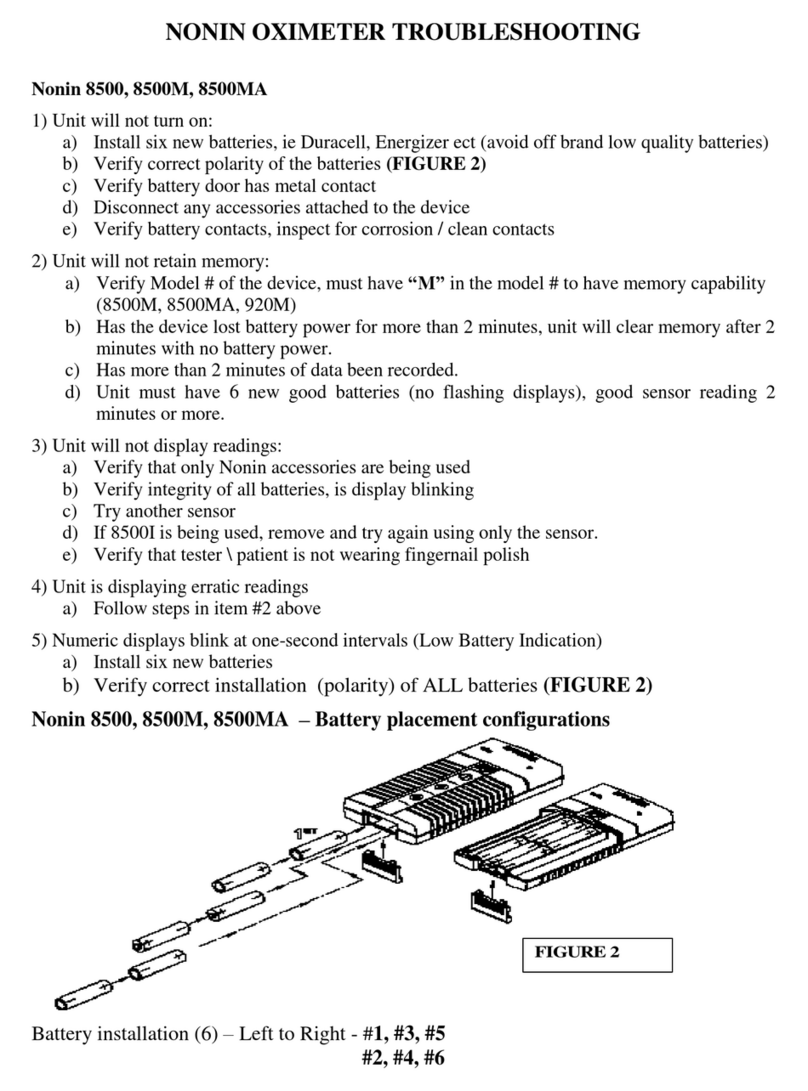

6. The backrest incorporates a self-storing paper roll. Figure 1. Model and Serial Number Location

Model &

Serial Number

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 3 Document #101522 RevB

Safety Information

The primary concern of The Brewer Company is

that the equipment is operated and maintained

with the safety of the patient and healthcare staff in

mind. To ensure safe and reliable operation:

•Read and understand all instructions in this

manual before attempting to install or operate

the unit.

•Ensure that appropriate personnel are in-

formed on the manual contents. This is the

responsibility of the purchaser.

•Ensure that this manual is located near the

table, or if possible permanently afxed to the

table.

SAFETY INFORMATION

COMPONENT IDENTIFICATION

Leg Section

Headrest

Backrest

Stirrups

Seat

Treatment

Pan

Headrest Linkage

Assembly

Programmable

Foot Control

Programmable

Hand Pendant

Figure 2. Component Overview

DANGER Indicates a hazardous

situation that, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

DANGER

WARNING

CAUTION

This is the safety alert symbol. It is used to

alert you to potential physical injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 4 Document #101522 RevB

SPECIFICATIONS

Power Cord

• Length...................Extends 70in. (Minimum) from table.

• Type..............................................................Detachable

• Conductors...................................18 AWG / 3 conductor

• Grade.............................................Hospital Grade Plug

Type of protection against electrical shock

Class......................….............................Class 1 Grounded

Patient Applied Parts................................................Type B

Type of protection against

ingress of water

• Table…….........................................................Ordinary

• Foot Control...........................................................IPX1

Paper Roll Sizes

• Regular.........................................................18 in. x 3.5 in.

