9

8

7

6

12

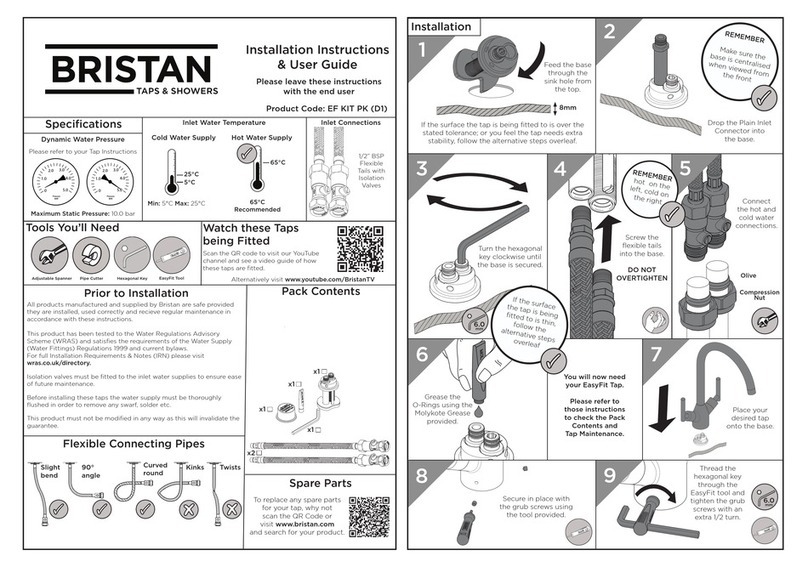

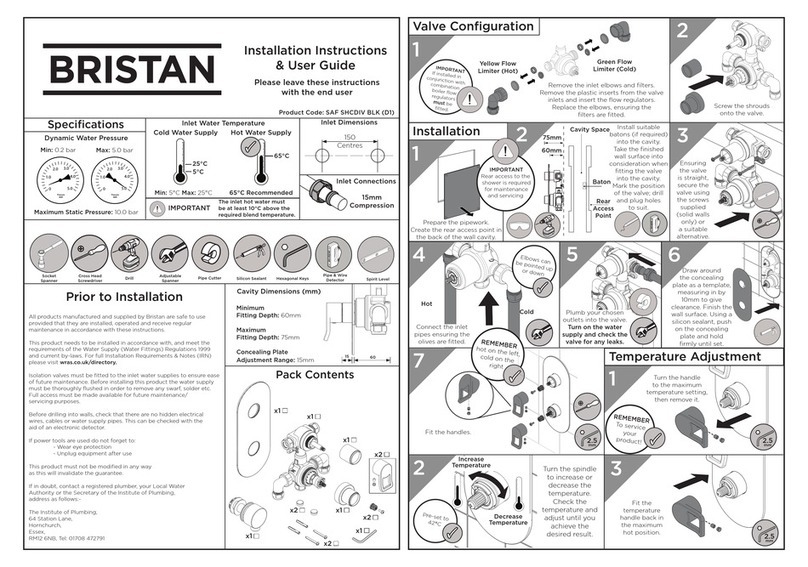

Insert riser rail into

lower bracket,

securing to the

wall.

4

3

2

5Troubleshooting

To reduce the build up of limescale and to ensure

this shower works to its maximum performance we

recommend this shower is serviced every 6-12 months

depending on the hardness of your water.

To replace any spare parts for your

shower why not scan the below QR Code

and search for your product.

Spare Parts

Servicing Intervals

Maintenance - Cartridge Cleaning

1

Symptom Cause Remedy

No flow or

low flow rate

Partially closed isolation valve. Open isolation valve.

Instantaneous water heater cycles on and o

as flow rate or pressure is too low.

Increase water flow rate or

pressure through system.

Head of water is below the

minimum distance required. 2 meters minimum required.

Hot or cold water being drawn o elsewhere

causing pressure changes or instantaneous

boiler temperature changes.

