8ORIGINAL INSTRUCTIONS

EN

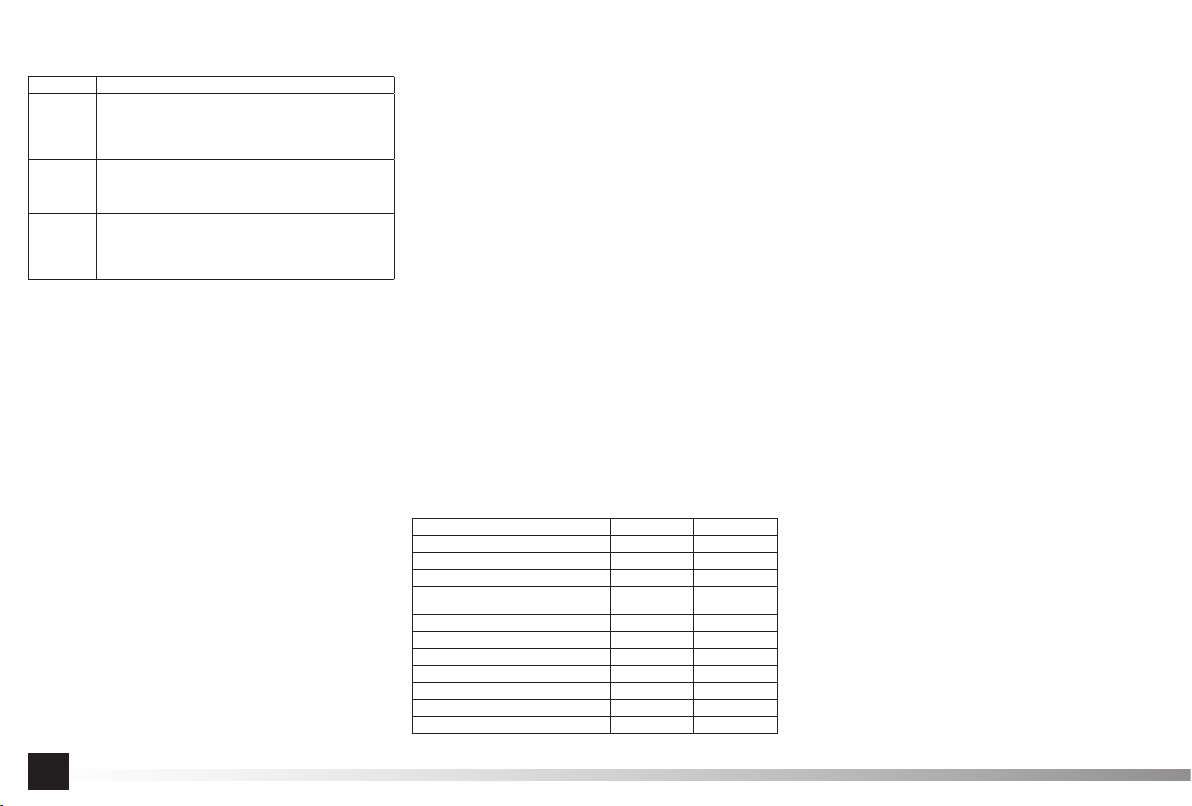

sure, that the object processed is attached securely. Do not work

with a tool without making sure that the limiter of tool inserted has

been installed. To avoid injuries, replace the limiter as soon as it

has been used, broken or deformed. Before the work rmly apply

the tool inserted to processed surface.

The threat associated with operation

A tool while operating may expose operator’s hands to threat

such as: crushing, hitting, cutting o, rubbing or heat. Wear prop-

er gloves to protect your hands. An operator and maintenance

sta should be physically capable to deal with number, weight

and power of the tool. Keep the tool the correct way. Keep bal-

ance and position of foot that guarantee your safety. Release the

pressure applied on start/stop device in case of power failure.

Use only lubricants that are recommended by the manufacturer.

Avoid direct contact with a tool inserted during and after com-

pletion of work, it may be hot. Use protective goggles, it is rec-

ommended to wear well matching gloves and protective clothes.

Threats associated with repeated movements

When using a pneumatic tool for a work consisting in repeated

movements, the operator is exposed to experiencing a discomfort

of palms, arms, neck or other body parts. In case of using a pneu-

matic tool, the operator should adopt comfortable position ensur-

ing proper foot posture and avoid strange posture or postures

not guaranteeing stability. An operator should change his posture

during prolonged work, this will help avoiding discomfort and fa-

tigue. If an operator is experiencing symptoms such as: long-term

or repeated discomfort, pain, pulsating pain, tingling, numbness,

burning or stiness, he should not ignore them, should tell about

that his employer and consult with a physician.