• Long.............................................................21 in. x 3.5 in.

Certications*.....UL60601-1; CAN-CSA C22.2 No. 601.1

Operating Conditions

• Temperature Range.......................................65

ºF to 85ºF

• Humidity Range..............................................10% to 90%

Transportation and Storage

• Temperature Range.....................................-20°F to 85°F

• Humidity Range..............................................10% to 90%

Weight of Table...................................................550 lbs.

Load Rating (maximum)

• Seat/Back...........................................................450 lbs.

• Legrest (Flat & Kneeling) ...................................450 lbs.

• Headrest.............................................................100 lbs.

Back Section Range.............0° (horizontal) to +85° ± 5°

Table Top Height Range.........19 ± 0.5 in. to 40 ± 1.0 in.

Leg Section Range..........0° (horizontal) to 90° (vertical)

Table Top

Tilt Range............... 0° (horizontal) to +30° ± 5° (foot up)

Dimensions

• Upholstered Headrest...............13 in. wide x 11 in. high

• Upholstered Top..................28.0 in. wide x 44.5 in. long

• Upholstered

Leg Rest ..…………………16.5 in. wide x 11.25 in. high

• Overall Length................................................69 in. long

• With Headrest/

Footrest Extended..........................................90 in. long

Electrical Rating

..................115 VAC nominal, 60 HZ, 5.8 amps maximum

Duty Cycle (10%)

................. 2 minutes on / 18 minutes off (motor run time)

WARNING

Explosion/Fire Hazard

Do not use this table in an explosive or oxy-

gen rich atmosphere. Failure to do so may

result in serious personal injury or death.

WARNING

Shock Hazard

When performing cauterization or similar

treatment, the patient must be insulated from

the metal portions of the table by non-con-

ductive material. Failure to do so may result

in electrical shock.

*Classied in the United States and Canada

per the standards listed above.

Certications

This product has been evaluated with respect to electrical

shock, re, and mechanical hazards only in accordance with

UL60601-1; CAN/CSA C22.2 No. 601.1

NOTICE

Electromagnetic Interference (EMI)

This product is designed and built to minimize electromagnetic

interference with other devices; however, if interference is

noticed between another device and this product, remove the

interfering device from the room or plug this product into an

isolated circuit.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 5 Document #101522 RevB

Overview

Perform the following sequence in order when setting up

the table:

• Uncrating

• Leveling the Table

• Installing the Power Cord

• Installing the Foot Control

• Installing the Hand Pendant

Uncrating

1. Using a 1/2” open-end wrench, or socket, unbolt the

table from the wooden shipping skid by removing the

four bolts located underneath the table’s base; two

on each side.

2. Remove the table from the shipping skid by sliding it

off the front of the skid. Be sure to lift at the correct

points as indicated in Figure 3. Position the table in

the desired room location.

3. Remove packing tape from stirrups (Figure 4). Pull

out treatment pan slide and remove packing tape

from the treatment pan assembly components.

Return treatment pan slide to its stowed position.

INSTALLATION

Figure 3. Table Lift Points

Figure 4. Stirrups and Treatment Pan

DO NOT lift at these points!

Lift table at these points

Do Not Lift by Stirrups or

Treatment Pan

NOTICE

Inspect Carton and Contents

Inspect all boxes and contents for

damage. Report any damage to the

carrier immediately.

No Sharp Tools

To avoid damaging the table’s

upholstery or painted surfaces, DO

NOT use a knife or other sharp object

to open the packaging.

NOTICE

Optimum Table Performance

For optimum table performance, allow the table to

reach room temperature before operating.

NOTICE

Table weight up to approximately 550 lbs.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 6 Document #101522 RevB

Leveling the Table

A leveling screw pad (Figure 5) is located in four places

under the table’s base.Adjust the leveling pads to

achieve a solid, level installation.

Installing the Power Cord

1. Remove the power cord from the shipping box.

2. Plug the female end of the power cord into the

receptacle on the table (Figure 6). Make sure

the plug end shape is correctly oriented to the

receptacle shape. Plug the male end of the power

cord into a 115 Volt grounded receptacle.

