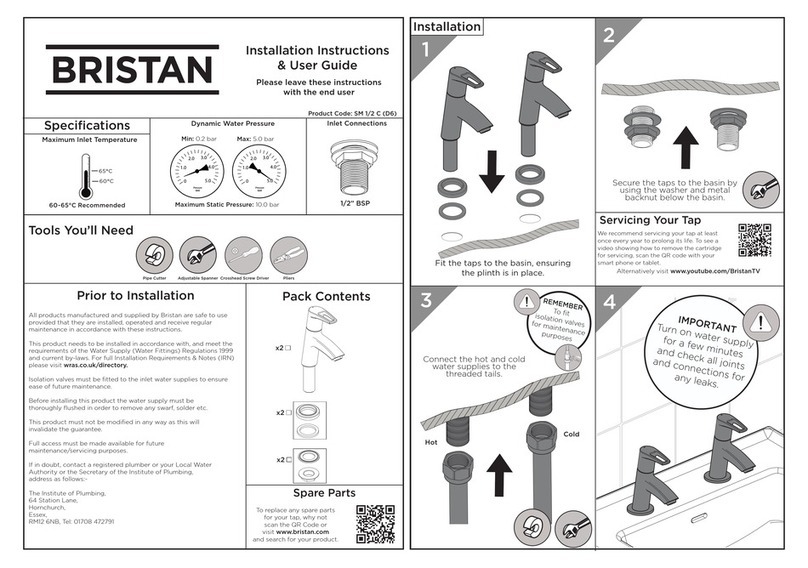

Bristan Blade BL BAS C User manual

Other Bristan Plumbing Product manuals

Bristan

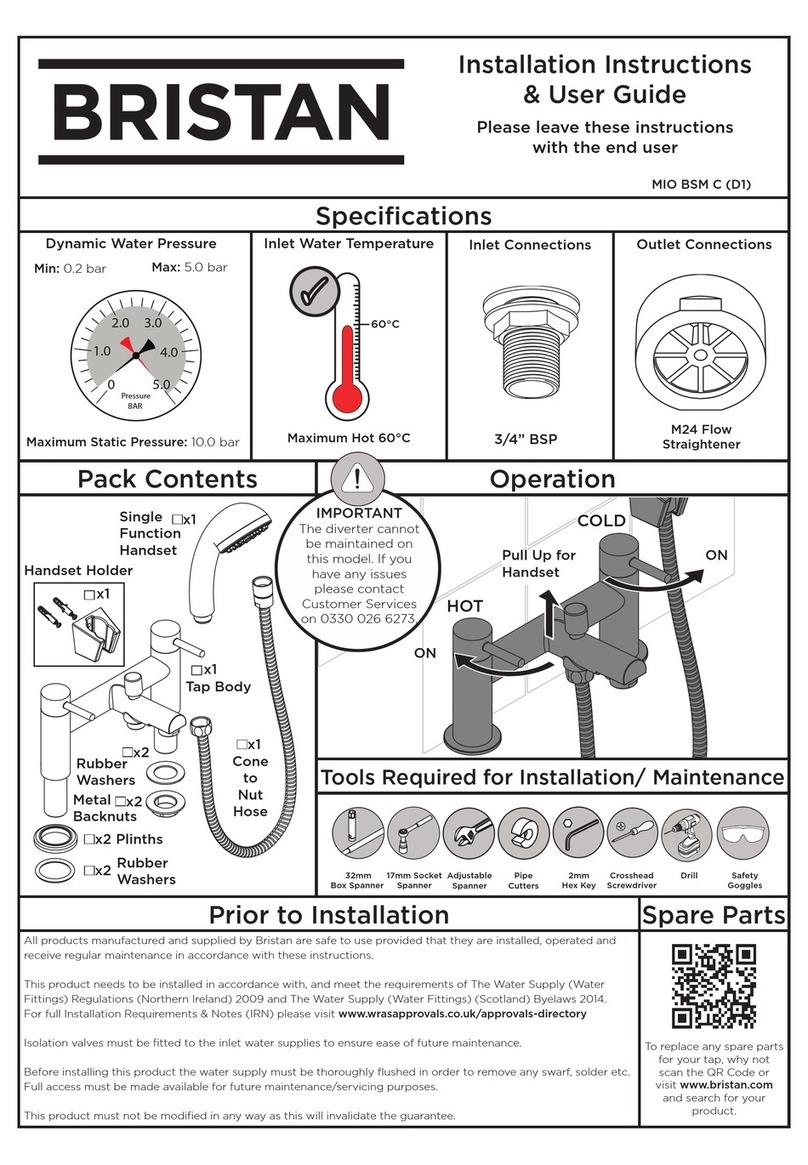

Bristan BRG 3HBAS C User manual

Bristan

Bristan W BTH12 C User manual

Bristan

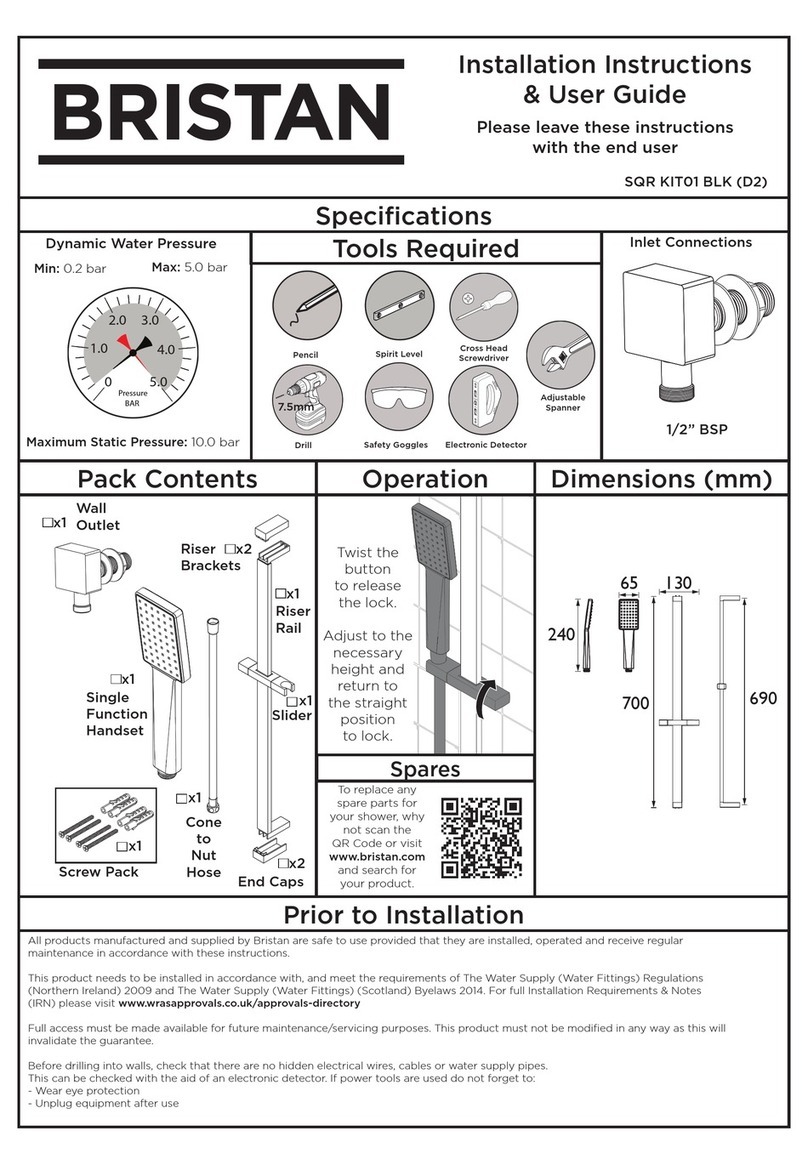

Bristan SQR KIT01 BLK D2 Wiring diagram

Bristan

