6

13.11Congurationoftheprocessdata ............................................................................................70

13.11.1Static input assemblies...................................................................................................70

13.11.2Static output assembly...................................................................................................71

13.12Congurationofthedevice .......................................................................................................71

13.12.1Congurationofthesafetypositionofsolenoidvalvesduringabuserror ....................71

13.12.2Congurationexample...................................................................................................72

13.13DisplayofthestatusLEDsintheeventofabuserror.............................................................73

13.13.1Status of the device status LED "Modules" ...................................................................73

13.13.2Status of bus status LED "Network" ..............................................................................74

14 IO-LINK-DESIGN ................................................................................................................................75

14.1 Networkprinciple/interfaces ...................................................................................................75

14.2 QuickstartforType8681IO-Link...............................................................................................76

14.3 Technicaldata/specication....................................................................................................76

14.4 IO-Linkmaster/communication/conguration...................................................................... 77

14.5 Electricaldataformthecontrolhead(IO-Link).........................................................................77

14.5.1 Electrical connection options / interface ........................................................................77

14.5.2 Electrical data of the control head..................................................................................78

14.5.3 Design aid.......................................................................................................................80

14.5.4 Electrical installation – IO-Link .......................................................................................82

14.5.5 Pinassignment(portclassAorB)..................................................................................83

14.6 Software/rmwareupdates .....................................................................................................84

14.6.1 Software..........................................................................................................................84

14.6.2 Firmware updates ...........................................................................................................84

14.7 Safetypositionifthebusfails ...................................................................................................84

15 BÜS/CANOPEN-DESIGN ....................................................................................................................85

15.1 Denition ..................................................................................................................................85

15.2 Networkprinciple/Interfaces ...................................................................................................85

15.3 QuickstartforType8681büS/CANopen...................................................................................87

15.4 büS/CANopenspecication ......................................................................................................88

15.4.1 General data ...................................................................................................................88

15.4.2 Total line length and drop line lengths of the bus cables ...............................................88

15.5 Electricalconnectionoptions.................................................................................................... 89

15.6 Electricaldataofthecontrolhead............................................................................................89

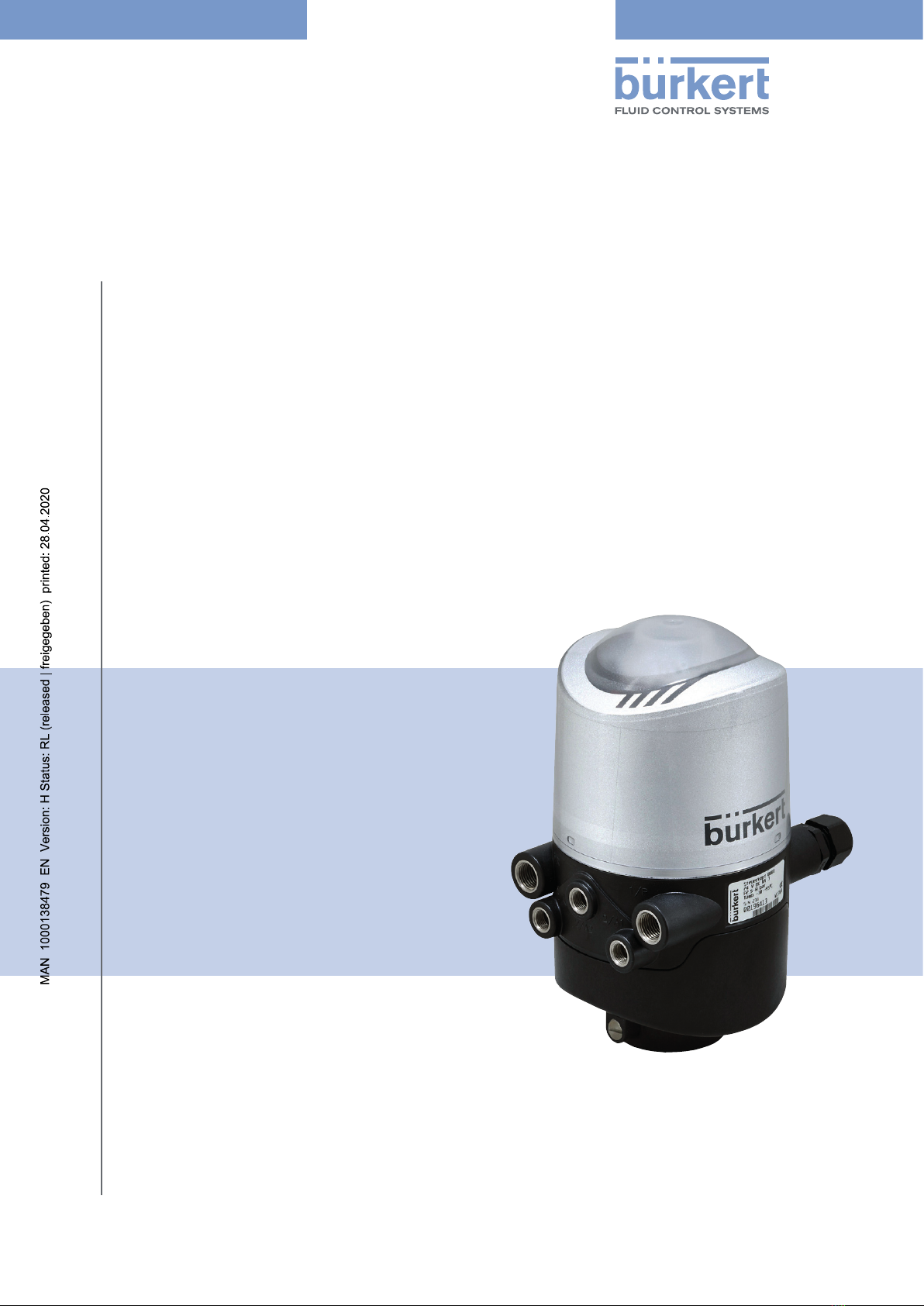

english

Control Head Type 8681