3

1 OPERATING INSTRUCTION ...................................................................4

1.1 Definition of terms / abbreviation ........................................... 4

1.2 Symbols .......................................................................................4

2 AUTHORISED USE ......................................................................................5

2.1 Explosion protection approval ................................................ 5

3 BASIC SAFETY INSTRUCTIONS ..........................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Contact addresses ................................................................... 7

4.2 Warranty ...................................................................................... 7

4.3 Information on the internet ......................................................7

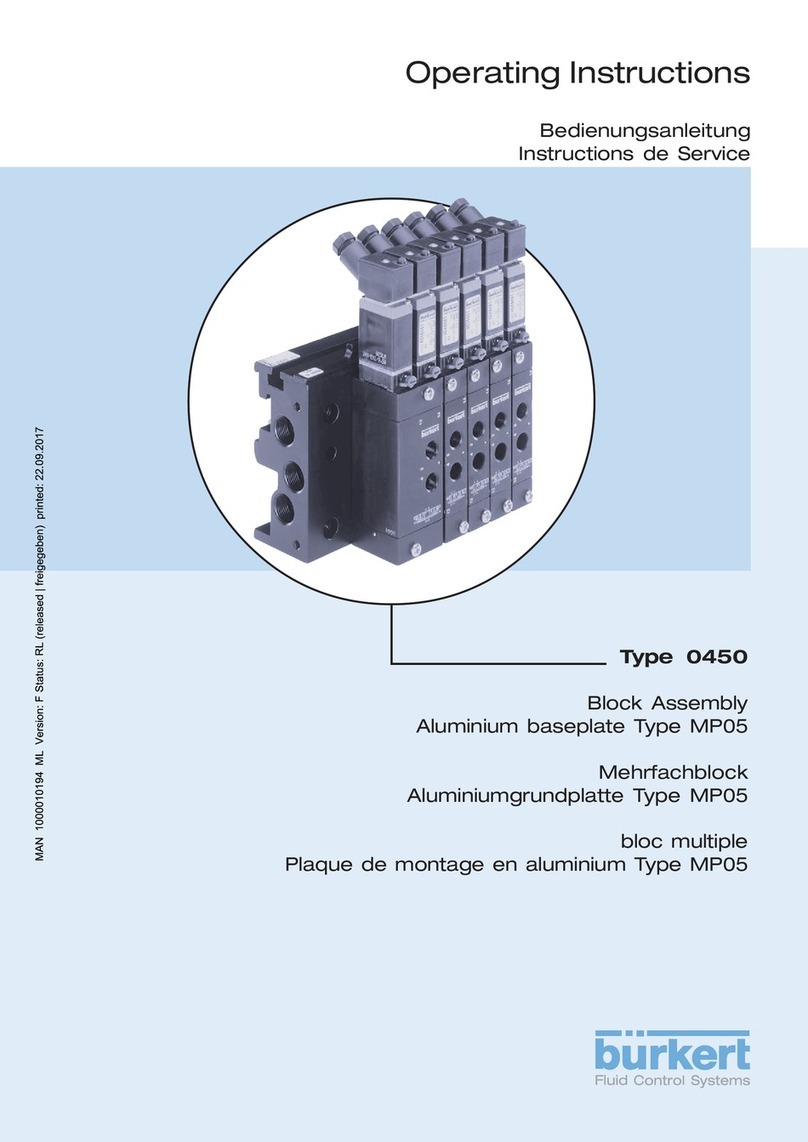

5 PRODUCT DESCRIPTION ........................................................................8

5.1 Design .......................................................................................... 8

5.2 Solenoid coil with cable outlet ............................................... 9

5.3 Solenoid coil with terminal box...............................................9

6 APPLICATION CONDITIONS OF THE DEVICES .......................10

6.1 Special conditions ...................................................................10

6.2 Operating conditions ..............................................................10

6.3 Operating temperature range ...............................................10

7 TECHNICAL DATA ..................................................................................... 11

7.1 Safety instructions ...................................................................11

7.2 Conformity .................................................................................11

7.3 Standards ..................................................................................11

7.4 Type label for explosions-risk areas ....................................12

7.5 Electrical data for solenoid coils with cable outlet ..........14

7.6 Electrical data for solenoid coils with terminal box ..........14

8 ACCESSORIES ........................................................................................... 15

8.1 Cable gland for terminal box .................................................15

8.2 External grounding connection for terminal box ...............15

9 INSTALLATION AND REMOVAL .........................................................16

9.1 Installation .................................................................................16

9.2 Electrical connection ..............................................................17

9.3 Removal .....................................................................................18

10 START-UP ......................................................................................................19

11 MAINTENANCE, REPAIR, TROUBLESHOOTING ...................... 19

11.1 Maintenance work ...................................................................19

11.2 Repair .........................................................................................19

11.3 Troubleshooting .......................................................................19

12 TRANSPORTATION, STORAGE, DISPOSAL ................................20

Table of contents

english

EPS 16 ATEX 1072 X