Do not use other water outlets when using the taps.

Airlock or partial blockage in the supply

pipework.

Flush through pipework to ensure removal of debris and

any airlocks.

Water

dripping

from shower

This is normal for a short time after using the

shower.

This is caused by residual water tension, the build up of

water in the shower.

If water continues to drip,

possibly due to the cartridge

Remove cartridge and clean, refer to 'Maintenance' section

before starting any maintenance.

Shower does

not turn on

Closed isolation valve. Open isolation valve.

Mains water supply turned o. Turn on mains water supply.

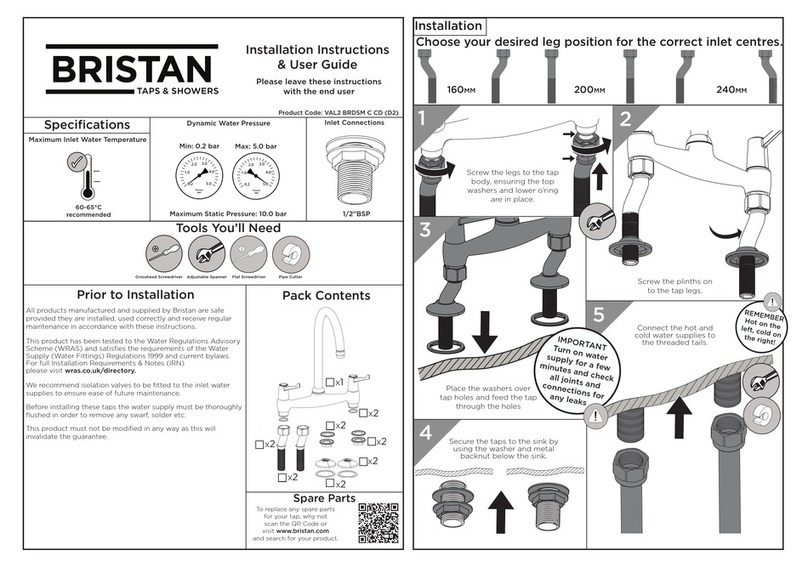

At Bristan, we want to make things as easy as possible for our customers. That’s why we oer solid guarantees on

all our products, eective from the date of purchase, to give you peace of mind.

To start your free guarantee simply scan the QR code and register your product.

Alternatively visit www.bristan.com/register.

For any other queries, please call our Customer Service on 0330 026 6273 where our expert team of advisors

will be able to oer you any help and advice.

For full guarantee terms and conditions visit www.bristan.com/guarantees.

4

2

1

Turn the shower on, letting

the temperature stabilise.

Temperature Setting 3

Remove O-rings and

soak all

components in

de-scaler and wash o

in clean water. Examine

all seals and replace if

needed.

Use WRAS

approved silicon based

grease on all seals.

Remove adaptor,

nut and cartridge.

Remove

temperature and

flow handle. Unscrew the flow

valve.