Installing the Foot Control

1. Remove the foot control from the shipping box.

2. Insert the cord into the foot control receptacle on

the table (Figure 6). Make sure the tab on the plug

is aligned with the groove in the receptacle, and the

plug is fully seated.

3. Thread the locking collar onto the receptacle.

4. Make sure the Controls On/Off switch located on the

backrest shroud is turned to the “ON” position. See

Figure 7.

Figure 5. Leveling Screw Pad (located under table)

Figure 6. Power Cord & Foot Control Cord Receptacles

Figure 7

INSTALLATION (CONTINUED)

Locking Collar

Receptacle

Foot Control and Hand

Pendant On/Off switch

Prevent Leveler Damage

Levelers must remain in the table and be fully engaged a

minimum of (3) turns. If levelers are not fully engaged in the base,

damage to the threading in the base and/or leveler can occur.

NOTICE

NOTICE

Conrm Voltage and Plug Type

See Specications Page for electrical rating of this unit.

Thethree-prongedgroundingplugonthetablepowercord

mustbepluggedintoamatchingthree-pronged,grounded,

non-isolated, correctly polarized 115 VAC receptacle.

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 7 Document #101522 RevB

Installing the Hand Pendant

1. Remove the hand pendant from the shipping bag.

2. Insert the cord into the hand pendant receptacle

on the backrest shroud. (Figure 8). Make sure the

tab on the plug is aligned with the groove in the

receptacle, and plug is fully seated.

3. Thread the locking collar onto the receptacle.

Figure 8

INSTALLATION (CONTINUED)

Receptacle

Hand

Pendant

Cord

Locking

Collar

WARNING

Shock Hazard

After installing or moving table, make sure

there are no damaged or exposed wires that

could result in electrical shock.

Figure 9

Power On/Off switches

1. The table is equipped with two On/Off switches that

disrupt the main power to the table.

2. The switches are located on the upper left and right

hand sides of the backrest shroud. See Figure 9.

3. In the “On” position the switch is lighted green. Both

switches must be in the On, lighted position for the

table to operate.

The foot control and hand pendant are moisture resistant

and run on low voltage. To avoid temporary or permanent

damage to the controls, do not immerse in water or liquids.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 8 Document #101522 RevB

Leg

Down Table

Down

Figure 10

Controls

1. See Figure 10 for the pedal and button identica-

tions on the foot control

2. See Figure 11 for the button identications on the

hand pendant

OPERATION

Program Recall

Mode

Stop

Program #3

Program #4

Tilt

Down

Back

Down

Program #2

Program #1

Program

Set

Leg

Up Table

Up

Tilt

Up

Back

Up

Unintended Operation

To avoid accidental operation, keep foreign objects away

from controls. Be sure the controls are not positioned below

the legrest or headrest linkage.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 9 Document #101522 RevB

Leg Up

Leg Down

Tilt Down

Tilt Up

Program Recall #2

Program Recall #4

Back Up

Back Down

Table Down

Table Up

Program Recall #1

Program Recall #3

Figure 11

OPERATION (CONTINUED)

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 10 Document #101522 RevB

OPERATION (CONTINUED)

Figure 11. Treatment Pan

Figure 12. Headrest Handles

Treatment Pan

1. To expose the treatment pan for use, grasp the tray

handle and pull until tray is fully extended (Figure 11).

2. The pan can be easily removed for cleaning with

the tray fully extended. Fully seat pan into tray when

clean.

3. Push the tray handle as far in as it will go to fully stow

the treatment pan after use. A light clicking sound will

be heard just before the pan reaches its fully stowed

position. (The light clicking sound is created by a

switch that allows the legrest to move upward).

Headrest Positions

1. To move the headrest, rotate the three handles to

their open position. Move the headrest to its desired

location. Rotate the 3 handles to their locked position

as shown in Figure 12.

2. Each section of the headrest can be adjusted

independently by rotating the handle to the open

position, moving the desired section, and then

rotating the handle to the closed position.

NOTE: Make sure all three handles are locked. A handle

is locked correctly when it is pushed past center and

the force of the clamping action pulls the handle into the

locked position and holds it there.