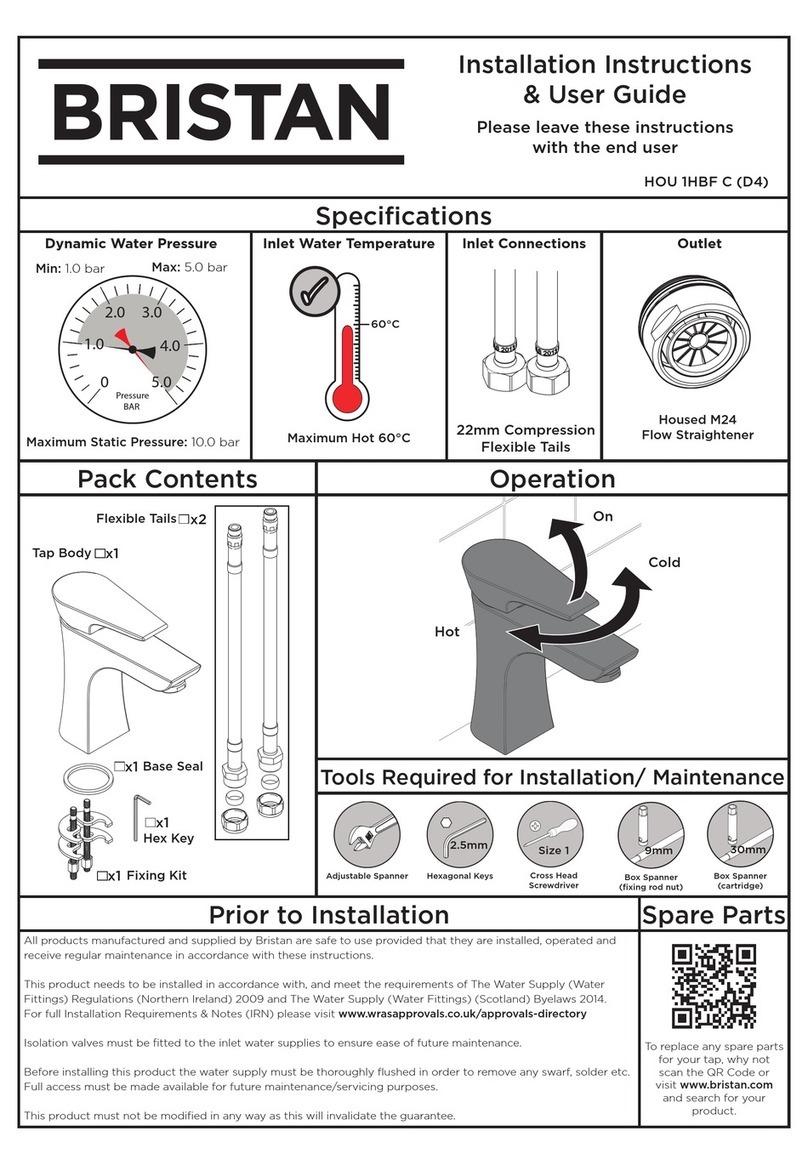

Bristan HOU 1HBF C Wiring diagram

Bristan

Bristan W BATH07 C Wiring diagram

Bristan

Bristan Java J SFSNK EF C User manual

Bristan

Bristan W BASIN06 C User manual

Bristan

Bristan EXD BAS C User manual

Bristan

Bristan ARM WORD01 C User manual

Bristan

Bristan JAVA J THBSMVO C Wiring diagram

Bristan