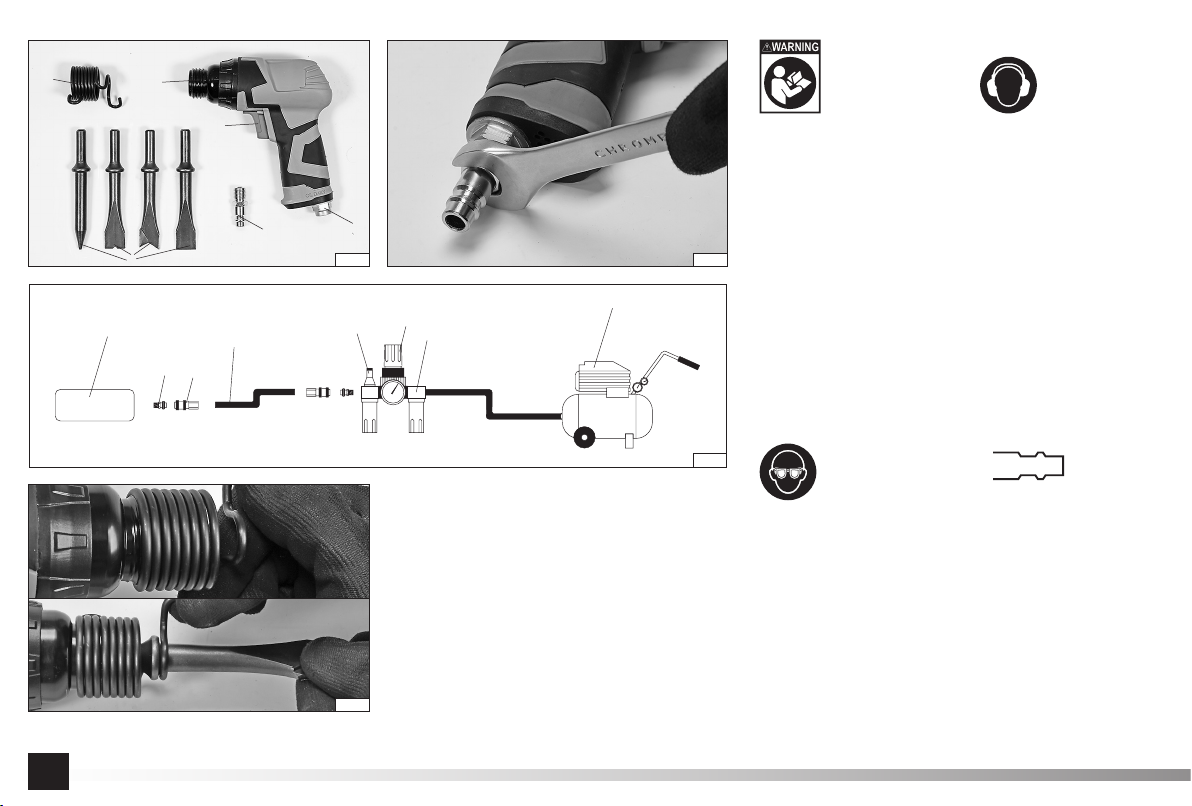

Threats associated with accessories

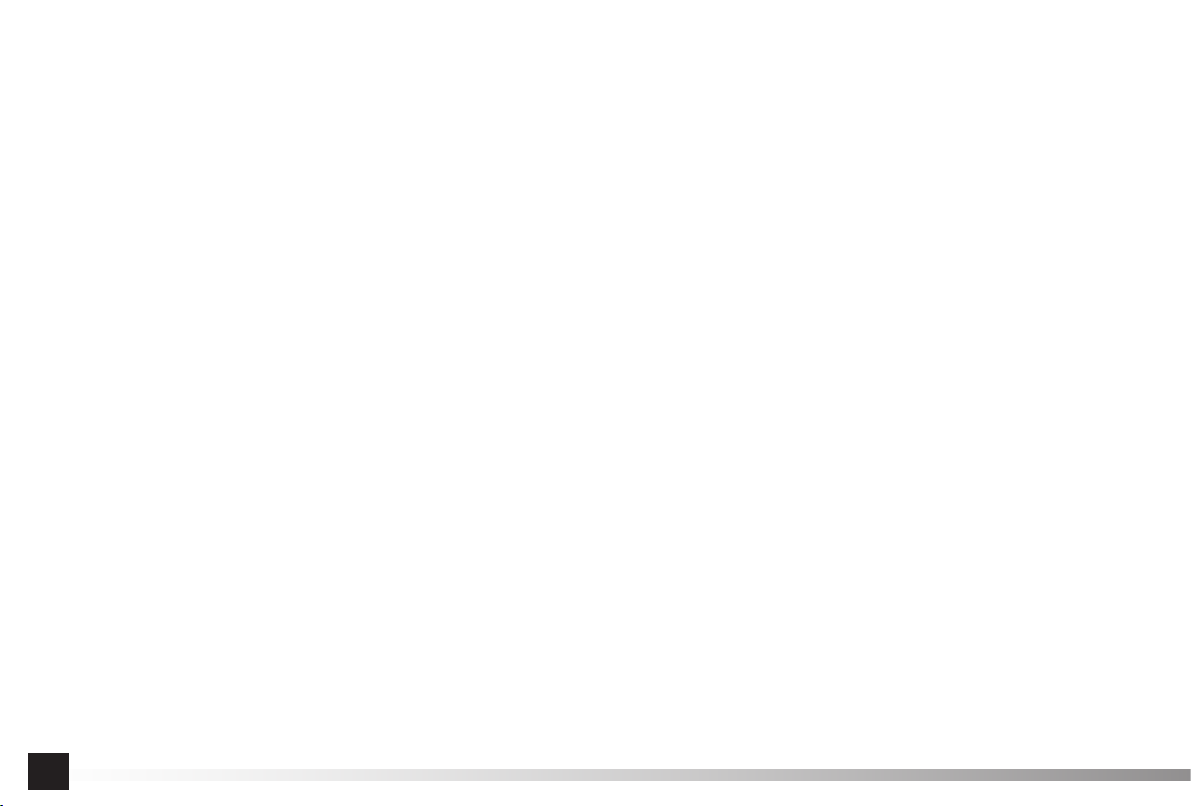

Disconnect the tool from power source before the replacement

of tool inserted or accessory. Use accessories and consumables

only in sizes and of types recommended by the manufacturer.

When appropriate, never use any chisels as hand tools in case

of hammers. They have been designed and subjected to heat

treatment with regard to use only with non-rotary impact tools.

When appropriate, in case of hammers and crushers, never use

blunt chisels, as they are subjected to big load and may break due

to fatigue of material. Use of blunt tool may increase oscillations

and that is why sharp tools should be used. In case of hammers,

when appropriate, never cool down the hot inserted tools in wa-

ter, this may result in brittleness and premature wear. In case of

hammers, when appropriate, damage or breaking of tool may

result from improper use of tool as a lever, e.g. when leveraging.

It is better to work by removing small fragments which will allow

avoiding jamming. Avoid direct contact with a tool inserted during

and after completion of work, it may be hot or sharp.