Headrest Handle

(Locked)

Upper Handle

(Locked)

Lower Handle

(Locked)

Tray

Treatment

Pan

Make sure headrest is securely locked into position before

use. Failure to have the three handles correctly locked could

result in headrest falling during a procedure which could result

in serious personal injury.

CAUTION

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 11 Document #101522 RevB

Figure 14. Legrest Kneeling Position

Legrest Kneeling Position

The legrest can be rotated to a kneeling position (Figure

14).

1. Grasp the legrest cushion on both sides.

2. Rotate the cushion upward until rotation stops.

3. Slide the legrest downward and rotate the cushion

downward to engage the stop. Two height positions

are provided.

Cam positioned in slot

Lift up over-center

1 2 3

Legrest Extension

In the horizontal position, the legrest can be extended 5”

to increase the overall length of the table (Figure 13).

Lift up on the legrest and pull outward to extend the

legrest. To return the legrest to the shortest position, lift

up on the legrest and push fully inward.

Figure 13. Legrest Extension

To prevent damage to the unit, the legrest must be returned

to the shortest position prior to lowering the legrest to the

vertical position.

NOTICE

OPERATION (CONTINUED)

Make Sure Legrest is Engaged with Stops

Make sure the legrest cushion is fully engaged with

the stops on both sides. When properly engaged, the

legrest cushion is parallel to the ground.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 12 Document #101522 RevB

Adjustable Stirrups

Operating the StirrupS

1. To operate the stirrups, grasp end of stirrup and pull straight

out of the table. Lift up slightly while sliding the stirrup out

(Figure 15).

NOTE: Applying any downward pressure when pulling stirrup

from table may make it difcult to move. Resistance is normal

and is part of the stirrup friction locking mechanism

2. Unfold stirrup upward to the fully open position.

3. Adjust the stirrup to the desired length by sliding it in or out.

Stirrup LateraL adjuStment

1. Lift end of stirrup and then rotate outward to

desired position (Figure 16).

2. When the desired position is achieved, lower the stirrup to

engage the lateral locking mechanism.

3. Check that lateral locking mechanism is engaged by

attempting to rotate stirrup assembly without lifting on the

stirrup end.

StOring the StirrupS

1. To store the stirrups in the table, grasp end of stirrup and pull

straight out to its full extension (Figure 17).

2. Fold stirrup down against bar, then rotate it to the inner most

lateral position and slide it back into the stowed position.

Figure 18. Afx No Attachments!

Use Stirrup Only as Designed

Do not use any part of the stirrup for attachment of any device (Figure 18).

Warranty will be voided. If knee crutches are required for use, order mounting

adapters, clamps, and rails shown in the Accessories Section.

NOTICE

Figure 15. Operating the Stirrups

Figure 16. Stirrup Lateral Adjustment

Pull Stirrup out, then unfold

Lateral

Locking

Mechanism

Figure 17. Storing the Stirrups

OPERATION (CONTINUED)

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 13 Document #101522 RevB

Figure 19. Paper Roll

Slot

Paper

Paper Roll

To change a paper roll, insert the paper through the slot

in the backrest shrouding and set the paper roll in the

holder (Figure 19).

OPERATION (CONTINUED)

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 14 Document #101522 RevB

TABLE ADJUSTMENTS

Figure 20. Table Height Positioning

Table Height Control

Table Height

The table top can be adjusted to any height between 19”

to 40”. (Figure 20)

1. To raise the table, depress and hold the Table/Up

function until the desired height is achieved.

2. To lower the table, depress and hold the Table/Down

function until the desired height is achieved.

WARNING

Area Not Clear Hazard

Before initiating movement keep personnel and equipment

clear of table to avoid personal injury or damage to the equip-

ment.

Actuator Travel Limit Protection

Each control function will automatically stop moving when

either the UP or DOWN travel limit is reached. If the foot pedal

is pressed with travel at its limit, the actuator will not operate.

Sensors prevent the actuator motor from operating when travel

limit has been reached, preventing wear of the actuator.

NOTICE

Avoid Continuous Operation

If the table is operated continuously causing the control

to exceed its allowable operating temperature, the control

will shut off. If normal operation ceases, do not attempt to

operate the table. Allow the table to cool for 10-15 minutes

before attempting to use again. The control will automatically

reset when it has reached a safe operating temperature.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 15 Document #101522 RevB

TABLE ADJUSTMENTS (CONTINUED)

Tilt Function

The table top can be tilted to any angle between

horizontal and +30° (foot end of table raised).