Bristan smile Mounting instructions

Bristan

Bristan Opac Series Mounting instructions

Bristan

Bristan Target TG SNK C User manual

Bristan

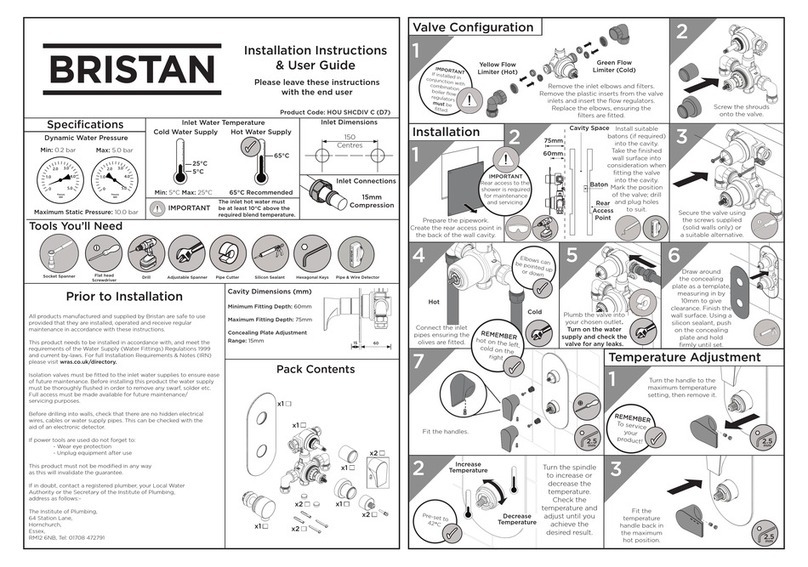

Bristan HOU SHCDIV C (D7) Wiring diagram

Bristan

Bristan JU BAS C User manual

Bristan

Bristan Pisa series Wiring diagram

Bristan

Bristan Options Bath User manual

Bristan

