1

1 OPERATING INSTRUCTIONS ........................................................................................................................................................3

1.1 Symbols used ..........................................................................................................................................................................3

1.2 Definition of the term "device" ........................................................................................................................................3

2 INTENDED USE ....................................................................................................................................................................................4

3 BASIC SAFETY INSTRUCTIONS .................................................................................................................................................5

4 GENERAL INFORMATION ................................................................................................................................................................6

4.1 Contact ........................................................................................................................................................................................6

4.2 Warranty conditions ..............................................................................................................................................................6

4.3 Information on the Internet ...............................................................................................................................................6

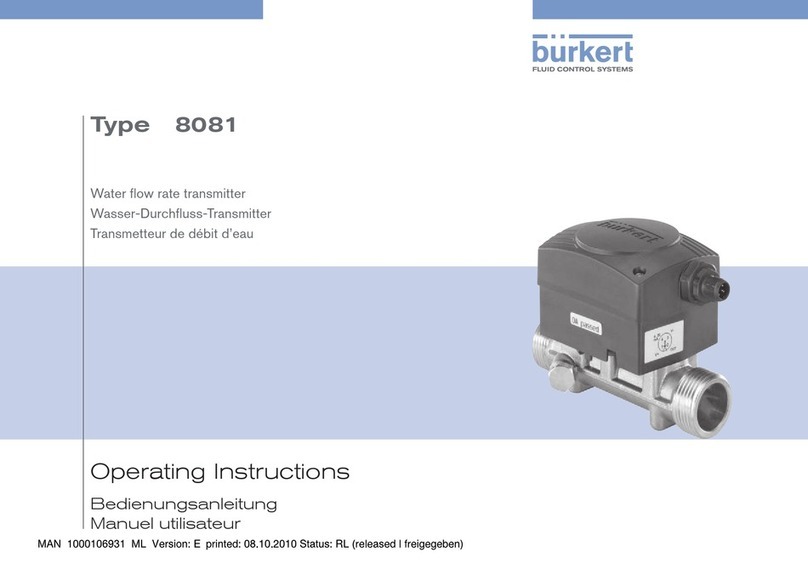

5 DESCRIPTION .......................................................................................................................................................................................7

5.1 General description ..............................................................................................................................................................7

5.2 Combined sensor ..................................................................................................................................................................7

5.3 Description of the rating plate ........................................................................................................................................8

6 TECHNICAL DATA ................................................................................................................................................................................9

6.1 Conformity to standards and directives ....................................................................................................................9

6.1.1 UL certification ..................................................................................................................................................9

6.2 Operating conditions ...........................................................................................................................................................9

6.3 Mechanical data ...................................................................................................................................................................10

6.4 Electrical data .......................................................................................................................................................................10

7 INSTALLATION AND COMMISSIONING ...............................................................................................................................11

7.1 Wiring a version with cable gland ..............................................................................................................................11

7.1.1 Using the device as a flow transmitter ..........................................................................................11

7.1.2 Using the device as a pulse divider ...............................................................................................12

7.2 Wiring a version with a 4-pin M12 male connector ..........................................................................................13

7.2.1 Using the device as a flow transmitter ..........................................................................................14

7.2.2 Using the device as a pulse divider ...............................................................................................14

7.3 Mounting the device on a flow sensor ....................................................................................................................16

8 ADJUSTMENT .....................................................................................................................................................................................17

8.1 Display unit .............................................................................................................................................................................17