(Figure 22).

1. To tilt the foot end of the table upward, depress and

hold the Tilt/Up function until the desired angle is

achieved.

2. To tilt the foot end of the table downward, depress

and hold the Tilt/Down function until the desired

angle is achieved. Figure 22. Tilt Function

Figure 21. Adjusting Backrest

Backrest Position Control

Figure 23. Do Not Allow Headrest to Contact Objects

Back Positions

The back can be adjusted to any angle between

horizontal and 85°. (Figure 21)

1. To adjust the back from a chair (upright) position to a

horizontal position, depress and hold the Back/Down

function until the desired angle is achieved.

2. To adjust the backrest from a horizontal position to a

chair (upright) position, depress and hold the Back/

Up function until the desired angle is achieved.

Tilt Function Control

Back Actuator-Push Only

The back is positioned by a “push only” actuator that raises

the back. When lowered, the actuator retracts and gravity

causes the back to lower.

NOTICE

Headrest Linkage Clearance

Use care when tilting the table to avoid contact between

the headrest linkage and the oor or other objects.

(Figure 23).

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 16 Document #101522 RevB

Figure 24. Legrest Positions

Legrest Positions

The legrest can be adjusted from a horizontal position to a

vertical position. Figure 24.

1. To adjust the legrest from a vertical position to a

horizontal position, depress and hold the Legrest/Up

function until the desired angle is achieved.

2. To adjust the legrest from a horizontal position to a

vertical position, depress and hold the Legrest/Down

function until the desired angle is achieved.

Legrest Position Control

TABLE ADJUSTMENTS (CONTINUED)

Treatment Pan Tray Must be Stowed

The legrest will not rise if the treatment pan tray is

extended. A light on the foot control labeled “Pan Out” is

illuminated. Depressing the legrest up function will cause

the light to blink and a double beep alarm to sound. If the

legrest is inoperable, check to ensure that the treatment

pan tray is in its fully stowed position.

NOTICE

Legrest Actuator-Push Only

The legrest is positioned by a “push only” actuator that

raises the legrest. When lowered, the actuator retracts and

gravity causes the legrest to lower.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 17 Document #101522 RevB

Using the Program Feature

1. The table can be programmed using the hand pendant or the foot control. Up to four different positions can be

programmed.

2. The table is already programmed from the factory with four preset positions. See Figure 25.

Position 1 Position 2 Position 3 Position 4

3. Tapping any of the four blue buttons (see Figure 11), numbered 1 through 4, will move the table to the position

programmed for that button. When the table is in a programmed position, the blue button for that position will be lit

on the foot control.

4. The mode in which the programmed positions are recalled can be set by the end user. The black AUTO-RUN

button (Figure 10) is used to set the recall motion to AUTO-RUN “ON” or AUTO-RUN “OFF”.

• In the AUTO-RUN ”ON” mode, a single instantaneous touch of a blue Program Recall button will recall that

position.

• In the AUTO-RUN “OFF” mode, the blue Program Recall button must be held down continuously until the table

reaches the programmed position.

5. A light on the foot control adjacent to the black AUTO-RUN button will indicate if auto run mode is ON or OFF.

6. To change the program recall mode, depress the black AUTO-RUN button for ve seconds, until two beeps are

heard.

7. When the table is moving in the auto run mode, motion of the table can be stopped by:

a. Tapping the “Stop” button on the foot control.

b. Tapping any pedal or button on the foot control.

c. Depressing any button on the hand pendant.

d. Flipping either of the two lighted switches located at the top of the backrest. See Figure 9.

Figure 25

TABLE ADJUSTMENTS (CONTINUED)

Treatment Pan Tray Must be Stowed

If the treatment pan tray is out, the position recall will not

work if the pre-set position requires the legrest to move

upward. Five beeps will sound, and the “Pan Out” indica-

tor light will ash on the foot control.

NOTICE

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 18 Document #101522 RevB

Programming the Table with the

Hand Pendant

1. Move the table to the desired position using the buttons on the hand

pendant. Simultaneously depress the number “1” and number “2”

buttons for three seconds. Release the two buttons. Depress one of

the four Program buttons (1 thru 4) on the hand pendant to store the

position. Two beeps will sound.