Bristan CART 06734B Original operating manual

Bristan

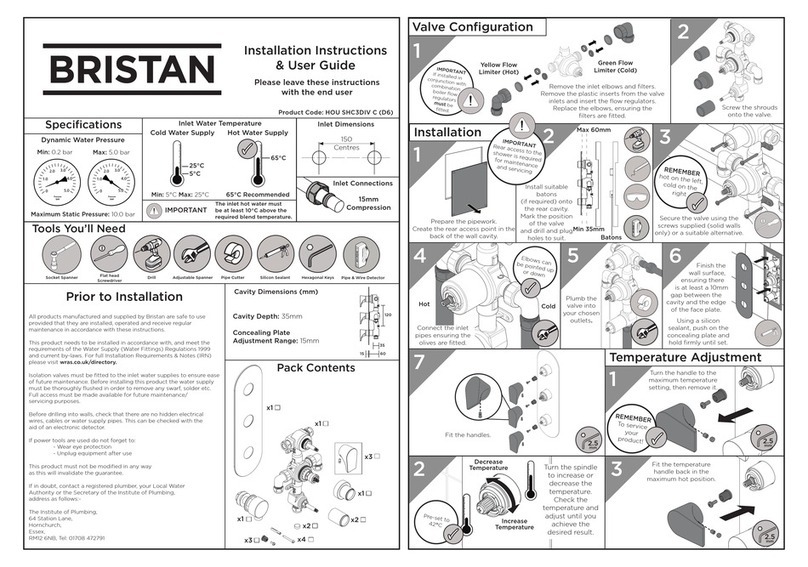

Bristan HOU SHC3DIV C Wiring diagram

Bristan

Bristan Liquorice Kitchen Sink Tap Wiring diagram

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

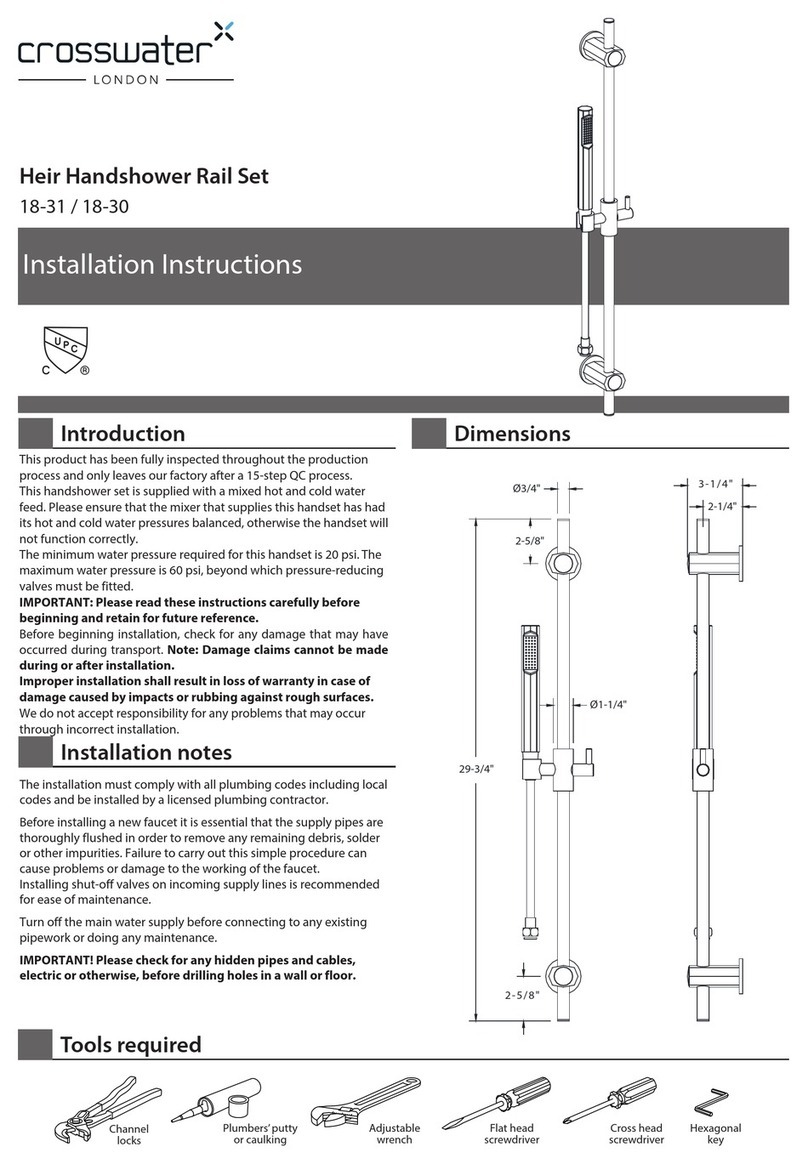

Crosswater

Crosswater Heir 18-31 installation instructions