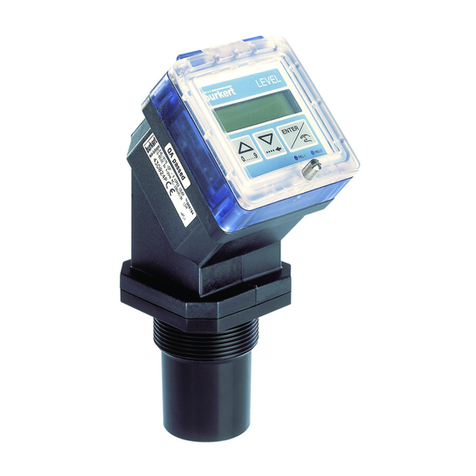

28045

ENGLISH

INTRODUCTION

1 INTRODUCTION

1.1 Symbols used ........................................................................................................................... 3

1.2 General Safety Instructions ...................................................................................................... 3

2 QUICKSTART

2.1 Installation................................................................................................................................. 4

2.2 Programming ............................................................................................................................ 5

2.3 Testing ...................................................................................................................................... 6

3 INSTALLATION

3.1 Installation Guidelines .............................................................................................................. 7

3.1.1 Mounting Positions ........................................................................................... .......... 8-9

3.2 Installation............................................................................................................................... 10

3.3 General Electrical Connection ............................................................................................... 11

3.3.1 Earthing the transmitter ............................................................................................... 11

3.4 Electrical wiring for the 8045 flow transmitter .........................................................................12

3.4.1 18-30 VDC without relay .............................................................................................. 12

3.4.2 18-30 VDC with relays ......................................................................................... ......... 13

3.4.3 Switches settings ......................................................................................................... 13

3.4.4 Connection of the Pulse Output .................................................................................. 14

3.5 Easy Link/Networking Connections ........................................................................................ 15

LINK 8630 Topcontrol ......................................................................................... 15

LINK 1067 Positioner without relay .................................................................... 16

LINK 8031 On/Off Top control ............................................................................. 17

4 PROGRAMMING AND OPERATION

4.1 Operating and Control Guide ................................................................................................. 18

4.2 Menu Guide ............................................................................................................................ 19

4.3 Main Menu .............................................................................................................................. 20

4.4 Calibration Menu .................................................................................................................... 21

4.4.1 Language ..................................................................................................... ................ 22

4.4.2 Engineering Units ........................................................................................................ 22

4.4.3 K-Factor ..................................................................................................................23-24

4.4.4 Output Current ............................................................................................................. 25

4.4.5 Pulse Output ................................................................................................................ 26

4.4.6 Relay (option) .............................................................................................................. 27

4.4.7 Filter Function .............................................................................................................. 28

4.4.8 Totalizer ....................................................................................................................... 29

4.4.9 50/60 Hz Noise Rejection ............................................................................................ 29

4.5 Test Menu ............................................................................................................................... 30

4.5.1 Offset adjustment ........................................................................................................ 31

4.5.2 Span adjustment.......................................................................................................... 31

4.5.3 Calibration of the zero point ........................................................................................ 32

4.5.4 Flow Simulation ........................................................................................................... 32

4.6 8045 settings .......................................................................................................................... 33

4.6.1 Type 8045 Flow transmitter at delivery ...................................................................... 33

4.6.2 8045 Flow transmitter user configuration ................................................................... 33

5 MAINTENANCE

5.1 Storing and Cleaning of the Sensor ............................................................................ 34

5.2 Trouble Shooting Guide ..........................................................................................34-35

6 ANNEX

6.1 Specifications .........................................................................................................36-37

6.2 Dimensions .................................................................................................................. 38

6.3 Design and Measuring Principle ................................................................................. 39

6.4 Type specification ........................................................................................................ 40

6.5 Standard Delivery ........................................................................................................ 40

6.6 Label type .................................................................................................................... 41

6.7 Spare Parts .............................................................................................................41-42