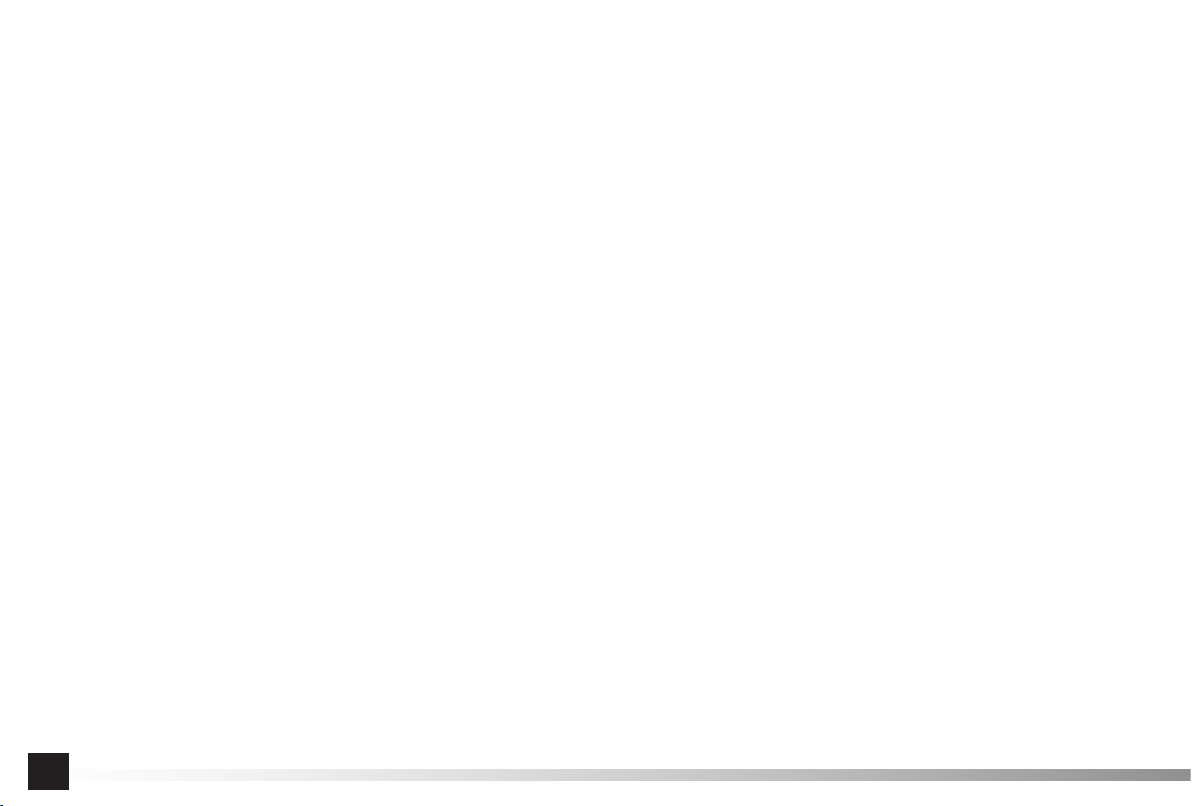

Threats associated with work place

Slipping, stumbling and falls are main causes of injuries. Avoid

slippery surfaces caused by using the tool, as well as risk of

stumbling caused by hoses with compressed air. Take care in

an unknown environment. There may exist hidden threats, such

as electricity or other utilities. Pneumatic tools are not designed

for use in areas exposed to explosion and are not isolated from

contact with electric power. Make sure, that there are no electric

conductors, gas pipes etc. that may pose a threat in case of any

damage caused by the tool.

Threats associated with vapours and dusts

Dust and vapours generated by use of pneumatic tool may cause

bad health condition (for example a cancer, birth defects, asth-

ma and/or skin inammation), indispensable are: risk assess-

ment and implementation of proper control measures in relation

to these threats. Risk assessment should include eect of dust

generated by tool and possibility of stirring the existing dust. Air

outow should be directed in such a way as to minimize stirring of

dust in dusty environment. In environment of dust or vapours, the

priority is to control them at the source of emission. All integrated

functionalities and accessories for collecting, extracting or mini-

mizing dust or smoke should be properly utilized and maintained

pursuant to manufacturer’s recommendations. Use respiratory

tract protectors, in accordance with employer’s instructions and in

compliance with hygiene and safety requirements. Operation and

maintenance of pneumatic tool should be carried out in accord-

ance with instructions contained in user manual, this will allow

minimizing the emission of vapours and dust. Select, maintain

and replace tools inserted in accordance with instructions of user

manual, to prevent increase in quantity of vapours and dust.

Threat of noise

Exposure to high level of noise may cause permanent and irre-

versible loss of hearing and other problems, such as noise in ears

(sounding, buzzing, whistling or humming in ears). Risk assess-

ment is indispensable, as well as implementation of appropriate

control measures in relation to these threats. Right controls in

order to minimize the risk may include activities such as: muing

materials that prevent “sounding” of object being processed. Use

ear protectors, in accordance with employer’s instructions and in

compliance with hygiene and safety requirements. Operation and

maintenance of pneumatic tool should be carried out in accord-

ance with instructions contained in user manual, this will avoid

unnecessary increase in noise level. If a pneumatic tool is tted

with a muer, always make sure that it is properly installed when

operating the tool. Select, maintain and replace worn-out inserted

tools used in accordance with instructions of user manual. This

will allow avoiding unnecessary noise increase.

Threats of oscillations

Exposure to oscillations may cause long-term damage of nerves

and blood vessels in hands and arms.

Dress warm clothes when working at low temperatures and keep

your hands warm and dry. In case of numbness, pain or whiten-

ing of skin of ngers and hand, stop using the pneumatic tool,

than inform your employer and consult with physician. Operation

and maintenance of pneumatic tool in accordance with instruc-

tions contained in user manual, will allow avoiding unnecessary

increase in oscillation level. Do not hold the tool inserted with your

free hand, this will increase exposition to oscillations. Grab the

tool lightly but securely, taking into account the required counter

forces, since the threat posed by oscillations is usually higher,

when the gripping force is higher. Hold additional handpieces

from central position and avoid putting pressure to the handpiece

until it stops. In case of crushers, remove smaller blocks of con-

crete to avoid jamming the tool. In case of crushers, move the

tool every few seconds. When displacing stop the tool since oscil-

lations reach high level if the tool inserted does not lean against

material that is being processed.

Additional safety instructions regarding the pneumatic tools

Compressed air may cause serious injuries:

- always cut o air supply, empty the hose from air pressure and