2. Move the table to a new position and repeat Step 1 for the three

additional program positions.

3. To recall one of the four programmed positions, press the program

button (1 thru 4) corresponding to that position

4. To change the AUTO-RUN program recall mode using the hand

pendant, simultaneously depress the number “3” and number “4”

buttons for ve seconds until two beeps are heard.

Programming the Table with the

Foot Control

1. Move the table to the desired position using the pedals on the foot control. Tap the black “Program” button.

The four blue buttons will light for three seconds. Tap one of the blue buttons (1 thru 4). The blue light for that

button will stay lit and two beeps will sound to indicate the position has been stored for that button.

2. Move the table to a new position and repeat Step 1 for the remaining blue buttons to store up to 4 programmed

positions.

3. To recall one of the four programmed positions, tap the blue button (1 thru 4) corresponding to that position.

4. Any of the programmed positions can be changed by repeating Step 1 above.

TABLE ADJUSTMENTS (CONTINUED)

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 19 Document #101522 RevB

Preventative Maintenance Table Care

If the table malfunctions, immediately remove your hand

or foot from the controls, unplug the power cord from the

receptacle, and assist the patient from the table. Service

the table prior to use.

NOTICE

• Inspect table every 6 months.

• Periodically inspect the electrical, foot control, and

hand pendant cords to ensure they are free of cuts

or damage.

• Inspect the mechanical functions to ensure satis-

factory operation.

• Check fasteners to make sure they are present

and tightened securely.

• Lubricate moving parts (such as back, tilt, and

legrest hinges) with a food grade silicon lubricant.

Loose Fasteners and Damaged Components

Failure to perform periodic inspections of the table

could result in equipment damage.

NOTICE

Wipe Spills Immediately!

The upholstery material is resistant to most medicinal type

stains, but may be damaged by solvents and dyes. Remove

any spilled uids from the upholstery immediately.

NOTICE

For the latest in Cleaning Guidelines visit:

www.brewercompany.com

Safety

The table has a built in safety feature which helps avoid injury to the patient or physician when recalling a programmed

position in the Auto-Run “ON” mode:

1. The table will stop moving downward once the legrest (in the stowed position) reaches a height of four inches off

the ground.

2. The legrest will stop lowering to provide one inch clearance between the legrest actuator and the lift column

shrouding.

3. The pelvic tilt will stop raising after moving to an angle of 10 degrees.

WARNING

Shock Hazard

Disconnect power by removing plug from

wall receptacle before servicing table.

MAINTENANCE

TABLE ADJUSTMENTS (CONTINUED)

Shop tables & accessories at

ExamTablesDirect.com

Printed in USA © 2017 20 Document #101522 RevB

ACCESSORIES

Listed below are the accessories which are authorized for use with this table.

Description Order No. Use/Restrictions

Urology Tray w/Hose & Bucket 100253 Conveniently and safely captures uids during urology

procedures.

Side Rails (qty 2) 99501 Used to attach accessories. Can be mounted to seat or

back.

Universal Socket Clamp (qty 1) 99502 Used to mount deluxe articulating knee crutches to ac-

cessory rail.

WelchAllyn IV Light Bracket

(customer installed) 102025 For mounting of WelchAllyn IV light.

Grab Bars (qty 2) 99497 Requires 99501 Side Rails for mounting to seat.

Articulating Arm Board 99499 Requires 99501 Side Rails for mounting to backrest.

WARRANTY

For Brewer Warranty Information:

Visit www.brewercompany.com or contact the Brewer Customer Service Department at (1-888-Brewer1).

Deluxe Articulating Knee Crutches 99504 Allows leg positioning for ease of examination.

Contains one LH and one RH Knee Crutch.

Side Rails (qty 2)

99501 Provides attachment point for Knee Crutch Clamps.

Universal Socket Clamp (qty 1)

99502 Clamps Knee Crutch to Side Rail.

Must order (2) two 99502 Universal Socket Clamps.

The following items are required for the Articulating Knee Crutch accessory:

Shop tables & accessories at

ExamTablesDirect.com

Table of contents

Other brewer Medical Equipment manuals