4

1

56

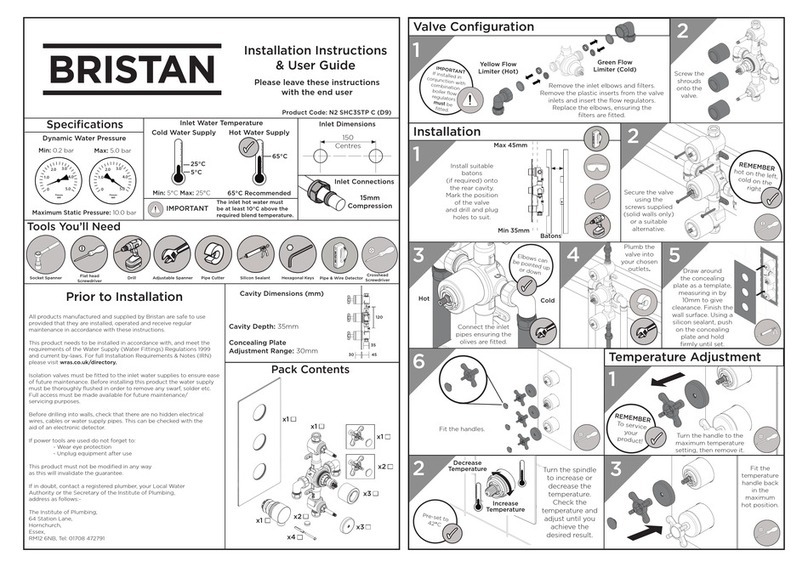

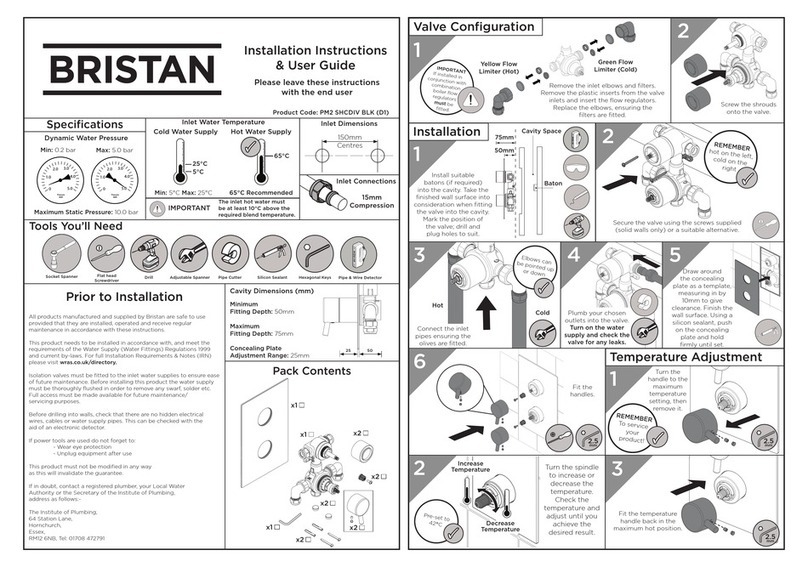

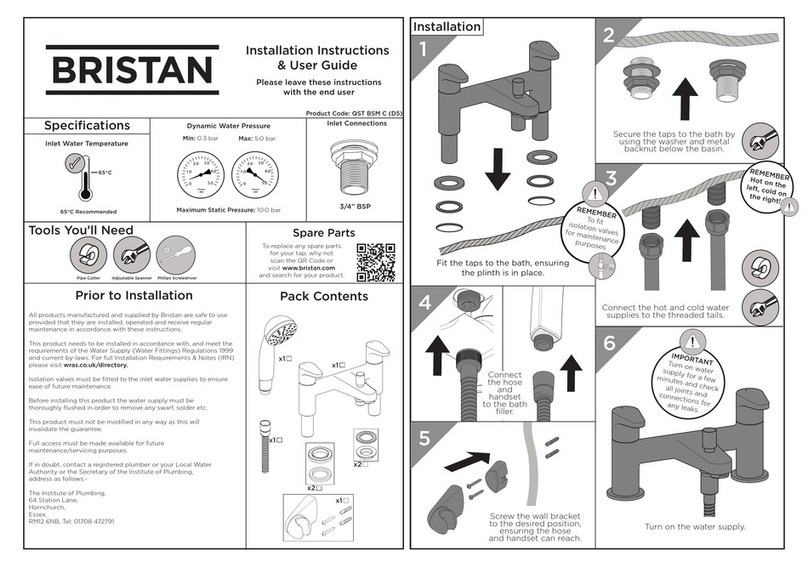

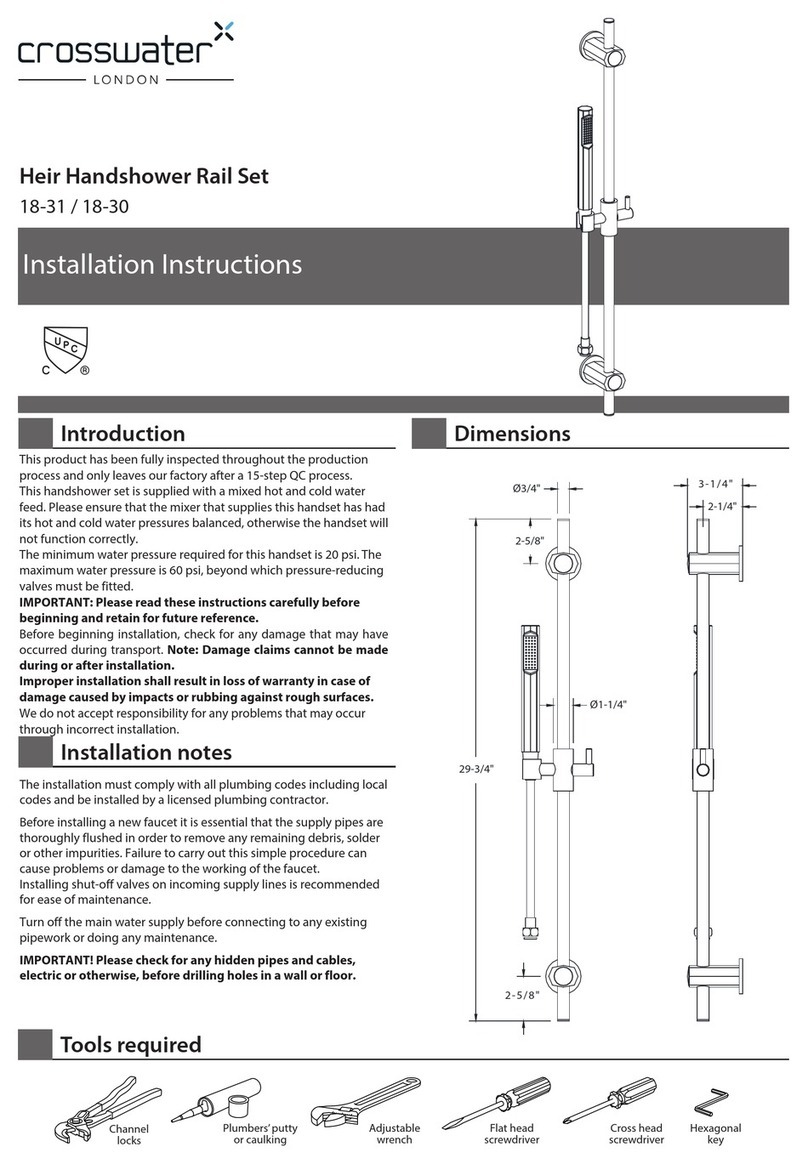

Riser Installation

23

Assemble the

riser, attaching

the hose retainer,

soap dish, slider

and both the

top and bottom

brackets.

Use the

assembled riser

to mark the

desired position

for the riser on

the wall.

Drill the

marked

holes.

Slide top

bracket onto

riser and

secure to wall.

Slide hose

through

hose retainer

before

attaching the

handset to

the shower.

Remove the

cap, screw and

temperature

handle.

Turn cartridge

spindle clockwise

to

decrease the

temperature. Turn

cartridge spindle

anti-clockwise to

increase the

temperature.

Reverse steps 1-2 to

reinstall the valve,

cartridge and handles.

Replace

nut and

adaptor,

ensure the

raised side is

facing towards

the back of the

valve.

Replace

cartridge and

turn spindle

anti-clockwise

to maximum

temperature.

Turn cartridge spindle clockwise to

decrease the temperature. Turn

cartridge spindle anti-clockwise to

increase the temperature.

Slide handle

onto adaptor

and turn

clockwise

until you meet

resistance,

12

Reverse steps 1-2 to

reinstall the valve and

secure handles.

REMEMBER

To service

your

product!